*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

What are the correct fuel system specs?

- stylingpat

-

Topic Author

- Offline

- Senior Member

-

- Posts: 44

- Thank you received: 0

What's the prime fuel pressure, Idle Fuel Pressure and correct voltage?

I'm reading 60 psi prime, then 55 psi idle and drive and getting 13.3v at the pump power wire

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2120

- Thank you received: 709

2. With ignition "ON," engine "OFF" and fuel pump running, pressure should be 415-455 kPa (60-66 psi).

Power voltage should be system voltage. 13.3v is good.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- stylingpat

-

Topic Author

- Offline

- Senior Member

-

- Posts: 44

- Thank you received: 0

They told me it was performing perfectly when they gave me the keys

Please Log in or Create an account to join the conversation.

- stylingpat

-

Topic Author

- Offline

- Senior Member

-

- Posts: 44

- Thank you received: 0

Its got a new fuel filter (PSI was exactly the same with old filter)

Voltage to the pump is good, we know that. So its not being starved for power

Something is burning out all my fuel pumps. They all last about 6 months. This is fuel pump #4, and this time I had the dealership figure it out. They repaired my fuse box and said the contacts were melted and too lose with the relay causing the pumps to burn out.

Now I got a warranty on my pump motor.

All the grounds are clean, I checked them all on fuel pump #3

Please Log in or Create an account to join the conversation.

- stylingpat

-

Topic Author

- Offline

- Senior Member

-

- Posts: 44

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2120

- Thank you received: 709

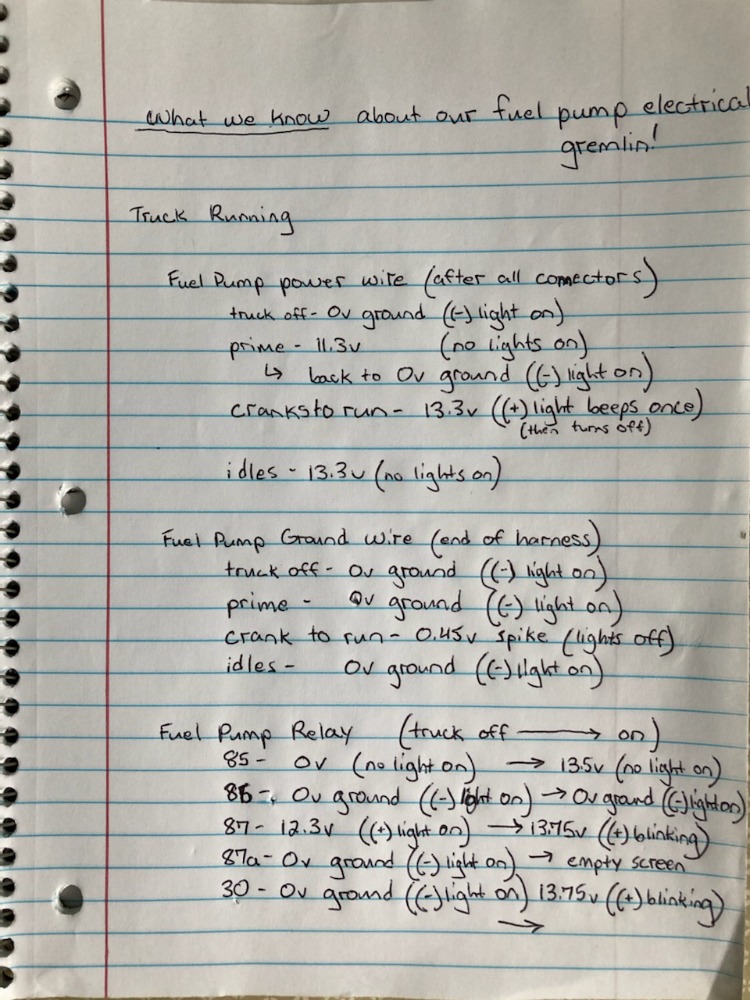

You have verified a good POWER feed at the pump (pump running) Now, back-probe the GROUND wire at the Fuel Pump (pump running) and check for voltage. If you have a bad ground, you will read a voltage higher than "near zero", on the GROUND wire.What should I test and check to find out why the pump is running low PSI, (a brand new pump/motor)

Voltage to the pump is good, we know that. So its not being starved for power

Something is burning out all my fuel pumps. They all last about 6 months. This is fuel pump #4,

All the grounds are clean,

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- stylingpat

-

Topic Author

- Offline

- Senior Member

-

- Posts: 44

- Thank you received: 0

You have verified a good POWER feed at the pump (pump running) Now, back-probe the GROUND wire at the Fuel Pump (pump running) and check for voltage. If you have a bad ground, you will read a voltage higher than "near zero", on the GROUND wire.

Is there a difference between checking the ground wire and checking the ground bolt?

Please Log in or Create an account to join the conversation.

- stylingpat

-

Topic Author

- Offline

- Senior Member

-

- Posts: 44

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2120

- Thank you received: 709

Yes. If the ground WIRE is bad, you will see a good ground at the bolt, but elevated voltage, on the ground wire, at the pump. Suppose there is corrosion in the wire, half way between the bolt and the pump. On the bolt side of the corrosion, the ground is still good. But, on the pump side of the corrosion, you may read elevated voltage. The more corrosion/resistance you have, the higher the voltage will be, on the pump side.Is there a difference between checking the ground wire and checking the ground bolt?

Check the ground as close to the pump as you can.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- stylingpat

-

Topic Author

- Offline

- Senior Member

-

- Posts: 44

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- stylingpat

-

Topic Author

- Offline

- Senior Member

-

- Posts: 44

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- jreardon

-

- Offline

- Platinum Member

-

- Posts: 520

- Thank you received: 198

6 minutes, 20 seconds: low voltage requires more amperage to get the same work done

Please Log in or Create an account to join the conversation.

- stylingpat

-

Topic Author

- Offline

- Senior Member

-

- Posts: 44

- Thank you received: 0

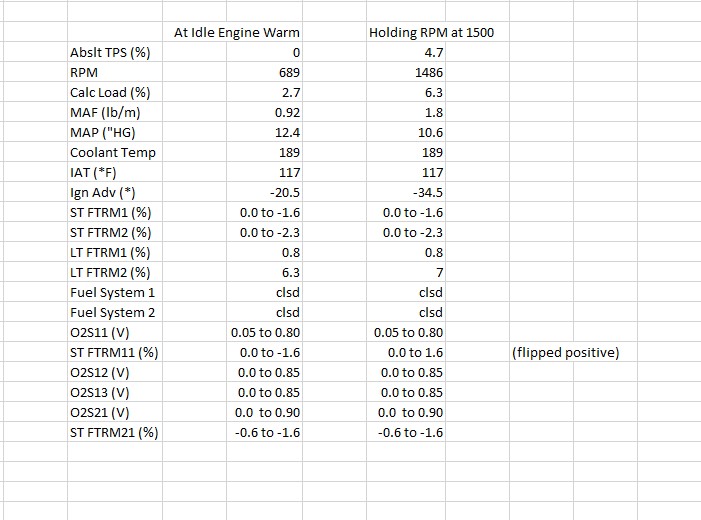

ScannerDanner just said these fuel systems are 55-65 psi. So maybe my electrical gremlin is gone! This will be the first fuel pump motor to last over 6 months!

Please Log in or Create an account to join the conversation.