*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

1995 Jeep Wrangler 2.5L 5 speed / CKP glitching causing misfire

- Theshorefix

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 2

4 years 4 days ago #52000

by Theshorefix

1995 Jeep Wrangler 2.5L 5 speed / CKP glitching causing misfire was created by Theshorefix

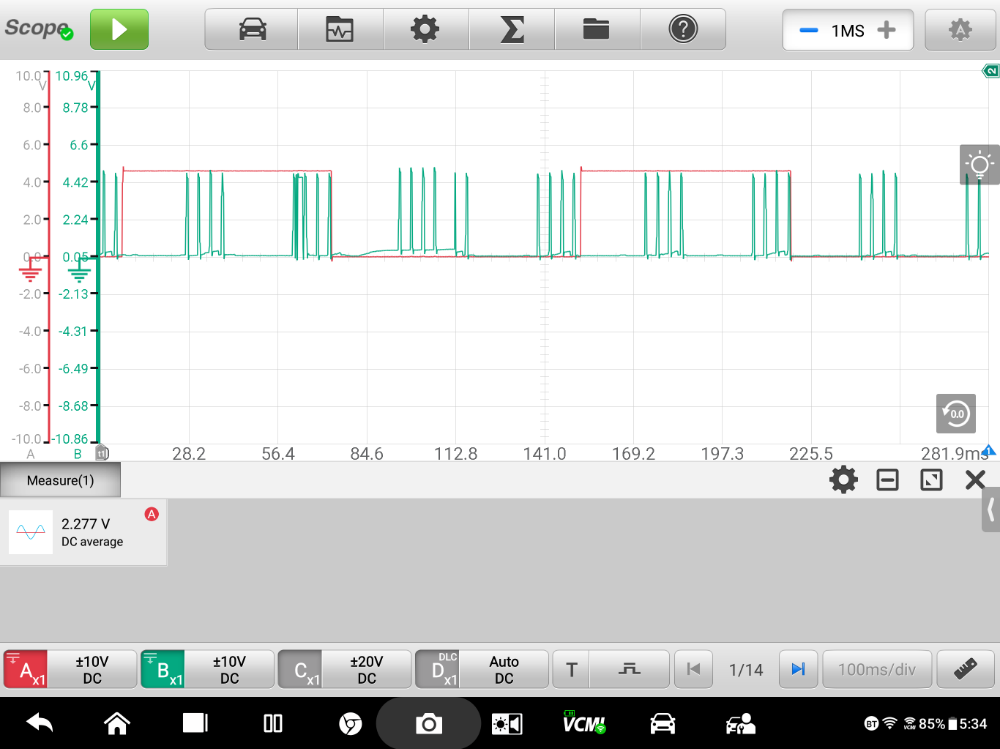

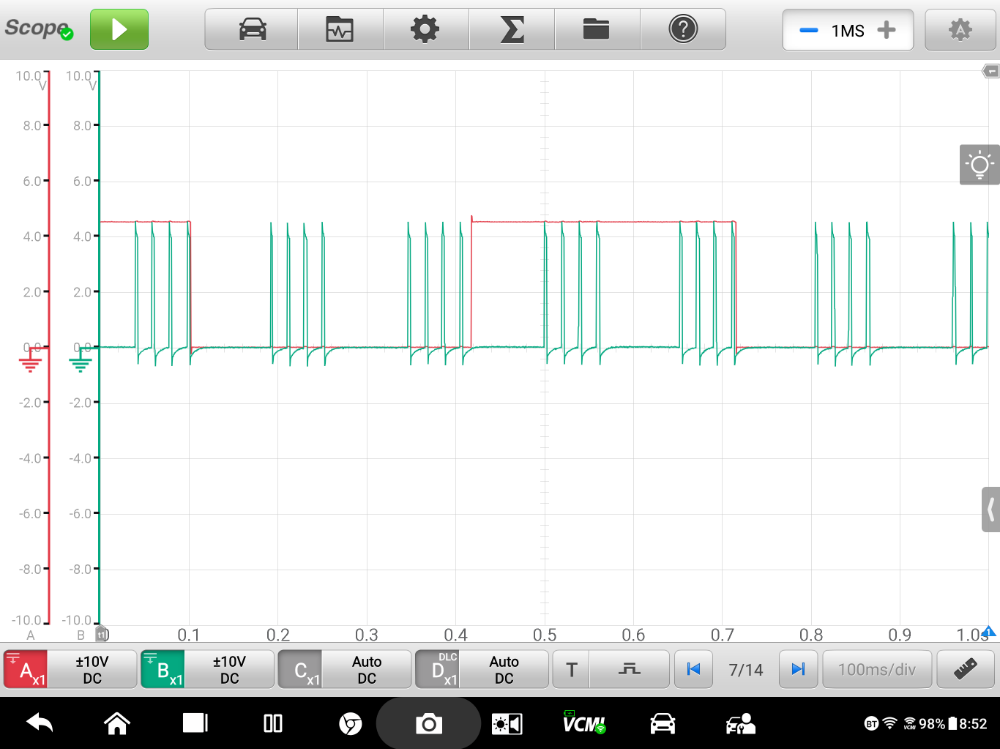

Okay so im not much on asking for help but I cant seem to find any answers. Im working on a 1995 Jeep Wrangler with a 2.5L & manual trans, customer had it towed in due to a no start no crank condition. First checked the battery voltage and it was 12.4 volts then checked the starter for xciter signal and just happened to use a lcd test light and notices a 3 volt drop at the starter. hooked up a jump pack directly to the starter main power feed and grounded to the housing of the starter is started and pulled it in and on a lift. After doing this we could never get the voltage drop to show its face agian and it would start fine under its own power, so we cleaned every ground on the engine and in engine bay and battery terminals. also to add background this jeep has been fully restored from the ground up including paint inside and out and under. while idling noticed a random misfire here and there at points almost causing a stall. pulled out the scope and found glitch at the coil secondary as in not firing at the right time. then checked it at the coil control wire had the same glitch causing the coil to fire when it shouldnt, then traced this all the was back to the crank sigal at the ckp connector it is a 5 ish volt wave form pulling up when it passes a notch in the tone wheel. ends up looking like 4 spikes grouped then space and repeats constantly. well here and there at no actual time interval but random there is a glitch in this signal. so we replaced the ckp with autozone ckp and it wouldnt start, got a standard one and it started up and was running great with a lot more uniform signal. test drove and next day started it and it started doing it again. In my research I saw that a lot of people suggested only using oem ckp as the aftermarket ones give a lot of problem. ordered a oem sensor and put it in and get a no start condition. the signal is also very weird and doesnt match the tone wheel. so put the old sensor in and did a power ground and signal check, wiring diagram says it is a 8v power supply and im getting 10.5 volts, I have about 10 mv on the ground and 4.95v on the signal with sensor unpluged. also this 8v supply is spliced into the vehicle speed sensor & cmp aswell. im getting the same readings at all 3 sensors. no change with vss unplugged either. In my experience I have seen 8v ref being around 9v but not 10.5, any feed back on this would be appreciated. I have added some screen shots of the old sensor before replacing it then the new sensor as soon as I replaced it and last of the new sensor glitching like the old one

wondering if the 10.5 volt supply is my problem and it damaged the new sensor because when i first put it in it was a perfect uniformed waveform and running a lot better

wondering if the 10.5 volt supply is my problem and it damaged the new sensor because when i first put it in it was a perfect uniformed waveform and running a lot better

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

Less

More

- Posts: 1230

- Thank you received: 462

4 years 4 days ago #52003

by juergen.scholl

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Replied by juergen.scholl on topic 1995 Jeep Wrangler 2.5L 5 speed / CKP glitching causing misfire

This is a conventional, distributor type ignition system, isn't it? Every time the crank pattern turns faulty there is a reflection of the coil activation to be seen, in occasions showing an insane dwell time around 50ms. Did you verify that the coil is ok since it went through a lot of abuse?

The erratic crank pattern I have seen over and over again related to issues with the sensor itself. I am (almost) sure you did install the new sensors with the spacer/cardboard on the tip, right? Did you make sure the surface where the sensor mounts is straight without any rust buildup? Also, the threads on the block where the mounting bolts goes are fine? The sensor stays tight, no play when the engine is warm? Wiggle test? Just for peace of mind you could borescope the reluctor on the crank and check that it's tight.

The 10ish voltage supply to the sensor is not critical at this point in my opinion, specially regarding the fact that the CMP doesn't act up with the same supply.

The erratic crank pattern I have seen over and over again related to issues with the sensor itself. I am (almost) sure you did install the new sensors with the spacer/cardboard on the tip, right? Did you make sure the surface where the sensor mounts is straight without any rust buildup? Also, the threads on the block where the mounting bolts goes are fine? The sensor stays tight, no play when the engine is warm? Wiggle test? Just for peace of mind you could borescope the reluctor on the crank and check that it's tight.

The 10ish voltage supply to the sensor is not critical at this point in my opinion, specially regarding the fact that the CMP doesn't act up with the same supply.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

The following user(s) said Thank You: Theshorefix

Please Log in or Create an account to join the conversation.

- VegasJAK

-

- Offline

- Platinum Member

-

- Silencing the Parts Cannon

Less

More

- Posts: 566

- Thank you received: 140

4 years 3 days ago #52009

by VegasJAK

"an open mind let's knowledge flow in and wisdom flow out for a man who has neither never listens to those who have both".

Replied by VegasJAK on topic 1995 Jeep Wrangler 2.5L 5 speed / CKP glitching causing misfire

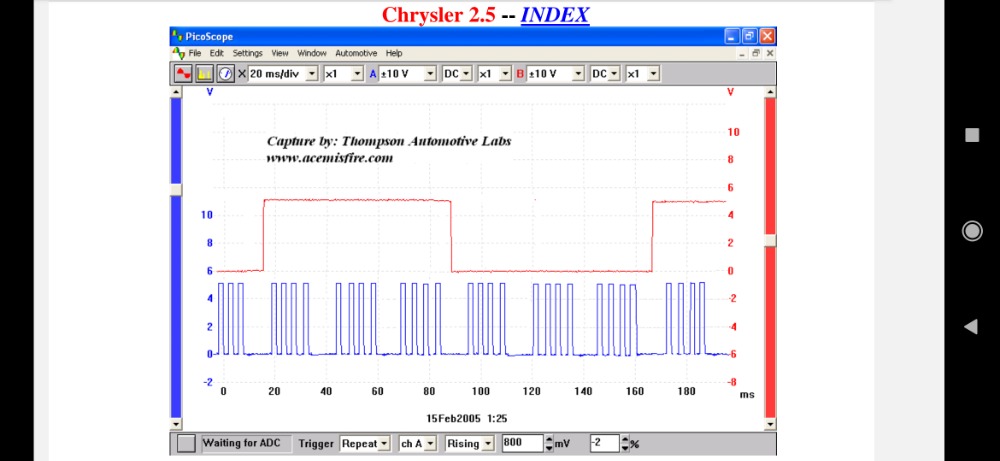

Cam Crank sync is off. Leading edge of cam sig should be half way between 3-4 and the trailing between 2-1.

"an open mind let's knowledge flow in and wisdom flow out for a man who has neither never listens to those who have both".

Being wrong doesn't bother me, it's being right and not understanding why that does

The following user(s) said Thank You: juergen.scholl, Theshorefix

Please Log in or Create an account to join the conversation.

- Theshorefix

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 2

3 years 11 months ago #52101

by Theshorefix

Replied by Theshorefix on topic 1995 Jeep Wrangler 2.5L 5 speed / CKP glitching causing misfire

Thank you for your knowledge of that... Would you by chance have or know of a known good wave form? Sorry on the late reply I've been out under the weather the last few days.

Please Log in or Create an account to join the conversation.

- Theshorefix

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 2

3 years 11 months ago #52102

by Theshorefix

Replied by Theshorefix on topic 1995 Jeep Wrangler 2.5L 5 speed / CKP glitching causing misfire

Just to let you know I used your advice and replaced the crank sensor again with a new coil, it stopped misfiring at idle and glitches but it has no power and tops out around 65 in 4th gear. A lot say that it's the motor that's in it, that the 2.5L just has no power.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

Less

More

- Posts: 1230

- Thank you received: 462

3 years 11 months ago #52110

by juergen.scholl

This is a good cam/crank relationship for the 2.5. As Scannerjohn noticed, yours different.

You could do an in-cylinder pressure sensor capture or a vacuum gauge reading at idle as well but it really looks like you have to put this engine in time.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Replied by juergen.scholl on topic 1995 Jeep Wrangler 2.5L 5 speed / CKP glitching causing misfire

This is a good cam/crank relationship for the 2.5. As Scannerjohn noticed, yours different.

You could do an in-cylinder pressure sensor capture or a vacuum gauge reading at idle as well but it really looks like you have to put this engine in time.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

Time to create page: 0.371 seconds