Transmission questions

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

First is an '07 Sierra that came with a slippage code. Watched the TCC go into full lockup and never saw the slip PID go anywhere near zero. :lol: 200K+ miles on it, went with a rebuilt transmission. Worked perfectly afterwards.

First question is about the TAP cells, and their diagnostic value (if any). I've been told that you can look at these and spot worn parts based on the adaptives, but I've never seen any known good values listed in service info. :blink: Here's the data, for anyone interested:

Before

www.scanshare.io/share/uPDlioZ0oUS3ygxEdA60Eg

After

www.scanshare.io/share/ARVFIPYewk6olI0AGRqr8A

Are these worth getting to know? Or skip it and stick to test driving?

Please Log in or Create an account to join the conversation.

- cheryl hartkorn

-

- Offline

- Platinum Member

-

- Posts: 692

- Thank you received: 130

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

cheryl hartkorn wrote: sure wish I could help. I know not a lick about the internals of the transmission. the electrical part isn't bad though

Me neither. :lol: Every shop I've worked for does transmission fluid services, or assembly replacement, and little in between.

Aside from diagnostic purposes, I wonder if this stuff could be used for pre-purchase inspections? Perhaps spot an impending P1811 Max Adapt/Long Shift. Or, it doesn't work that way. :silly:

Please Log in or Create an account to join the conversation.

- ecwurban

-

- Offline

- Premium Member

-

- Posts: 125

- Thank you received: 25

I just think there are too many variables that go into adapts to try and look too deeply into them. If a person drives like a maniac then the adapts will have extreme values. Plus when you get in it and drive normally you'll swear the accumulator springs are broken. Especially on the 1-2 and 2-3 shifts. You can get super hard shifts and have it be perfectly normal if it's just used to a totally different driving style.

Chevy's are VERY susceptible to bad MAFs. We've done quite a few trannies that were taken out because of bad MAFs. The MAF is one of the primary sensors used in calculating engine load. A bad MAF can throw your shifts right out and eventually harm the transmission. Chevy's are also pretty susceptible to vacuum leaks affecting shifts.

If you get a transmission gear ratio error code (P0730 - P0736) then 95% of the time it's an internal issue and will need a rebuild or replacement. Sometimes you can get lucky and it'll be caused by a faulty speed sensor of the pressure control solenoid but you would have a code for one of those as well.

TCC slippage is one of the worst things to deal with. Especially if the rest of the transmission is in good working order. If you're light cursing and the TCC is 100% applied then you want to see less than 10 RPM on a good vehicle. If you have excessive slippage then you're either looking at a control issue (TCC solenoid), or a pressure leakage (valve body, internal transmission part, or torque converter) or a burned lockup clutch. If the fluid is really dark and burned and the transmission otherwise shifts good then I would say put a new converter and TCC solenoid in it. You'd want to pull the pan to change the filter and do a fluid service anyways so changing the solenoid would be easy. And if you were to change the transmission then you'd want to get a new torque converter anyways. It's still taking a chance but it's a pretty decent chance it'll fix the problem. So long as the rest of the transmission feels good that is. Then the customer would be looking at $1000 versus $3000. The only downside is if it doesn't fix it then they still have to fork over another $3000. But at least you could get one without the torque converter so you wouldn't be paying for that twice. You'd only be losing on the labor and the solenoid. If you were looking at doing the entire valve body and the converter then I would say just go with an entire transmission. It's not as likely and the valve body would be a loss if you had to do a transmission afterwards.

But ya, with trannies you mostly go by feel on the road test. Flareups between shifts or slipping almost always mean that tranny needs rebuilding. A good way to stress them is to load up a gear then immediately get off the throttle before it upshifts then get right back on that throttle hard. Do that a few times and you'll make a weak gear start slipping. Another good thing is to pull the filter and rip the casing off it with vice grip pliers. Then cut the filter envelope open and look inside it. If you see chunks of metal or clutch material then that thing is done. A lot of times the clutch material will look like black flakes of plastic. If a transmission is just starting to go then the inside of the pan can look clean yet it can have a lot of crap inside the filter. And if you see lots of metal then make sure to flush the cooler lines really good before you put the new transmission in. And get a new torque converter.

Please Log in or Create an account to join the conversation.

- SniperDan

-

- Offline

- Senior Member

-

- Posts: 78

- Thank you received: 28

I do warranty work for a used car company, and we sell a TON of Ford Fusions. The transmissions in these vehicles are highly adaptive and susceptible to driver inputs. I deal with almost one complaint a month on these cars of hard shifting, and they are just about always recently purchased vehicles.

The fix is almost always the same, relearn transmission adaptives and test drive for about 30 miles like a sane individual. My theory is the the guys that do our RECON drive these cars like animals before they hit the lot, and when a 60 year old grandmother of 4 purchases the car she ends up driving a car that shifts like a top fuel dragster.

"Without data, you are just another person with an opinion."

~W. Edwards Deming

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

ecwurban wrote: Hey, sorry about the delay. I personally don't look too much into TAP/CVI values. You could compare before/after after changing a transmission. It's always a good idea to clear trans adapts after a transmission replacement on newer vehicles. If you don't then it's not the end of the world as it'll relearn anyways. It's just not the nicest on the new transmission if the previous one had an adapt that was out to lunch.

I just think there are too many variables that go into adapts to try and look too deeply into them. If a person drives like a maniac then the adapts will have extreme values. Plus when you get in it and drive normally you'll swear the accumulator springs are broken. Especially on the 1-2 and 2-3 shifts. You can get super hard shifts and have it be perfectly normal if it's just used to a totally different driving style.

No problem, thanks for getting back to me! I meant to include Chrysler in there, too, but you mentioned that for me.

Totally answers my question as far as adaptives. I knew they were important to performance, but I didn't know how much driving habits could influence them. :blink: I've heard that GM keeps separate sets of adaptives for different drivers based on which key is in the ignition, but I've never taken the time to test that claim.

If you get a transmission gear ratio error code (P0730 - P0736) then 95% of the time it's an internal issue and will need a rebuild or replacement. Sometimes you can get lucky and it'll be caused by a faulty speed sensor of the pressure control solenoid but you would have a code for one of those as well.

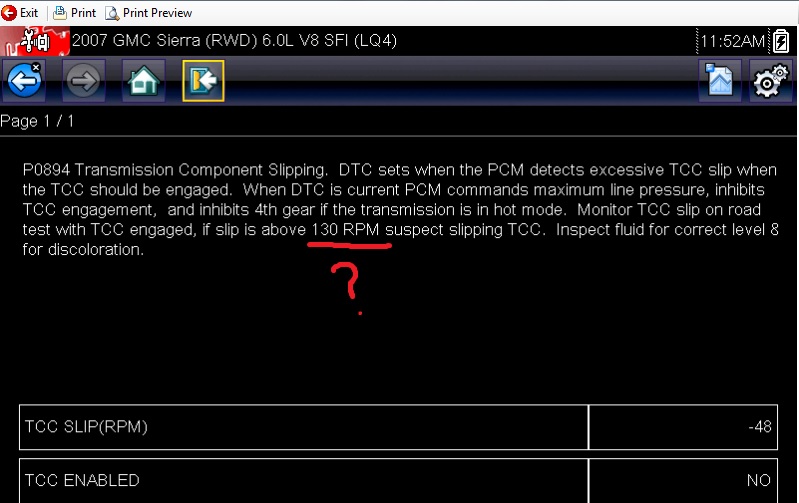

Ah yeah, seen those, pretty much death codes for the trans. :lol: This '07 Sierra was showing me a P0894 "Transmission Component Slipping". Gotta love the straightforward code descriptions!

TCC slippage is one of the worst things to deal with. Especially if the rest of the transmission is in good working order. If you're light cursing and the TCC is 100% applied then you want to see less than 10 RPM on a good vehicle.

I think your rule of 10 RPM is right on. I'm glad you mentioned that, 'cause the Troubleshooter for this code had this to say:

130 RPM? That's pretty generous! :ohmy: I've diagnosed many TCC shudders that fell well below that number, and still had internal issues.

But ya, with trannies you mostly go by feel on the road test. Flareups between shifts or slipping almost always mean that tranny needs rebuilding. A good way to stress them is to load up a gear then immediately get off the throttle before it upshifts then get right back on that throttle hard. Do that a few times and you'll make a weak gear start slipping.

Ooooh, good stuff, I like it.

Please Log in or Create an account to join the conversation.

- ecwurban

-

- Offline

- Premium Member

-

- Posts: 125

- Thank you received: 25

But ya, less than 10 is considered good on a light cruise, flat road, low engine load. A new trans should have less than 5. If the rest of the tranny is junk then that's easy. But if the rest of the tranny is great then it's hard to decide where to go. If you try saving money just changing a component then you could easily end up spending more by the time it actually gets fixed. Not to mention a customer is going to be hesitant to authorize much. As far as they're concerned the vehicle still drives fine. They don't notice the lack of lockup and they certainly don't care about it enough to start throwing thousands at the vehicle. Some older trannies will let you have all gears with a malfunctioning lockup.

Unless this JUST happened then you're not going to have a slipping TCC with nice red fluid. The converter is usually the prime source of heat through fluid shear. If they do any amount of highway driving with a malfunctioning TCC then that fluid is going to get hot. But all this doesn't mean that the converter itself is necessarily the problem. A lot of newer vehicles are going to two TCC solenoids. One On/Off and a separate PWM solenoid to either allow partial applications or to gradually apply the clutch for dampening purposes. Plus a lot of valve bodies will have two dedicated TCC valves. On that's a simple On/Off valve and another that regulates pressure to the TCC.

There's really no way of knowing without ripping everything apart and doing air checks. That's a lot of time... Some vehicles are nice enough to give you TCC line pressure taps that you can throw a gauge into but even that check takes 40+ minutes. By the time you bring the vehicle in, hook up the gauge to one port, rig up the gauge, go for road test then repeat on the other port. And you'd need a 0-300 PSI gauge on a 10+ foot hose. If you get good pressures and it still slips then you can feel pretty good about changing just the converter. If you have crappy pressures then you're looking at internals. The problem is you can't put in a used valve body in a customer's car. You will get comeback after comeback. New/reman valve bodies are expensive. Usually half the price of the entire transmission. If the valve body doesn't fix the problem and you opt for a dealer transmission then you will have wasted that valve body. If you get one from a rebuilder then you can specify not to get the valve body and they'll lower the price a bit but you'll still be out at least half of what you paid for the valve body. Then there's the time of switching them over.

Unfortunately that's the nature of trannies. We hardly ever touch the 4L60e/4L80e trannies in chevy trucks and vans. If it just needs a basic rebuild with new seals, clutches and solenoids then we can do it cheaper than a dealer reman trans. But if we start needing any hard parts or the valve body then we're looking at more money than what we could have bought a complete unit from Chev for. Not to mention their trannies come with a 3 year/100,000 mile warranty where the customer can go to any dealer for warranty work and you're not on the hook for it. Chevy is great but Ford is totally out to lunch on what they want for their dealer units!

Please Log in or Create an account to join the conversation.

- ecwurban

-

- Offline

- Premium Member

-

- Posts: 125

- Thank you received: 25

Then for kickdowns you'll want to do something similar. Except you'll want to let off the throttle for a bit longer. So it drops to about the mid point of the gear. Then hard and steady on the throttle just enough for it to cause a kickdown. Then pay attention to the shift. Is it delayed? Hard? Any flare up? And keep on steady throttle through the entire shift and into the lower gear.

Something you can do for upshifts is keep on steady medium-light throttle and right when it upshifts give the throttle a quick punch then back to steady. See if you can make it flare up.

Please Log in or Create an account to join the conversation.