Cannot fix Single cylinder misfire under load.

- type3sqr

-

Topic Author

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 0

Here is the new screenshot.

So, what do I need to do next? Josh had mentioned testing the injectors and others have mentioned testing voltage drops. If you guys could walk me through how to perform these tests, or point me to a site that explains it I'd appreciate it. I will also try to drive this again and make it misfire to see what the scope reads considering my previous attempt was wrong.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

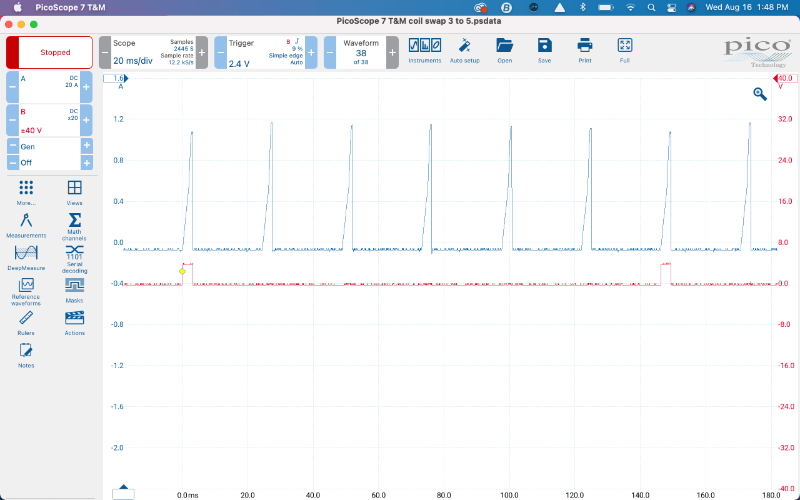

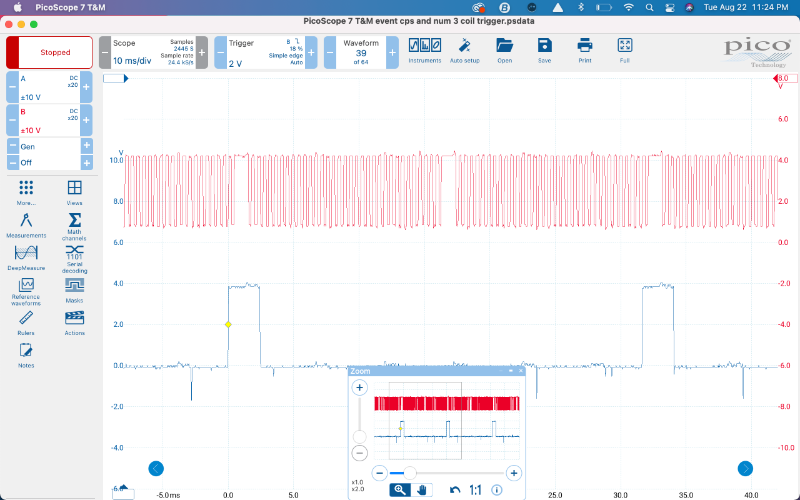

1 - how would still current flow through the coil as indicated by the blue trace without being triggered?

2 - the shape and time of the sync signal (red trace) looks nowhere normal for a coil trigger.

Where the signal onthe red trace disapperars is probably when the kijector was shut down.

Though the difference in coil current is not normal I would not focus on that for now. It maybe caused by different coil designs, simple as this. 9 amps is still enough to fire a coil under heavy load in my book.

Try to capture both injectors of the missing and of a good cylinder when the misfire occurs, one cylinder at a time.

You also may want to take crank sensor capture under different load and rpm conditions to check for any possible deviations that may cause the ecm to see a misfire, be it real or not.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

1 - how would still current flow through the coil as indicated by the blue trace without being triggered?

2 - the shape and time of the sync signal (red trace) looks nowhere normal for a coil trigger.

Where the signal onthe red trace disapperars is probably when the kijector was shut down.

Though the difference in coil current is not normal I would not focus on that for now. It maybe caused by different coil designs, simple as this. 9 amps is still enough to fire a coil under heavy load in my book.

Try to capture both injectors of the missing and of a good cylinder when the misfire occurs, one cylinder at a time.

You also may want to take crank sensor capture under different load and rpm conditions to check for any possible deviations that may cause the ecm to see a misfire, be it real or not.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

1 - how would still current flow through the coil as indicated by the blue trace without being triggered?

2 - the shape and time of the sync signal (red trace) looks nowhere normal for a coil trigger.

Where the signal onthe red trace disapperars is probably when the kijector was shut down.

Though the difference in coil current is not normal I would not focus on that for now. It maybe caused by different coil designs, simple as this. 9 amps is still enough to fire a coil under heavy load in my book.

Try to capture both injectors of the missing and of a good cylinder when the misfire occurs, one cylinder at a time.

You also may want to take crank sensor capture under different load and rpm conditions to check for any possible deviations that may cause the ecm to see a misfire, be it real or not.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- type3sqr

-

Topic Author

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- type3sqr

-

Topic Author

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 0

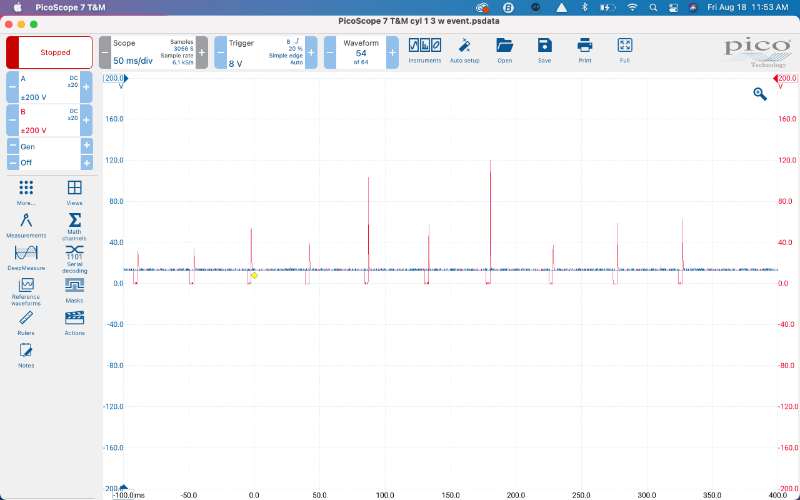

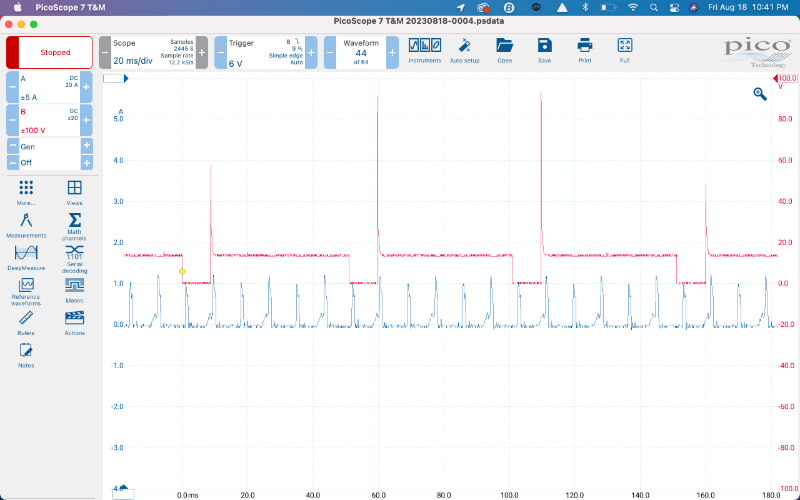

So I hooked up my 2 channel scope to the port injectors on 1 and 3 to get a comparison and then made the truck misfire like before. It looks like the port injectors turn off at around 2300 rpm, so I will need to try the direct injectors next. All I could tell from the capture was that both of the injectors turned off at 23-2500 rpm and after the misfire happened at around 3500 rpm, only number 1 injector came back on when the engine rpm came down.

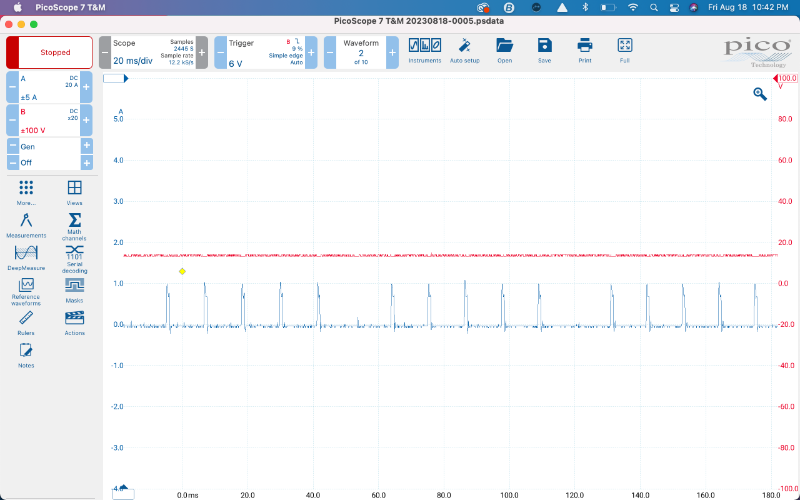

This is where both turned off at around 2300 rpm or so.

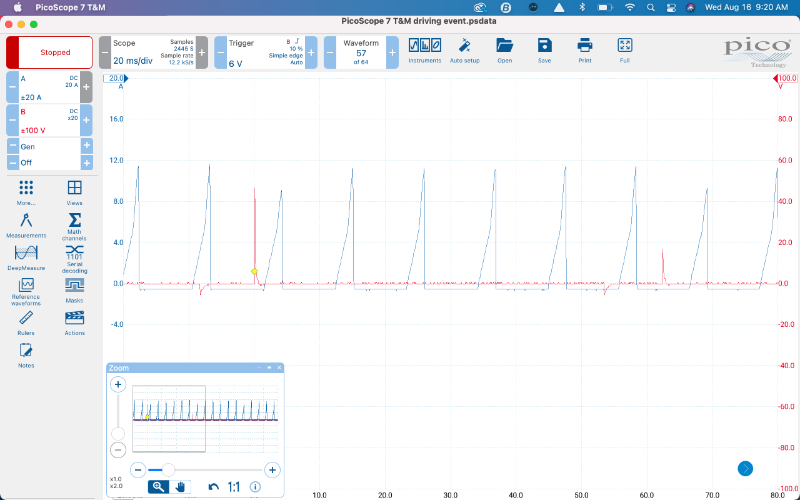

And this is after the misfire and as the port injectors turn back on.

Please Log in or Create an account to join the conversation.

- JoshuaK

-

- Offline

- Senior Member

-

- Posts: 50

- Thank you received: 5

I've read that port injectors are used when the engine is cold and at low RPM, so that would make sense that they would shut down at 2,300 RPM.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

Then get another capture, this time connected to #1 and #3 GDI injectors. .

This may allow to relate the misfire on #3 with 'somerthing' concerning the direct injection..

Did you ever play with the GDI injectors, swapping them around or looking for pressure changes in the rail while activating them?

Often GDI injectors' power feeds are grouped in pairs, so probably no fault there.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- type3sqr

-

Topic Author

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 0

When I installed the engine back in March or so, the misfire was present. I installed a rebuilt set of direct injectors then and the misfire has stayed on cylinder 3. I suppose there is a chance that the new set had a bad injector and I just happened to install it on the same cylinder that already had the issue, but I doubt it.

I have not tried to do any work on the GDIs. I do not have a scan tool that can do that activate them individually or check the pressure in that rail. I've only been able to check fuel pressure in the port rail. I did however already replace the high pressure pump last year. From what I've read and watched videos on, the GDIs get different voltages on both the negative and positive feeds from the ECM, so I may have to use both channels to view each direct injector. I'm hoping I can get a signal off of one of those by themselves so I can see both direct and port injectors like you requested.

Please Log in or Create an account to join the conversation.

- type3sqr

-

Topic Author

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 0

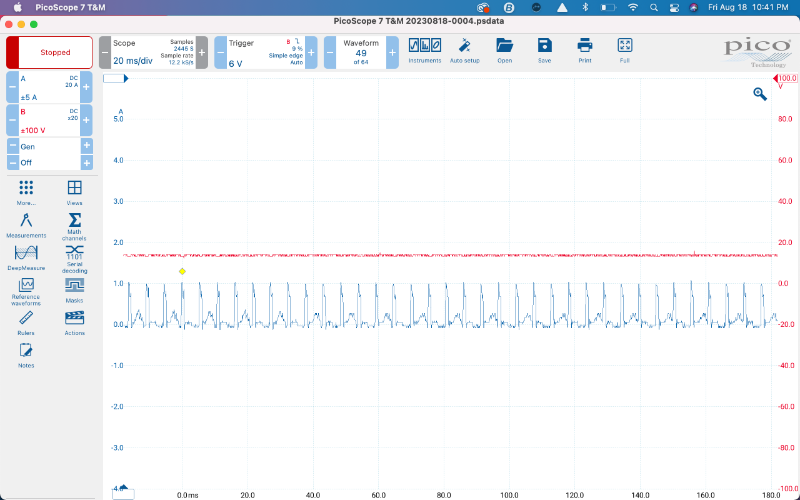

I can not see any differences in the current ramping between the cylinders, but there is definitely a hump every other firing. Once the misfire happens, that humps no longer exists. I don't know why, but thats the only thing I could see that was different before and after the event. I will add photos below. I did the same tests with my trigger on cylinder 1 port injector and the capture looks exactly the same.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

Is there anything else on this circuit that provides power to the port injectors?

So it's the port injector that (gets) shut(s) down, good to know.Do the same test with the GDI injectors.

Misfire detection is based on crankshaft acceleration so a varying/defective ckp signal may cause an issue. I would look at the ckp signal under varying load/rpm conditions, again with the highest sample rate possible, alone and with the CMP signal.

Is there any misfire count for the companion cylinder, mane in Mode 6?

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- type3sqr

-

Topic Author

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 0

I believe the power wire to the port injectors does not power anything else. Just so we're on the same page though, the tests I did last night was the current probe on the direct injectors with only channel b on cylinder 3 port injector for triggering.

What I believe I've proved though is that after the misfire, the ecm turns both the port and direct injector off for cylinder 3, but the coil does not seem to be affected.

During normal driving both sets of injectors are used up until around 2300 rpm or so and after, the port injectors turn off and that also seems to be the case under load as well. Generally speaking this misfire has happened only under load at higher rpm which makes me believe that the port injectors aren't part of the issue. Josh had mentioned earlier in this thread that he thinks its a spark issue, but I couldn't see any differences in before or after the misfire with the the current clamp on the power wire to the coils. Perhaps that is the lower sample rate? I will try to resolve that and test again.

I have not tested the crank sensor yet, but will try that as well.

When looking at my scan tool, I am seeing a misfire count for cylinder 3, and maybe 1 or 2 misfires on an adjacent cylinder, but will have to check again to see which one.

Please Log in or Create an account to join the conversation.

- type3sqr

-

Topic Author

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- JoshuaK

-

- Offline

- Senior Member

-

- Posts: 50

- Thank you received: 5

I can't remember - did you scope current on the coils under the fault condition?

Please Log in or Create an account to join the conversation.

- JoshuaK

-

- Offline

- Senior Member

-

- Posts: 50

- Thank you received: 5

You should scope the direct injectors and find the precise moment that #3 cuts out (intentional shutdown) and see if there's any anomaly in the pattern in the few seconds before that moment.

If after all this you can't find any problem, I would swap #3 direct injector with another one.

Please Log in or Create an account to join the conversation.

- type3sqr

-

Topic Author

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- type3sqr

-

Topic Author

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 0

I don't mind swapping the direct injectors if you think that's needed. I'll need to get new intake gaskets though beforehand. They are the metal crush type and I don't think they are reuseable. Do you think I need to replace the direct injector seals when I swap them? They are the teflon type.

Please Log in or Create an account to join the conversation.

- JoshuaK

-

- Offline

- Senior Member

-

- Posts: 50

- Thank you received: 5

Please Log in or Create an account to join the conversation.

- type3sqr

-

Topic Author

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 0

Hopefully the quote part works now so you guys know who I'm responding to.I don't know about the seals but I assume they should be replaced.

I tried unplugging the direct injectors and the motor would stall at idle after it warmed up and wouldn't run at all even with my foot on the throttle, so that was a no go.

I did another current ramp test on the power feed to the coils and made the truck misfire. I see nothing in waveform that suggests that the coil isn't firing.

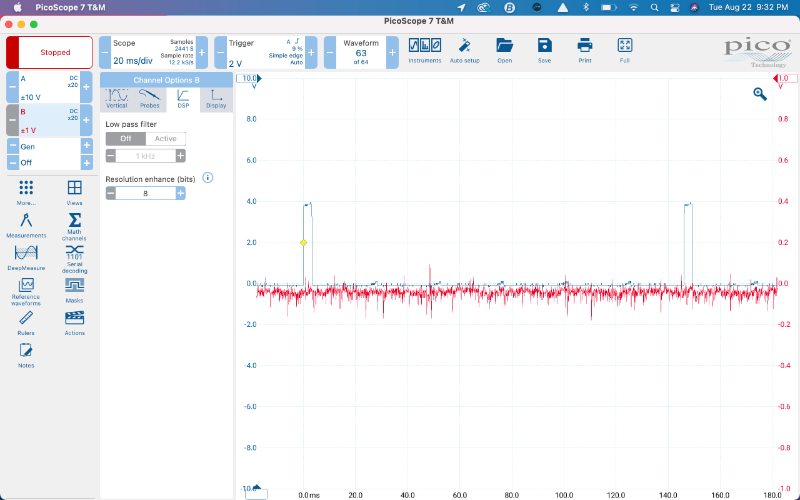

I tested the CPS to see if it was acting up during the event and again, I see nothing to suggest that.

I then tried hooking up the IGF for a shot of its waveform and I couldn't get a signal. I checked as best I could online and in the wiring diagrams I've been using for this truck to see if toyota uses that extra coil wire for a ground or for IGF and it appears that I should be getting a squarewave out of that wire to signal that the coil did in fact fire. All I'm seeing is what appears to be a random trash signal that doesn't see to match anything. I'd really like to confirm this at some point if possible. I am currently watching ScannerDanner video "operation and testing coil over plug ignition (4 wire) toyota/lexus" so if my truck is the same as this one, I should be able to get a signal. I am using my main lead on the signal wire at the ecm for bank 1 and the ground is grounded to the frame of the truck (same ground I'm using for the other lead). This is the only waveform I got from this.

I will try again next chance I get to do this test again, with both banks.

Please Log in or Create an account to join the conversation.

- type3sqr

-

Topic Author

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 0

Please Log in or Create an account to join the conversation.