Home made in cylinder transducer

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4901

- Thank you received: 1092

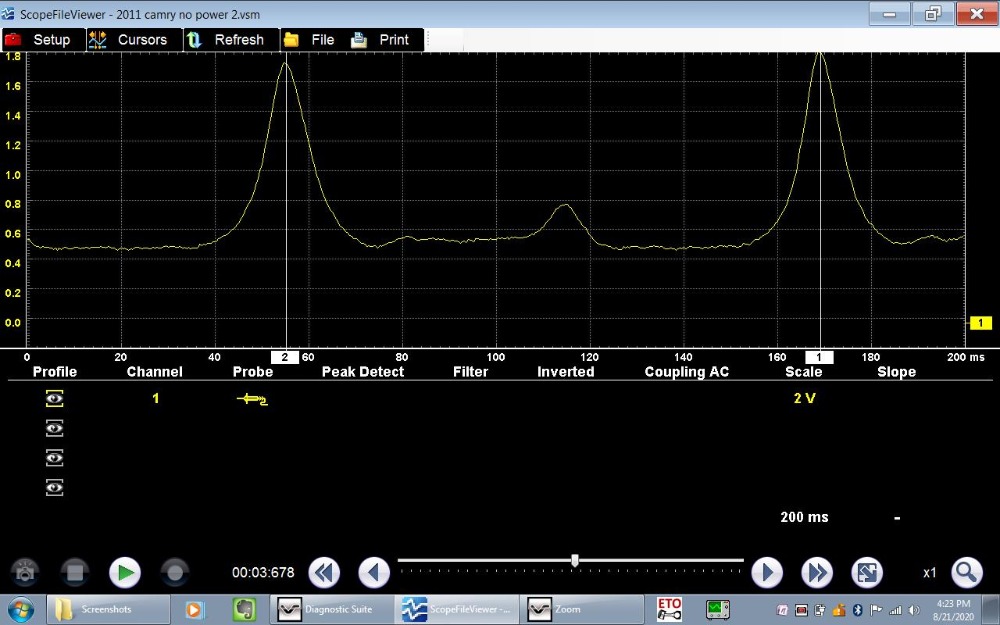

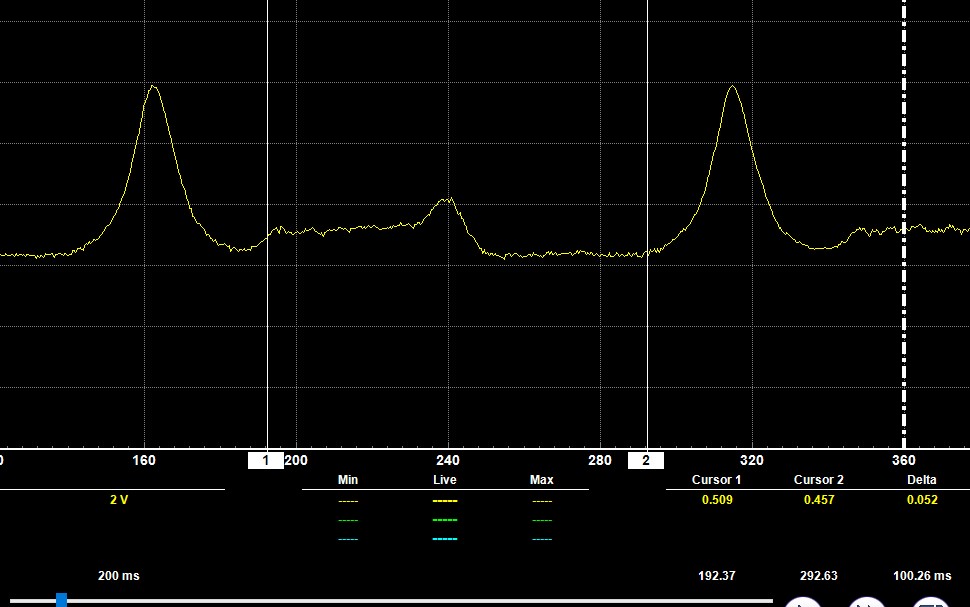

This sensor reports 0.5@atmosphere (sea level here in The Commonwealth).

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6039

- Thank you received: 1517

Did you happen to save the scan data from your test drive? I'd like to have a look, if possible.

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4901

- Thank you received: 1092

And anyone else for that matter if you want to PM me an email address.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Paul

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4901

- Thank you received: 1092

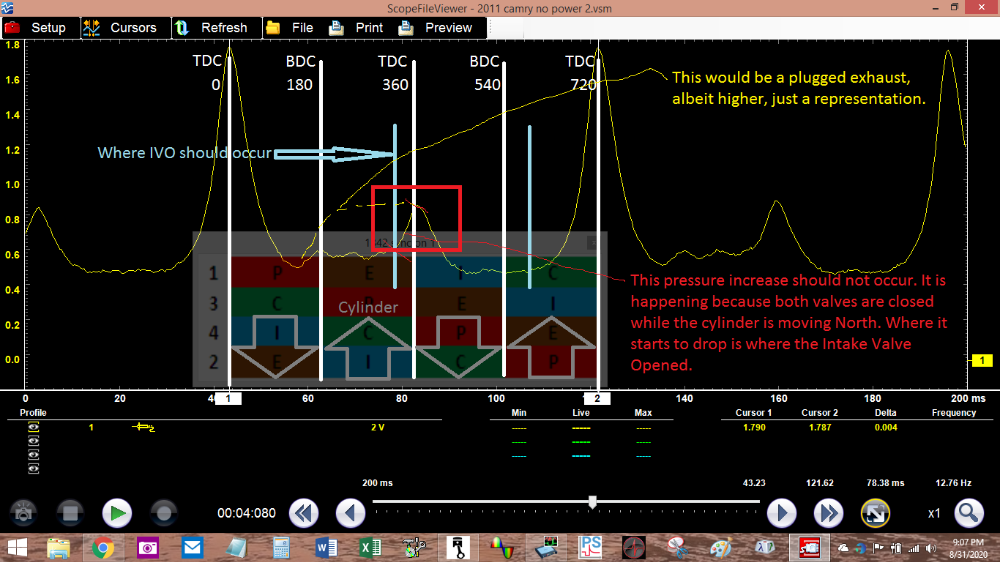

I think I see what you mean.

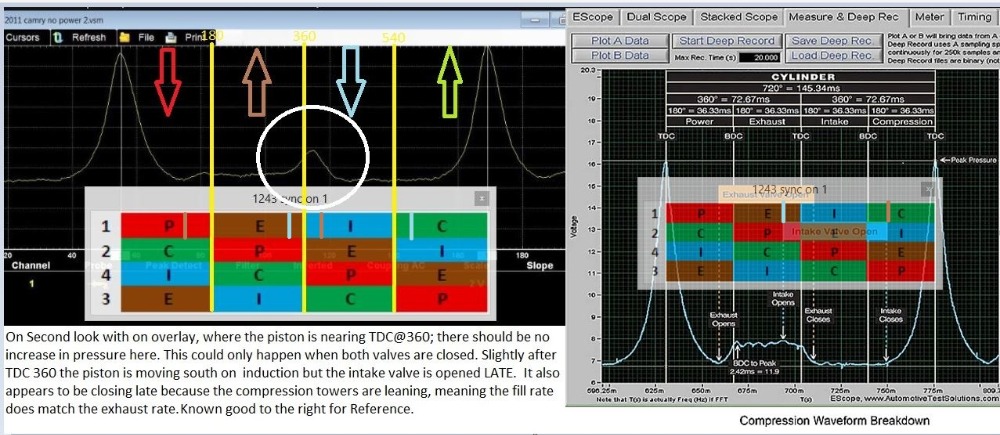

It looks like the rise in pressure is at the end of the exhaust stroke, like the valve closed early. That did make me scratch my head.

I decided to not pursue timing because the back pressure is confirmed to be excessive with a mechanical gauge, and because this is a DOHC inline four cylinder with a cam sensor on each cam. I figured it would have recognized a timing issue, but I know that's not exactly fool proof logic.

Plus it's not a customers car, so no big deal if it ends up needing a chain set after the cat, the car does have more than a quarter million miles.

I will let you know when we get a cat on it.

I am still quite new with in cylinder wave forms, so I appreciate the insight of more knowledgeable techs like yourself.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

The hump is the result of both valves being closed as the piston is ascending nearing TDC Exhaust. Shortly after TDC the piston is descending on the induction stroke, the Intake valve should have opened before 360, but it opens late, then the pressure drops. You can also see it close late at 630 degrees when it should have closed around ~ 585.

I tried to overlay the known good for your reference.

Paul

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Paul

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4901

- Thank you received: 1092

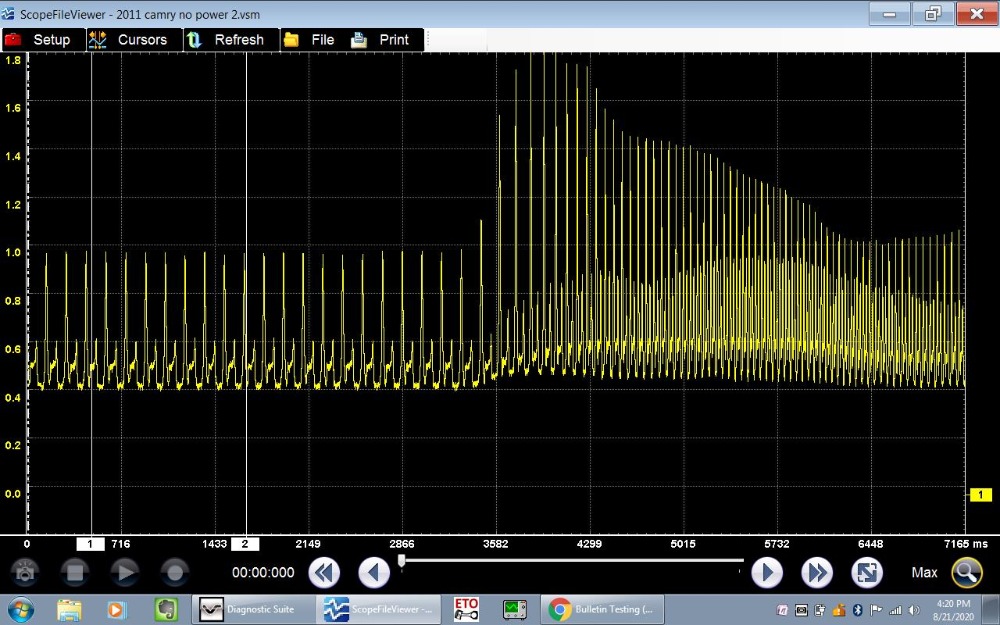

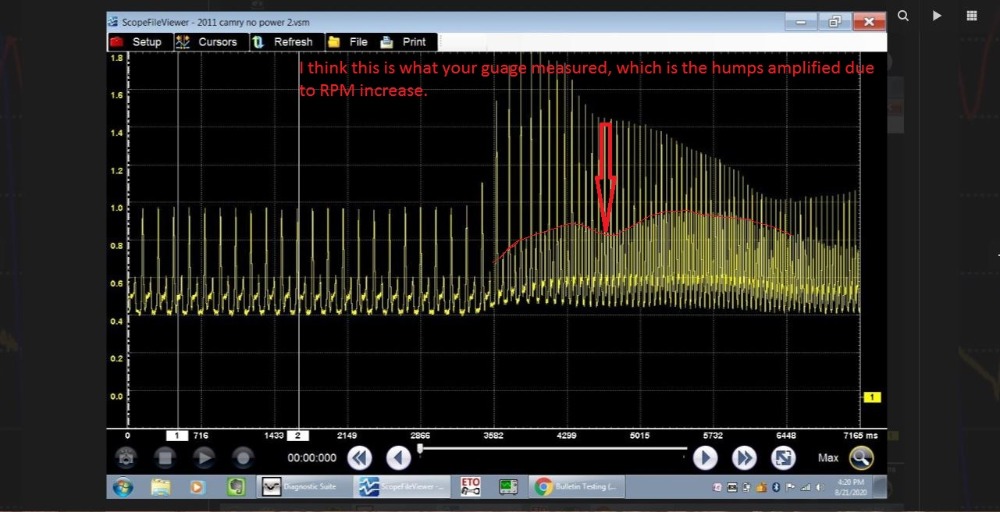

Do you think that that those "humps"at the end of the exhaust plateau measured in cylinder would have been measurable by my mechanical gauge in the exhaust stream?

The only cause for pressure in the exhaust that I have encountered so far is a restriction.

Thanks again for your input and for taking the time to analyze my wave forms.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Weycraze wrote: Please keep me posted on your findings Noah.I'm now wondering that your mechanical gauge was just measuring those humps which would be amplified with RPM increase.

If the humps are caused by the exhaust valve closing early they wouldn't affect exhaust pressure. If they showed up anywhere, outside the cylinder, it'd probably be as pulses in the intake.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6039

- Thank you received: 1517

Noah wrote: I will let you know when we get a cat on it.

The anticipation is killing me. :woohoo:

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Now I'll throw this in there if all the cylinders had the same waveform; that would point towards timing ie chain stretch. But if the hump is just this lone cylinder, by virtue of engine design, a lifter issue.

The reason I lean towards timing/chain stretch is the duration of that intake event which I approximated at ~240-50ish degrees which is a very plausible spec, without knowing the true spec.

It would be sweet of you to post the vsm files you have.

Paul

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6039

- Thank you received: 1517

Weycraze wrote: Actually no, Matt T pointed that out, sometimes I get a little ahead of myself. A gauge in an O2 bung would not pick that up. Only an in-cylinder transducer would pick up the restriction when exhaust valves open. Thanks, Matt T!

If it makes you feel any better, I had the EXACT same reaction when I first saw the in-cylinder waveform. Noah will tell you - I said timing problem. :silly:

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

It will be very interesting to see the outcome here.

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4901

- Thank you received: 1092

I see it.

But...

If I never put a transducer in it and only did a back pressure test, I would put a cat in it with 100% confidence.

Especially considering there's a sensor on each camshaft and that there are no codes.

I'm not saying the chain isn't stretched, the miles alone suggest it may be. But if I hadn't used a transducer, I'd have no reason to suspect it.

I will post the file when I'm back at work.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Weycraze wrote: Thanks, Matt T!l

You're welcome Paul. It seemed plausible at first glance. Took me "a minute" to catch that the exhaust valve would have to be closed for it to be causing the pressure hump.

The strange thing about this engine appearing to have a timing problem is that the exhaust looks advanced but the intake retarded which seems unlikely unless someone has been in there.........

I think, too damn much :lol: ,there are a couple things which might be making things look strange. First is this engine probably has VVT which might be altering the valve timing??

Second is RPM isn't going to be constant on a 4 banger with a dead hole. Speed will drop during the dead holes power stroke then build back up. So cursors equally dividing 720* between TDC compressions aren't going to line up perfectly with the other BDCs and TDC.

One other thought on the exhaust hump is it might be caused by exhaust vale overlap. The next cylinder opening its exhaust valve while the transducer cylinders exhaust valve is still open. That next cylinder could be causing a spike in exhaust backpressure which gets pushed into the transducer cylinder??

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4901

- Thank you received: 1092

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

2AR-FE motor gained the Dual VVT-i system (variable valve timing with intelligence), driving intake and exhaust camshafts within 50 and 40 degrees accordingly concerning crankshaft angle. What is more, valve overlap varied from 7 to 97 degrees while intake and exhaust duration was equal to 244 degrees.

I figured up the time for 2 x 244* - 7* overlap and set the cursors to it. It seems to fit the waveform pretty good.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

This is a non-turbo engine, so this hump is preventing 'scavenging' in the combustion chamber. This Rise in pressure at the end of the Exhaust stroke as the piston is approaching TDC can only be because of all Valves Closed.

Never stop Learning.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

Weycraze wrote: This Rise in pressure at the end of the Exhaust stroke as the piston is approaching TDC can only be because of all Valves Closed.

Recently I was reminded in another post that we have to be VERY careful with qualifiers like always, never, must be, can only....

There are other possibilities to cause such a rise in pressure, for example a blown head gasket on a neighboring cylinder being on compression stroke. This usually will show up as a rise in pressure in the last 20 to 30 degrees before TDC exhaust in the affected cylinder, depending on the severeness of the leak.

Sure, there would be other symptoms like low compression and it would affect both neighboring cylinders in a similar fashion..

Another variable is a stuck open EGR valve .....

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

But, that is absolutely correct, based on the cylinder chart in the post if there was a head gasket leak between Cyls 1&2, and 2 was on the Exhaust stroke, 1's Power stroke would be evident exactly as you describe.

So there definitely are other variables.

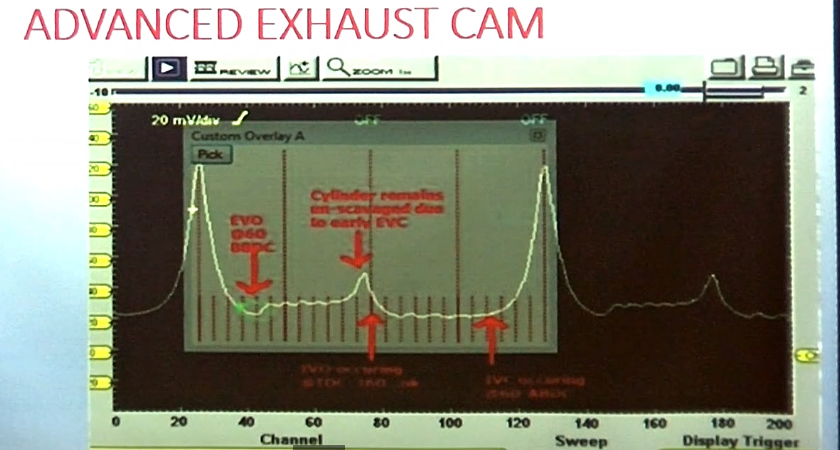

Interestingly enough, the waveform sure matches this one; but that would really depend when EVO occurs.

Thanks,

Paul

Never stop Learning.

Please Log in or Create an account to join the conversation.