*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

DIY Pressure Transducer

- bruce.oliver

-

- Offline

- Elite Member

-

- Posts: 318

- Thank you received: 88

Please Log in or Create an account to join the conversation.

- SailorBob

-

- Offline

- Elite Member

-

Please Log in or Create an account to join the conversation.

- bruce.oliver

-

- Offline

- Elite Member

-

- Posts: 318

- Thank you received: 88

SailorBob wrote: Set the pico to use 1 khz low pass filtering and that should clean it up. You're just seeing electrical noise probably.

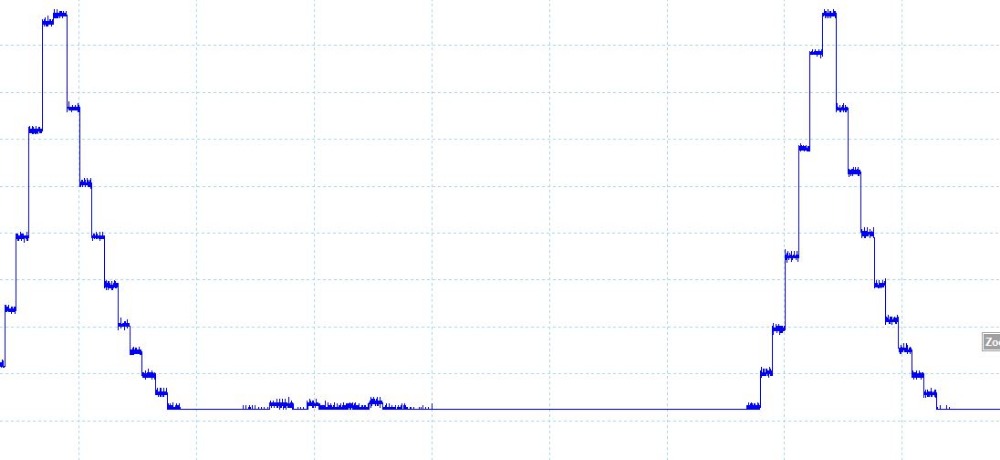

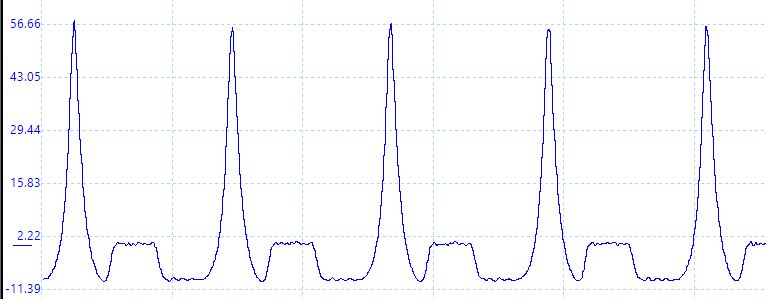

It's not noise. I am used to seeing that on waveforms. It's like Andy described, distinct steps in the waveform. Like the transducer responds to slow for the software.

Please Log in or Create an account to join the conversation.

- ShaoLin68

-

- Offline

- New Member

-

- Posts: 3

- Thank you received: 2

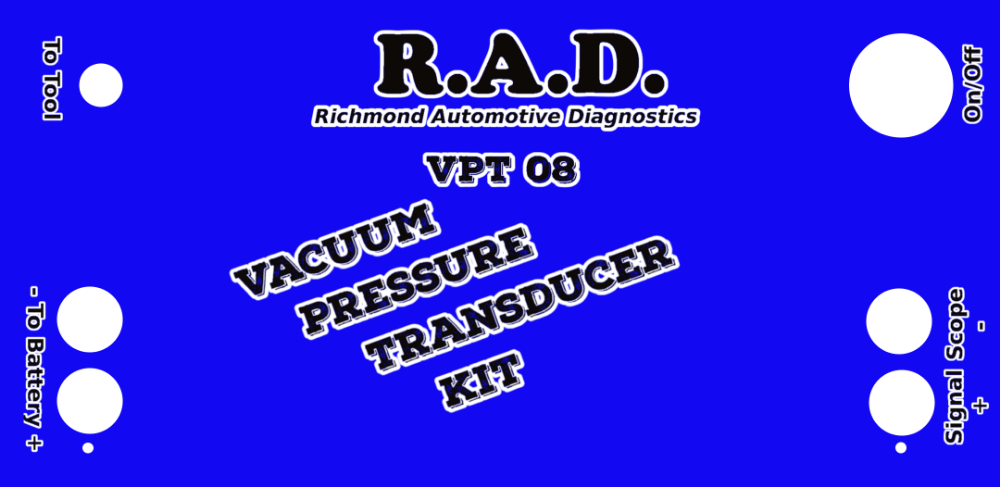

I am making a dedicated set of transducers myself that will be able to be used with either a pico or a verus..

15psi for Vacuum (which converts to 30 in Hg, which is what a regular vacuum gauge reads anyway),

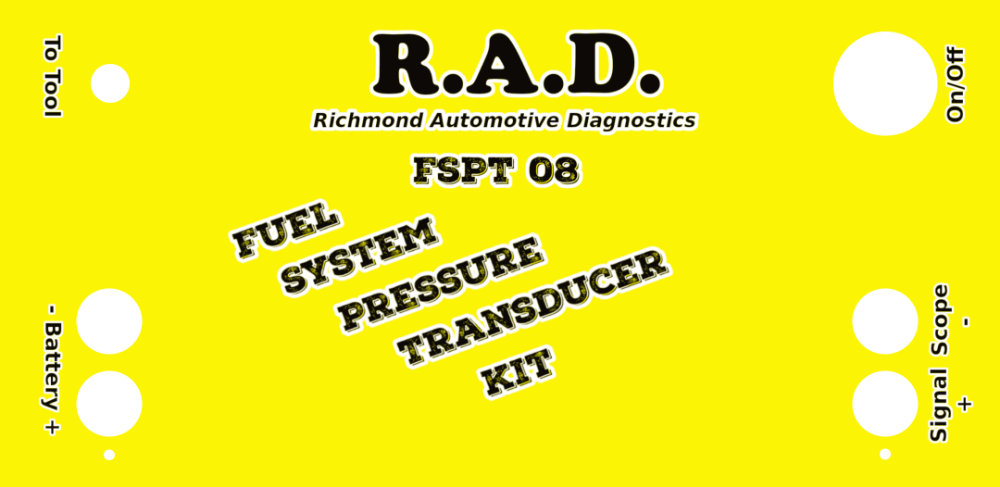

150psi for fuel pressure (a fuel pressure gauge goes up to 140psi),

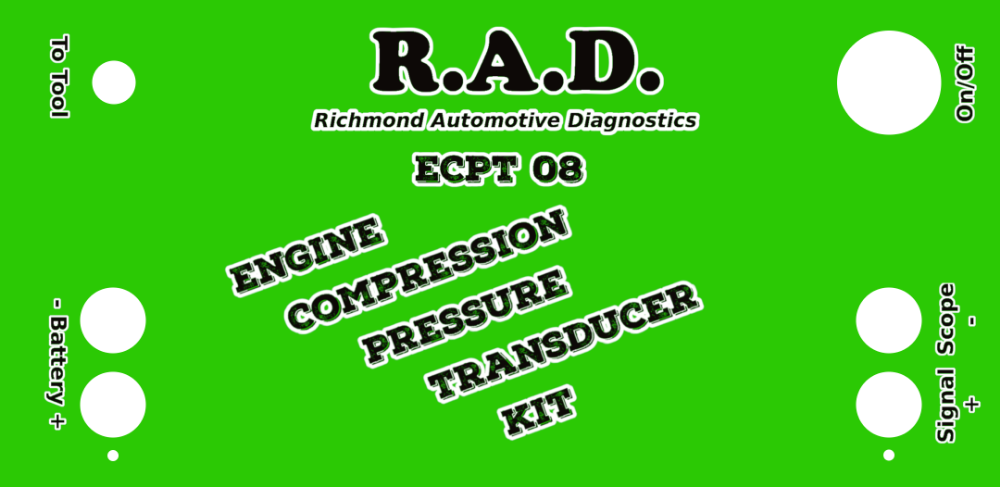

300psi for Gas engine compression (which is what a regualar gauge goes to),

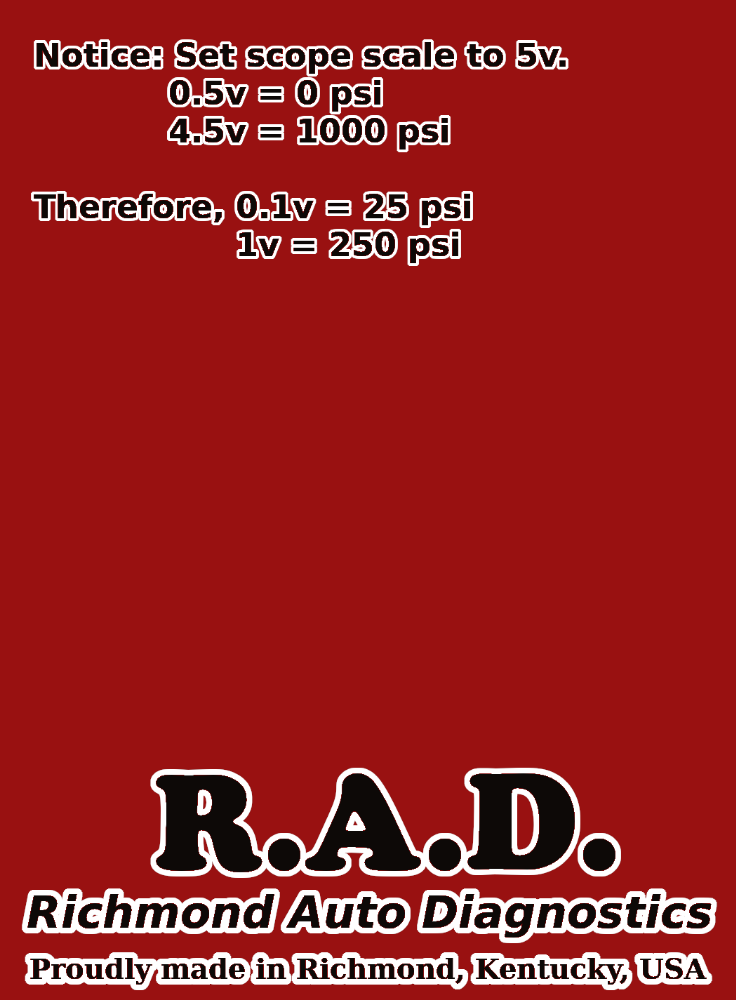

and a 1000psi for Diesel engine compression (which is what a diesel compression gauge goes to.. Im a truck driver, I had to make one for trucks.. LOL)

over the Thanksgiving holiday, I am going to build the ones I have the stuff for so far.. for the electrical, I am using battery power/ground, then going to a 12v/5v stepdown to supply the transducers with the correct voltage.. there will be an LED at the power plug to let you know there is power, and an LED at the signal out to let you know there is signal going to the scope..

I will then post some videos showing them, and showing how to use them so you get the best results.. I dont have access to a verus but I will be testing it on a Hantek 1008C.. I have a 98 Infiniti I30 that will be my test mule..

but that wont be for another month and a half.. I just wanted to point out that the transducers use a 5v and produce a 0psi reading at 0.5v and maximum psi reading at 4.5.. have a good day..

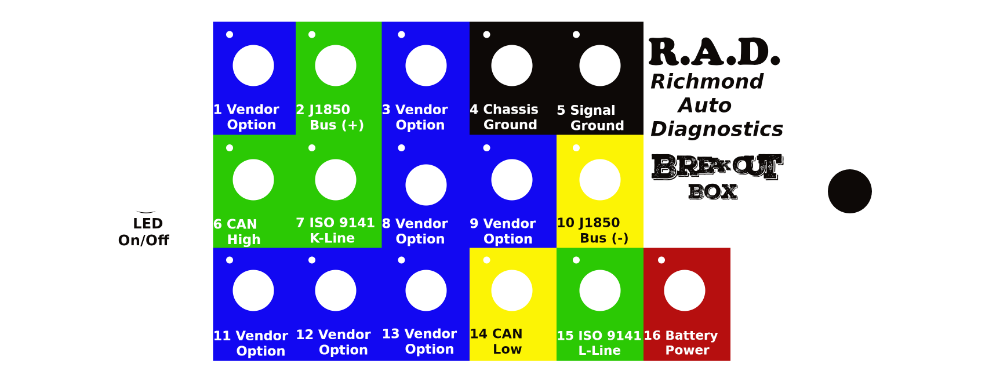

heres a sneek peek at the labels..

Please Log in or Create an account to join the conversation.

- SailorBob

-

- Offline

- Elite Member

-

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1036

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- SailorBob

-

- Offline

- Elite Member

-

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1036

SailorBob wrote: I wouldn't say it doesn't matter - what you need to pay attention to is the Nyquist sampling rate - basically to accurate render the signal, in this case pressure changes, you need a transducer that can respond twice as fast as the signal changes. In dry air at 20*C air pressure changes propagate at the speed of sound, 343.2 m / s , which works out to 3.4 centimeters per millisecond. Or 1.34 inches per millisecond. So for in cylinder pressure readings I'd look for a transducer with at least a one millisecond response time, or really maybe even a little faster than that. Practically speaking, the one I use is rated one millisecond and it seems to produce good waveforms. When paired with 1 khz lpf I get nicely detailed clean waveforms.

Nothing to do with the sampling rate, in fact the steps are only really noticeable when the change is pressure is slow .

Take for a example a sensor rated at 250 psi ---- a sensor with 8 bit internal processing will only have 255 possible analogue output voltages so it will work in steps of approximately 1 psi.

On a 250 psi sensor a resolution of 1 psi steps is better than 0.5% of full scale is more than is required in any real world application.

But by matching the sensors max full scale range to what is being measure the size of the step change in output voltage is reduced choosing 100 psi sensor for running compression tests will improve the step resolution to 0.4 psi, but won't read high enough pressure for cranking compression tests which normally require around 200psi on older gasoline engines and can be 10 to 20% higher on GDI units.

It is of course fairly easy to smooth out the step changes with either an RC filter on wiring between the sensor and scope or on a scope with inbuilt software filters using a low pass filter but detail will be lost.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Sooknanan

-

- Offline

- New Member

-

- Posts: 17

- Thank you received: 5

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1036

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Sooknanan

-

- Offline

- New Member

-

- Posts: 17

- Thank you received: 5

Please Log in or Create an account to join the conversation.

- Sooknanan

-

- Offline

- New Member

-

- Posts: 17

- Thank you received: 5

Please Log in or Create an account to join the conversation.

- Sooknanan

-

- Offline

- New Member

-

- Posts: 17

- Thank you received: 5

This what I bought

Sent from my iPhone using Tapatalk

Please Log in or Create an account to join the conversation.

- bruce.oliver

-

- Offline

- Elite Member

-

- Posts: 318

- Thank you received: 88

Those are the same ones that I got. I've replaced my homemade transducer with a WPS500 kit. Very happy with itSooknanan wrote: Pressure Transducer Sender Sensor... www.amazon.com/dp/B0748C27LN?ref=yo_pop_ma_swf

This what I bought

Sent from my iPhone using Tapatalk

Please Log in or Create an account to join the conversation.

- Sooknanan

-

- Offline

- New Member

-

- Posts: 17

- Thank you received: 5

Your waveform had the same issues as mine.

Sent from my iPhone using Tapatalk

Please Log in or Create an account to join the conversation.

- Sooknanan

-

- Offline

- New Member

-

- Posts: 17

- Thank you received: 5

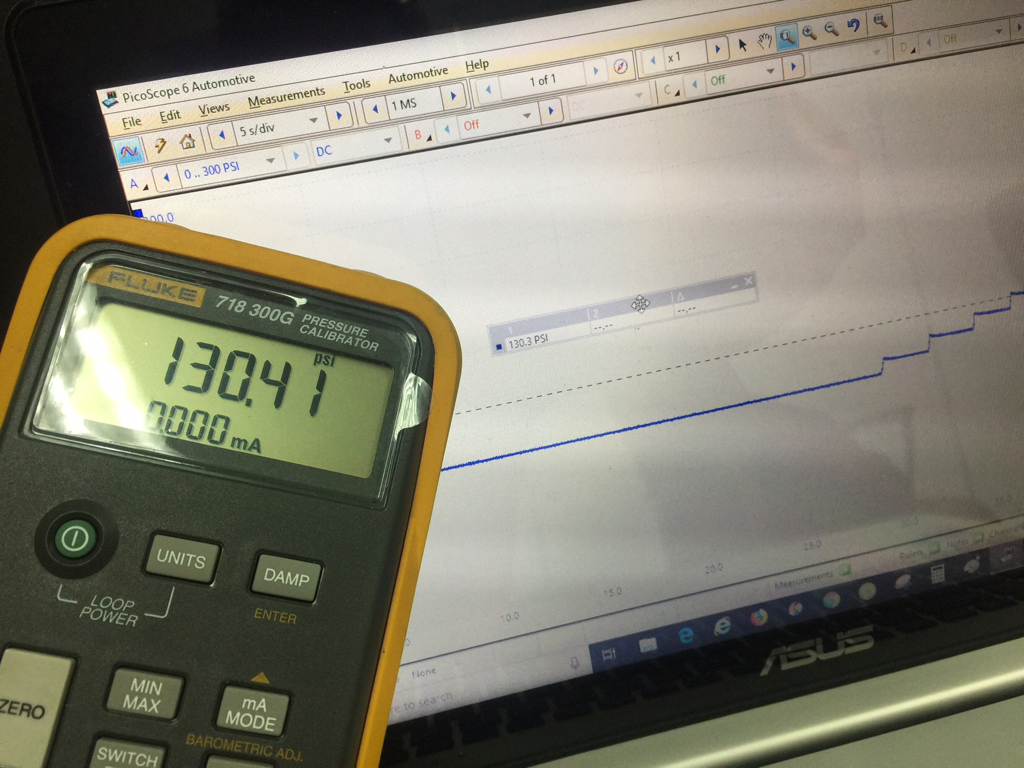

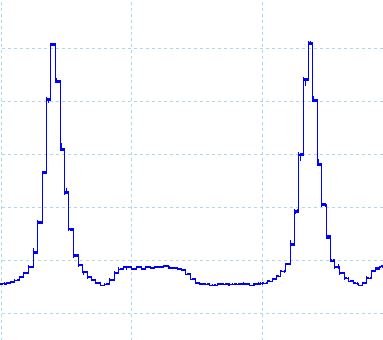

So I tried a 0-100psi on running compression to compare to the 0-300 and it was similar.

After some filtering with the 0-300psi I got this. I will settle with this for now since the waveform is still readable.

Please Log in or Create an account to join the conversation.

- tloftis

-

- Offline

- Junior Member

-

- Posts: 26

- Thank you received: 0

store.snapon.com/Pressure-Transducers-Ki...500-PSI-P636904.aspx

and could we use one of these to use multiple tranducers at one time:?

store.snapon.com/Pressure-Transducers-Ki...Adaptor-P637559.aspx

Please Log in or Create an account to join the conversation.

- tloftis

-

- Offline

- Junior Member

-

- Posts: 26

- Thank you received: 0

store.snapon.com/Pressure-Transducers-Ki...-Ultra--P737766.aspx

Please Log in or Create an account to join the conversation.

- tloftis

-

- Offline

- Junior Member

-

- Posts: 26

- Thank you received: 0

Description

• Adapts standard meter jacks to EEPV302AL, EEPV302AT and EEPV302AH pressure transducers (not included)

• Provides connection of transducer plug to standard meter jacks, and provides power to the pressure transducers

• Use up to two transducers simultaneously

• View results on VERDICT®/MODIS® Ultra/MODIS® Edge/VANTAGE® Ultra/M2 Meter

I am too cheap to buy one LOL Will have to sourse everything. see attached image

Please Log in or Create an account to join the conversation.

- Jose santos

-

- Offline

- New Member

-

- Posts: 2

- Thank you received: 0

Please Log in or Create an account to join the conversation.