Home made in cylinder transducer

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1197

- Thank you received: 446

Noah wrote:

I do still have access to the Accord by the way. It's out in the yard with no tires, I just haven't had the ambition to go out there pull the head.

!!Go for it, Forest:) !!

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

Noah wrote: I do still have access to the Accord by the way. It's out in the yard with no tires, I just haven't had the ambition to go out there pull the head.

If it's past the point you can do any more running tests a cylinder leakdown test would probably be enough. That's if you can get compressed air out to it.

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

Matt T wrote:

If it's past the point you can do any more running tests a cylinder leakdown test would probably be enough. That's if you can get compressed air out to it.

Yeah, I regret not doing the leak down test before she was put out to pasture.

It likely still runs but is quite far away from an air line now, lol.

I've really got to start from scratch now with the failure of the sensor I was counting on using. Very disappointing.

I think it's worth it to revisit the refrigerant pressure sensor and try to develop a repeatable test procedure as far as scope set up is concerned, to gather accurate, interpretable information

I pulled the valve cover off the Accord this week and turned the engine with a ratchet out in the yard didn't see anything right away up top. I'm not looking forward to the support bracket that goes from the intake to the block. That's really the only hard part of doing it out in the yard.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Noah wrote: Yeah, I regret not doing the leak down test before she was put out to pasture.

It likely still runs but is quite far away from an air line now, lol.

I just experimented with my 4 gallon 125 psi compressor. With a 100% leak it took me 5 seconds to crank the reg up then I got 15 seconds run time before the inlet gauge started dropping. A 60% leak I got 20 seconds run time but it would probably be useable for finding where the leak was for a minute total. So if you've got a decent sized portable air tank might be worth carrying it out there.

Noah wrote: I think it's worth it to revisit the refrigerant pressure sensor and try to develop a repeatable test procedure as far as scope set up is concerned, to gather accurate, interpretable information.

They looked really good other than the inconsistency at atmospheric pressure. I think it's worth playing around with power supplies and 'scope settings to see if you can get that repeatable.

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

I got tired of losing my mouse or keyboard dongle to capture in cylinder or vacuum patterns.

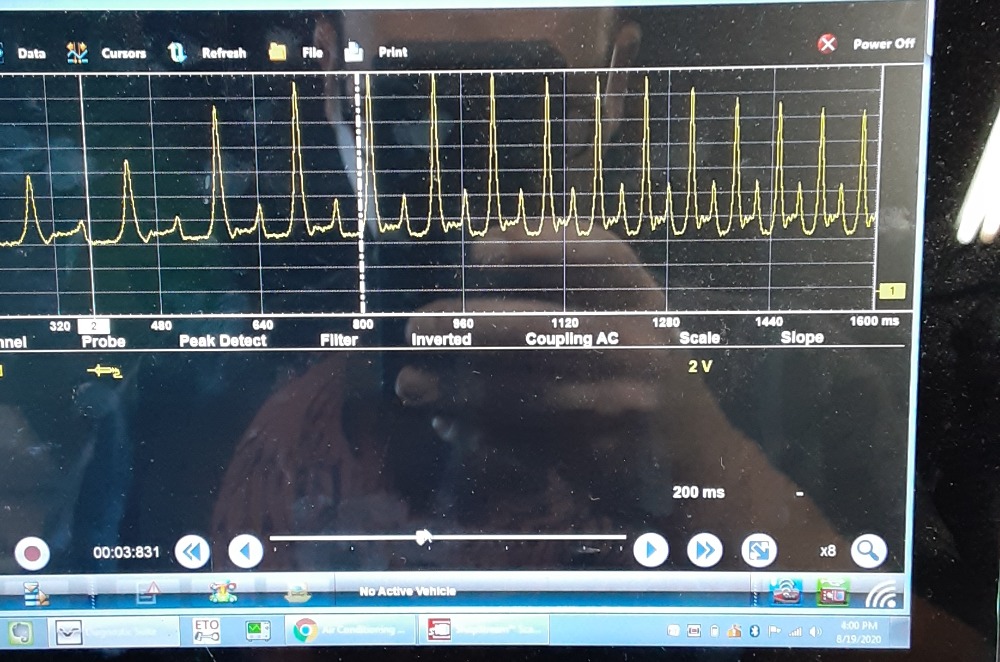

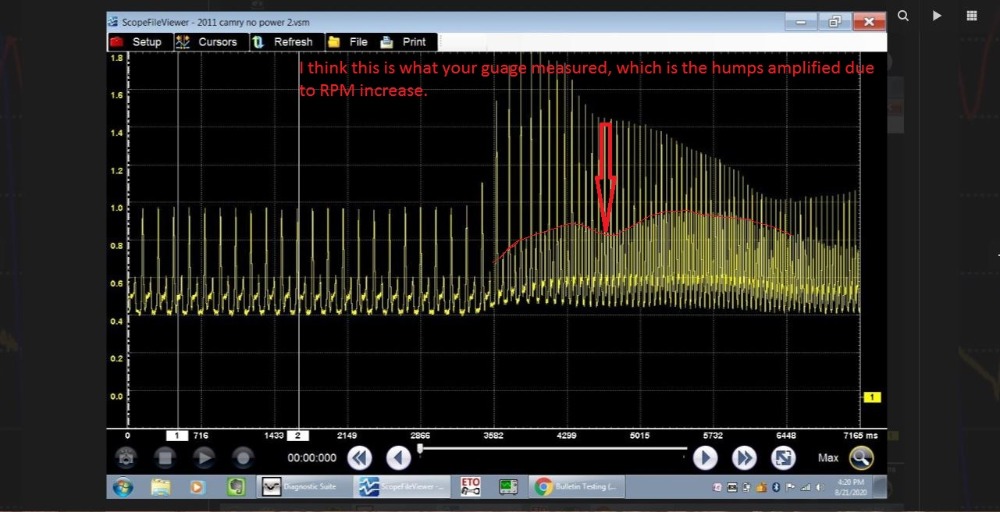

I also caught a Camry with a restricted catalytic converter using one of my homemade transducers:

Before I realized the Amazon sensor was garbage a gave the transducers I had made to Tyler, so I rigged one up quick to diag a no power complaint that one of the other mechanics a previously looked at. He pretty much drove it with the o2 sensor out of the manifold (with no improvement) and bailed.

I've never had luck with that "test".

That mechanic has been there 20 years, so the boss doesn't believe me right away when I present him with conflicting diagnosis.

Since the o2 had already been removed, and since this was my first suspected exhaust restriction using the in cylinder technique, I backed up my data with a good old gauge.

2psi @ idle and maxed out on the pressure scale on a rev in neutral.

I'll upload a cleaner capture from the Verus today, but the pattern is very similar to what I got from the Accord with the "bad engine".

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Noah wrote: Matt is going to love the newest addition to my scope

You can run transducers on all four channels now :lol:

Noticed the USB symbol on the back of that 'scope module. Didn't realize you could run it detached from the scan tool.

www.snapon.com/Diagnostics/US/KB/Using-t...4-Meter-Remotely.htm

Noah wrote: I also caught a Camry with a restricted catalytic converter using one of my homemade transducers:

SNIP

I'll upload a cleaner capture from the Verus today, but the pattern is very similar to what I got from the Accord with the "bad engine".

The trace definitely shows exhaust stroke pressure increasing with RPM. The pressure "spike" at the end of the exhaust stroke looks similar to the Accord. Is the Camry also an I4? Also what was the complaint on the Camry? Just low power or rough running?

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

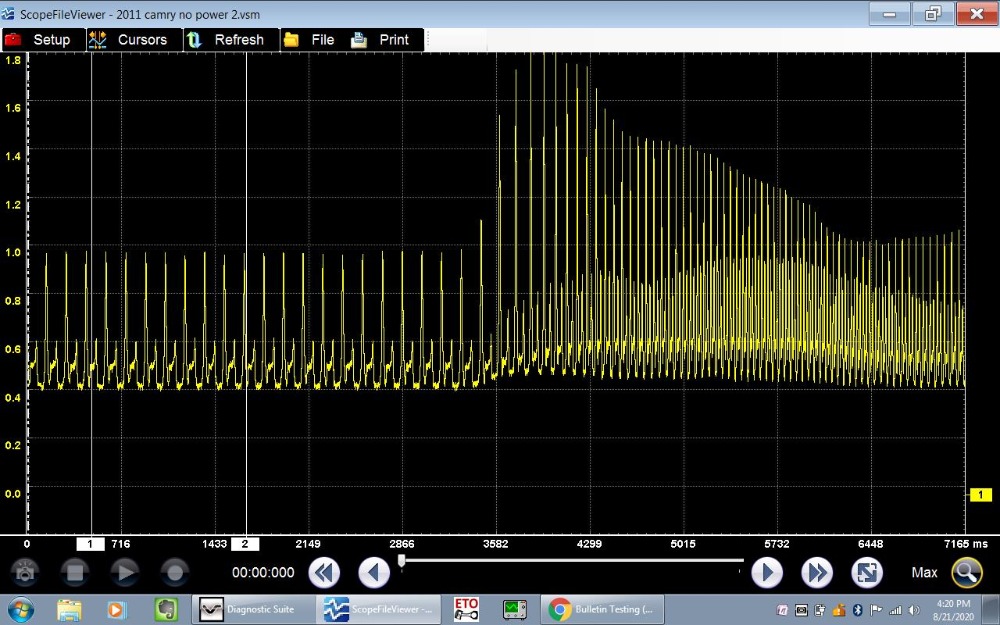

Test drive revealed that o2s went rich under full throttle, load was high (EDIT: Calculated load was 100% for the duration of my wide open throttle pull.

Absolute load touched 100% at tip in, but quickly dropped to around, and remained near, 55%.), so I skipped fuel delivery and decided to revisit exhaust back pressure.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

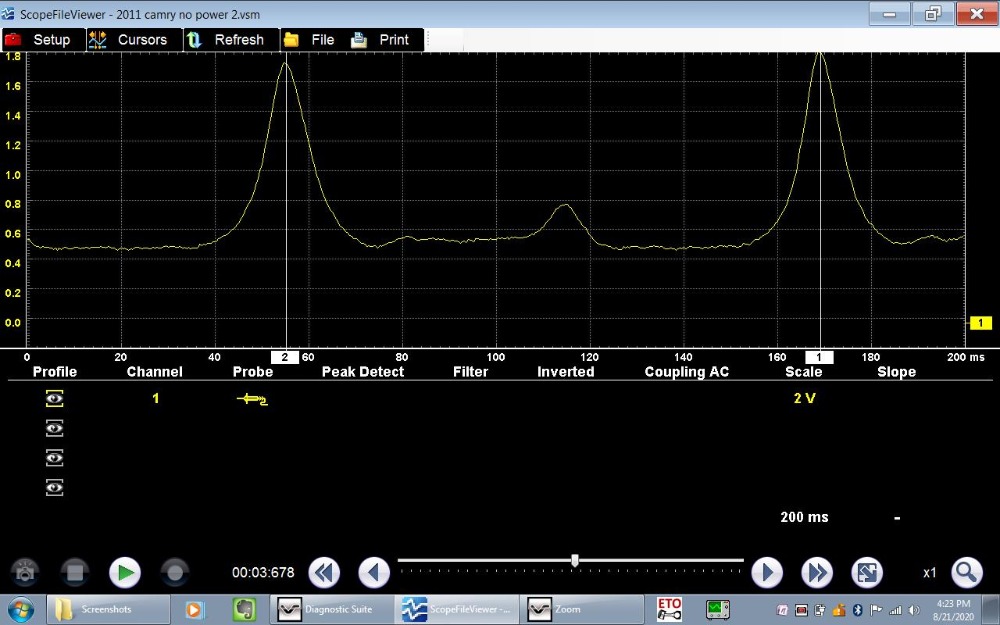

This sensor reports 0.5@atmosphere (sea level here in The Commonwealth).

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Did you happen to save the scan data from your test drive? I'd like to have a look, if possible.

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

And anyone else for that matter if you want to PM me an email address.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Paul

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

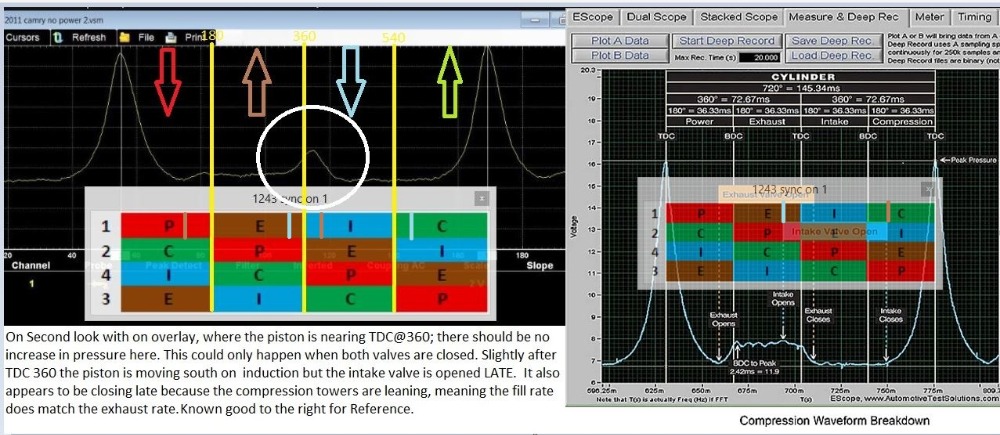

I think I see what you mean.

It looks like the rise in pressure is at the end of the exhaust stroke, like the valve closed early. That did make me scratch my head.

I decided to not pursue timing because the back pressure is confirmed to be excessive with a mechanical gauge, and because this is a DOHC inline four cylinder with a cam sensor on each cam. I figured it would have recognized a timing issue, but I know that's not exactly fool proof logic.

Plus it's not a customers car, so no big deal if it ends up needing a chain set after the cat, the car does have more than a quarter million miles.

I will let you know when we get a cat on it.

I am still quite new with in cylinder wave forms, so I appreciate the insight of more knowledgeable techs like yourself.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

The hump is the result of both valves being closed as the piston is ascending nearing TDC Exhaust. Shortly after TDC the piston is descending on the induction stroke, the Intake valve should have opened before 360, but it opens late, then the pressure drops. You can also see it close late at 630 degrees when it should have closed around ~ 585.

I tried to overlay the known good for your reference.

Paul

Never stop Learning.

Please Log in or Create an account to join the conversation.

Paul

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

Do you think that that those "humps"at the end of the exhaust plateau measured in cylinder would have been measurable by my mechanical gauge in the exhaust stream?

The only cause for pressure in the exhaust that I have encountered so far is a restriction.

Thanks again for your input and for taking the time to analyze my wave forms.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Weycraze wrote: Please keep me posted on your findings Noah.I'm now wondering that your mechanical gauge was just measuring those humps which would be amplified with RPM increase.

If the humps are caused by the exhaust valve closing early they wouldn't affect exhaust pressure. If they showed up anywhere, outside the cylinder, it'd probably be as pulses in the intake.

Please Log in or Create an account to join the conversation.

Noah wrote: I will let you know when we get a cat on it.

The anticipation is killing me. :woohoo:

Please Log in or Create an account to join the conversation.

Now I'll throw this in there if all the cylinders had the same waveform; that would point towards timing ie chain stretch. But if the hump is just this lone cylinder, by virtue of engine design, a lifter issue.

The reason I lean towards timing/chain stretch is the duration of that intake event which I approximated at ~240-50ish degrees which is a very plausible spec, without knowing the true spec.

It would be sweet of you to post the vsm files you have.

Paul

Never stop Learning.

Please Log in or Create an account to join the conversation.