Fuel Trim Discussion and hopefully some guidance....

- Smeter12

-

Topic Author

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 4

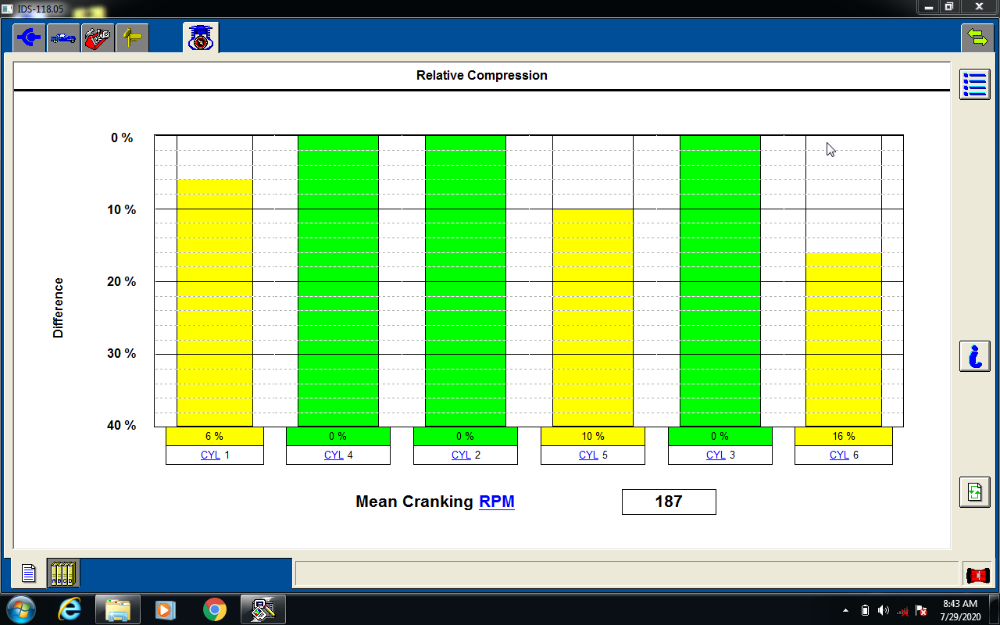

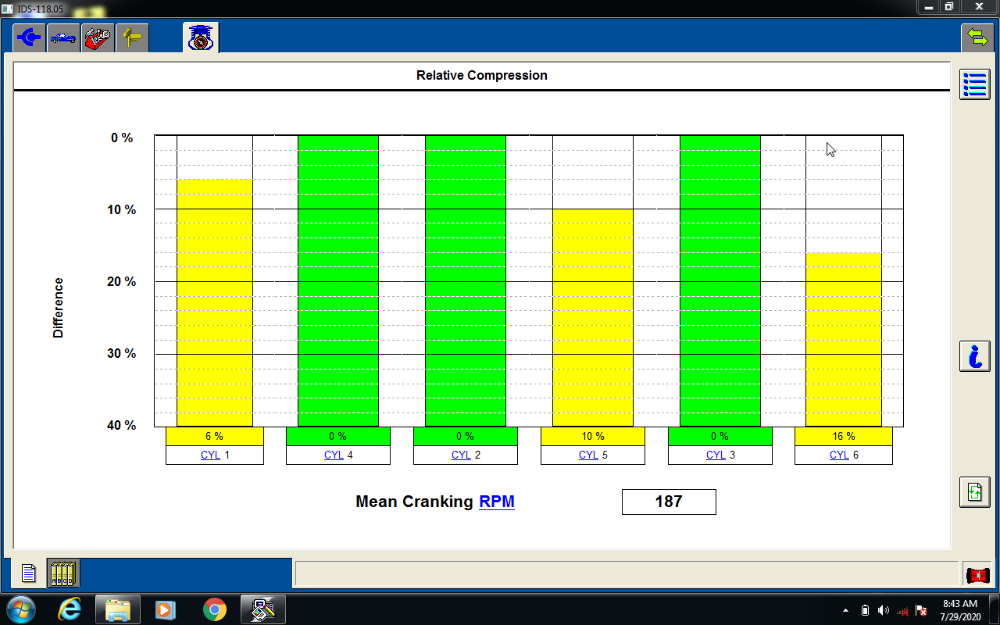

Before I get down and dirty by checking compression of each cylinder and/or a leak down test, would the attached pics of Ford's IDS "Relative compression test" and "Power Balance Test at 1126 rpm and 1926 rpm" be of any assistance?

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6070

- Thank you received: 1533

Smeter12 wrote: Before I get down and dirty by checking compression of each cylinder and/or a leak down test, would the attached pics of Ford's IDS "Relative compression test" and "Power Balance Test at 1126 rpm and 1926 rpm" be of any assistance?

That's what I'm talking about.

FWIW, I trust the IDS RC test when it suggests a low cylinder. Here's a link to where I was experimenting with the same test:

www.scannerdanner.com/forum/diagnostic-t...flow-test.html#10022

Please Log in or Create an account to join the conversation.

- Smeter12

-

Topic Author

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

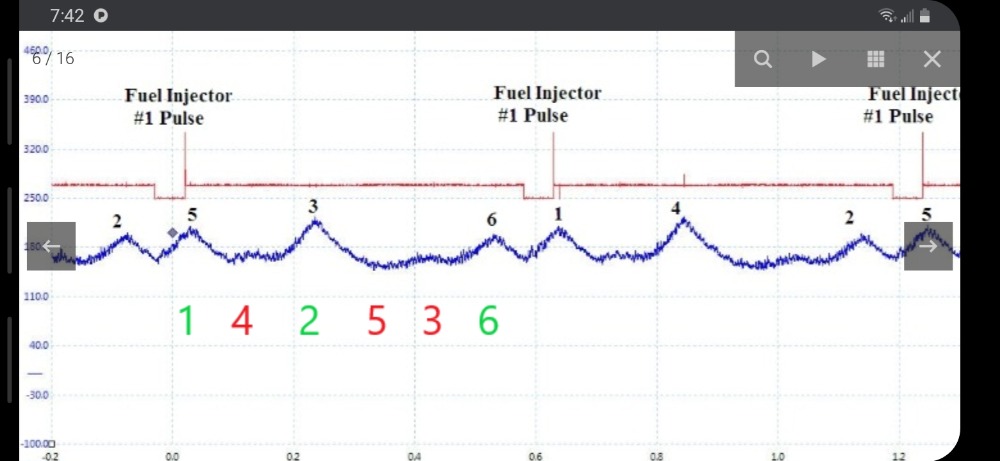

Smeter12 wrote: Matt T wrote: "That injector definitely ain't firing every 180*".[/size]

Not sure I understand. It is not unreasonable for a manufacturer to spray all injectors every half turn of the camshaft (i.e. one full turn of the crankshaft) when trying to get the vehicle started.... respectively.... am I missing something?

You're missing how a 4 stroke engine works. The intake, compression, power and exhaust strokes are all half a crankshaft revolution/180* so the engine takes two crankshaft revolutions/720* to go from compression stroke to compression stroke on one cylinder.

So it's obvious that injector wasn't firing every 180* because there were too many noticeable compression humps between firings. A 6 cylinder will have one or two compression strokes per 180* not three.

Please Log in or Create an account to join the conversation.

- guafa

-

- Offline

- Platinum Member

-

- Posts: 477

- Thank you received: 80

I am lost with this one. We are looking for fuel trims and misfires, but that compression waveform seems an engine which not even start. Is this engine running?

Why are we watching secondary spikes at every cylinder? Shouldn't be watching 1&5 cylinder spikes?

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

Those two factors alone point straight to a compression issue, even more so as it passes the water test for vacuum leaks.compression

The cranking compression test result is fairly clear very poor compression on three cylinders, personally I wouldn't even bother with a leak down or old style compression test as it looks to me like a major valve issue rather than a piston ring issue either sticking valves or a really badly burned valve as shown in Tylers screen cap.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Fallontech

-

- Offline

- New Member

-

- Posts: 5

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Fallontech

-

- Offline

- New Member

-

- Posts: 5

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Fallontech

-

- Offline

- New Member

-

- Posts: 5

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Smeter12

-

Topic Author

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 4

For what it is worth, sorry for the delay in getting the concluding results to this post. With that said, I got down and dirty by doing a compression test on this 2002 Ford Ranger 3.0L V6 as per Tyler's recommendation.

Background info on the compression test:

- started the engine up and let it idle until warm; turn off

- removed all 6 spark plugs

- used my Lang Tools TU-30A Compression Tester Set (i.e. I believe this gauge set is expensive enough to give reliable compression readings) to take compression readings

- pulled fuel pump relay out of relay box (as wife was my assistant for cranking the engine from the cabin of the vehicle)

- disconnected 4 pin wiring harness to ignition coils (knowing my luck, residual fuel would be hanging around and I would have had a 6 nozzle flame thrower)

- attached my battery jumper box to ensure battery would have full power while testing all 6 cylinders

- wife cranked the engine with the gas pedal to the floor

Here are the results from the gauge compression test:

- Cylinder #1 - 25 psi

- Cylinder #2 - 135 psi

- Cylinder #3 - 170 psi

- Cylinder #4 - 115 psi

- Cylinder #5 - 25 psi

- Cylinder #6 - 5 psi

Additional testing:

- checked the crankcase - blocked off the intake (i.e. breather) to the crankcase as well as exhaust (i.e. where PCV valve sits) and shoved a vacuum gauge into the oil dipstick. After a little bit of time, I had a reading of -7 psi.

- water test - did the good old "scannerdanner" test looking for intake leaks, but I couldn't find any. Not sure about the lower plenum though as it is somewhat difficult to get water down there at the front (i.e. 12 o'clock) and rear (i.e. 6 o'clock) of the lower intake plenum.

For sh*ts and giggles, I've attached the compression test results from the Ford IDS software to this post (i.e. Pic 7). Pretty cool how the IDS software dialed in the strength/compression of each cylinder and how it corresponds to the gauge compression test results.

CORRECT CONCLUSION BASED ON THE NUMBERS?

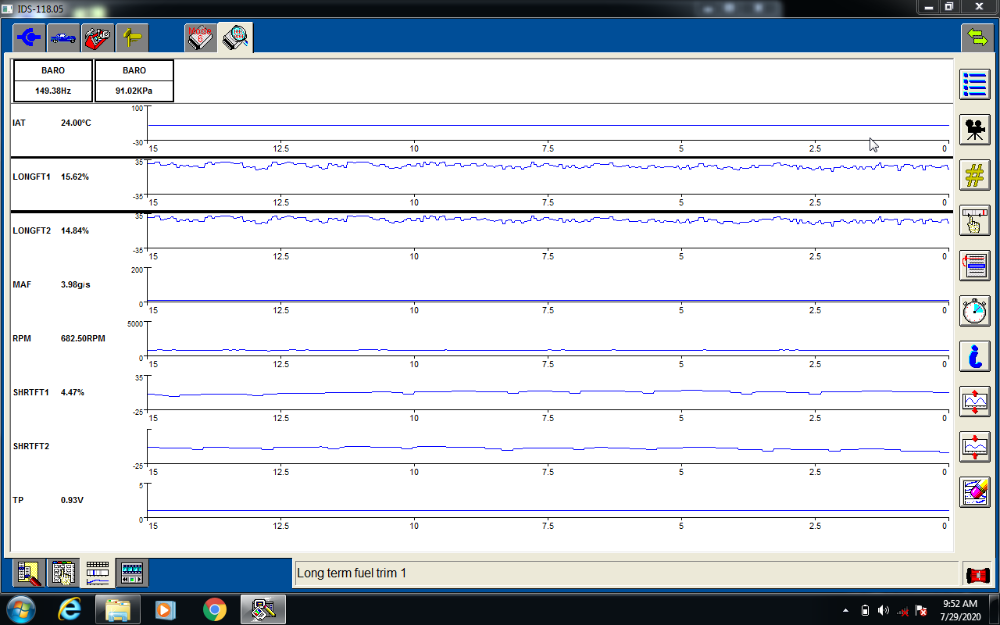

I really don't think the pistons (piston and/or its compression rings) are bad seeing that the crankcase could build good vacuum with the breather and PCV valve area blocked off. Instead, I think I have some type of valve train issue in both the left and right cylinder head. Using the fuel trim numbers (noted at the beginning of this post thread and in Pic 26 attached to this post) and the gauge test compression results, I am guessing cylinder 1, 5, and 6 have some type of valve train issue where by the valves (intake & exhaust or both) are not seating properly and are allowing large amounts of intake air (i.e oxygen) into the cylinder [hence the high positive LTFT numbers** at idle (pic 26)] on the intake stroke. Good conclusion?

** when looking at the LTFT numbers, focus on the line graph and how it stays high around 30 and not the 15.62% and 14.84% which simply represent a moment in time measurement as the snapshot was taken

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4963

- Thank you received: 1113

Smeter12 wrote: Matt T wrote: "That injector definitely ain't firing every 180*".

Not sure I understand. It is not unreasonable for a manufacturer to spray all injectors every half turn of the camshaft (i.e. one full turn of the crankshaft) when trying to get the vehicle started.... respectively.... am I missing something?

If it were actually firing every 180° it would be evident in this waveform.

This is showing one injection event every 720°

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.