Fuel Trim Discussion and hopefully some guidance....

- Smeter12

-

Topic Author

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 4

VEHICLE INFORMATION:

On today's dinner menu, we have a 2002 Ford Ranger with a 3.0L V6 (i.e the Ford Vulcan 3.0L engine that produces a neck snapping 150 bhp). When connecting my Mac Mentor/OTC Genysis and going into manufacturer specific I get the following codes:

BACKGROUND INFO

1) P0301 - misfire on cylinder #1

2) P0305 - misfire on cylinder #5

3) P0316 - misfire on startup

As per Ford IDS scan tool the fuel trim are as follows:

At idle:

Bank 1 - STFT: +1.54%

LTFT: + 29%

Bank 2 - STFT: + 9.73%

LTFT: + 29%

At about 1500 RPM

Bank 1 - STFT: - 0.33%

LTFT: + 12.1%

Bank 2 - STFT: - 3.17%

LTFT: +12.5%

Took the Ranger for a test drive, and the data PID "Caluclated Engine Load" (i.e. VE test) was 99.6% at 4970 rpm (as per the Mac Mentor scantool).

Monitored the rear O2 sensor, and once the cat was warmed up, I had voltage readings of 0.6V to 0.8 V so I am concluding that fuel delivery is not an issue.

MY TANGIBLE DIAGNOSTICS:

I figured... okay... breathing of the engine is good based upon the 99.6.....so the chances of a valve train issue and/or piston issue was ruled out in my mind. Based on the fuel trim numbers at idle and 1500 rpm, I thought I was dealing with some type of vacuum leak. Likely, the lower plenum was leaking by the block / head. Being told that smoking the intake would not show anything with regards to the lower plenum leaking, I decided to (based on advice) to remove the PCV valve and plug the hole where the PCV valve came out of, insert a vacuum gauge into the oil dipstick tube, and start the engine. If I did have a lower plenum leak, I should have had a vacuum reading on my gauge - I did not. Putting things back together (i.e. remove plug and put PCV valve back), I plugged the intake vent into the crankcase and watched my vacuum gauge go down to -7 psi. Looks like crankcase and lower plenum gaskets are okay.

MY CONFUSION:

Heck, I am always confused! Nevertheless, I am hoping someone can help me minimize that by responding to this post. Based on the fuel trim numbers (i.e. double digits), one would think there is a problem mechanical problem with the engine. Yet, the testing of the crankcase function and VE test show otherwise. I have always been taught fuel trims numbers will help lead you to the system that is not functioning properly (i.e. air, fuel, or ignition). In my case, the breathing seems good and the fuel deliver is there (based upon the rear O2 sensor's voltage). The only system left (unless I am missing something) is ignition. But, if I had an ignition problem, the LTFT numbers should be single digits off idle. Anyways, hoping someone can chime in as I have had enough of this sh*t box for today. I am sure a night of sleep will rekindle love for the vehicle.... well.... some love anyways. As always, thanks in advance for posting.

Please Log in or Create an account to join the conversation.

- cj1

-

- Offline

- Premium Member

-

- Posts: 87

- Thank you received: 12

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6070

- Thank you received: 1533

If you're rocking the IDS, you can also use the Cylinder Contribution Test/Power Balance Test to ID weak cylinders. The only reason I bring that up is the P0316, which pretty clearly spells out some kind of significant misfire.

I tend to agree that you're still chasing some kind of vacuum leak. Unfortunately, there's still several more suspects to cross off the list.

Brake cleaner is also an option, though it's not my favorite. I'd suggest that only if the water doesn't show an issue.

Please Log in or Create an account to join the conversation.

- guafa

-

- Offline

- Platinum Member

-

- Posts: 477

- Thank you received: 80

Please check my logic.

I have this idea that V.E test is useful for high rpm range (no dirty, no ground issues).

At idle is better to check vacuum pressure or air flow. Being said this, please post those numbers.

Please Log in or Create an account to join the conversation.

- Smeter12

-

Topic Author

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 4

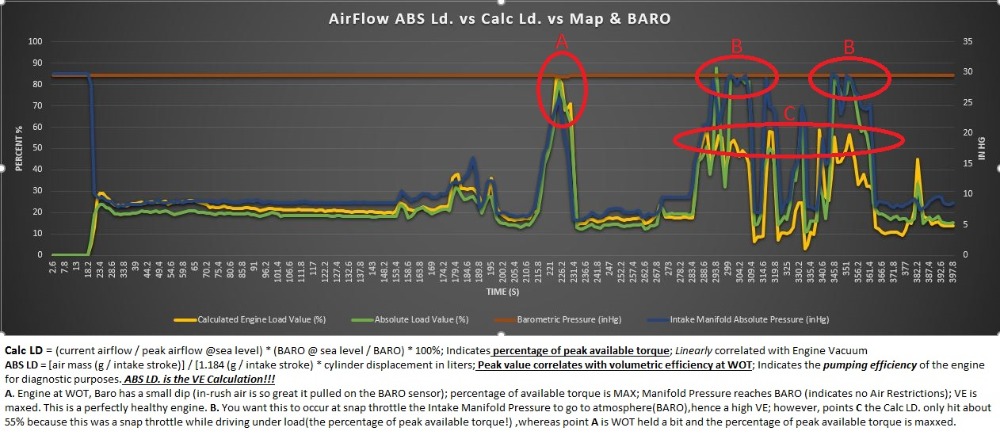

As for the VE test - I wasn't really confident that I was getting good numbers from my MacMentor noting how the VE test showed 99.6% while being logged into Global OBDII. At idle, while being logged into Global OBDII, the MacMentor should a VE of 51%. Thus, I used my VERUS to challenge the VE test. I logged into manufacturer specific (on my VERUS) and logged the PIDS RPM, MAF (g/s); IAT; and Baro (in Hg). Once I did a wide open throttle in 2nd gear, I plugged the respective numbers into a VE calculator and got a VE test result of about 82%. Considering how my engine was running, this was a more plausible result. Nonetheless, with a 82% result you are in a grey area - does the engine indeed have a breathing problem or is there a MAF, intake plumbing, and/or valve train issue.

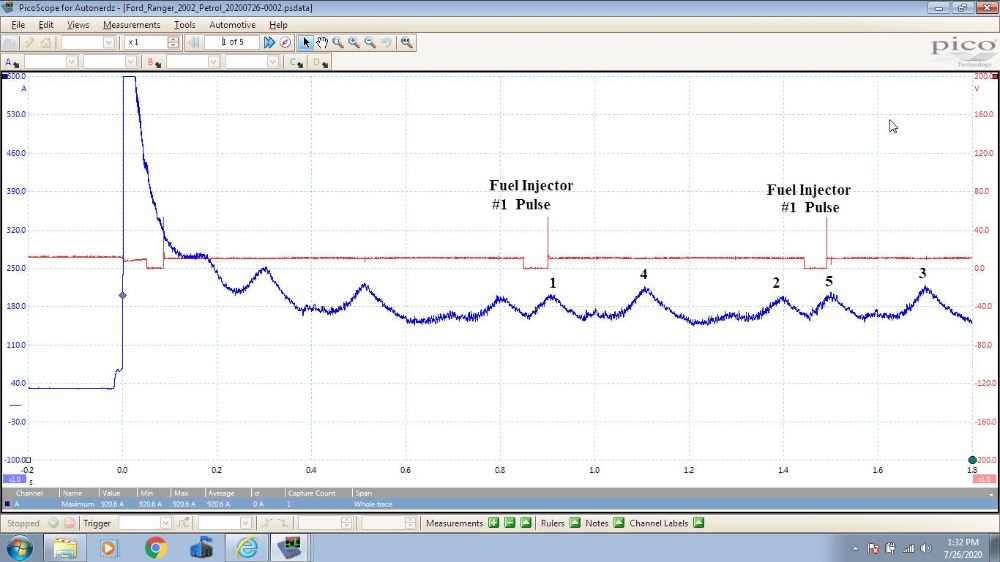

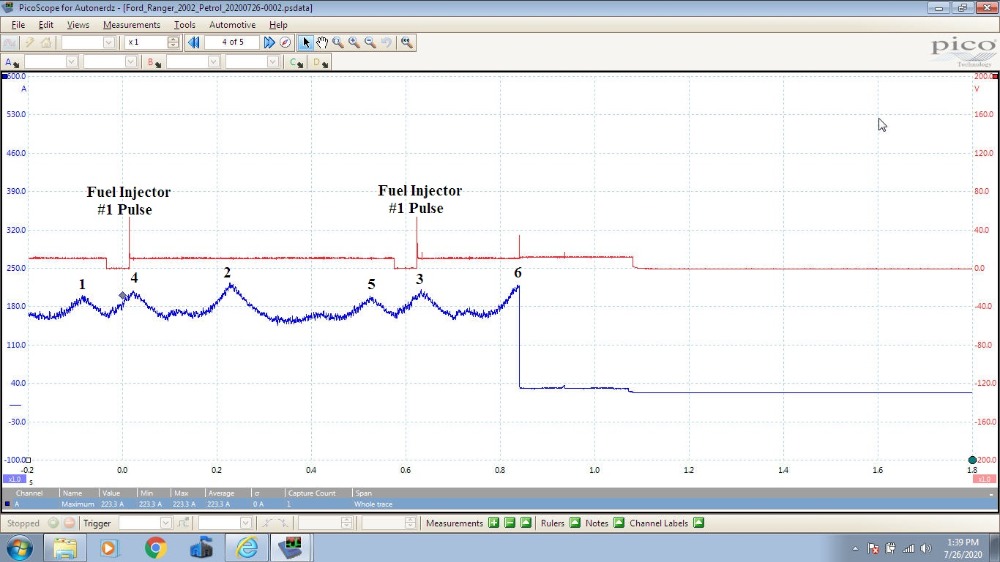

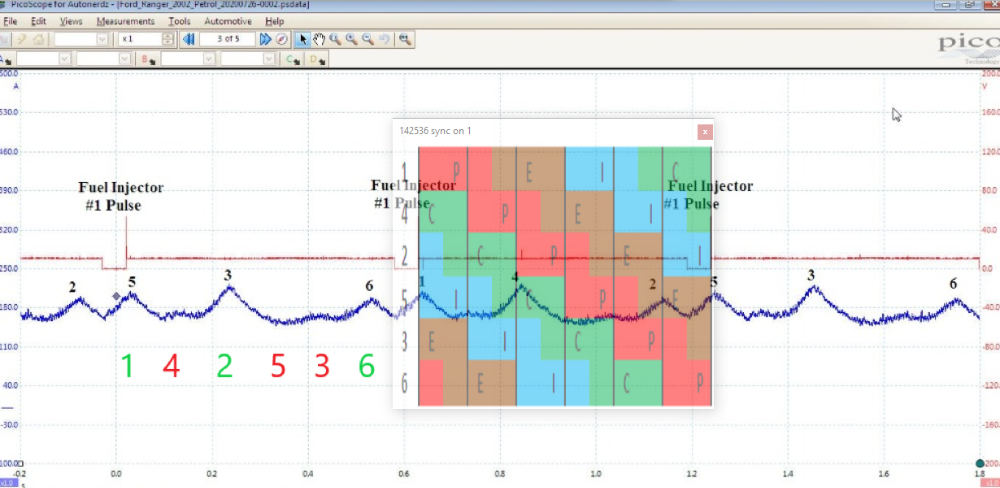

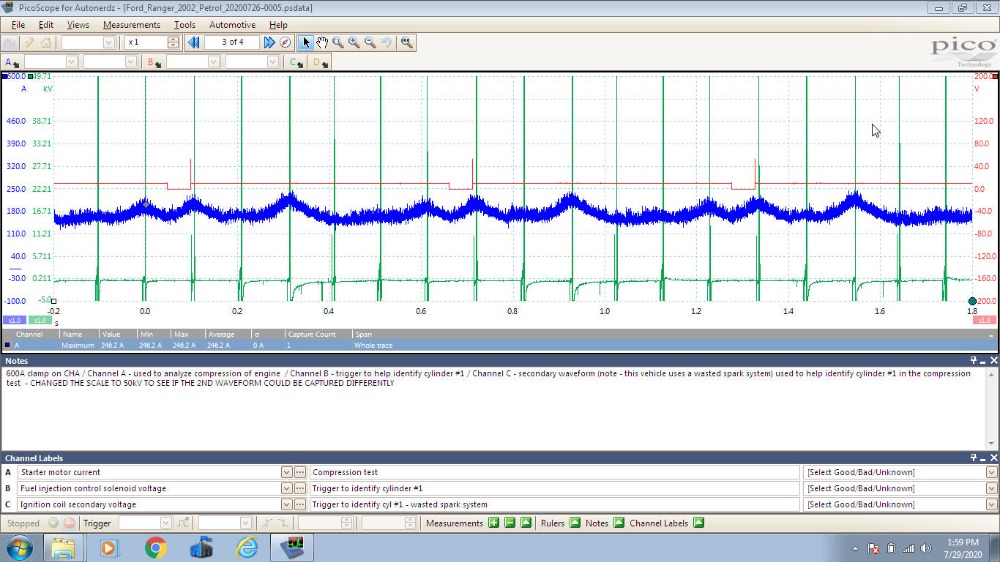

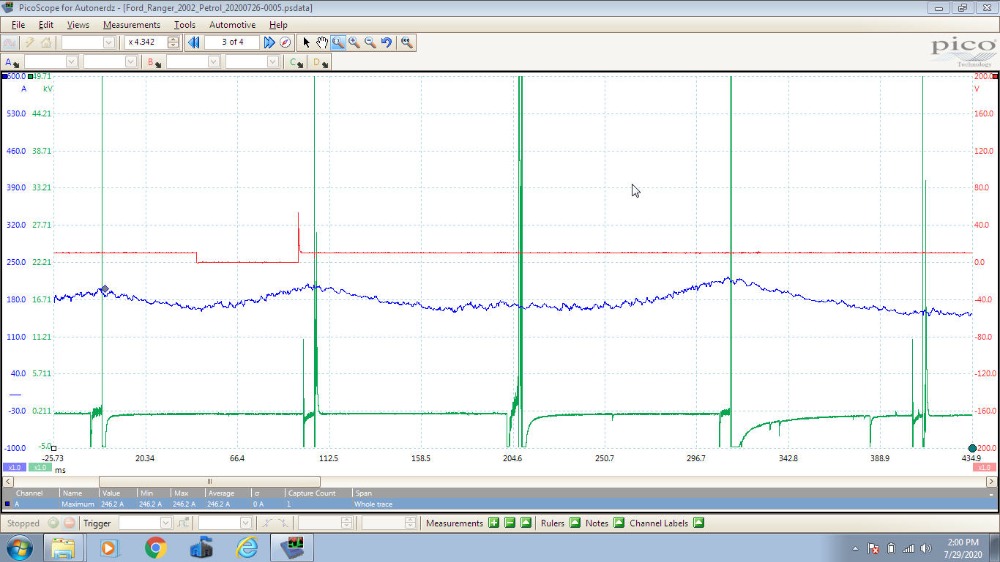

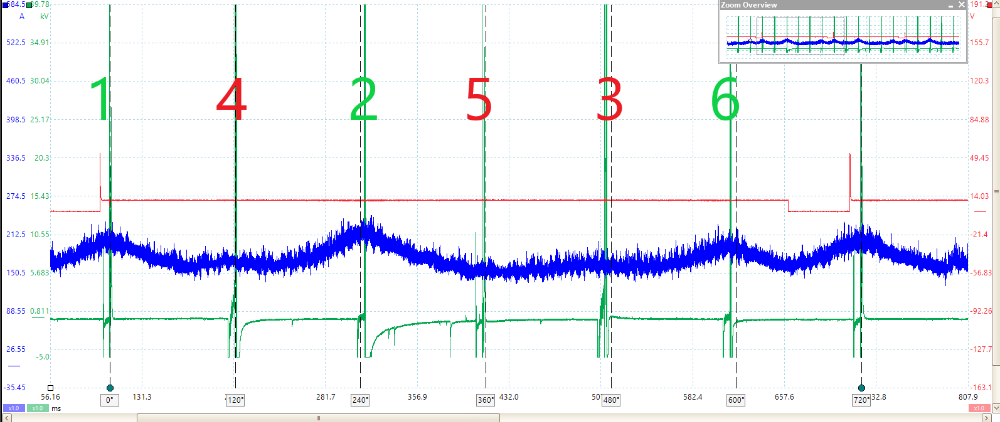

In an effort to check compression (i.e. eliminate a potential valve train issue), I performed a relative compression test with my Picoscope. The result of this test are attached in 4 pics. Here are my questions from attached 4 Picoscope pics:

A few things to keep in mind while looking at the 4 attached pics:

- firing order is 1-4-2-5-3-6

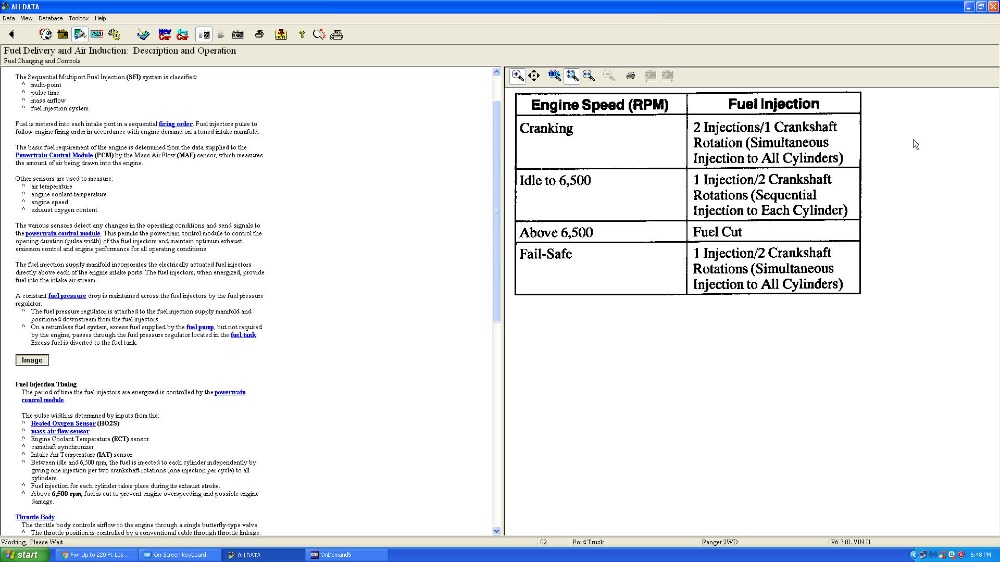

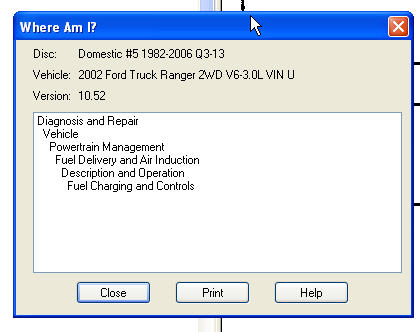

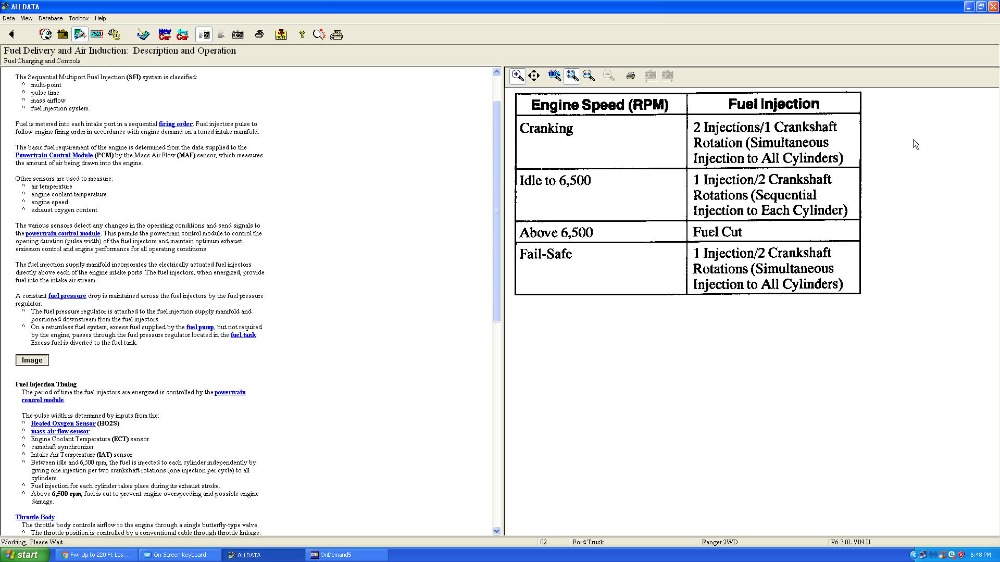

- when looking at the 4 attached pics, I am assuming that have I labelled the peaks (i.e. power stroke / fuel spraying) properly. Please remember, the fuel strategy of the Ford 3.0 V6 PCM sprays the fuel injector 2x every crankshaft rotation while cranking (i.e. when engine speed is lower then idle)

Again, here are my questions:

1) Is compression on all 6 cylinders good (note - mileage on vehicle is about 162,000 miles)? I think it is, however I am not sure. The peaks of cylinder #2 and cylinder #5 are lower then the rest. During the compression test, battery strength was good, however, the starter motor was "okay" (vs excellent) for delivering turning power. Am I just dealing with a starter motor issue then rather then a compression issue in cylinders #2 and #5?

2) why is the amperage low for so long between cylinders #4 and #2 as well as #3 and #6 while cranking? Again, is the "okay" starter motor in this truck to blame for that part of the wave form?

3) in pic 4, it seems the timing is off as the compression peaks of the cylinder no longer line up with the timing of injector #1 spraying. Again, is this the starter motor / battery dying off because I may have been cranking to long.

As always - thanks in advance for whatever the heck you want to share from that thing in between your two ears!

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Smeter12 wrote: Please remember, the fuel strategy of the Ford 3.0 V6 PCM sprays the fuel injector 2x every crankshaft rotation while cranking (i.e. when engine speed is lower then idle)

If you're correct it'd be once per crank revolution not twice. But are you 110% sure about that cranking strategy? I'd be 'scoping the CKP, or a plug wire, to get a 2nd opinion on that one. If that injector pulse really is once per crank rev you're only cranking at 100 rpm. And I think I can see a couple weak compression attempts between the humps.....

Smeter12 wrote: 3) in pic 4, it seems the timing is off as the compression peaks of the cylinder no longer line up with the timing of injector #1 spraying. Again, is this the starter motor / battery dying off because I may have been cranking to long.!

That one looks mislabeled to me.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6070

- Thank you received: 1533

Smeter12 wrote: Following up on Tyler's suggestion of "use mode 06 and check Test ID $53" to see how bad the misfires are - logged into mode 06 through the Ford IDS and found it really wasn't helpful for misfire counting while the IDS was hooked up through my laptop.

Sorry that didn't work.

Did the IDS allow you to do the Cylinder Balance test?

Once I did a wide open throttle in 2nd gear, I plugged the respective numbers into a VE calculator and got a VE test result of about 82%. Considering how my engine was running, this was a more plausible result. Nonetheless, with a 82% result you are in a grey area - does the engine indeed have a breathing problem or is there a MAF, intake plumbing, and/or valve train issue.

82% out of a OHV engine is pretty good, IMO.

In an effort to check compression (i.e. eliminate a potential valve train issue), I performed a relative compression test with my Picoscope. The result of this test are attached in 4 pics. Here are my questions from attached 4 Picoscope pics:

There's definitely a compression problem here. More than one. I don't know which injector you chose for a sync, but assuming injector #1, this is what I'm seeing:

I added in my own notations on the left, and a timing overlay on the right. I hesitate to get too scientific about this waveform, since I don't know which injector we're syncing off of. Using injectors for a relative compression sync is tricky, since injectors can fire at just about any time during the compression or power stroke, and not necessarily at TDC.

Speaking of injectors, how did you disable starting while you were taking this waveform?

Please remember, the fuel strategy of the Ford 3.0 V6 PCM sprays the fuel injector 2x every crankshaft rotation while cranking (i.e. when engine speed is lower then idle)

I mean no offense here, but are you sure about that? :huh: Because I couldn't find anything about that in the Theory and Operation for this model year.

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

From the looks of it you have a valve issue going on weather it be valve lash issue or a few cam lobes wiped out.

Please Log in or Create an account to join the conversation.

- Smeter12

-

Topic Author

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 4

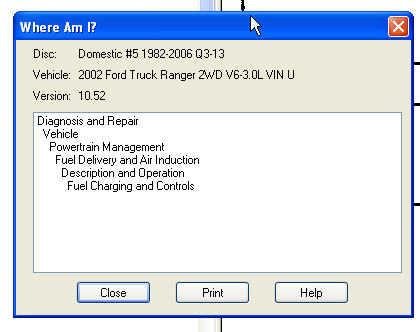

Yeah, you are right. I described the PCM's pulsing strategy of the fuel injectors incorrectly. Please see the attached pics to see the path I used in Alldata to find it as well as the description in Alldata. Thanks for pointing out that mistake.

Considering both your post and Hardtop2dr's post - I screwed things up in pic 4. Will take another kick at the can and repost my findings.

Please Log in or Create an account to join the conversation.

- Smeter12

-

Topic Author

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 4

No offense taken (with regards to me properly communicating how the injector pulse works while cranking) - I appreciate you outlining how I poorly noted how the PCM pulsed the injectors. Taking AllData at face value, it says the PCM for a 2002 Ranger with a 3.0L engine will pulse the injector 2x per crankshaft rotation (simultaneous injection to all cylinders) while cranking (see attached pics). I do admit that sometimes Alldata can apply some of its info to the wrong year, make and model. But again, the 2 injections per 1 crankshaft rotation seems to be good info.

As for Mode $06 - I will revisit that task. When I was using the IDS, it was late at night and cranky pants (i.e. me) here wanted to go to bed so I didn't give that part of the diagnostics proper attention.

As for the cylinder balance test - I didn't think about doing that. Let me navigate the IDS software to see if I can find that in the menu system and get back to you on that one.

Okay - I will not worry about the 82% on the VE test and consider that a pretty good result.

I would like to redo the relative compression test by sync the ignition system with cylinder #1 firing, but I am not sure how to do that on a wasted spark system on the primary side. If memory serves me right, there are only 4 wires at the ignition coil. Do I probe wire 1 (tn/wh) of the 4 pin connector to show when cylinder #1 is being pulsed on the primary side?

I disabled starting by pulling the fuel pump relay and then cranked the engine. There is now a little voice inside of me that says I screwed that up too - did I?

As always - thoughts appreciated and thanks in advance.

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6070

- Thank you received: 1533

Smeter12 wrote: I would like to redo the relative compression test by sync the ignition system with cylinder #1 firing, but I am not sure how to do that on a wasted spark system on the primary side. If memory serves me right, there are only 4 wires at the ignition coil. Do I probe wire 1 (tn/wh) of the 4 pin connector to show when cylinder #1 is being pulsed on the primary side?

That'd work. Unfortunately, being a waste spark system, that coil will get fired at #1 TDC compression AND exhaust. That means you won't be able to tell the difference between cylinder #1 and #5. :silly: That's what these kinds of sync probes are for:

www.aeswave.com/Trigger-Pickup-Inductive...antagePRO-p8662.html

If you have a secondary ignition pickup for your Pico, you can also use one of those on the spark plug wire for #1. You'll be able to tell the difference between #1 and #5 based on the height of the spark firing line.

I disabled starting by pulling the fuel pump relay and then cranked the engine. There is now a little voice inside of me that says I screwed that up too - did I?

Nah, that's fine.

If possible, a clear flood crank would be easier/faster. That'd eliminate injector pulse and possibly result in higher compression humps due to the throttle going wide open.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Calc LD is not to be confused with VE. It is a measure of the Percentage of Peak available Torque.

ABS LD. Peak value correlates with volumetric efficiency at WOT; it indicates the pumping efficiency of the engine for diagnostic purposes.

ABS LD. is the VE.

For example, you perform a WOT run and the ABS LD doesn't MAX out, there is an air restriction. Also at WOT,. the Intake Manifold Pressure should rise to meet the BARO which is Atmospheric pressure. Makes Sense? The throttle plate is wide open, the pressure should equalize to BARO as fast as possible. So if your BARO is 29.92 InHg and on a WOT test you can't achieve more the 20 InHg, you've got an Air Restriction that needs to be diagnosed, whether its an Intake Restriction, Valve Issue Restriction, or an Exhaust Restriction.

I hope this helps you.

Paul

Never stop Learning.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

Weycraze wrote: So if your BARO is 29.92 InHg and on a WOT test you can't achieve more the 20 InHg, you've got an Air Restriction that needs to be diagnosed, whether its an Intake Restriction, Valve Issue Restriction, or an Exhaust Restriction.

l

An exhaust restriction will make the MAP reading go....HIGH!

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

jeurgen.scholl you are absolutely correct! Thank you very much, I should have been more clear on this instead of listening to my train of thought while typing.

When there is an exhaust restriction, the MAP value will equal atmospheric value as soon as the throttle plate is opened and the engine fails to accelerate.

My description is misleading in dealing with known good.

Again, thank-you for the clarification.

Paul

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Smeter12 wrote: But again, the 2 injections per 1 crankshaft rotation seems to be good info.

Alldata is obviously wrong on this one. That injector definitely ain't firing every 180*. The way you numbered the relative compression traces is with the injector firing once per crankshaft revolution. That makes it look like you have some compression on all 6 cylinders.

What the rest of us are seeing is a normal SFI injector pulse once every two crank revolutions on an engine with serious mechanical problems.

Please Log in or Create an account to join the conversation.

- Smeter12

-

Topic Author

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 4

I did take a capture of my secondary waveform from cylinder #1. Please see the attached 2 pics as well as the actual PSdata file from Picoscope.

I haven't got a clue at what I am looking at as I am new to wasted spark as well as Picoscope. I am assuming the secondary waveform capture is proper. If so, Tyler, can you give a few comments as to what I am looking at?

Thanks.

Please Log in or Create an account to join the conversation.

- Smeter12

-

Topic Author

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 4

Not sure I understand. It is not unreasonable for a manufacturer to spray all injectors every half turn of the camshaft (i.e. one full turn of the crankshaft) when trying to get the vehicle started.... respectively.... am I missing something?

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6070

- Thank you received: 1533

It's tough to say which cylinder is which based on the secondary waveform, because the 50kV scaling cuts off the peaks of the firing lines. It's the peaks of the firing lines that helps us determine if the spark plug is firing on compression or exhaust. Compression in the cylinder or not.

I borrowed this page from Paul's book for reference:

At this point, I think you have enough evidence to justify pulling plugs and manually testing compression/leak down on every cylinder. And that's coming from someone that hates manual gauge testing.

Please Log in or Create an account to join the conversation.

- Smeter12

-

Topic Author

- Offline

- Senior Member

-

- Posts: 58

- Thank you received: 4

Tyler wrote: "Did the IDS allow you to do a cylinder balance test?"

Tyler, I am running Ford IDS version 118.05. I navigated through the menu system, but I could not find a way to turn off an injector one by one.

Hope this post helps

Please Log in or Create an account to join the conversation.