Home made in cylinder transducer

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 835

- Thank you received: 138

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

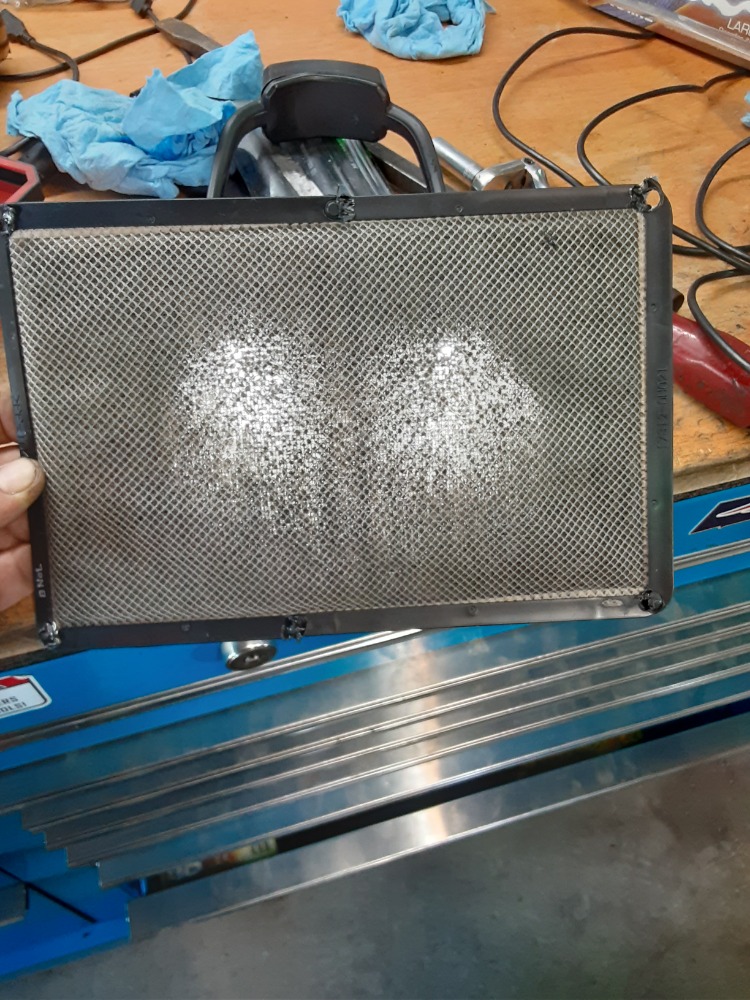

The air filter looks to be brand new-ish.juergen.scholl wrote: Is it possible that the air filter was/is coming apart and restricting the airflow?

I once experienced this on a Ford F150 where the plastic cone came off the filter. The car would bog down on heavy accelerating/WOT as the cone was sucked into and blocking off the air.

There was this bit of under britches integrated into the lid of the filter housing assembly.

And there were some leaves in the bottom of the box, pre filter, but I don't think either one explains the change in symptoms.

It still barely ran with all of that off the car until I gave the throttle a right boot work out.

I returned said under britches to it's place in the filter box and it still runs just the same.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

Weycraze wrote: Atta boy Noah, awesome diag. Looks like you were up against a couple of issues and came out ahead. Tell your Boss to put the old Cat in and take her for a ride!! He'll come back and thank you!

Nice Work,

Paul

Thank you Paul, it still doesn't feel like a win though.

Many unanswered questions...

As for the boss, I'm not interested in convincing anyone at the shop. I find that when I'm doubted, the universe has a way of eventually delivering my vindication.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Noah wrote: Many unanswered questions...

One quick thing you could do is have a look for camshaft position PIDs. Might tell us whether the cam timing is screwed up or something the PCM is doing.

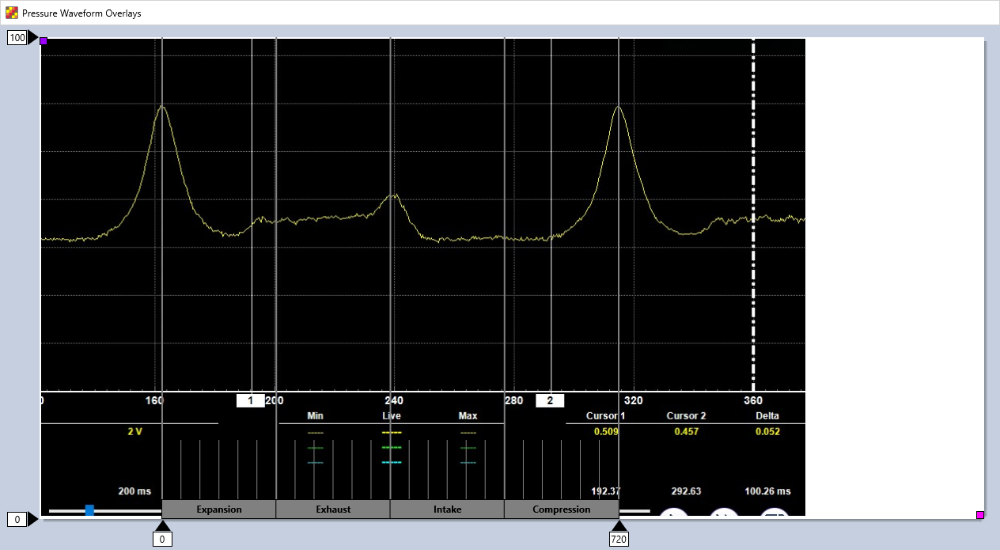

Another would be to put a transducer in the O2 sensor bung to see if there are any pressure pulses which could be affecting the in cylinder waveform. Best to do this with another transducer in cylinder but if you don't have two of them an ignition sync would be good enough.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

- John Curtis

-

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 109

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

Please Log in or Create an account to join the conversation.

al514 wrote: So you connected both power and ground from the USB cable and then connected the scope to the ground at the sensor to monitor the signal? I've been building my own pick ups and sensors so I have to try this. Can you draw up a little diagram, if not too much trouble.

If you've got a 3 wire transducer you give it 5v power and 0v from the USB and scope the signal wire. There's some discussion on whether or not to also tie the USB 0v to scope ground earlier in the thread.

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

al514 wrote: So you connected both power and ground from the USB cable and then connected the scope to the ground at the sensor to monitor the signal? I've been building my own pick ups and sensors so I have to try this. Can you draw up a little diagram, if not too much trouble.

It's very simple. The sensor is 3 wires. It wants 5v and ground to operate, the USB port is capable of delivering this power and ground.

(Matt T is wise to be apprehensive about sourcing this power and from the scope. I haven't hurt anything yet and don't think I will, but the possibility can't be over looked!)

The third wire on the sensor goes to channel one on the scope. Done.

I don't even hook up a ground lead to the scope every time, but when I do it's to the car, not the sensor ground. I honestly haven't tried using the sensor ground.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

Thank you for your insight! Now that the power has been restored, I haven't been afforded the opportunity for much follow up testing. I do have some test drive scan data that isn't very revealing (vvt PIDs don't respond, I'm told that's a common snap on thing with toyota).John Curtis wrote: The EVO is advanced, but it's closing almost on time. This to me can be an indicator of valves out of adjustment. A tailpipe waveform tailpipe waveform along with the in-cylinder could confirm this. But the opening early with the spike does look like an advanced cam. Pretty nice capture with that sensor.

I'm very pleased with the waveform that sensor produces. I bought 3 sensors on Amazon thinking they would be better but the resolution doesn't even come close.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- VizoEdward

-

- Offline

- New Member

-

- Posts: 13

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

I frequently use mine with more than one channel.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

I bench tested mine with a vacuum hand pump and a cylinder leak down tester, and just wrote down the voltage to pressure correlation.

It's pretty linear from what I recall. Most of the time when I do use the transducer, I'm less worried about the actual pressure and more interested in the shape of the waveform.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

www.7pcb.com/

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

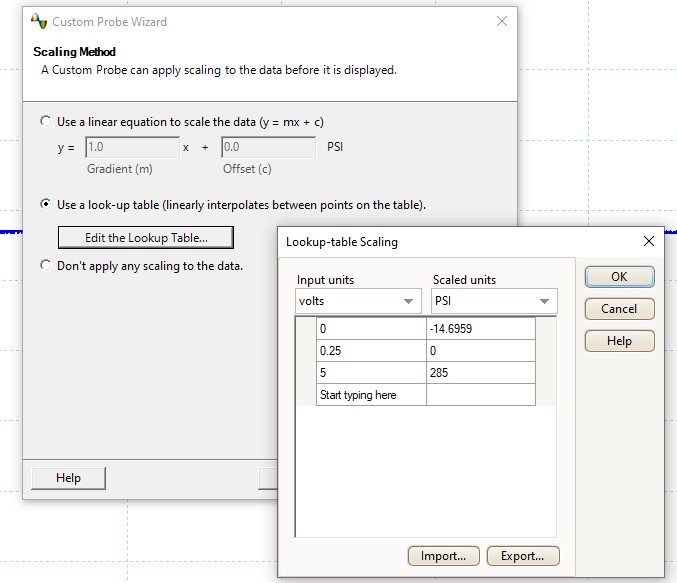

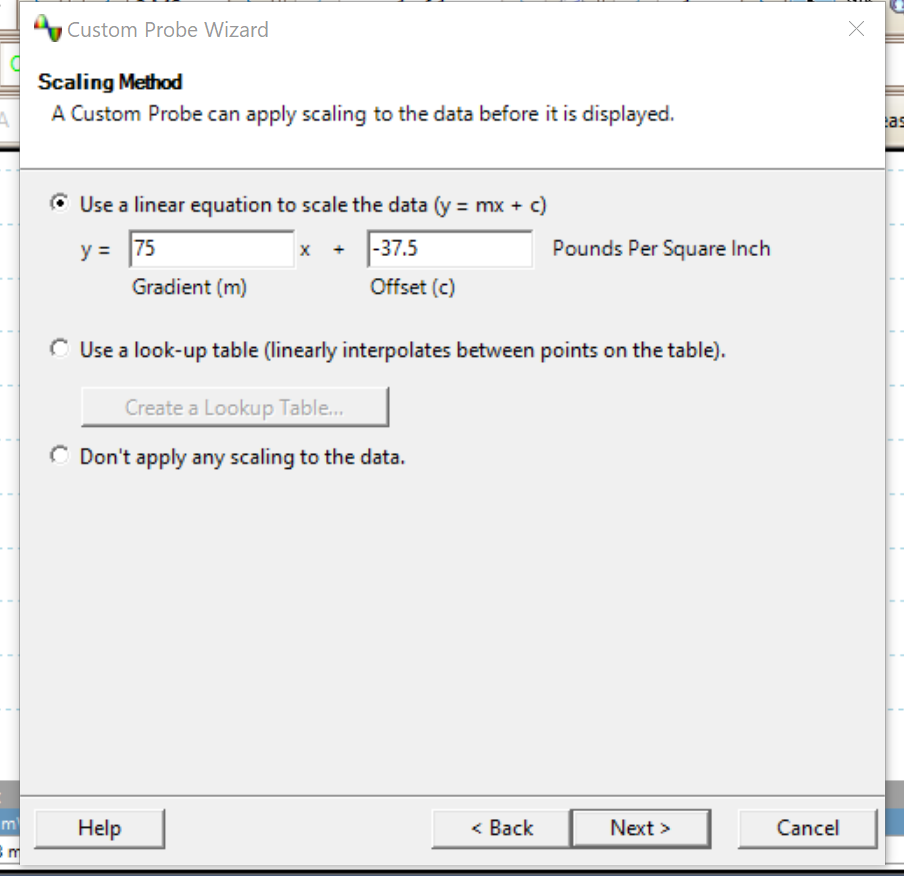

The setup I have works really well, it's a 300psi transducer, and measures vacuum if the correct calculation is put into pico custom probe settings. I just need to figure out how to lower the setting by 2 psi. That's all

Try using a lookup table. Numbers I threw in are guesses for a 300 PSIA 0-5 V transducer. You'll have to adjust the voltages in the table to match your transducer. Also bear in mind that if you do have an absolute transducer the PSIG zero will drift around a bit due to changes in barometric pressure.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

Really my only complaint using salvaged pressure sensors is the lack of accurate voltage to psi scaling.

I recently discovered that the oil pressure sensor on Chrysler 3.6l V6 engines is just about a perfect 1-1 scale using the 100psi transducer setting on Snap-On scopes.

When bench tested against a trusted gauge I never saw more than a 3psi variance up to 100psi on the Verus Edge and Vantage Pro scope.

And, bonus, since I can use the transducer preset, now I can power the sensor with the appropriate AUX connector on the scope and not the USB port. (The aux power source is only switched "on" when selecting a preset that requires it, so on voltage scale the transducers need a different 5v power source)

I have changed a handful of the oil filter housings on these engines under the intake manifold (mostly Grand Cherokees and Chrysler 300s) and decided to harvest the pressure sensors.

It's a pretty common issue so chances are if you're in an independent repair shop, you'll have a chance to score one no charge.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1197

- Thank you received: 446

- Did you take a scope capture of both the pressure reading and the signal voltage as such at the same time?

- Do you happen to know the range/ max. pressure this sensor is capable; does it work with snap throttle acceleration reaching the 300 psi region?

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.