2011 Jeep Grand Cherokee Air Suspension Faults

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

I enjoyed this most recent premium video

Still really digging the transparent overlay with the scope traces and scan data. I think Paul has struck a good balance in that regard.

For anyone who hasn't seen it, watch it! What are you waiting for? I'm going to ruin the whole thing right now for you, so go! Watch it already!

This 2011 Grand Cherokee ended up having a blown fuse resulting in an inoperative air suspension and associated fault codes.

Paul followed up with an amperage measurement on the suspension compressor from the fuse panel with an amp clamp.

Initial pump turn on was measured to be over 80 amps. Which sounds like it could be on the high side, but seriously, who really knows unless you've measured a hand full of them.

It was helpful for me to see how Paul handled this diagnosis. This is obviously an intermittent issue or an isolated occurrence, which could have been handled multiple ways. I could see a hypothetical shop seeing the blown fuse as justification to replace the compressor.

On the other hand; if you send it back with a shiney new fuse after spending an hour chasing a problem that may not exist, and the problem resurfaces, how do you handle the customer? Even if you're Scanner Danner himself, as far as the average motorist is concerned, you just had the car for an hour and didn't find anything. Do they bring it back? Do they play repair-shop-roulette?

Of course, I'm sure Pete's Garage handles the customer relations.

I just faced a similar complaint on a Volvo XC90 that had blown the fuel pump fuse, and the customer wanted the fuel pump replaced for insurance. When the mechanic realised what a job it was going to be, he asked me to look it over before diving in. I did pretty much what Paul did, and found pretty much the same thing. Nothing...

I told the mechanic that there wasn't enough evidence for me to support replacing the pump. He ended up passing on the job, not wanting to do the job for no reason.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

In the from the ever reliable

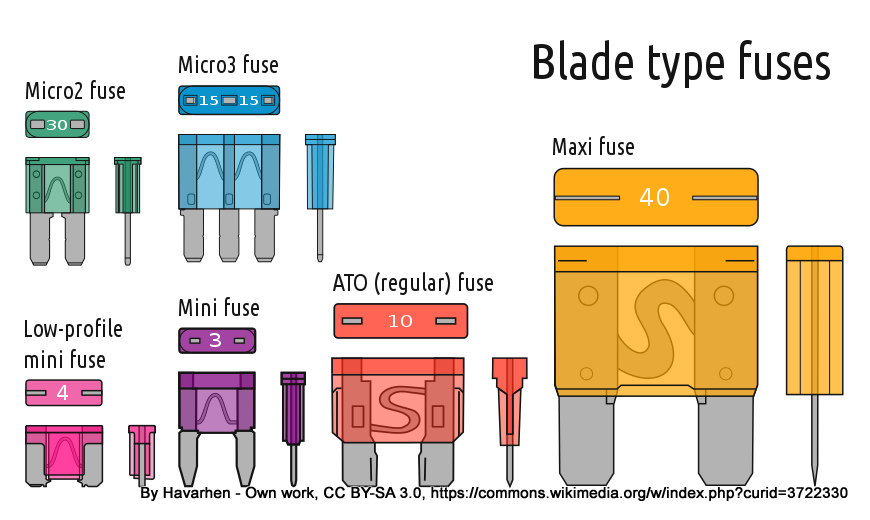

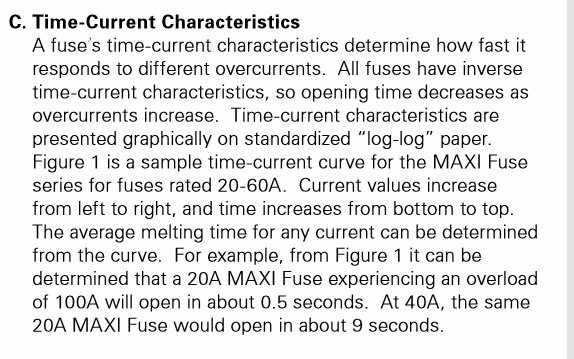

The speed at which a fuse blows depends on how much current flows through it and the material of which the fuse is made. The operating time is not a fixed interval, but decreases as the current increases. Fuses have different characteristics of operating time compared to current, characterized as, according to time required to respond to an overcurrent condition. A standard fuse may require twice its rated current to open in one second, a fast-blow fuse may require twice its rated current to blow in 0.1 seconds, and a slow-blow fuse may require twice its rated current for tens of seconds to blow.

Fuse selection depends on the load's characteristics. Semiconductor devices may use a fast or ultrafast fuse as semiconductor devices heat rapidly when excess current flows. The fastest blowing fuses are designed for the most sensitive electrical equipment, where even a short exposure to an overload current could be very damaging. Normal fast-blow fuses are the most general purpose fuses. The time delay fuse (also known as anti-surge, or slow-blow) are designed to allow a current which is above the rated value of the fuse to flow for a short period of time without the fuse blowing. These types of fuse are used on equipment such as motors, which can draw larger than normal currents for up to several seconds while coming up to speed.

In-rush curent on motors is a tricky one, I am starting to think looking at in-rush current and voltage drop with a fast scope can lead you to think there is a problem when there isn't. I have watched the Pico starter and battery test on the Pico Automotive channel and suspect because of the speed of the scope the voltage failure criteria they use may flag batteries as failing that are perfectly serviceable.

From my seagoing days I recall to reduce start-up curent a lot of industrial compressors have an "unloader valve" that and vents to atmosphere only closes as as the rpm builds up.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

Because of the high in-rush curent fuses used in circuits with motors and solenoids age faster and the more times the compressor repeats on/off cycles the faster the aging

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

Maybe repeated exposure to over amperage from inrush current under normal operating conditions could fatigue a fuse?

I agree with you about using a scope to measure inrush current.

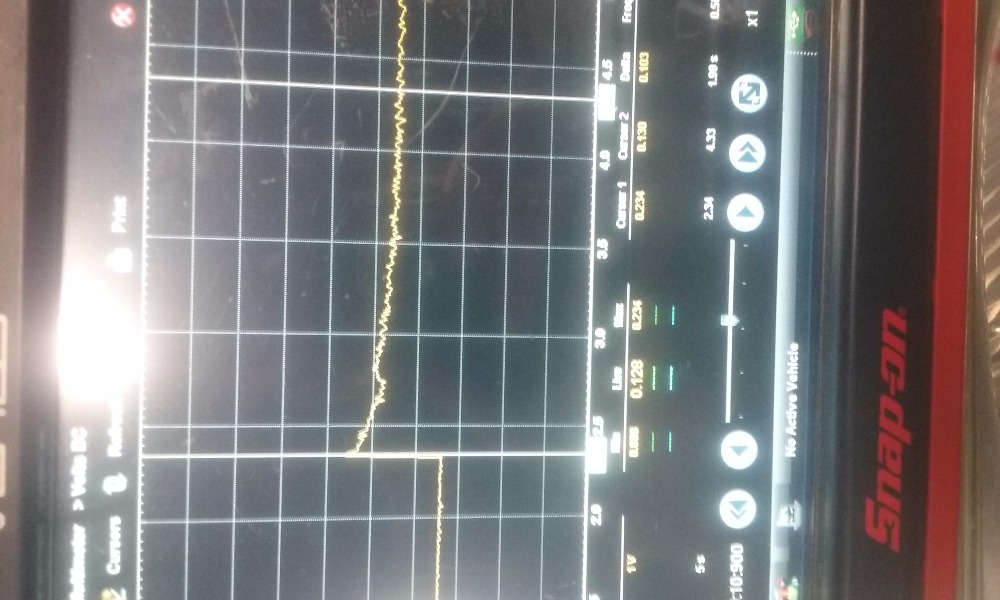

Paul was using the graphing meter function of the Verus in this case, but I would be willing to bet that if measured with the scope, that until turn on spike would have been even higher.

I really only use my meter now with the amp clamp instead of the scope for just that reason. Unless of course I'm looking for a current waveform.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- ScannerDanner

-

- Offline

- Administrator

-

- Religion says do, Jesus says done!

- Posts: 961

- Thank you received: 500

I don't think so Noah. The graphing meter of the VP will catch a 300 micro second change in a signal regardless of time base. I specifically chose the graphing meter so I could not only show the initial turn on, but also, the run time after without messing with sampling of the scope.Noah wrote: That's an interesting theory.

Maybe repeated exposure to over amperage from inrush current under normal operating conditions could fatigue a fuse?

I agree with you about using a scope to measure inrush current.

Paul was using the graphing meter function of the Verus in this case, but I would be willing to bet that if measured with the scope, that until turn on spike would have been even higher.

I really only use my meter now with the amp clamp instead of the scope for just that reason. Unless of course I'm looking for a current waveform.

Does that make sense? I don't think the lap scope would have shown the spike to be higher. I may be wrong but I think 300 millionths of a second glitch capture should have been good to catch that spike.

Don't be a parts changer!

Please Log in or Create an account to join the conversation.

- ScannerDanner

-

- Offline

- Administrator

-

- Religion says do, Jesus says done!

- Posts: 961

- Thank you received: 500

Early stages of pump failure (mechanically) is the issue in my opinion.

Don't be a parts changer!

Please Log in or Create an account to join the conversation.

- ScannerDanner

-

- Offline

- Administrator

-

- Religion says do, Jesus says done!

- Posts: 961

- Thank you received: 500

Noah wrote:

I enjoyed this most recent premium video

Still really digging the transparent overlay with the scope traces and scan data. I think Paul has struck a good balance in that regard.

For anyone who hasn't seen it, watch it! What are you waiting for? I'm going to ruin the whole thing right now for you, so go! Watch it already!

Thanks Noah! I'm trying to use it so it is not distracting. I am aware that it can be if I am not careful.

Don't be a parts changer!

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

I was drawing more on my own experience measuring fuel pumps with the Verus (scope) vs my DMM.

I noted around 10 amps average inrush on the last 3 or 4 pumps I had the chance to measure with the scope.

Even when set to min max, my DMM wouldn't catch anywhere near that.

I'll have to start trying with the graphing meter function, or even my old school Vantage.

Thanks for taking the time reply, I appreciate it!

Keep up the good work, learning more everyday!

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- ScannerDanner

-

- Offline

- Administrator

-

- Religion says do, Jesus says done!

- Posts: 961

- Thank you received: 500

Noah wrote: I'll have to start trying with the graphing meter function, or even my old school Vantage.

Thanks for taking the time reply, I appreciate it!

Keep up the good work, learning more everyday!

For sure. I believe it is the min/max histograph that made the Vantage a household name. In the GMM mode it is not sampling the signal like a scope does. All of the "power" is reserved for the min/max changes in voltage. I know I'm not stating that correctly, but I'm close.

Thanks Naoh!

Don't be a parts changer!

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6076

- Thank you received: 1536

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

Well, it's not an electric motor, but I got to do some comparison testing today with the amp clamp and my meters.ScannerDanner wrote:

Noah wrote: I'll have to start trying with the graphing meter function, or even my old school Vantage.

Thanks for taking the time reply, I appreciate it!

Keep up the good work, learning more everyday!

For sure. I believe it is the min/max histograph that made the Vantage a household name. In the GMM mode it is not sampling the signal like a scope does. All of the "power" is reserved for the min/max changes in voltage. I know I'm not stating that correctly, but I'm close.

Thanks Naoh!

The pics aren't great, I apologize ahead of time.

2001 Honda Civic LX.

AC compressor clutch measured at 20amp fuse in under hood fuse box.

The clutch was using around 10 amps on average.

The min max of the Vantage picked up 19 amps on turn on. nearly 20amps using the graphing function.

The min max capture of the Owon meter was less impressive, only reading 12 amps on turn on.

The lab scope picked up 21 amps at turn on (20 amp fuse circuit) and the graphing meter function picked up 23 amp at turn on.

So it seems that as far this instance is concerned, the scope and the graphing meter are on even ground as far as capturing initial turn on spikes.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6076

- Thank you received: 1536

Sooooooooo, was the shorted clutch part of the customers complaint? It's A/C related in June, so probably.

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

Yes, it's been almost a week long fiasco of everyone at the shop swapping relays and poking at the power wire of the pump.Tyler wrote: Good stuff, Noah! I feel like your post could answer a lot of questions about the capabilities of various test equipment.

Sooooooooo, was the shorted clutch part of the customers complaint? It's A/C related in June, so probably.

Original complaint was no AC. The mechanic that drew the job wanted me to make sure he was right, and it needed a pump.

The was no continuity through the clutch, but I warned him it still wasn't getting powered up.

Pump changed, no engagement (no surprise).

Three more days and 3 more guys scratching their heads.

The boss let's me use the shop after hours, so I told him it's look at it between jobs.

Blown fuse....

So I took some extra time to do some current measurements for us!

I wasn't expecting 10 amps, but it falls within the 80% usage Paul mentioned in the Jeep video.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6076

- Thank you received: 1536

Noah wrote: Blown fuse....

:lol: Probably the same kind of guys that always comment on Paul's videos, "You shoulda checked the fuses FIRST." :silly:

I wasn't expecting 10 amps, but it falls within the 80% usage Paul mentioned in the Jeep video.

So that's the new clutch on the replacement compressor? :huh: 'Cause man, I've never seen a clutch draw that much... I consider four amps high on most systems. It uses a 20A fuse?

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6076

- Thank you received: 1536

Andy.MacFadyen wrote: A bit more on fuses and transient over current...

Link to full PDF document

Good stuff, sir!

Please Log in or Create an account to join the conversation.

- Dylan

-

- Offline

- Moderator

-

- Belgium, Europe

- Posts: 1461

- Thank you received: 327

Thx for the PDF Andy

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

I was thinking at first maybe the fan was also on that circuit, but the fan was coming on even when the compressor was not functioning.

I

Sent from my SM-G360P using Tapatalk

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6076

- Thank you received: 1536

Noah wrote: I've been out sick for a couple days, but I'm glad I'm not the only one who thought that was high.

I was thinking at first maybe the fan was also on that circuit, but the fan was coming on even when the compressor was not functioning.

Sorry to hear you've been sick, sir!

Please Log in or Create an account to join the conversation.