Testing fuel injectors with a knock sensor

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6083

- Thank you received: 1537

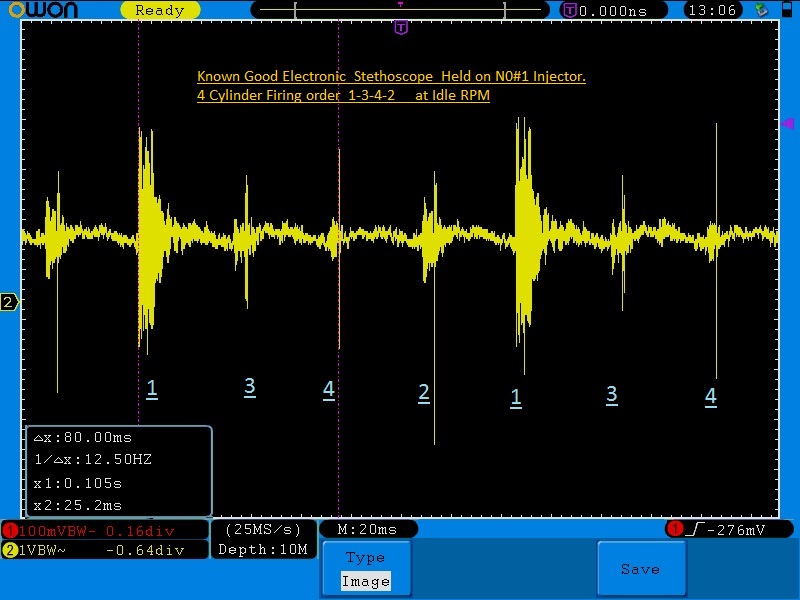

Anyway, the concept kinda makes sense. We can definitely hear injectors working with a screwdriver and our ears, why wouldn’t a knock sensor work? Coupled with a lab scope, we might be able to distinguish individual injector firings... Right? Let's find out.

Kudos to Noah for hooking me up with a variety of knock sensors for this experiment. He sent the sensors AND the pigtails? What a boss!

It seemed to provide the cleanest signal, and its male threaded end made for easier testing. I did try some Nissan and Ford sensors, but neither seemed to produce similar results. YMMV. In all captures, the sensor is being held to the middle of the fuel rail, as touching it to the ends didn’t seem to make any difference to the waveform. FYI, the test subject is an ‘04 Scion xA.

"Hey, Tyler, don't you have to ground the knock sensor?" That's what I thought, but apparently not :dry: I experimented with grounding the sensor, but saw no difference. *shrugs* Onto the waveforms!

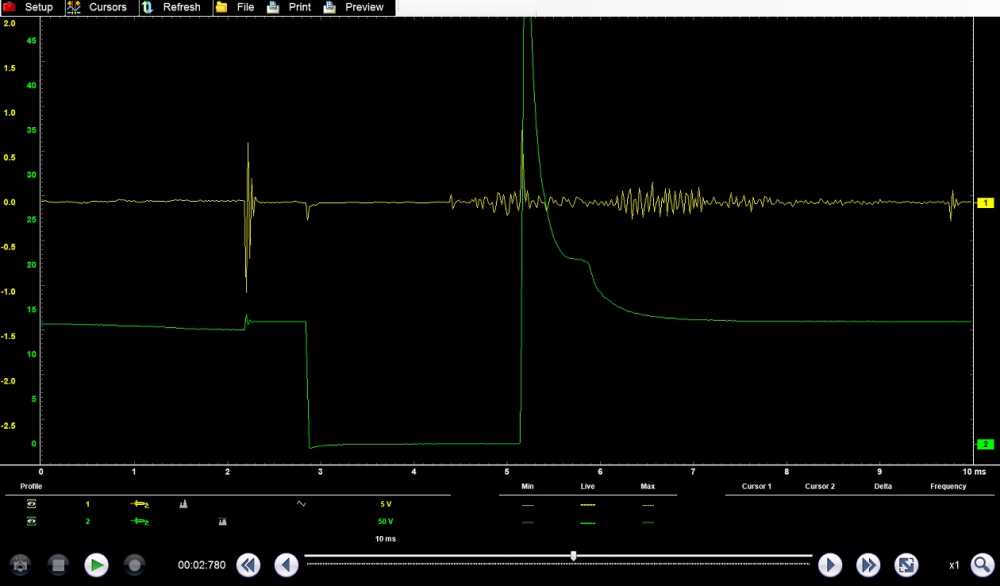

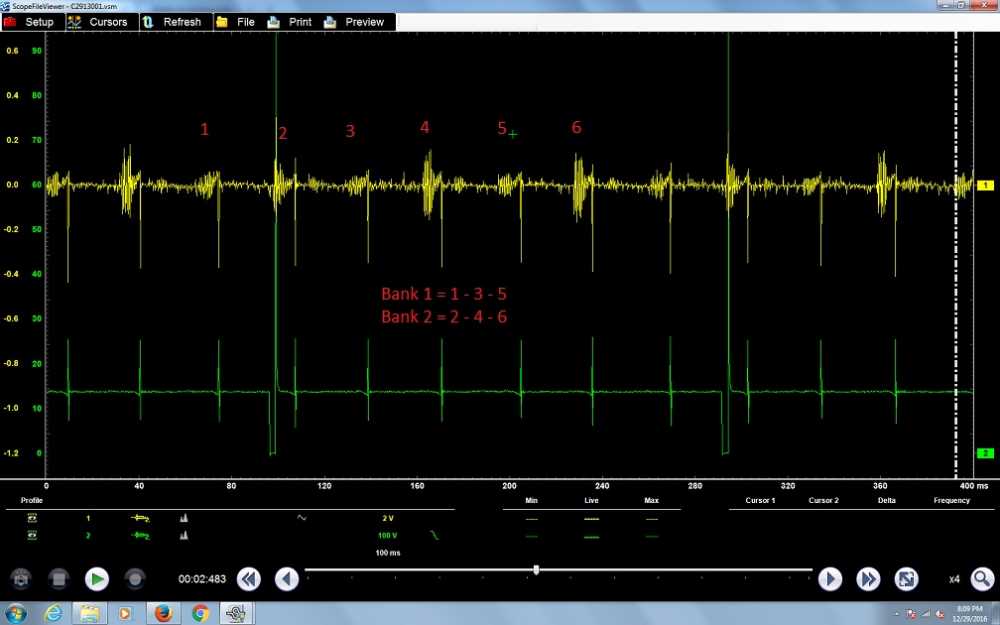

The scope settings took some tweaking to get a usable picture, but this is what I ended up with. Yellow is the knock sensor, green is the #1 injector trace. Note that the vertical spikes are NOT the injector events, but actually ignition feedback. It's confusing because this engine has a COP ignition system AND fires the injectors not long after TDC compression. Unfortunately, I couldn’t find a way to get those spikes out of the picture without losing the injector events

A zoomed in view on one injector event showed some cool detail:

It looks like the majority of the vibration generated by the injector comes from the injector pintle slamming home after the voltage pintle hump. I figure this is what you’re actually ‘hearing’ when you listen to an injector with a screwdriver.

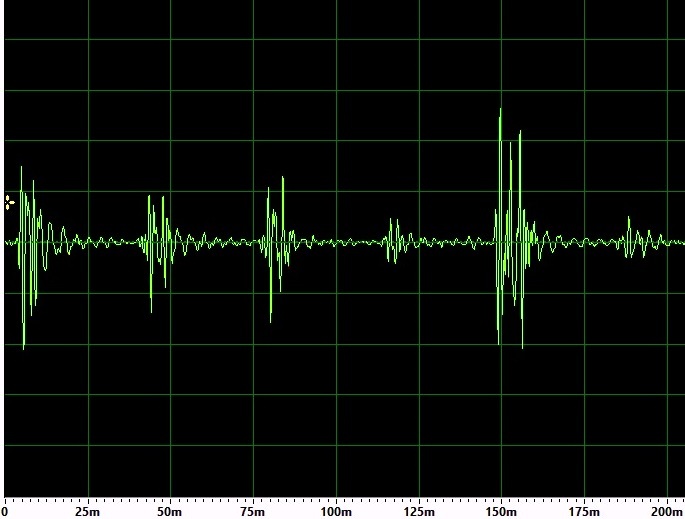

So, can we see an inoperative injector with this setup? Let’s find out! I unplugged one injector:

It’s not much, but you can see a missing vibration three events away from the #1 injector firing. Since the firing order is 1-3-4-2, we can deduce that the #4 injector isn’t working. It works! :woohoo:

But what are the variables? I have to assume rail design is a factor, especially on V6 and V8 engines. Would this work well on a 5.3L with a solid pipe joining both rails? Or, would I need to do two separate captures? Vortec spider systems? More experimentation is needed.

Of course, this isn’t a pinpoint test either. It’ll show an inoperative injector but not why. It won’t show a flow or spray pattern problem. Plus, knowing how to read the waveform is key. Not all engines will look this way, and having a good idea of what it’s supposed to look like is important. The time necessary to get good at this may not pay off for everyone.

Thoughts? Comments? Questions? Hate? Post it up!

Please Log in or Create an account to join the conversation.

- rockp2

-

- Offline

- Elite Member

-

- Posts: 167

- Thank you received: 40

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4974

- Thank you received: 1115

A little hard to "read" the waveform, but there is a clear difference between a working and non working injector.

Do you think using a/c coupling would provide more definition?

Glad you're getting use out of them! I believe that one is from a Civic, good eye!

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Dylan

-

- Offline

- Moderator

-

- Belgium, Europe

- Posts: 1461

- Thank you received: 327

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6083

- Thank you received: 1537

Dylan wrote: Man, just love this. Always experimenting with things. :woohoo:

ScannerDanner.com Forums: Misusing tools since 2014

Noah, thanks to you on this one! I thought it was AC coupled? I gotta go check the capture.

rockp2, thanks sir! Your microphone analogy is perfect.

Work is insane this week, but I may try to get my hands on a V6 and give this another go.

Please Log in or Create an account to join the conversation.

- Dylan

-

- Offline

- Moderator

-

- Belgium, Europe

- Posts: 1461

- Thank you received: 327

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4974

- Thank you received: 1115

When I saw it on my phone, I thought that was the "slope" indicator!

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6083

- Thank you received: 1537

Dylan wrote: 1 wire sensor so a resonant one? Just wondering when you say this one seemed to provide the cleanest signal... Compared to a 2 wire non-resonant?

Yeah, I actually didn't know there was a difference 'till I went and looked it up . :blush: Hey, learn new stuff every day!

I'm not sure I have a legitimate non-resonant sensor available to try... I wonder what makes/models out there use them? A few of the sensors I got have two wires at the connector, but only one going to the sensor itself. The other ends up as a signal shield.

Please Log in or Create an account to join the conversation.

- Dylan

-

- Offline

- Moderator

-

- Belgium, Europe

- Posts: 1461

- Thank you received: 327

Yeah, I actually didn't know there was a difference 'till I went and looked it up.

Neither did I

Found an article on this topic, it's from 2008 I know

www.wellsve.com/sft503/counterp_v12_i2_2008.pdf

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6083

- Thank you received: 1537

Dylan wrote:

Yeah, I actually didn't know there was a difference 'till I went and looked it up.

Neither did IBut I remember this was a test question when working for Toyota. So I had to look it up myself :lol:

Found an article on this topic, it's from 2008 I knowHere's the link in case anyone is interested:

www.wellsve.com/sft503/counterp_v12_i2_2008.pdf

Oooh, I like that article! And here I was thinking knock sensors were just knock sensors :lol:

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

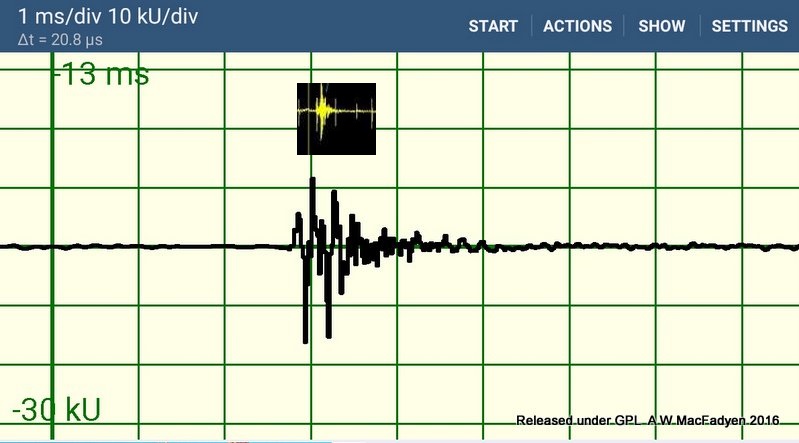

The waveform is very similar Tylers result with the Honda knock sensor on the fuel rail.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6083

- Thank you received: 1537

Andy.MacFadyen wrote: Some good ideas in this thread, I am still puzzled that my trial clipping a contact microphone to an injector produced nothing. I don't have any knock sensors or microphones to hand so working off car I improvised and used cell phone running an audio app and Bosch pencil injector pulsed by an injector tester.

The waveform is very similar Tylers result with the Honda knock sensor on the fuel rail.

Holy crap, Andy :ohmy: That's awesome! What phone app did you use for this? Please tell me it's for Android

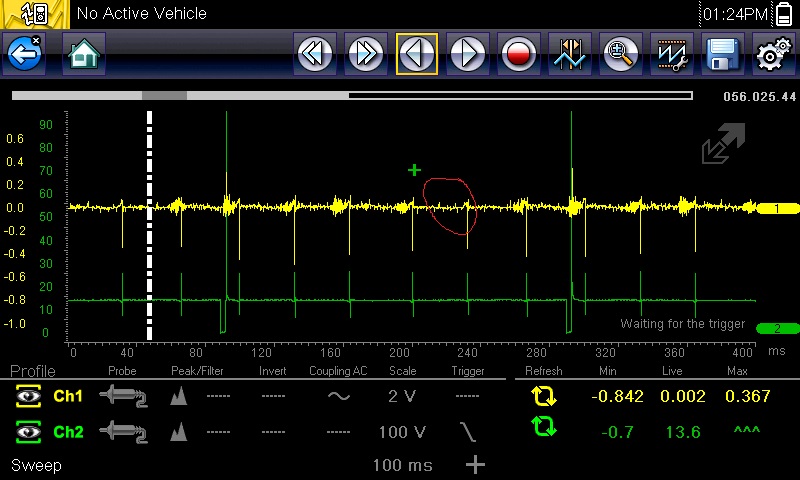

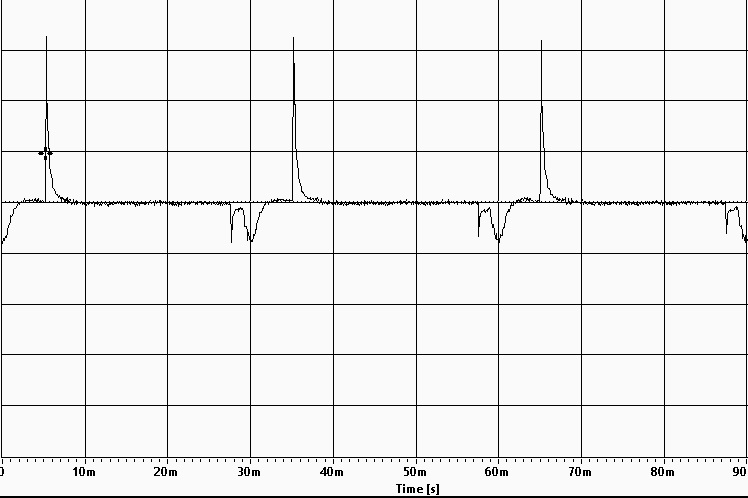

Finally got time to play with a V6 today, pretty happy with how the waveform turned out.

I also noticed a difference in the amplitude of the injector "events" between banks. I marked up this capture with all injectors firing:

The knock sensor was attached to bank 2 fuel rail, thus the stronger injector vibrations. These rails are joined by a metal fuel pipe, with banjo bolts on both ends, so clearly there's enough rigidity there to carry vibrations from the other rail

Please Log in or Create an account to join the conversation.

- Dylan

-

- Offline

- Moderator

-

- Belgium, Europe

- Posts: 1461

- Thank you received: 327

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

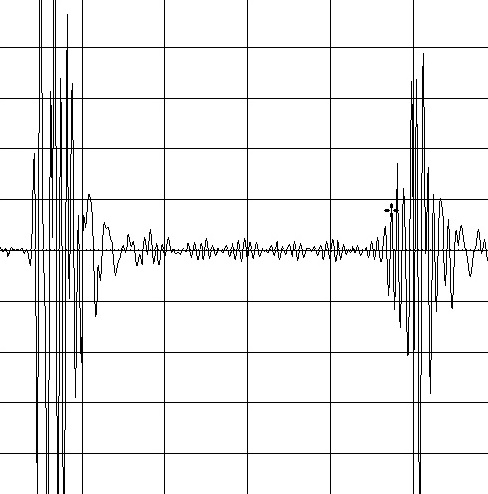

The first thing I tried was using the

little moving coil speakers from a set of headphones (from Poundland) as microphones plugged into a the microphone input of USB soundard and looked at with a nice PC Soundcard Oscilloscope program Link to program home page.

The result is a good capture but not what I expected fom Tyler's and my own previous experiments.

In any event it would not be a practical method on a running engine.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

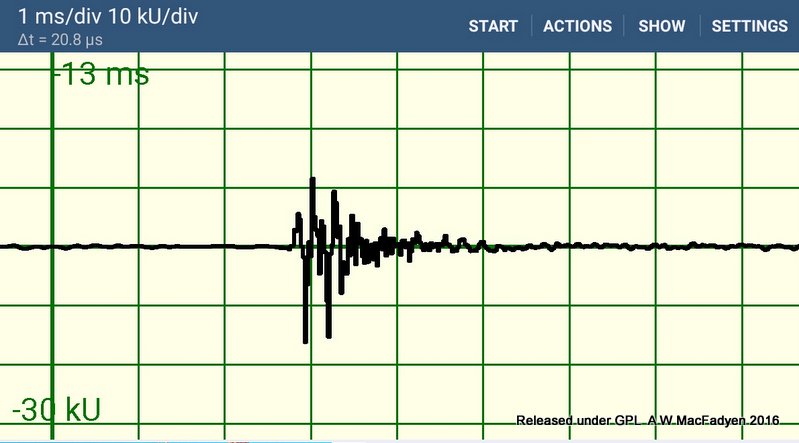

At this point it occurred to me that a sonic reversing sensor might work --- and it did

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6083

- Thank you received: 1537

Dylan wrote: Cool Tyler! So what did you do in the first capture? Nothing on cilinder 6....

Yep, that's the injector I unplugged!

Continued

Next stage test on running engine.

Still using soundcard oscilloscope.

Man, that's a clean capture. :ohmy: It looks like you can still see the rail resonating after an individual injector event. Was this a four cylinder engine? What kind of ignition design?

The biggest problem with the knock sensor method is the EM noise. The scope has to be set up to 'see' the injector vibrations, but it also picks up just about anything else at that level of sensitivity. Wondering if a different scope or knock sensor might help with that... Your reversing sensor really seems to produce less noise overall.

Also, being honest, I had to look up what you meant by sonic reversing sensor :blush: :lol:

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

Gunson Electronic Stethoscope

No time to test it properly but it looks like it is the answer, using a PC speaker cable it plugs straight into the PC microphone input and it gives a good signal voltage for the scope.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Eddie daGrouch

-

- Offline

- New Member

-

- Tinker 2nd Class

- Posts: 5

- Thank you received: 0

Using a knock sensor, which is tuned for events of a much lower frequency, will filter out the very data you are trying to read. On top of that, a simple trace will only show amplitude, and a higher trace only shows what that particular sensor thinks is loud within it's sensitivity range AND that range may not be linear and can be effected by it's own resonance.

That's all I had prepared at the start of this reply so now I need to type out loud to organize my thoughts. I'm not an auto mechanic by trade so bear with me.

a. You are trying to interpret audio into a visual means.

b. An injector event covers a wide frequency range - the pintle movement and the spray.

c. You want a wide band sensor that's cheap, has a flat response curve, and standardized.

To me it sounds like (pun intended) an electret microphone element.

How about putting a mic on the end of a gooseneck and sticking it near the output of the injector and triggering it with a pulser? Run the mic through an amp then split the output to both headphones and an audio app that can do a spectral graph. With a good headset and ears you should be able to hear the spray and tell if it's crisp or dribbly due to a sticky pintle. Those of us with hearing loss can use the spectral graph to compare with a good injector.

Pulling an injector can be a pain but pulling a spark plug or throttle body and sticking a mic (or endoscope) nearby should be a breeze in comparison. Since it's all hard reflective surfaces inside an intake I imagine you could hear all the injectors from the TB by stuffing a rag around the mic cord to block outside noise.

If I had a pulser I'd grab my laptop, stuff a mic down my TB"s throat and try it out.

Remember to rotate your spark plugs every 3,000 miles.

Please Log in or Create an account to join the conversation.