Slow times at the shop - GIVE ME YOUR TESTING SUGGESTIONS

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

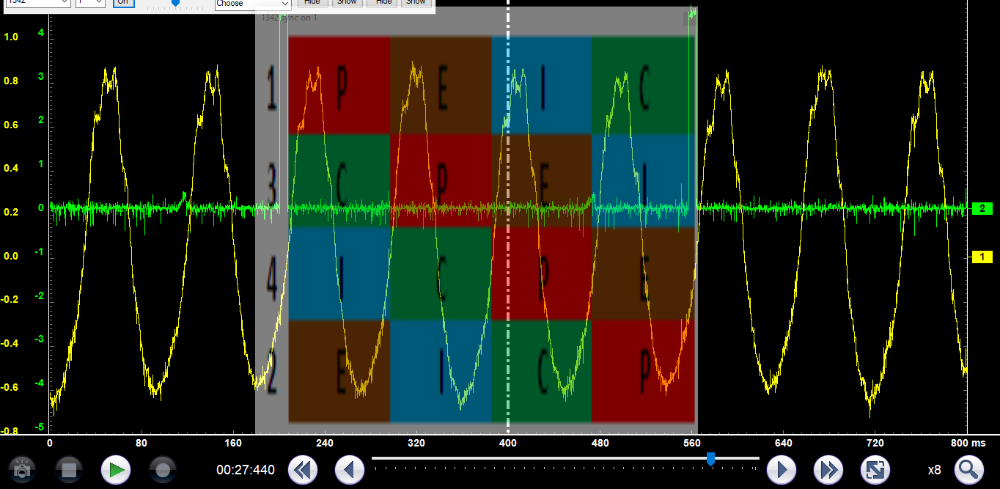

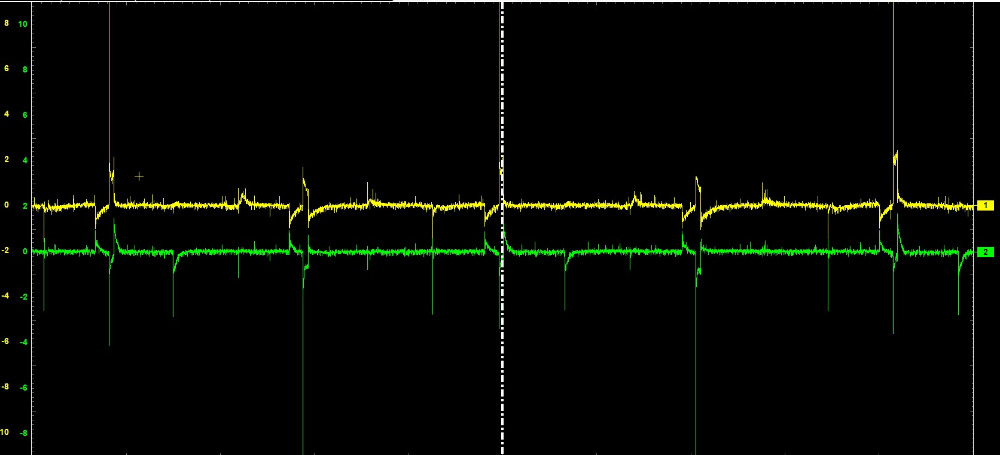

Meanwhile, we're trying out our new Wynn's decarbon service on a '16 Hyundai Sonata. 100K+ miles, never been cleaned. Complaint of a roughness when cold. Here's what the Cody's sensor has to say about the intake pulls:

Will repeat the test when we're done with the service.

Please Log in or Create an account to join the conversation.

- Dylan

-

- Offline

- Moderator

-

- Belgium, Europe

- Posts: 1461

- Thank you received: 327

We use a granulate to clean the intake on GDI's. Works pretty good. Not the most fun thing to do but hey if it works. But I'm curious about the Wynn's decarbon service.

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2151

- Thank you received: 723

Just thought I'd throw this out there for discussion because I have always struggled to understand this (and still do).

As I'm typing this, I'm thinking of a circuit with two resistors in series (resistors are sparkplug gaps). Applying the voltage drop principle, I can understand how voltage could drop passed the "Compression Air Gap" and still have enough energy to jump the "Non-compression Air Gap". But, how could the coil release "X" amount of voltage to jump the "Non-compression Air Gap", then step voltage UP to jump the "Compression Air Gap"?

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

Dylan wrote: We use a granulate to clean the intake on GDI's. Works pretty good. Not the most fun thing to do but hey if it works. But I'm curious about the Wynn's decarbon service.

It doesn't really seem to have done much? Other than make smoke. :silly: I'll post the before and after borescope pictures we took. I retook intake waveform as well.

In general, I haven't been impressed with chemical solutions to heavy carbon deposits. As a maintenance item, maybe, done on a regular schedule. IMO, the granulate you use (or just manual cleaning) is the only real solution.

Just thought I'd throw this out there for discussion because I have always struggled to understand this (and still do).

Askin' the real questions.

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2151

- Thank you received: 723

Tyler wrote: I'm trying to think if we have any waste spark cars at the shop to experiment with

I'm not sure if I have one in the shop, right now, either. Now, I am thinking about capturing Secondary Ignition, from both the compression cylinder and the companion cylinder, simultaneously, on the same coil fire, with two separate ignition probes. I can't believe I haven't done this, before. :ohmy: I wonder if a time delay between cylinders could be seen? :huh:

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2151

- Thank you received: 723

This is a .vsm file. I had to add the .PSDATA extenstion, because the forum does not have .vsm files on the "allowed file" list. Click the link and SAVE the file. After it downloads, RENAME it and delete the .PSDATA extension. (You may have to un-check "hide extensions of known file types" in Control Panel\Folder Options.) Now, you can open it with Shopstream Connect.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Tutti57

-

- Offline

- Platinum Member

-

- Posts: 1096

- Thank you received: 253

Any tips on some applicable situations with those would be great.

Nissan Technician

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

Like most techniques (and just about anything else we do), practice makes perfect. I dunno that I have exact known good values for every vehicle/engine combination? But I have ranges. Within that range, I don't ask questions. I can make suggestions about ranges to use, but I believe that kind of thing is best left up to the one doing the testing.

The value of Load (especially Absolute Load), in my experience, is a quick indicator of engine breathing issues. No known good or VE calculator necessary. If I run a suspect vehicle through 1st at WOT and get an Absolute Load number I like, I scratch most breathing problems off my list of suspects. If the Load number isn't high enough, I start asking questions.

Using Global OBD for Load is best, in my experience. The PID definitions and calculations are standardized, and not subject to the whims of the OEM. Load is Load is Load on the Global side.

Please Log in or Create an account to join the conversation.

- Tutti57

-

- Offline

- Platinum Member

-

- Posts: 1096

- Thank you received: 253

How about evap testing dodge/jeeps? No bi-directionally vent control. I know some use a pump, but am not very familiar with the design. I have to do some reading there. There is a service port in the front but service info says to put some in the back. I guess pull the hose off the LDP and pump it through there?

Nissan Technician

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

www.scannerdanner.com/forum/diagnostic-t....html?start=34#31239

The root problem on that truck was a stuck intake runner control system. There's a bunch of other examples in there where I install problems to see what happens. :silly:

Again, a 'good' range comes from seeing known good engines several times. In general, I expect OHC/DOHC engines to do at least 80% Absolute. OHC/DOHC engines with VVT are expected to do 90% or better. Some GM engines I've looked at will do closer to 100%. Most newer Nissan engines (with dual VVT) will do 95-100%.

Now for the variables.

On turbocharged speed density systems, however, Absolute Load is more useful because boost pressure is the sum of several components working correctly. I like to see at least 175% from 2.7L and 3.5L EcoBoost engines. Maybe closer to 150-160% for the four cylinder versions. I don't see those nearly as often.

I like Absolute Load for turbo MAF systems, as well. GM 1.4L LUV and LUJ engines will do around 160%. Mini's with the N18, 170%.

Sorry for the brain dump. :blush:

How about evap testing dodge/jeeps? No bi-directionally vent control.

I love CDJR Leak Detection Pump/Natural Vacuum Leak Detection/Evaporative System Integrity Module systems. :lol: I think they're easier to test? And I find that CDJR products are less likely to leak in crappy locations, like pump seals or filler necks. Maybe that's just my location.

LDP/NVLD systems fail regularly for stuck pressure 'switches'. Instead of a tank pressure sensor, they use a switch that opens/closes in the presence of a specified amount of vacuum. A couple inH2O, IIRC. Less than that or more than that, the system doesn't know and doesn't care. So, if you can put the tank under a vacuum and don't see the switch change state, that switch sucks. Verify wiring and PCM integrity using typical SD switch input methods, then change the switch.

Leak testing is straightforward, like you said. Either put the smoke in the vent side, or put it in at the purge and cap/pinch the vent. No scan tool required. Purge valves rarely fail, in my experience.

ESIM systems are even easier. Besides the purge, the only moving part is the ESIM switch itself (on the canister), which fails all the time. This video explains it better that I can:

For ESIM leak codes, it's easy breezy. Pinch/plug the vent out of the ESIM and introduce smoke. Flow gauge goes to zero? The leak code is false due to a failing ESIM switch. Replace it. Flow gauge shows a leak? Find it. Run the sevice bay test afterwards to make sure it's all happy.

Please Log in or Create an account to join the conversation.

- Tutti57

-

- Offline

- Platinum Member

-

- Posts: 1096

- Thank you received: 253

Nissan Technician

Please Log in or Create an account to join the conversation.