*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

Re:Re:Re:PLEASE explain this to me. 2 weeks of troubeshooting.

- TaoRepair

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

3 years 5 months ago #55821

by TaoRepair

PLEASE explain this to me. 2 weeks of troubeshooting. was created by TaoRepair

vehicle is a 2007 hyundai elantra. No start.

Crankshaft position sensor functioning. Camshaft position sensor functioning, both outputting PWM between 0-5v to manufacturers specification. The pulses are in proper time, iwith the crankshafts "long" low signal coinciding with camshafts signal's rising and falling edges. Within 5 teeth (or pulses) as specified.

There is spark, removed all plugs, still in power wires, and watched all fire strongly.

injectors have power and a pulse, although cant find exact spec for pulse voltage, although there is definitely a pulse, look fine.

Compression on all cylinders. 30 and 60 psi on second stroke.

No fault codes.

the car will not start.

starter fluid sprayed into cylinders makes no difference.

Battery voltage 12.4 +

timing marks are on.

HOW is this possible. The fuel is good, fluid levels normal.

Does anything come to mind, what does one check after this?

Thank you so much in advance for any poor soul that descends into this problem with me. I have years of experience repairing modern vehicles and am at a loss.

Crankshaft position sensor functioning. Camshaft position sensor functioning, both outputting PWM between 0-5v to manufacturers specification. The pulses are in proper time, iwith the crankshafts "long" low signal coinciding with camshafts signal's rising and falling edges. Within 5 teeth (or pulses) as specified.

There is spark, removed all plugs, still in power wires, and watched all fire strongly.

injectors have power and a pulse, although cant find exact spec for pulse voltage, although there is definitely a pulse, look fine.

Compression on all cylinders. 30 and 60 psi on second stroke.

No fault codes.

the car will not start.

starter fluid sprayed into cylinders makes no difference.

Battery voltage 12.4 +

timing marks are on.

HOW is this possible. The fuel is good, fluid levels normal.

Does anything come to mind, what does one check after this?

Thank you so much in advance for any poor soul that descends into this problem with me. I have years of experience repairing modern vehicles and am at a loss.

Please Log in or Create an account to join the conversation.

- Ben

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1097

- Thank you received: 215

3 years 5 months ago #55822

by Ben

Replied by Ben on topic Re:PLEASE explain this to me. 2 weeks of troubeshooting.

I think your saying it has 30 and 60 psi of compression? it should have 150 ish while cranking... Also the spec is not within 5 teeth more like within 5 degrees (depending on crank teeth count there's roughly 10 degrees per tooth so 5 teeth would be 50 degrees out of time (which is a lot) sounds cut and dry this is a blown motor , im sure you can hear that the motor sounds like it's spinning fast (some people say it sounds like it's not spinning fast enough because you don't hear the sound of compression strokes)

Sent from my SM-G781V using Tapatalk

Sent from my SM-G781V using Tapatalk

The following user(s) said Thank You: TaoRepair

Please Log in or Create an account to join the conversation.

- TaoRepair

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

3 years 5 months ago #55823

by TaoRepair

Replied by TaoRepair on topic Re:PLEASE explain this to me. 2 weeks of troubeshooting.

Yes it has 30 and then goes up to 60 with next stroke. Wow I was totally misled, my accomplice in failure here felt sure 50 PSI was adequate. I did not read into it further, but you sure as hell are right. We changed a head gasket after an overheating issue and the compression improved vastly as it was 5 psi prior. This is hilarious . God bless you.

I KNEW it was something to do with a physical deficiency as everything else was there. But man I overlooked the most blatant factor. I have been working on cars for years and always thought 30-50 was sufficient. Dude i got 3 cars here with the exact same issue LMAO. I swear we even googled it and must have clicked on the single forum that was run by someone dumber than me. Everything online corroborates what your saying. IF we remachined the head, would you expect this to be a possible resolution? Or would the lower end typically require resurfacing as well? Its literally the cheapest car on the US market, cost us under 2k.

I KNEW it was something to do with a physical deficiency as everything else was there. But man I overlooked the most blatant factor. I have been working on cars for years and always thought 30-50 was sufficient. Dude i got 3 cars here with the exact same issue LMAO. I swear we even googled it and must have clicked on the single forum that was run by someone dumber than me. Everything online corroborates what your saying. IF we remachined the head, would you expect this to be a possible resolution? Or would the lower end typically require resurfacing as well? Its literally the cheapest car on the US market, cost us under 2k.

Please Log in or Create an account to join the conversation.

- Ben

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1097

- Thank you received: 215

3 years 5 months ago #55824

by Ben

Replied by Ben on topic Re:Re:PLEASE explain this to me. 2 weeks of troubeshooting.

If it was overheated badly I would suspect the rings were probably cooked as well, cranking compression should never on any engine be lower than 100 most should be 140-150 and some above that

Sent from my SM-G781V using Tapatalk

Sent from my SM-G781V using Tapatalk

The following user(s) said Thank You: TaoRepair

Please Log in or Create an account to join the conversation.

- TaoRepair

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

3 years 5 months ago #55825

by TaoRepair

Replied by TaoRepair on topic Re:PLEASE explain this to me. 2 weeks of troubeshooting.

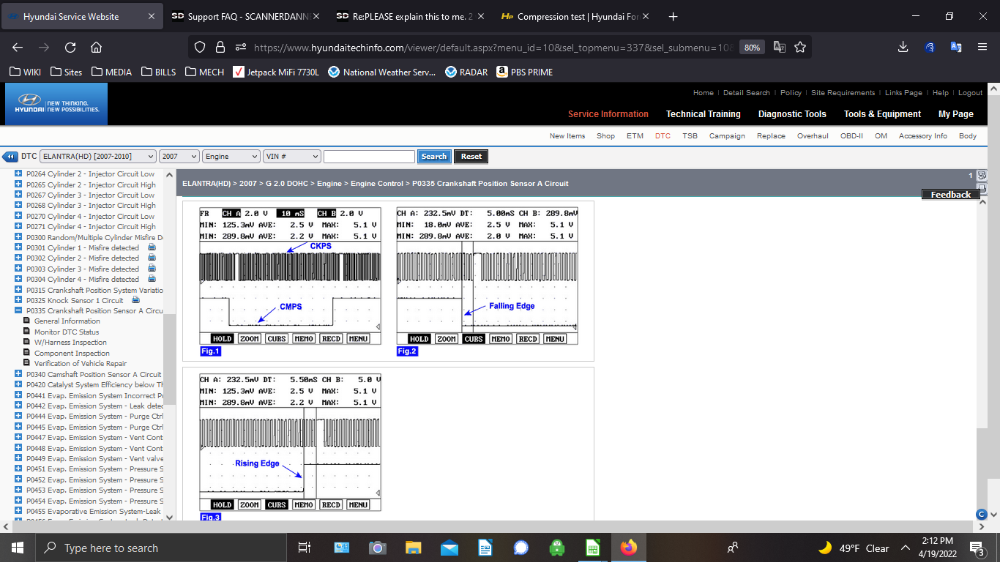

And here was the crankshaft / camshaft timing, It looked near identical, But im positive your answer is the culprit, im not even half of the required compression at 30-60. Would one need like a lathe or CNC machine to fix this or is there any other way, considering all the vehicles displaying this issue overheated at some point.

Please Log in or Create an account to join the conversation.

- TaoRepair

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

3 years 5 months ago #55826

by TaoRepair

Replied by TaoRepair on topic Re:Re:PLEASE explain this to me. 2 weeks of troubeshooting.

would you personally, if in this situation, replace the rings in an attempt to resolve? The head gasket certainly helped bring all cylinders up to a uniform 30-60 psi, but the rings have not been changed. Just to be clear, when a vehicle overheats, blows a head gasket, and not ran further, the KNOWLEDGEABLE mechanic would 1. resurface, 2 replace head gasket, and 3 replace piston rings. and expect the engine to be saved? ( with a high degree of success to justify expense) . Or considering the car being 2k, would the smart mechanic just scrap it?

Please Log in or Create an account to join the conversation.

- Ben

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1097

- Thank you received: 215

3 years 5 months ago #55827

by Ben

Replied by Ben on topic Re:Re:Re:PLEASE explain this to me. 2 weeks of troubeshooting.

Well my opinion (ASE Master tech, Shop Owner) I do in cylinder pressure testing , crankcase pressure sensor in oil dipstick, and leak down testing before any disassembly if I find any leakage anywhere besides headgasket, and or valves I will replace the motor if a vehicle is getting a headgasket I always send the head to the machine shop to get resurfaced and valves checked

Sent from my SM-G781V using Tapatalk

Sent from my SM-G781V using Tapatalk

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

Less

More

- Posts: 4914

- Thank you received: 1098

3 years 5 months ago #55828

by Noah

"Ground cannot be checked with a 10mm socket"

Replied by Noah on topic Re:Re:Re:PLEASE explain this to me. 2 weeks of troubeshooting.

I completely agree with Ben.

If I was in your position, I would lob a junkyard engine in it.

My two cents

If I was in your position, I would lob a junkyard engine in it.

My two cents

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tutti57

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1096

- Thank you received: 253

3 years 5 months ago #55845

by Tutti57

Replied by Tutti57 on topic Re:Re:Re:PLEASE explain this to me. 2 weeks of troubeshooting.

When you did the compression test, did you let it crank and watch the gauge bounce up just two times, or did you continue cranking and it just never went above that 60psi? Just curious.

You could try squirting some oil in the cylinder and try the test to see if anything changes. This could indicate a ring issue or that the cylinders were washed down, which can cause low compression.

I'm not saying the motor is good, just throwing out a couple of other things.

I know I have read this compression "spec" where the second stroke is supposed to be at least twice the first, but can't remember where I read it. Maybe it's an indication of something if it passes or fails that test, but I'd want to see what it ends up being after more cranking.

You could try squirting some oil in the cylinder and try the test to see if anything changes. This could indicate a ring issue or that the cylinders were washed down, which can cause low compression.

I'm not saying the motor is good, just throwing out a couple of other things.

I know I have read this compression "spec" where the second stroke is supposed to be at least twice the first, but can't remember where I read it. Maybe it's an indication of something if it passes or fails that test, but I'd want to see what it ends up being after more cranking.

Please Log in or Create an account to join the conversation.

Time to create page: 0.310 seconds