*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

Crank, no start, has spark, no fuel pressure

- TroyStevens

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

Background: 98 Pontiac GTP with 97k miles. It's the 3.8l v6 Supercharged, (VIN 1, if that makes a difference).

The "Service Engine Soon" light wasn't on for the 2 days my wife drove it, but the TCS Light had been on for nearly a year evidently. Stored codes are:

-P1571 : Desired torque signal PWM duty cycle is less than 5% or greater than 95%.

-P1573: Loss of ABS Serial Data

-P1811: Max adapt and long shift mode

The first 2 codes I'm assuming refer to the ABS, while the P1811 sounds like it might point more towards an AT Pressure Control Solenoid? Not sure, but that isn't even my question. After reading through his service records, it appears all 3 DTC's have been an ongoing issue for at least a year. Although restoring the ABS would be great, my primary concern right now is to get this thing running.

The car had a new fuel pump and filter put in it about a year ago and had been running perfect until a few days ago.

I replaced the battery yesterday, since the old one was very old. I verified battery voltage and also charged it separately.

During the crank, the "Service Engine Soon" light does come up with key on and the light stays there throughout the crank.

There are no new codes.

Inline spark tester showed spark. I also removed the upper boots on the coils and the spark easily jumped between each two.

The noid light on injector illuminates during the crank.

-I also get an RPM signal on the dash during the crank.

-I can hear the fuel pump cycle for the first few seconds during key-on.

-Tried doing a fuel pressure test twice at the rail and it showed absolutely nothing, 0 psi during prime and 0 psi during crank.

-I should mention though that when I try to connect my pressure tester to the Schrader, I'm getting fuel there. I'm also getting fuel between cranks if I attempt to bleed some fuel out of the Schrader.

-I can get it to fire by spraying starting fluid in the intake, (past the MAF of course).

-The vacuum line on the fuel pressure regulator is dry and doesn't smell like gas.

-All fuses are good. I swapped the fuel pump relay with the horn relay and no change.

So I'm thinking everything points to a fuel delivery problem although I'm clearly unqualified to confirm where. I really don't know how to properly test a fuel pressure regulator on a car that doesn't run though. If it isn't the regulator, my next best guess would be the fuel resistor/ low speed fuel pump relay. Clearly my guesses aren't as good as most of you, so I'd welcome any advice as far as where to go from here.

Thank You.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6042

- Thank you received: 1519

I appreciate all the info you provided. Despite the uncertainty, you've got pretty good diagnostic direction. You know the fuel pump spins (during a prime, anyway), and you know you lack fuel pressure (if you trust your gauge). Reading theory and operation on this two-speed pump system says the resistor only comes into play AFTER startup. During cranking, full voltage is supplied to the pump through the normal fuel pump relay and the normally closed contacts of the speed control relay.

A faulty regulator is possible? But I rarely find failed regulators that allow ALL the fuel to bypass. If you want to be 110% sure, find the return line at the fuel rail, disconnect it and plug the rail side. If there's no improvement, reconnect the line and move on with your diagnosis.

Service info suggests there's a fuel tank access in the trunk? If there is, I'd suggest getting access to the top of the pump and checking power/ground at the pump itself during a crank. If the pump has everything it needs to work, and it isn't, that pump sucks.

IMO, the only variables left would be an internal leak in the pump assembly (the flex hose between the pump and the hanger), or low fuel level (car is parked on a hill, fuel level sender is lying, like that).

Please Log in or Create an account to join the conversation.

- TroyStevens

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

I should've included in the original post about the fuel level being on half tank and level ground. I will try the fuel regulator test. I searched for hours last night about how to bench test a regulator and couldn't come up with a definitive answer. There's plenty of tests for regulators with the vehicle running, but seems there are far less when it isn't. I do have a fuel pressure tester, a cylinder leak down tester, and a meager vacuum line tester, but nothing to create the vacuum, (cue the big air-pump disguised as a car, lol).

The regulator is easy to get to and remove. Would you have any other suggestions for bench-testing a regulator? I'm not opposed to buying additional tools as needed either, provided I can get them immediately. If I buy a brake bleeder with the gun-style pump, could that create sufficient vacuum to test whether or not my regulator is working as it should? I don't even know of how much vacuum I should be looking for.

I also added this vehicle to my alldata account, but I find myself more frustrated than anything when using it, since most troubleshooting steps they provide involve dealer-level diagnostic equipment. I'm constantly getting side-tracked doing Google searches for the tools they suggest to see if there's anything remotely equivalent that doesn't cost several thousands.

I also just got the Autel PowerScan P100, but still too dumb to use it. I'm especially worried about energizing the wrong side of a circuit and damaging the PCM. Not a single video on their site about how to use it, and most YouTube vids I see it are for promotional purposes with very limited real-world application demonstrations. I did email them and spoke to their "support", which was a new guy who knew nothing about the tool, but he assured me he'd contact an engineer and convey my questions, then call me back. That was 6 days ago.

Anyways, sorry for rambling on. Thanks again for your suggestions thus far.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6042

- Thank you received: 1519

I searched for hours last night about how to bench test a regulator and couldn't come up with a definitive answer. There's plenty of tests for regulators with the vehicle running, but seems there are far less when it isn't.

...

The regulator is easy to get to and remove. Would you have any other suggestions for bench-testing a regulator?

I can't say I've ever bench tested a regulator? :huh: I'm sure it can be done. But I hesitate to have you base your diagnosis on a test that I don't have any practical experience with, and no known good values.

That's why I suggested blocking the return line - with no return path, the pump is forced to deadhead and produce its maximum pressure. If the fuel pressure now goes 80+ PSI, then we can think about testing the regulator.

I also added this vehicle to my alldata account, but I find myself more frustrated than anything when using it, since most troubleshooting steps they provide involve dealer-level diagnostic equipment. I'm constantly getting side-tracked doing Google searches for the tools they suggest to see if there's anything remotely equivalent that doesn't cost several thousands.

Navigating service info is definitely a learned skill. :lol: GM does love their specialty tools, too.

I also just got the Autel PowerScan P100, but still too dumb to use it. I'm especially worried about energizing the wrong side of a circuit and damaging the PCM.

That'd be this one, right?

www.amazon.com/Autel-Powerscan-PS100-Aut...trical/dp/B07TX8QLYN

Looks like a decent copy of the Power Probe 2. :huh: That'll work for testing power and ground at the pump, if you choose to. No switch flipping required.

Please Log in or Create an account to join the conversation.

- TroyStevens

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

Regarding the PS100, you are correct in that it's much like the PowerProbe. I actually read a ton of reviews where owners of the PowerProbe preferred the PS100, although I'm not qualified to comment either way as of yet.

I'm about to head out and play with the car some more. I sure hope it isn't a wiring issue, since that's where I'm lacking the most knowledge.

As an aside, if you ever need any painting advice, please feel free to ask. I'm a Moderator on the world's largest painting forum for professional painters, PaintTalk.com. Although the site is for pros, I'd gladly answer any/all questions about painting should you ever have any. I'm just not used to being on this side of the fence where I'm always asking for help without ever providing any.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6042

- Thank you received: 1519

Thank you for your time and advice. Now I understand the process of checking the regulator in place as you initially suggested. When you first said to check to see if the situation improved, I just assumed you were referring to seeing if the car would start with the return line plugged. Didn't realize you were referring to monitoring pressure at the rail. Probably obvious to a more skilled hand, but not this guy.

Nah, that's not you, I could have been clearer about what I was looking for. :blush: My mistake!

I'm about to head out and play with the car some more. I sure hope it isn't a wiring issue, since that's where I'm lacking the most knowledge.

Let us know what you find.

As an aside, if you ever need any painting advice, please feel free to ask. I'm a Moderator on the world's largest painting forum for professional painters, PaintTalk.com. Although the site is for pros, I'd gladly answer any/all questions about painting should you ever have any. I'm just not used to being on this side of the fence where I'm always asking for help without ever providing any.

I appreciate that!

Please Log in or Create an account to join the conversation.

- TroyStevens

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

The voltage readings I took with the key off are probably worthless, since it sounds like the circuit needs to be loaded in order to accurately test for voltage. My key-on tests were done within 1 second of turning the key to the on position, just fyi. I also waited for at least 5 seconds between tests with the key back off before turning it back on, (as suggested by Paul).

The 4 pin connector you described is unfortunately all white wires now, but I do have readings for them if it matters.

Without your help, I'd be wasting a bunch of time taking voltage and resistance measurements then I'd spend the next day staring at those measurements, so thank you, really.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6042

- Thank you received: 1519

To clarify, I'm using the PS100 in voltage mode with the positive connected to battery positive and negative connected to battery negative. I kept the connection the same for both voltage and resistance, but I have no idea if that was right.

Perfect.

The voltage readings I took with the key off are probably worthless, since it sounds like the circuit needs to be loaded in order to accurately test for voltage. My key-on tests were done within 1 second of turning the key to the on position, just fyi. I also waited for at least 5 seconds between tests with the key back off before turning it back on, (as suggested by Paul).

Not worthless? But not ideal. If you have one available, an incandescent test light will work. You can use the little ground alligator clamp on the PS100 as a connection point for the test light.

The 4 pin connector you described is unfortunately all white wires now...

Because they changed the pump pigtail with the pump. :silly: That's not a knock on the shop that installed the pump - Depending on which pump you get, you may not have a choice. It just makes testing more interesting.

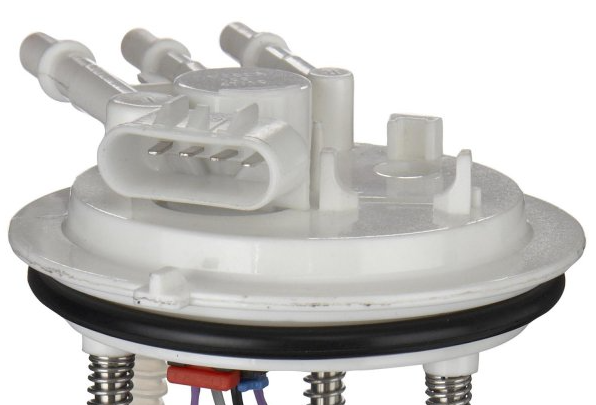

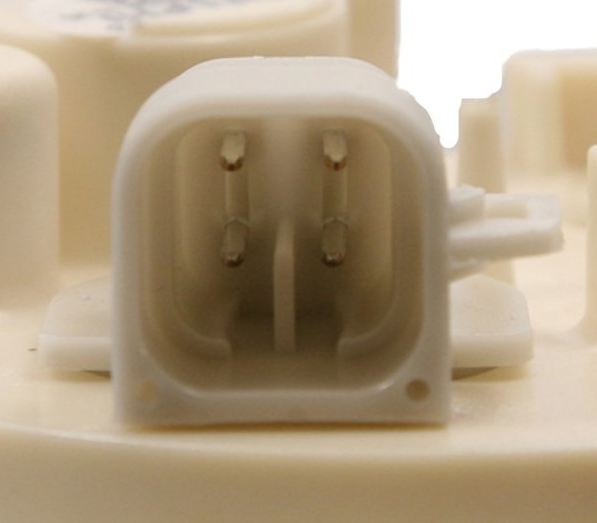

Does the pump have an in-line connector like this?

Or a double decker style like this?

Please Log in or Create an account to join the conversation.

- TroyStevens

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

To clarify, this test was done during engine crank with PS100, positive end to B+ and negative to B-

Upper-left pin reads 0v, 19.9Ω

Upper-right pin reads 5v, OL

Bottom-left pin reads .1v, 23Ω

Bottom-right pin reads 11.9v, OL

The one thing I hadn't mentioned is that yesterday, in a last-ditched effort, I took the relay to the fuel pump resistor and bent pin 85 outwards, then placed it back in. It's nothing I've ever done before, but the car got the best of me and it had it coming. I had actually read many suggestions about doing this with the same year, make & model car exhibiting the same symptoms. It didn't work though. The car just laughed at me. Not sure if that will affect the readings above, but I just now remembered. Evidently, bending pin 85 is supposed to bypass the low-speed setting, make it fire right up, and allow me to ride off into the sunset. Included is a link to the YouTube vid for reference.

Fuel Pump Resistor Bypass

Please Log in or Create an account to join the conversation.

- TroyStevens

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

partshawk.com/pub/media/catalog/product/...12fc/f/g/fg0151v.jpg

The second pic is the male end of that 4 pin connector from which I took my measurements.

partshawk.com/pub/media/catalog/product/...12fc/f/g/fg0151c.jpg

The black 3 pin connector wires on the male end of the car are brown/black, green wire in the middle, then an orange/black wire.

The third pic is female end of the 3 pin connector on top of the pump

partshawk.com/pub/media/catalog/product/...12fc/f/g/fg0151h.jpg

Please Log in or Create an account to join the conversation.

- TroyStevens

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

(In my OP, I said this was my Father-in-Law's car who just passed away, not to be confused with my Dad who died in 2011, just fyi).

Anyways, I'll update as soon as I have some constructive feedback. I have a feeling my electrical tests have been performed completely wrong. Thanks.

Please Log in or Create an account to join the conversation.