*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

Re:tell me what I am seeing Intake pulse 2004 dodge

- AJeep18

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 34

4 years 2 months ago #50442

by AJeep18

tell me what I am seeing Intake pulse 2004 dodge was created by AJeep18

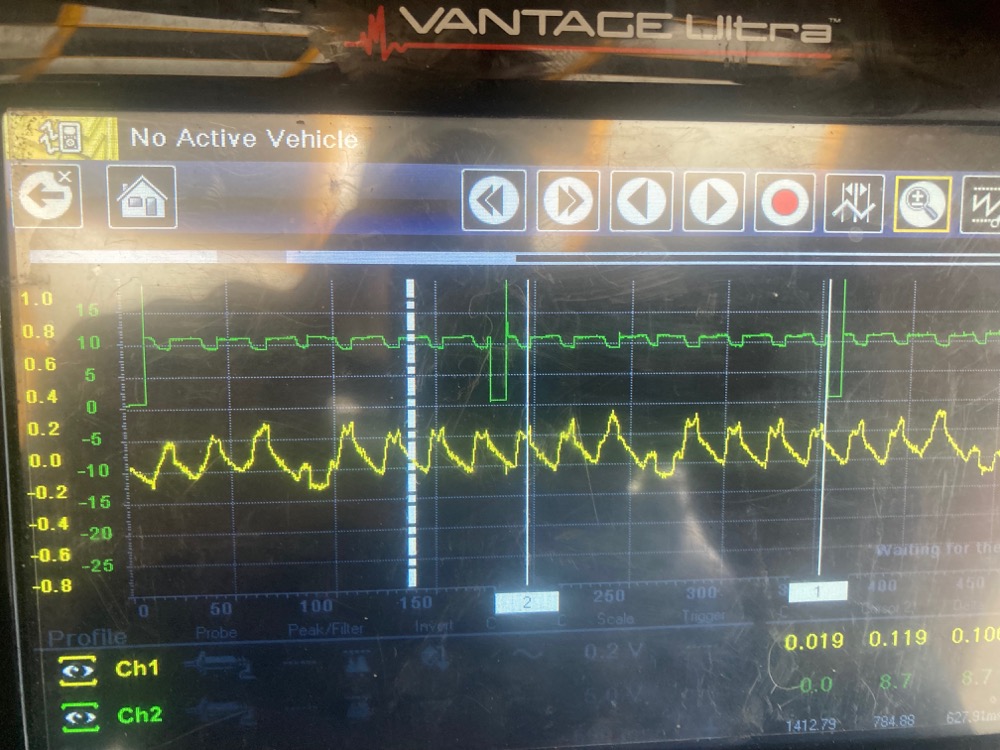

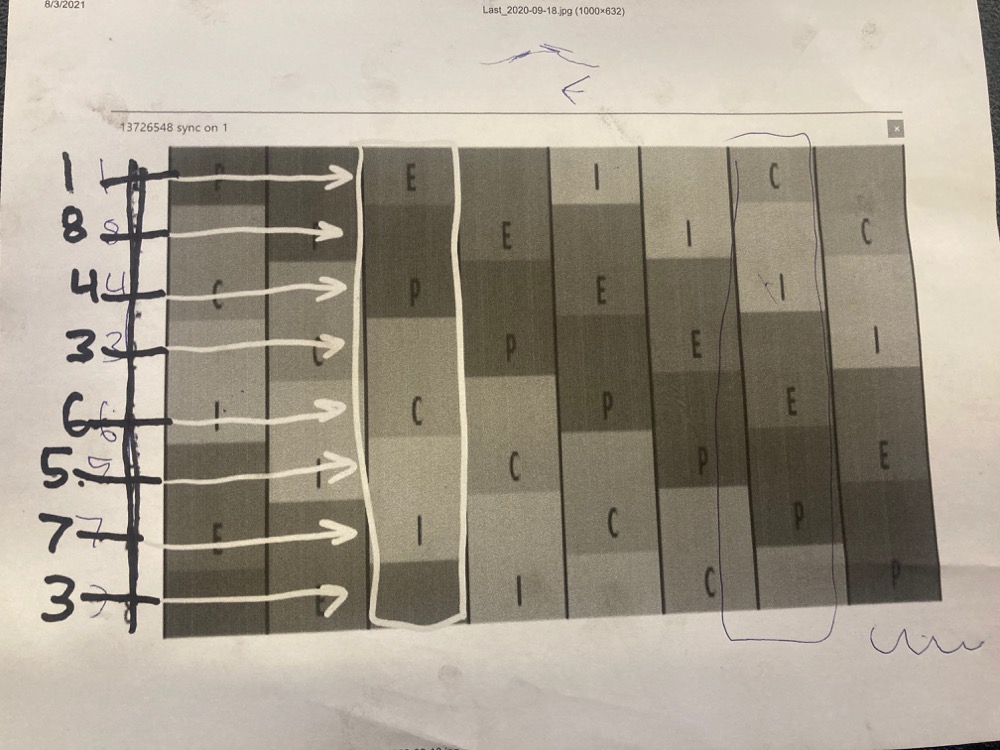

Working on a 2004 dodge 1500 5.7. Customer noticed that the truck had a bad misfire and so they replaced coils, spark plugs and injectors. Still missing. Brought it into the shop had a ton of codes so I saved and cleared them all. Sounded like it was running on only 4 cylinders. Did a relative compression test. Sure enough: dead hole. I also took an intake pulse waveform synced off the injector the same with the RC waveform. (I wasn't sure how else to do it on a Waste Spark system). Found out it was cylinder #4, leakdown test showed the exhaust valve and I noticed a broken valve spring. All that to ask, I want to know what I can learn from my intake pulse waveform.

Please Log in or Create an account to join the conversation.

- AJeep18

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 34

4 years 2 months ago #50443

by AJeep18

Replied by AJeep18 on topic tell me what I am seeing Intake pulse 2004 dodge

I cannot get the intake pulse to post... it says:

Image MIME type (%s) is not allowed (%s).

It is converted to a JPEG.... just like all the others

Image MIME type (%s) is not allowed (%s).

It is converted to a JPEG.... just like all the others

Please Log in or Create an account to join the conversation.

- AJeep18

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 34

4 years 2 months ago - 4 years 2 months ago #50444

by AJeep18

Replied by AJeep18 on topic tell me what I am seeing Intake pulse 2004 dodge

Got it as a PDF

Last edit: 4 years 2 months ago by AJeep18.

Please Log in or Create an account to join the conversation.

- Ben

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1097

- Thank you received: 215

4 years 2 months ago #50446

by Ben

Replied by Ben on topic Re:tell me what I am seeing Intake pulse 2004 dodge

Is that intake cranking or running? purchased or homemade pulse sensor? If homemade what size disc? I don't see anything very usable in that waveform but I don't have as much experience with the pulse sensor as some of the other eagle eyes here! I did experiment with different size disc's and I can tell you a 25mm disc didn't make a usable waveform I then jumped to a 48mm disc and it was everything you could ask for in a pulse sensor although it sounds horrible with full engine vacuum.... but the waveform is beautiful! Lastly I doubt you'd see much from an exhaust valve in an intake waveform I usually suspect intake issues in intake waveform and exhaust issues in exhaust waveform although misfires severely affect exhaust waveform as well so maybe hard to decipher there as well? RC for the win though huh!

Sent from my SM-G781U using Tapatalk

Sent from my SM-G781U using Tapatalk

Please Log in or Create an account to join the conversation.

- AJeep18

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 34

4 years 2 months ago #50447

by AJeep18

Replied by AJeep18 on topic Re:tell me what I am seeing Intake pulse 2004 dodge

I think it was a purchased homemade one I think

. Bought it from a fellow forum member. I is about 1.5" on the outside but I don't know how big the disc in the middle is. I thought I remembered watching one of John Throrton's videos and he had some example waveforms that did show an exhaust valve problem. I think the explanation was something like: on the intake stroke the exhaust valve is still somewhat open, so the pressure in the exhaust manifold gets past the valve into the cylinder and intake causing an increase in pressure... maybe I am just imagining hearing that though... I am pretty new to pulse sensor usage. I mainly work on turbo charged diesel and haven't really found a big use for them.

Please Log in or Create an account to join the conversation.

- AJeep18

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 34

4 years 2 months ago #50449

by AJeep18

Replied by AJeep18 on topic Re:tell me what I am seeing Intake pulse 2004 dodge

Honestly I can't remember... I think it was while it was running.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

Less

More

- Posts: 1230

- Thank you received: 462

4 years 2 months ago #50459

by juergen.scholl

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Replied by juergen.scholl on topic Re:tell me what I am seeing Intake pulse 2004 dodge

The time for a complete firing cycle, based on the sync signal, is around 42ms. So engine speed is about 2800, 2900. Engine speed that high will make it VERY difficult to obtain useful information in this case. You may want to try capturing the intake at cranking/idle speed.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- AJeep18

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 34

4 years 2 months ago #50460

by AJeep18

Replied by AJeep18 on topic Re:tell me what I am seeing Intake pulse 2004 dodge

Ok I will remember that for next time! It didn’t want to idle very well so I was revving it some. Next time I have an issue I will do it cranking. Would it have been beneficial to do one of the exhaust as well? Do I understand correctly that you just put the hose in the pulse sensor a few inches up the tailpipe?

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

Less

More

- Posts: 1230

- Thank you received: 462

4 years 2 months ago - 4 years 2 months ago #50461

by juergen.scholl

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Replied by juergen.scholl on topic Re:tell me what I am seeing Intake pulse 2004 dodge

An exhaust pipe pressure reading will give you additional information and this always is beneficial...

It's best to do this test under cranking condition with a suspected valve issue. With the engine running you would go after cylinder specific misfires...

Yes, you do stick the sensor a couple of inches into the tailpipe. Split exhaust systems may/will alter the waveform.

It's best to do this test under cranking condition with a suspected valve issue. With the engine running you would go after cylinder specific misfires...

Yes, you do stick the sensor a couple of inches into the tailpipe. Split exhaust systems may/will alter the waveform.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Last edit: 4 years 2 months ago by juergen.scholl.

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

Less

More

- Posts: 2120

- Thank you received: 709

4 years 2 months ago #50465

by Chad

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Replied by Chad on topic Re:tell me what I am seeing Intake pulse 2004 dodge

As others have stated, you would be better off capturing pressure pulses while cranking, not running. A running Exhaust waveform can be very useful to identify a missing cylinder. However, a running intake waveform is very chaotic and not very useful, in most circumstances. To Identify valve sealing problems, cranking is the way to go.

Looking at Intake can reveal issues with the exhaust valves. And, vice-versa. If #4 exhaust valve is leaking, then the Intake Pull for #4 will be weaker than the rest of the cylinders. This is because the cylinder is pulling air in from the exhaust, as well as the intake. Exhaust/Intake valve overlap is very distinguishable in an Exhaust waveform.

It is best to use an ignition strike to sync with. The problem with an Injector event is that you don't really know WHEN this event happens in the 720° cycle. Lining the Pistion Chart up with an Injector strike is not accurate. The chart is laid out to sync with TDC. Injectors don't fire at TDC. If you have a waste spark system, set your trigger HIGHER than the companion cylinder exhaust strike. The cylinder you are syncing with will be under compression, raising the firing KV. You want to trigger of the taller spike. On the piston chart, the taller strike will align with TDC of the Compression stroke, and the shorter spike will align with TDC of the Exhaust stroke.

www.aeswave.com/Pressure-Waveform-Acquis...er-eBook-p10037.html

www.aeswave.com/Pressure-Waveform-Acquis...-Steckler-p9892.html

Looking at Intake can reveal issues with the exhaust valves. And, vice-versa. If #4 exhaust valve is leaking, then the Intake Pull for #4 will be weaker than the rest of the cylinders. This is because the cylinder is pulling air in from the exhaust, as well as the intake. Exhaust/Intake valve overlap is very distinguishable in an Exhaust waveform.

It is best to use an ignition strike to sync with. The problem with an Injector event is that you don't really know WHEN this event happens in the 720° cycle. Lining the Pistion Chart up with an Injector strike is not accurate. The chart is laid out to sync with TDC. Injectors don't fire at TDC. If you have a waste spark system, set your trigger HIGHER than the companion cylinder exhaust strike. The cylinder you are syncing with will be under compression, raising the firing KV. You want to trigger of the taller spike. On the piston chart, the taller strike will align with TDC of the Compression stroke, and the shorter spike will align with TDC of the Exhaust stroke.

www.aeswave.com/Pressure-Waveform-Acquis...er-eBook-p10037.html

www.aeswave.com/Pressure-Waveform-Acquis...-Steckler-p9892.html

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

The following user(s) said Thank You: jreardon, AJeep18

Please Log in or Create an account to join the conversation.

- AJeep18

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 34

4 years 2 months ago #50478

by AJeep18

Replied by AJeep18 on topic Re:tell me what I am seeing Intake pulse 2004 dodge

Thank you! I knew an injector was not the right way to do it but I could not figure out any other way.... I will remember for next time!

Please Log in or Create an account to join the conversation.

Time to create page: 0.364 seconds