*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

Cam timing causing a P0420?

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2120

- Thank you received: 708

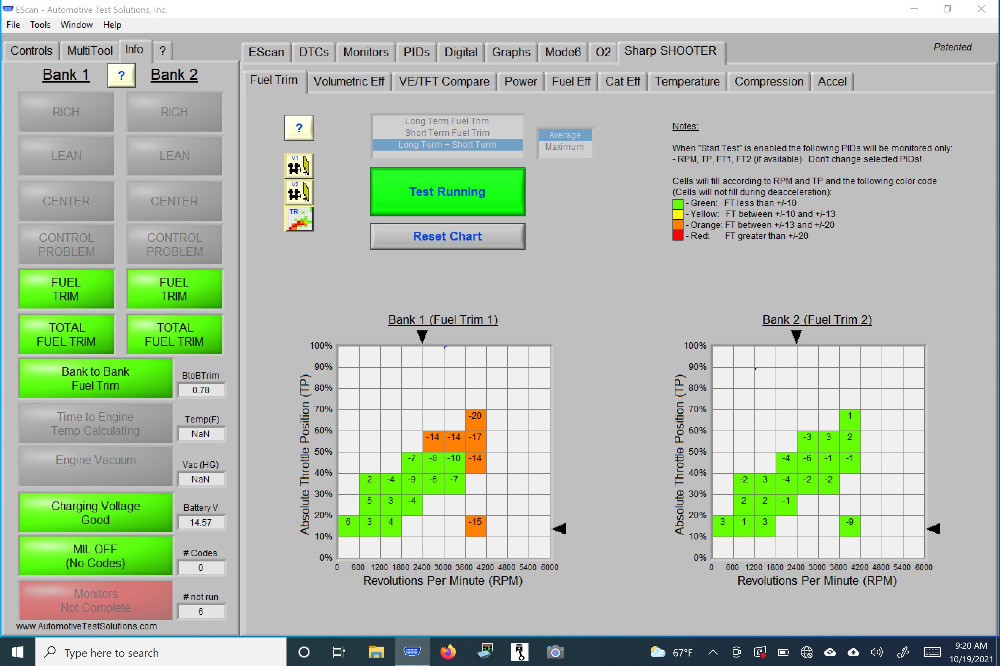

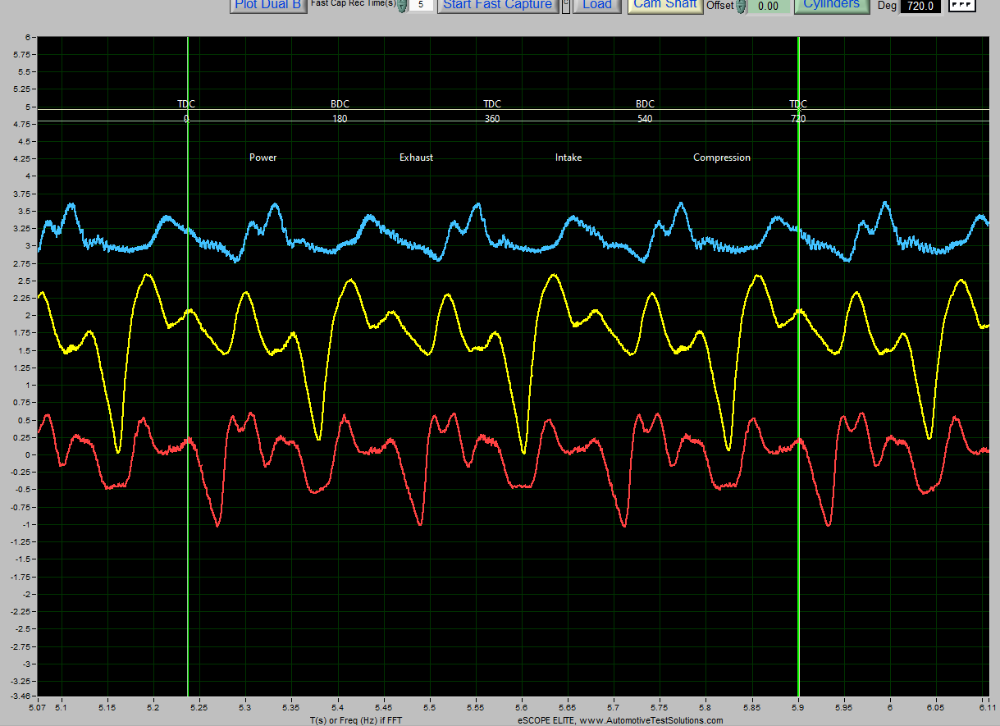

3 out of 4 cam/crank difference/variation pids show -3° to -4°, at idle. Bank 2 exhaust is close to 0°. All cams seem to phase, as they should during a test drive. I observed the Bank 1 Upstream sensor hanging around 750mv to 850mv, at idle. It looks like it is trying to switch, but is stuck in the RICH range.

Bank 1 Yellow is Upstream. Red is Downstream.

The Bank 1 Downstream sensor will begin to cycle like you would expect the upstream sensor to cycle, while the Upstream sensor is stuck RICH. I checked and the connectors are not reversed. Inducing a vacuum leak drives the sensor lean, momentarily. I called the Upstream sensor "lazy" and shotgunned a new sensor at it. No difference (re-installed old sensor). I stuck a pulse sensor in the tail-pipe and intake. I can see a distinct Bank-to-Bank issue in the exhaust waveform.

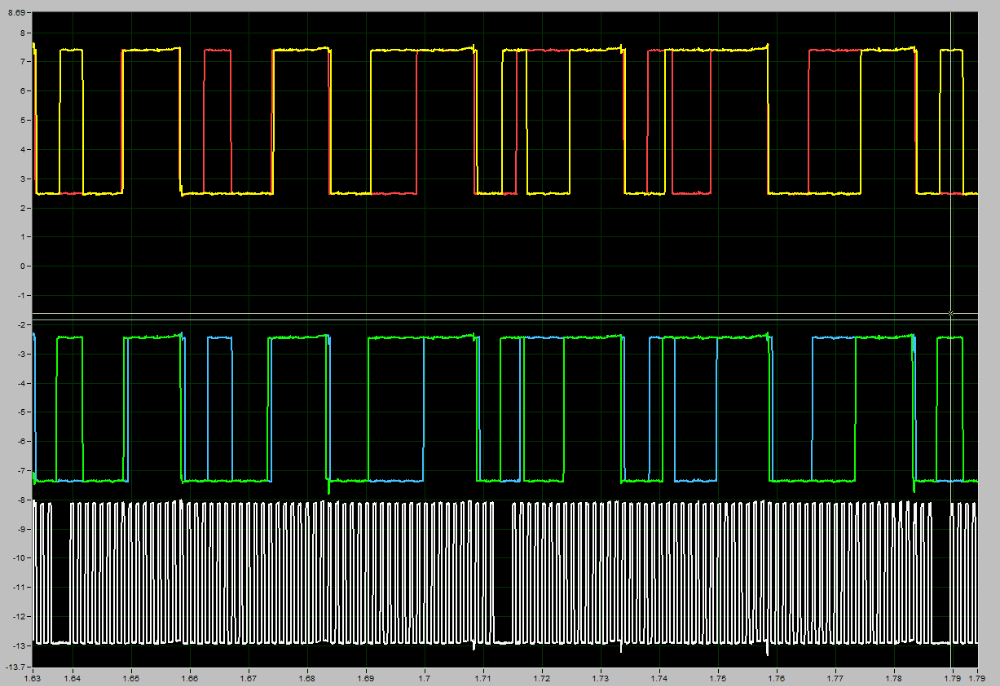

I compared Cams and Crank to a Known Good. They match up pretty well, I think. Only a few degrees of differences. I have seen worse. RC looks good, in my opinion. This vehicle runs great, with the exception of the fuel smell during accel and poor fuel mileage. No chain slap/rattle noise. I would recommend new chains, just based off of mileage (157,000) but, I want to be sure I get to the bottom of the P0420. Exhaust back pressure is 1 1/2 psi @ 3000 rpm.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

I don't think a 4 or 5 degree deviation on cam timing is possibly the root cause of the P0420.

From your description I understand that the upstream sensor on bank one is reporting a truly rich condition. The O2 sensor detects the condition, nevertheles at higher rpm/loads the pcm isn't in fuel control anymore.

While running "a year or so" with this issue the replacement cat got damaged. Do you know why the previous converter(s) was changed, same reason? The underlying cause was rich running and was left unaddressed so it repeated itself?

If the scan/scope data shows similar injection on times for both banks you may want to compare the pressure drop of the injectors from bank 1 to bank 2 or switch them bankwise. They may have different flow rates.

Your pressure pulse reading seems to be taken cranking, do you observe the same difference in exhaust pulses at idle as well? Could the design of the exhaust system contribute to the bank to bank difference?

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2120

- Thank you received: 708

I wouldn't, normally, think so either. But everything else looks good, with the exception of the B1S1. I am struggling with the "Chiken? Or, the egg?", on that. Is that the cause? Or, the effect of a bad CAT? Lack of exhaust back-pressure makes me think it is the Chicken.I don't think a 4 or 5 degree deviation on cam timing is possibly the root cause of you the P0420.

While running "a year or so" with this issue the replacement cat got damaged. Do you know why the previous converter(s) was changed, same reason? The underlying cause was rich running and was left unaddressed so it repeated itself?

I'm not sure what the history is. I will call and interrogate the muffler shop, tomorrow. I got the impression that the currently installed Cats may be the second set that the muffler shop has installed. I'm not sure. They told me that they had talked to the manufacturer. The manufacturer refused to warranty, saying that there must be an underlying issue. This makes me think that these Cats are the second replacements. I will get the full scoop on this, tomorrow.

I may do this, tomorrow. I haven't pursued this avenue because fuel trims at idle look good.If the scan/scope data shows similar injection on times for both banks you may want to compare the pressure drop of the injectors from bank 1 to bank 2 or switch them bankwise. They may have different flow rates.

The exhaust waveform was engine Cranking. Not, running. I haven't looked at them with the engine running. I'll add that to "the list". The two exhaust banks "Y" together, into one pipe. Then the one pipe splits, and "Y"s back into two tail pipes. All in a, relatively, straight line. The capture was taken from one tail-pipe, with a wet rag stuffed into the other tail pipe. I will play around, and re-test this, tomorrow. I think I may even pull the the Upstream O2 sensors and capture exhaust pulses from the bung holes.Your pressure pulse reading seems to be taken at idle, do you observe the same difference in exhaust pulses at idle as well? Could the design of the exhaust system contribute to the bank to bank difference?

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Cheryl

-

- Offline

- Platinum Member

-

- Posts: 1214

- Thank you received: 215

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6042

- Thank you received: 1519

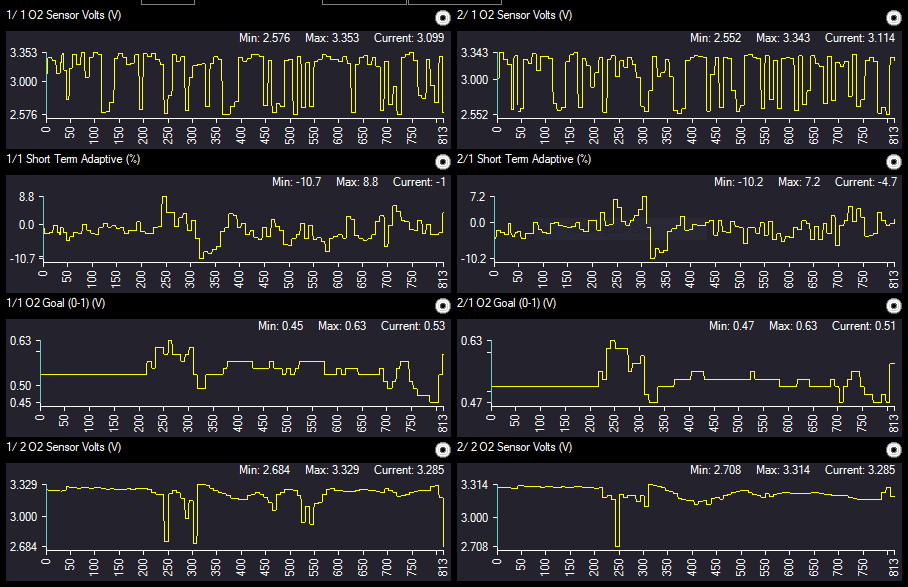

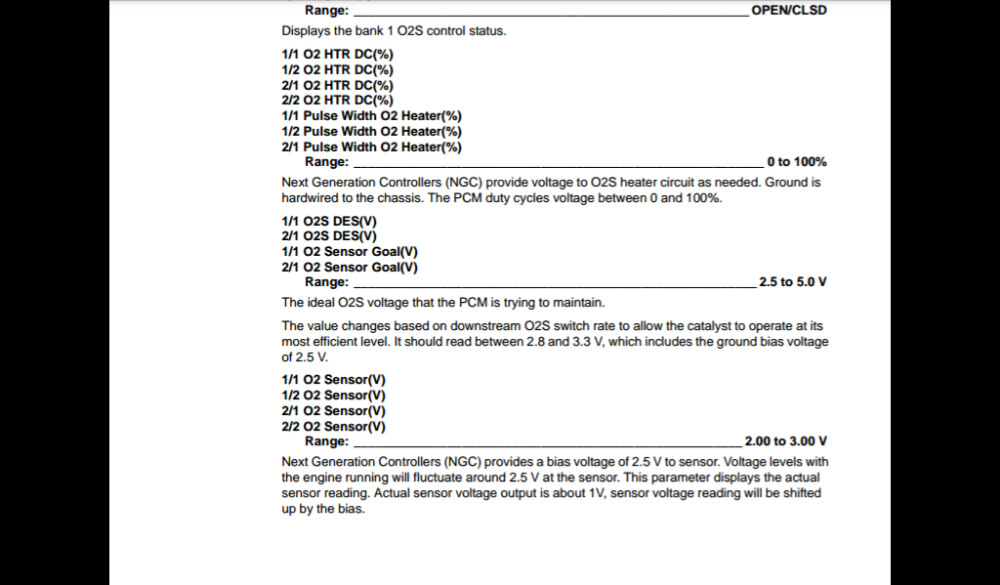

Do you know what the O2 Goal (0-1) (V) PIDs are reading on the manufacturer side? I suspect they're part of the downstream fuel control strategy. A large difference bank-to-bank might suggest an exhaust leak OR a cat that just isn't storing oxygen the way it should.

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2120

- Thank you received: 708

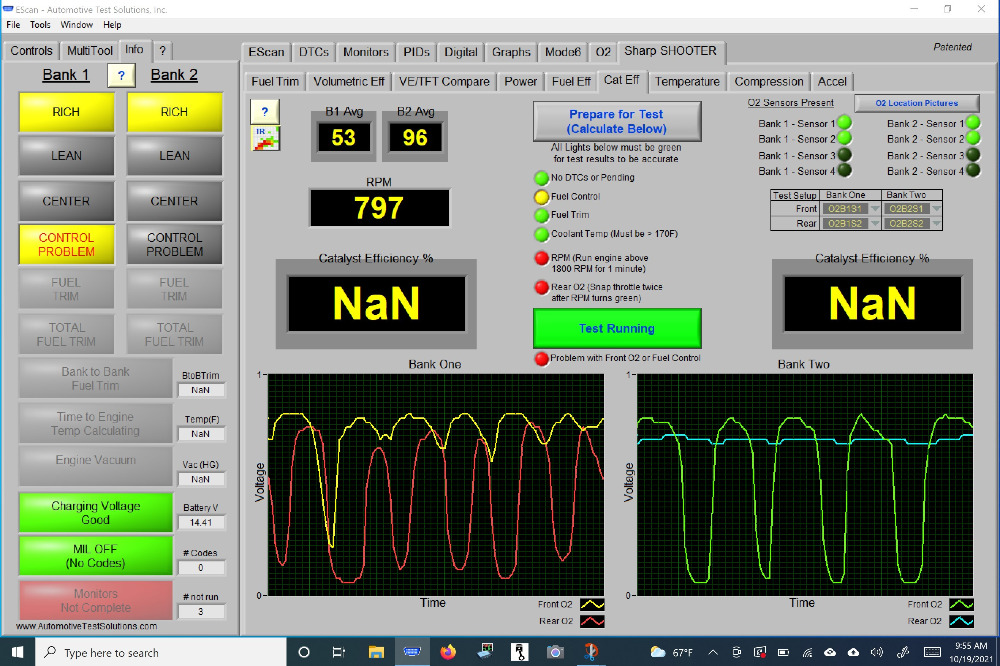

B1S1 goal is .750

B2S1 goal is .570

So...now, I need educated. Why would the Bank 1 goal be .750?

I know that the cat is bad. I have been tasked, by the muffler shop, to determine the cause of the failure. They just installed them (aftermarket), earlier this year in March.A large difference bank-to-bank might suggest an exhaust leak OR a cat that just isn't storing oxygen the way it should.

The manufacturer is refusing to warranty, claiming there must be an underlying issue. At this point, I feel like I am chasing a ghost. I am going to cut the cat out, and re-look at the exhaust waveforms. If the Bank-to-bank anomaly goes away with the Cat, I have to conclude that the Cat should be warrantied. The muffler shop will "eat it".

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6042

- Thank you received: 1519

Yeah, me too. :silly: I nearly got my ass kicked by a Chrysler 300 about a year ago, and I've been watching O2 Goal on known good cars ever since. No training material or service info that I've found talks about it's usage. Just me making it up as I go.Good timing, Tyler. I was just about to cut the cat out, to eliminate it from the equation. Good call, too. I had not paid any attention to the Goal pid.

B1S1 goal is .750

B2S1 goal is .570

So...now, I need educated. Why would the Bank 1 goal be .750?

From that '13 T+C I uploaded:

O2 Goal starts trending up around frame 200 when the downstream goes low, and the Short Term reacts around the same time. So, if your O2 Goal on B1 is high, then I'd say the PCM isn't happy with the downstream O2 behavior. Which makes sense - it's switching when it should be steady above .6-.7V. Meanwhile, the upstream O2 is trending rich. I'm surprised it hasn't set an O2 slow response code yet. :huh:

Aftermarket. Play stupid games, win stupid prizes. As usual, as long as it's not misfiring or drinking fluids (oil/coolant/fuel), then it's done IMO.I know that the cat is bad. I have been tasked, by the muffler shop, to determine the cause of the failure. They just installed them (aftermarket), earlier this year in March.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2120

- Thank you received: 708

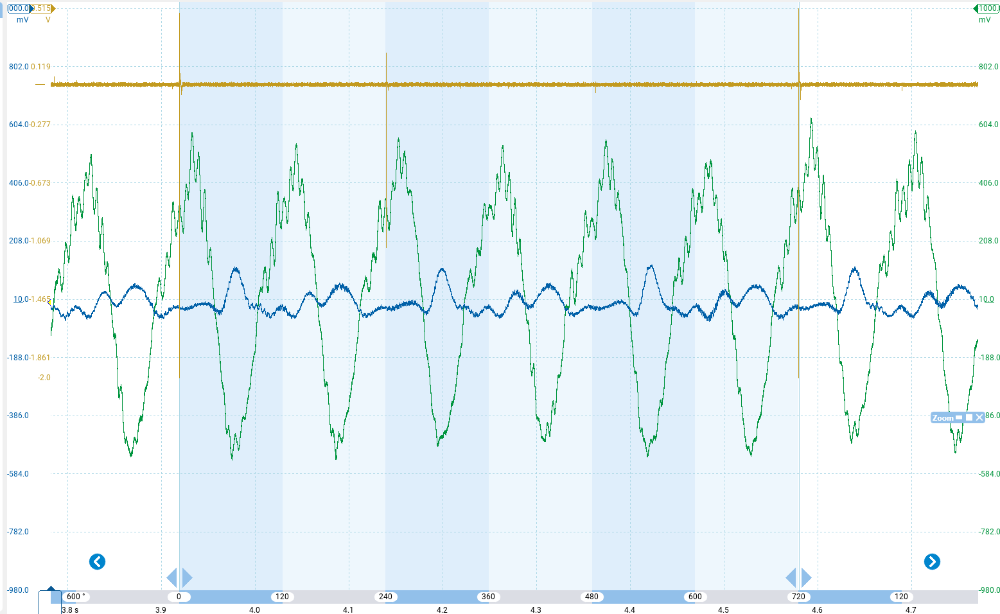

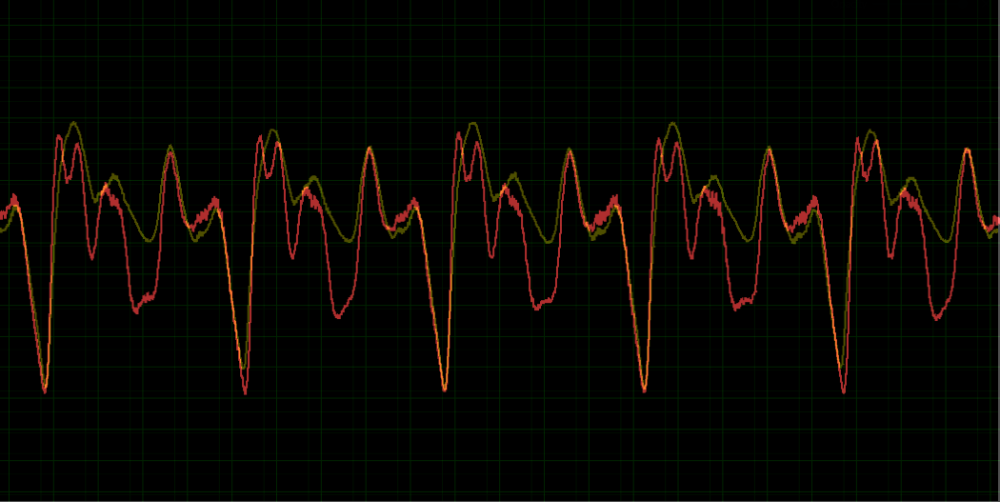

For anyone interested, here is a follow-up on the exhaust waveforms. First is waveform with a pulse sensor in each upstream bung hole, and one in the tail pipe.

Bank 1 (slightly restricted) Bank 2

Here is a Bank 1 offset, and over-layed atop Bank 2.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

Just to make sure I understand this correctly:

The exhaust pressure waveforms were taken with the damaged cat still in place and during cranking, at around 700 ms for the complete cycle, right?

I'd call this a VERY tough one and wouldn't dare to point at the catalytic converter just based on the back pressure waveforms...

Is there any chance you can get exhaust pressure readings once the new converter is in place? (I know, most probably not...)

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- VegasJAK

-

- Offline

- Platinum Member

-

- Silencing the Parts Cannon

- Posts: 566

- Thank you received: 140

Agree fully with Paul that low tech is still a viable way to diagnose. It so easy to misinterpret waveforms.

Please let me know if my thinking is off. We learn by our mistakes and God knows I have made a lot of them in my life time.

"an open mind let's knowledge flow in and wisdom flow out for a man who has neither never listens to those who have both".

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2120

- Thank you received: 708

It was never a question of IF, or IS the cat bad. That has been known from the beginning. The question was "Is there an underlying issue that CAUSED the cat to fail?"I had called this a bad cat to myself from the beginning.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2120

- Thank you received: 708

Yes. Those waveforms were while cranking, with the bad cat, still, installed.The exhaust pressure waveforms were taken with the damaged cat still in place and during cranking, at around 700 ms for the complete cycle, right?

Is there any chance you can get exhaust pressure readings once the new converter is in place? (I know, most probably not...)

I asked the owner to bring it back, after the new cat has been installed, so that I could look at some "AFTER" data, pro bono. He said he would. I hope he does.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- VegasJAK

-

- Offline

- Platinum Member

-

- Silencing the Parts Cannon

- Posts: 566

- Thank you received: 140

Juergen points out a cause as a true rich condition which would have lead to the original cat going bad. But, Chad was tasked with why the new cat failed. It's failure had nothing to do with the true rich condition as the cat was found to be defective. Two distinct problems. So we're back to what is the true rich condition. I have to admit Tyler lost me on the 02 goal readings.

"an open mind let's knowledge flow in and wisdom flow out for a man who has neither never listens to those who have both".

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2120

- Thank you received: 708

I'm not sure but, It is my understanding/belief that the rich condition/Goal of .750 was caused by the down stream O2 sensor cycling lean, due to the bad cat? A Downstream fueling strategy? If/When the owner brings it back, I will update.So we're back to what is the true rich condition. I have to admit Tyler lost me on the 02 goal readings.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4914

- Thank you received: 1098

Did you happen to observe if the upstream O2 activity returned to normal after the new cat? I definitely would have called a lazy o2 early on.

The 5-ish degrees of timing definitely threw a variable into the mix also.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6042

- Thank you received: 1519

...with a pulse sensor in each upstream bung hole...

Sorry not sorry. :silly:

But seriously, well done on making the call! It's never easy being the third (or fourth?) party trying to sort out a mess.

I'm not sure but, It is my understanding/belief that the rich condition/Goal of .750 was caused by the down stream O2 sensor cycling lean, due to the bad cat? A Downstream fueling strategy?

That's my understanding, anyway. :silly: I think O2 Goal represents the PCM's modification of the fuel calculation to make the downstream O2 behave correctly. Values above .45V represent adding fuel, less represents subtracting. I could be off about the .45V value? But that's what I usually see. Why didn't they just call it 'downstream fuel control' or 'post-catalyst fuel trim'? Because Chrysler, that's why.

IMO, part of the issue is that the PCM *assumes* a working catalyst when making changes to O2 Goal. Evidently, even when a P0420 is set, the PCM will still crank up O2 Goal to get what it wants.

Please Log in or Create an account to join the conversation.