VE Calculations and Lean Codes

- Wood

-

Topic Author

- Offline

- Junior Member

-

- Posts: 26

- Thank you received: 7

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

What vehicle, engine, mileage and year ? Flex Fuel ????

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Wood

-

Topic Author

- Offline

- Junior Member

-

- Posts: 26

- Thank you received: 7

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6076

- Thank you received: 1536

Hopefully that helps! As far as my diagnostic approach is concerned, Load and VE are the same thing. Both are based primarily on the MAF, and both be low in the case of a underreporting MAF or a engine breathing issue. Both will show high if the engine is breathing correctly and the MAF is reporting correctly. Neither can distinguish between a misreporting sensor and a breathing issue on their own.

There's another thread we had going in the Diagnostic Tools section that's also worth reading. Tons of testing and good info in there:

www.scannerdanner.com/forum/diagnostic-t...s-absolute-load.html

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Wood

-

Topic Author

- Offline

- Junior Member

-

- Posts: 26

- Thank you received: 7

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6076

- Thank you received: 1536

www.scannerdanner.com/forum/scannerdanne...8-low-power.html#933

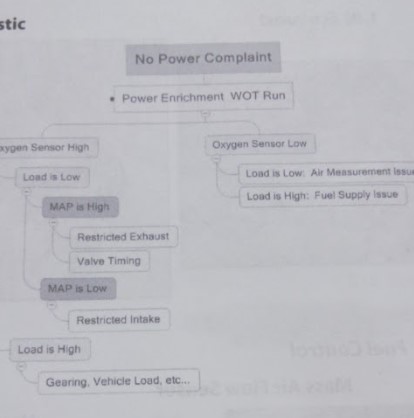

Short story, I installed a intake restriction in a Chevy truck, and that flow chart pinned it down.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Flatrater

-

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 18

Where did you see it? I created that about 15 years ago

Please Log in or Create an account to join the conversation.

- ScannerDanner

-

- Offline

- Administrator

-

- Religion says do, Jesus says done!

- Posts: 961

- Thank you received: 500

Don't be a parts changer!

Please Log in or Create an account to join the conversation.

- Flatrater

-

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 18

Sharing it is fine, but I only see part of it in your post.

Please Log in or Create an account to join the conversation.

- Flatrater

-

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 18

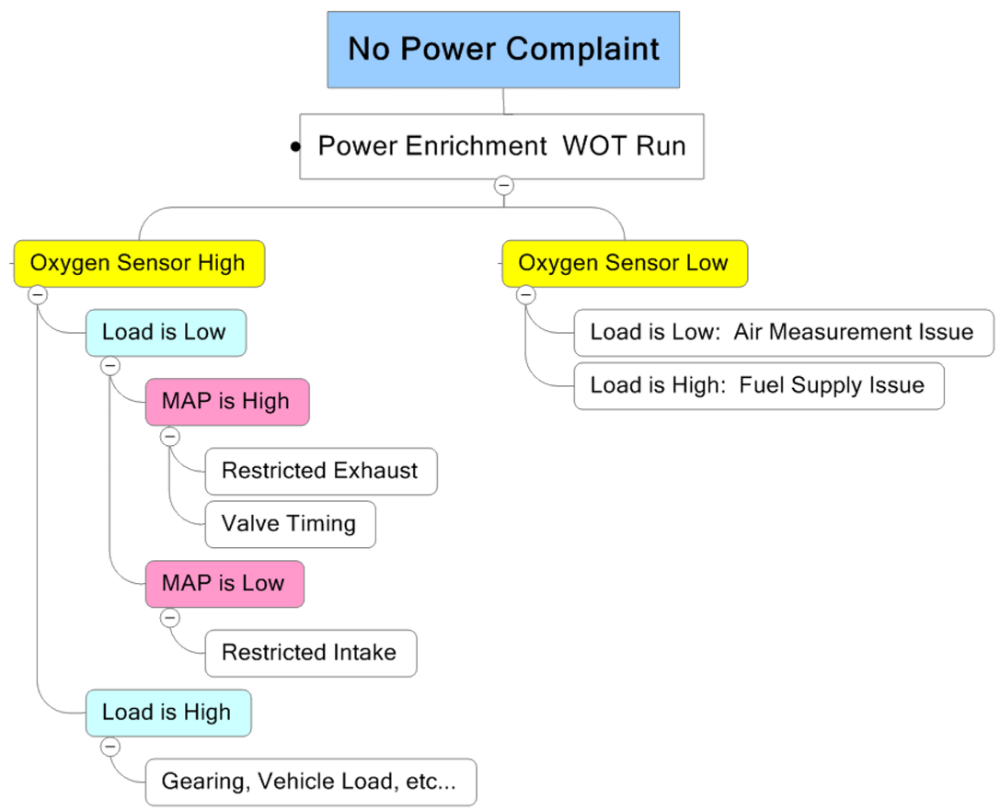

You might see this in an SMP class as well. I use Mind Manager for mapping out classes and diagnostic procedures.

It seems that a lot of technicians have been steered towards VE testing etc. when a 40,000 foot view would serve them better. As a flatrate drive tech, time was everything if I wanted to pay the bills

Please Log in or Create an account to join the conversation.

- Flatrater

-

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 18

I was a slow learner, so I needed it

Please Log in or Create an account to join the conversation.