07 Toyota Sienna, fuel delivery problem

- wyatt

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 24

- Thank you received: 6

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

(Thanks for the shout out!)

Quite the fuel pump circuit!

:blink:

I'm glad Paul took the time to go over it in it's entirety.

I'm also enjoying the transparent scope overlays, great stuff.

I do have a question about the amperage test at the pump resistor.

The old pump was pulling around 4 amps at idle in the low speed mode.

That turns out to be around half the amperage that the replacement pump was pulling.

This is exactly where I get tripped up using my amp clamp in this kind of diagnosis.

Ok, there's some current draw on the system. This presumably indicates the condition of the power and ground.

But even if we knew for a fact that the pump should be pulling 8 amps, how can we use the 4 amp measurement to point us toward a faulty pump?

I could see second guessing myself and the measurement, wondering if the low current is a symptom of maybe a bad ground or some other voltage drop.

Like I said, I get tripped up with the amp clamp like this all the time. I just can't see the smoking gun and end up loading the circuit myself or volt drop testing at the component.

Any tips, pointers or experiences are welcomed from everyone!

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

I hope you don't mind if I merge the two.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- ScannerDanner

-

- Offline

- Administrator

-

- Religion says do, Jesus says done!

- Posts: 961

- Thank you received: 500

Noah wrote:

(Thanks for the shout out!)

Quite the fuel pump circuit!

:blink:

I'm glad Paul took the time to go over it in it's entirety.

I'm also enjoying the transparent scope overlays, great stuff.

I do have a question about the amperage test at the pump resistor.

The old pump was pulling around 4 amps at idle in the low speed mode.

That turns out to be around half the amperage that the replacement pump was pulling.

This is exactly where I get tripped up using my amp clamp in this kind of diagnosis.

Ok, there's some current draw on the system. This presumably indicates the condition of the power and ground.

But even if we knew for a fact that the pump should be pulling 8 amps, how can we use the 4 amp measurement to point us toward a faulty pump?

I could see second guessing myself and the measurement, wondering if the low current is a symptom of maybe a bad ground or some other voltage drop.

Like I said, I get tripped up with the amp clamp like this all the time. I just can't see the smoking gun and end up loading the circuit myself or volt drop testing at the component.

Any tips, pointers or experiences are welcomed from everyone!

I totally understand what you're saying Noah.

This is why I was trying to show the initial turn on of the pump but could not because of the high speed mode activation during initial start up.

I actually could have but chose not to and here is one of the main reasons why:

If there was say resistance on the feed or ground side of the pump, when the high speed mode activated, I would have had a pressure rise and once I saw the psi dropping even in the high speed mode, I made the call.

I think my logic here is correct. Thoughts?

Don't be a parts changer!

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

It would certainly take a good power and ground to support the high current when the motor turns on. This is something I'll have to pay more attention to the next time I break out the amp clamp.

So you're saying that even with a poor ground for the pump that there definitely would have still been a pressure change when the circuit switched between high and low pressure modes?

Thanks for coming over and joining the conversation, we all know how busy you are. I appreciate you taking the time to help me wrap my head around it, lol.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- wyatt

-

Topic Author

Topic Author

- Offline

- Junior Member

-

- Posts: 24

- Thank you received: 6

Please Log in or Create an account to join the conversation.

- ScannerDanner

-

- Offline

- Administrator

-

- Religion says do, Jesus says done!

- Posts: 961

- Thank you received: 500

Noah wrote: So you're saying that even with a poor ground for the pump that there definitely would have still been a pressure change when the circuit switched between high and low pressure modes?

Thanks for coming over and joining the conversation, we all know how busy you are. I appreciate you taking the time to help me wrap my head around it, lol.

Yes, though you could argue the volume was also changing because of the snap throttle test.

But think about it. Difference in potential is what is important. 12v on feed, bad ground reading 4v.

14v on the feed will still raise your current flow even though ground voltage may rise a bit from additional current.

I'm rambling...

Thanks Noah

Don't be a parts changer!

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- ScannerDanner

-

- Offline

- Administrator

-

- Religion says do, Jesus says done!

- Posts: 961

- Thank you received: 500

Also 4 amps was plenty of current to produce more psi than what we had at idle. I think.

Don't be a parts changer!

Please Log in or Create an account to join the conversation.

- ScannerDanner

-

- Offline

- Administrator

-

- Religion says do, Jesus says done!

- Posts: 961

- Thank you received: 500

Don't be a parts changer!

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1113

lol, that's awesome!ScannerDanner wrote: Just filmed an 07 Navigator 5.4 with low psi today. Initial turn on amperage was 21 amps. No crawling on the ground for this old man today

I think that's where I have the most trouble, is knowing how much amperage any particular component should be running at.

With voltage it's pretty cut and dry, but with the current measurements, I guess you need the experience to tell. I just don't have the confidence with that tool yet to GET that experience.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

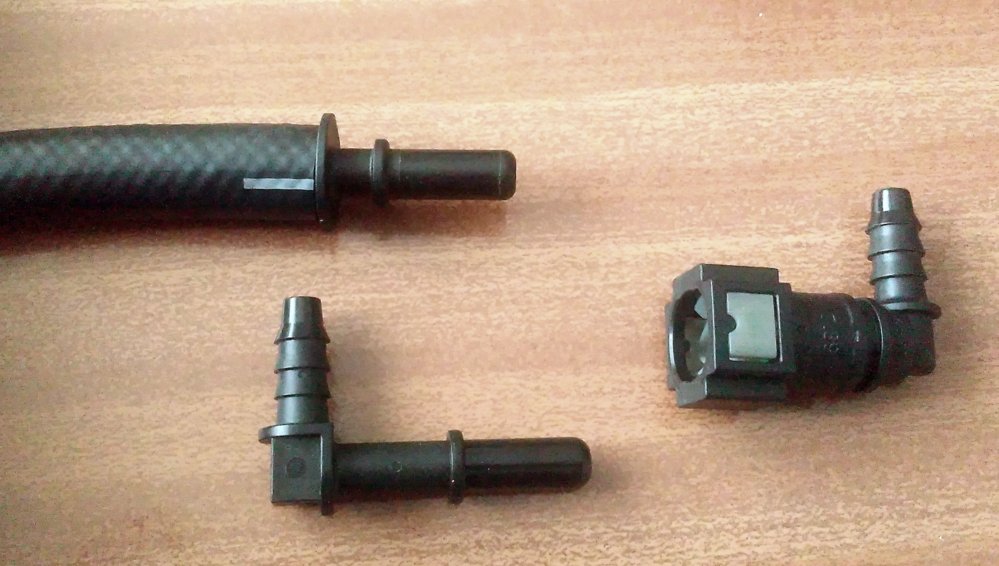

I recently bought some right angled quick release adaptors for my fuel pressure gauge so I can do most euro boxes without faffing. They are especially good for connecting at the in-tank fillter outlet on Valeo systems I would post a link but the ebay seller has disapeared.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Mossy1985

-

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 4

Long winded and maybe well off topic but thought i would bring it up anyway ☺

Thanks guys

Searching for knowledge

Please Log in or Create an account to join the conversation.