Toyota rav4 2008... Got me stumped!!!!

- Kirby

-

Topic Author

- Offline

- Junior Member

-

- Posts: 24

- Thank you received: 9

Yhanks for yur input guys and girls!

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

So let me get this straight - If the tank is 1/2 full, and you plug the cluster in, it'll read 1/2, right? If I were to then suck the tank dry, the gauge would never move from 1/2 full? Then, cycle the cluster connector, and it'd show empty?

How about a variable resistor in place of the fuel level sender? If you were to vary the resistance of that circuit manually, would the gauge respond?

I gotta think about this one. :lol:

Please Log in or Create an account to join the conversation.

- Caritech

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 10

Please Log in or Create an account to join the conversation.

- JeffBirt

-

- Offline

- Premium Member

-

- Posts: 129

- Thank you received: 34

Please Log in or Create an account to join the conversation.

- Ben

-

- Offline

- Platinum Member

-

- Posts: 1097

- Thank you received: 215

Sent from my SM-N920P using Tapatalk

Please Log in or Create an account to join the conversation.

- Doc n2mx

-

- Offline

- Senior Member

-

- Posts: 44

- Thank you received: 10

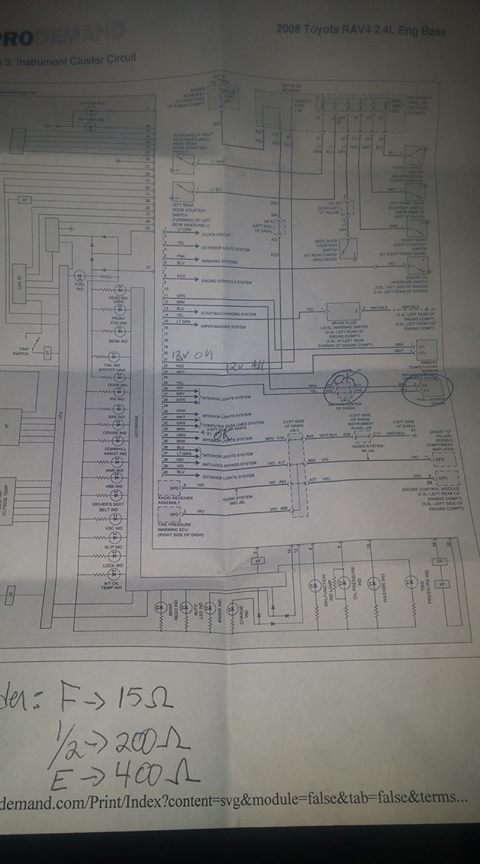

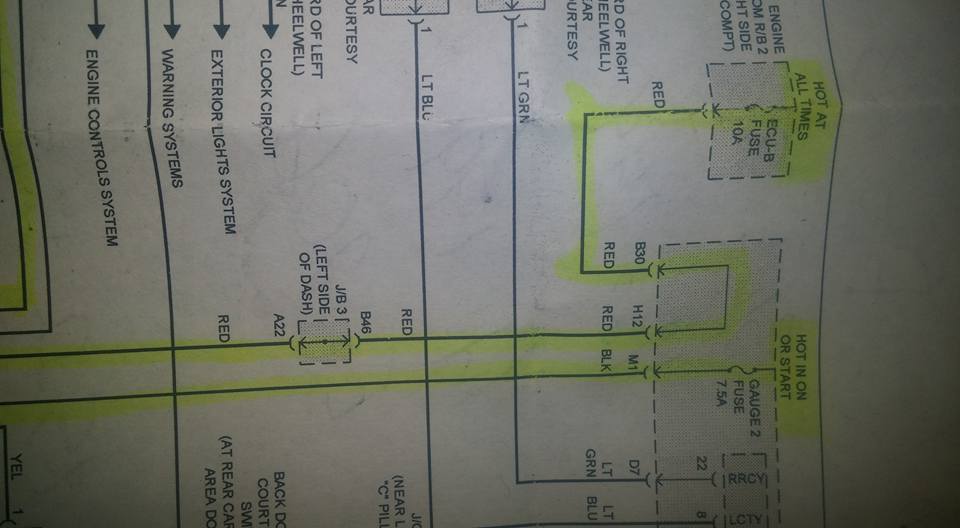

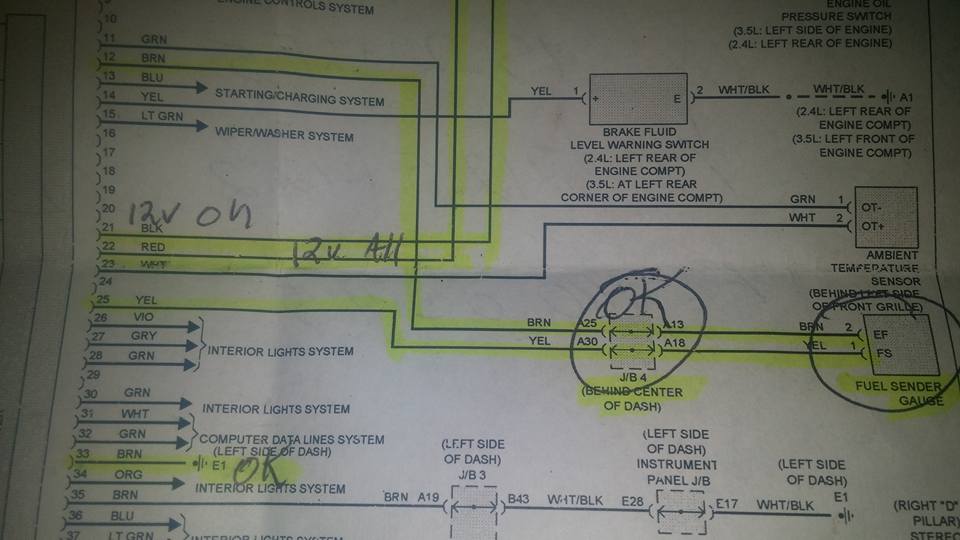

The first thing I would do is look at a wiring diagram for the sending unit / pump. Next I would look to see any common connections that are associated with this circuit.. If there is a relay I would test the control side and the load side.

You say that you unplug it and re plug it and it works, I would think I look at some kind of control side. Check your wire diagram for all common grounds as well. Don’t for get to check any relays!

Let me know how you make out.

Doc n2mx

Please Log in or Create an account to join the conversation.

- GeekDIYMechanic

-

- Offline

- Premium Member

-

I would assume overall powers and grounds would be good since you didn't indicate any other cluster issues, but I have been wrong many times before. You know what happens when you assume. LOL

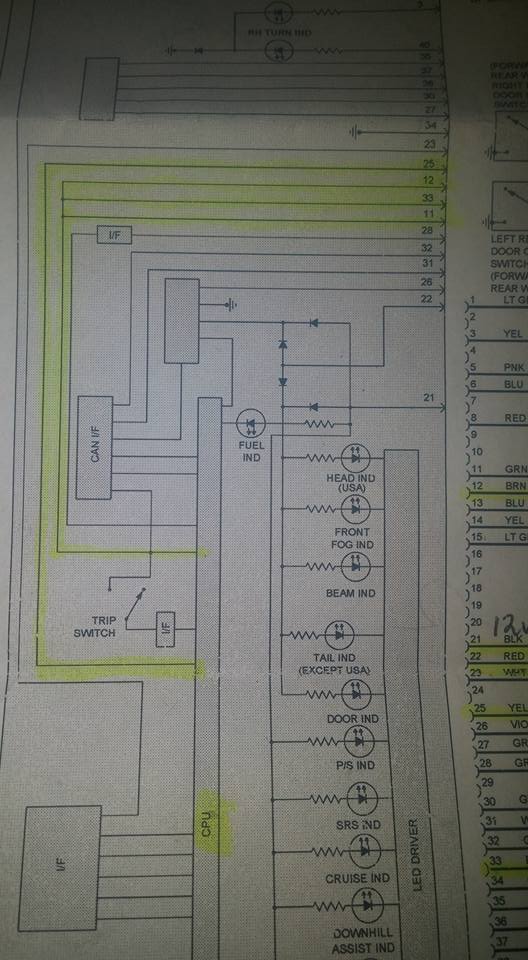

Somehow the gauge does not know when to hold a value and when to allow it to change.

I like the idea of using a variable resistor or use a variety of resistors to check signal integrity and gauge response. But, from what you have said, it appears to be a gauge issue.

Please Log in or Create an account to join the conversation.

- Kirby

-

Topic Author

- Offline

- Junior Member

-

- Posts: 24

- Thank you received: 9

Please Log in or Create an account to join the conversation.

- cheryl hartkorn

-

- Offline

- Platinum Member

-

- Posts: 692

- Thank you received: 130

Please Log in or Create an account to join the conversation.

- Kirby

-

Topic Author

- Offline

- Junior Member

-

- Posts: 24

- Thank you received: 9

Please Log in or Create an account to join the conversation.

- cheryl hartkorn

-

- Offline

- Platinum Member

-

- Posts: 692

- Thank you received: 130

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

This kind of reminds me of when the tank is filled with the key on, but it doesn't register until the key is cycled.JeffBirt wrote: I seem to recall some vehicles came with a gauge that maintains its reading with the key off. It seems like when the gauge received power it was free to move and when the key was off the lack of power caused it to maintain the reading. This is from my hazy memory from seeing one years ago as a kid and wondering how it worked.

What happens if you disconnect the sender at the tank and reconnect it? The gauge should go to empty with the tank sender unplugged, I'm curious to see if it goes back to the incorrect value, reports the correct level, or doesn't move at all.

The system looks about as basic as they come, weird issue... :blink:

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Kirby

-

Topic Author

- Offline

- Junior Member

-

- Posts: 24

- Thank you received: 9

Please Log in or Create an account to join the conversation.

- GeekDIYMechanic

-

- Offline

- Premium Member

-

When you say you unplug it, where are your unplugging it? At pump or behind fuel gauge?

In the past, I do remember someone telling me their is circuitry present to not make the needle bounce as you drive, caused by fuel moving around in tank as we drive. How does this car handle this?

Again, maybe it is real obvious via the diagram, but I cannot make it out. Sorry if this is the case. I know you have done your homework.

Please Log in or Create an account to join the conversation.

- Kirby

-

Topic Author

- Offline

- Junior Member

-

- Posts: 24

- Thank you received: 9

For the bouncy needle, i assume the cluster takes readings every time or so to ajust for the fuel level decreasing.... but on this one the customer went for a 300km trip and the gage never moved.... talk about fuel economy!!!! lol!!! And thanks for all your inputs!

Please Log in or Create an account to join the conversation.

- ephotrod

-

- Offline

- New Member

-

- Posts: 14

- Thank you received: 16

Please Log in or Create an account to join the conversation.

- Kirby

-

Topic Author

- Offline

- Junior Member

-

- Posts: 24

- Thank you received: 9

Please Log in or Create an account to join the conversation.

- Kirby

-

Topic Author

- Offline

- Junior Member

-

- Posts: 24

- Thank you received: 9

ephotrod wrote: The problem maybe internal in the cluster, such as the servo or a loose or worn contact. From my understanding you've checked from the sending unit to the cluster with all test passing. If that's the case your attention next maybe the cluster. Chevrolet is famous for having a series of bad clusters. I always check from point to point in a methodical manner, not doubting my results until I'm at the of ther end and fully finished. You've gone from the float to the the back of the cluster now check to the needle!

As i mentionned, the cluster also was replaced.... Based on all the other tests.... Same problem.....

Please Log in or Create an account to join the conversation.

- cheryl hartkorn

-

- Offline

- Platinum Member

-

- Posts: 692

- Thank you received: 130

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

Kirby wrote: The unplug it part: I unplug the connector at the back of the cluster 40pin connector.... Sorry for the diagram... will try to upload it in two parts....

For the bouncy needle, i assume the cluster takes readings every time or so to ajust for the fuel level decreasing.... but on this one the customer went for a 300km trip and the gage never moved.... talk about fuel economy!!!! lol!!! And thanks for all your inputs!

Maybe you're onto something here... How DOES the cluster decide when to move the needle? :huh: No modern gauge is directly tied to it's sensor input, otherwise it'd be swinging all over the place, so there has to be some logic involved.

Some input to the cluster is missing? Something to clue it in that, "Hey, the vehicle is moving, keep an eye on the fuel level." Have you already gone over powers and grounds at the cluster?

Please Log in or Create an account to join the conversation.