*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

2005 Jeep Wrangler Rubicon Unlimited 4.0/MT - Need CPK/CMP Waveform

- ltklein

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

4 years 4 months ago #49472

by ltklein

2005 Jeep Wrangler Rubicon Unlimited 4.0/MT - Need CPK/CMP Waveform was created by ltklein

Hi,

Been doing quite a bit of troubleshooting on my Jeep, which I'll detail out. At this point, I need a known good CPK/CMP waveform for a 2005 or 2006 Wrangler 4.0

Vehicle has 161,000 miles.

Making a short story long - I was on vacation 700 miles away when at 70 MPH, the Jeep went into limp mode. Testing at Autozone showed a P0340 and P0344. Ordered and replaced the Cam sensor as I was equipped to do so in the parking lot. Cleared codes, let it cool down and went for a drive. 15 minutes later it went back into limp mode.

Single code - P0344

Had to drop it at a small dealer and in their troubleshooting they cut and bypassed the wiring to the Cam Sensor and sent me on my way. 32 miles later it went into limp mode again. Had to be home and limped it within 260miles of home.

I don't know if they did a CAM/Crank relearn.

At home, installed a new OPDA (because they fail in 2005s) and took a look at the cam gear. Didn't look too bad. Aligned the new OPDA at TDC with the pin in place according to the Factory Shop Manual.

Still throws a P0344.

Couldn't find any issues with the harness, or the bypass. Bought a Hantek 1008b oscilloscope and monitored the Cam, Crank and 5v signals. All are clean and solid even when it throws a code. Reinstalled original sensor and same result.

Since I have to pay $125 to get a relearn done, I want to ensure I have a properly timed signal going to the PCM before I get that. Also want to ensure that my timing chain doesn't have too much slop or jumped a tooth - so I'm looking for a known good waveform.

Reviewing other folks with the same issue, solutions varied from replacing the Cam sensor 3 to 4 times, cam/crank relearn, new camshaft, and fairly commonly a new PCM.

So, I want to verify I'm sending the PCM a known good, in time signal before I drop $800-1300 there, or know that I'm in time before I start looking for worn crankshaft issues.

Though the OPDA is aligned according to the FSM, there is a small amount of rotational slop that I can work with to see if I can bring the signal in time, if that's what the issue is.

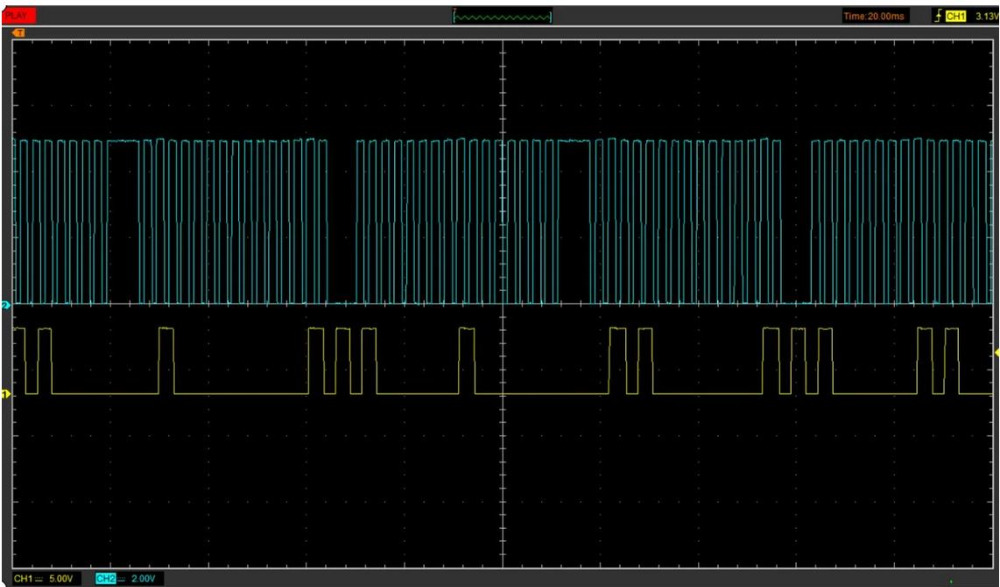

Attached is my CAM/Crank - NOT a known good!...

Thanks!

Roger

Been doing quite a bit of troubleshooting on my Jeep, which I'll detail out. At this point, I need a known good CPK/CMP waveform for a 2005 or 2006 Wrangler 4.0

Vehicle has 161,000 miles.

Making a short story long - I was on vacation 700 miles away when at 70 MPH, the Jeep went into limp mode. Testing at Autozone showed a P0340 and P0344. Ordered and replaced the Cam sensor as I was equipped to do so in the parking lot. Cleared codes, let it cool down and went for a drive. 15 minutes later it went back into limp mode.

Single code - P0344

Had to drop it at a small dealer and in their troubleshooting they cut and bypassed the wiring to the Cam Sensor and sent me on my way. 32 miles later it went into limp mode again. Had to be home and limped it within 260miles of home.

I don't know if they did a CAM/Crank relearn.

At home, installed a new OPDA (because they fail in 2005s) and took a look at the cam gear. Didn't look too bad. Aligned the new OPDA at TDC with the pin in place according to the Factory Shop Manual.

Still throws a P0344.

Couldn't find any issues with the harness, or the bypass. Bought a Hantek 1008b oscilloscope and monitored the Cam, Crank and 5v signals. All are clean and solid even when it throws a code. Reinstalled original sensor and same result.

Since I have to pay $125 to get a relearn done, I want to ensure I have a properly timed signal going to the PCM before I get that. Also want to ensure that my timing chain doesn't have too much slop or jumped a tooth - so I'm looking for a known good waveform.

Reviewing other folks with the same issue, solutions varied from replacing the Cam sensor 3 to 4 times, cam/crank relearn, new camshaft, and fairly commonly a new PCM.

So, I want to verify I'm sending the PCM a known good, in time signal before I drop $800-1300 there, or know that I'm in time before I start looking for worn crankshaft issues.

Though the OPDA is aligned according to the FSM, there is a small amount of rotational slop that I can work with to see if I can bring the signal in time, if that's what the issue is.

Attached is my CAM/Crank - NOT a known good!...

Thanks!

Roger

Please Log in or Create an account to join the conversation.

- jreardon

-

- Offline

- Platinum Member

-

Less

More

- Posts: 520

- Thank you received: 198

4 years 4 months ago - 4 years 4 months ago #49478

by jreardon

Replied by jreardon on topic 2005 Jeep Wrangler Rubicon Unlimited 4.0/MT - Need CPK/CMP Waveform

Here's an '06 4.0L courtesy of Ray Yergeau & Autonerdz @

diag.net/msg/m2of4ucg2qq9ay0rl5ixgwbykc

i.imgur.com/QfNmvw5.gif

i.imgur.com/QfNmvw5.gif

Last edit: 4 years 4 months ago by jreardon. Reason: add p0344 info

The following user(s) said Thank You: Noah, ltklein

Please Log in or Create an account to join the conversation.

- ltklein

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

4 years 4 months ago #49483

by ltklein

Replied by ltklein on topic 2005 Jeep Wrangler Rubicon Unlimited 4.0/MT - Need CPK/CMP Waveform

Thank you so much! 2 weeks trying to get this on the various Jeep forums.

Comparing the two - the leading edge middle pulse of the "triples" on mine is lagging a fair amount. Lining up on the leading edge of the double pulse shows me it's at least 1 crank pulse behind.

Exactly what I wanted to learn.

I'm going to give my OPDA a bit of a twist and see if I can match this and see what I get. Figure I may then need to get the cam/crank relearn done to fully know. Will get back with my findings.

Since the OPDA is an odd creature, I'll describe it a bit for people who haven't encountered it.

The OPDA (Oil Pump Drive Adapter) is like the base of a distributor. It engages the camshaft and drives the oil pump...so when they fail it's a bad thing. It also contains a reluctor wheel/tone wheel with notches that the Camshaft Position Sensor picks up. That's the 1-3-1-2-3-2 pattern in the trace.

It has an alignment hole in the wheel under the cap and when you buy it new there's a plastic pin to keep it in position while installing.

First the crank is turned to TDC according to the mark on the balancer. Then you drop in the OPDA and pull the pin. That assures proper alignment between cam and crank.

Of course there's some slop in there...so a cam/crank relearn lets the PDU factor in a correction.

I'm hoping if I can adjust it within the slop, I can get it to match the known good trace, it will bring it in the range that a cam/crank relearn can correct for.

That's the shade tree version.

I'll post up what I learn...

Comparing the two - the leading edge middle pulse of the "triples" on mine is lagging a fair amount. Lining up on the leading edge of the double pulse shows me it's at least 1 crank pulse behind.

Exactly what I wanted to learn.

I'm going to give my OPDA a bit of a twist and see if I can match this and see what I get. Figure I may then need to get the cam/crank relearn done to fully know. Will get back with my findings.

Since the OPDA is an odd creature, I'll describe it a bit for people who haven't encountered it.

The OPDA (Oil Pump Drive Adapter) is like the base of a distributor. It engages the camshaft and drives the oil pump...so when they fail it's a bad thing. It also contains a reluctor wheel/tone wheel with notches that the Camshaft Position Sensor picks up. That's the 1-3-1-2-3-2 pattern in the trace.

It has an alignment hole in the wheel under the cap and when you buy it new there's a plastic pin to keep it in position while installing.

First the crank is turned to TDC according to the mark on the balancer. Then you drop in the OPDA and pull the pin. That assures proper alignment between cam and crank.

Of course there's some slop in there...so a cam/crank relearn lets the PDU factor in a correction.

I'm hoping if I can adjust it within the slop, I can get it to match the known good trace, it will bring it in the range that a cam/crank relearn can correct for.

That's the shade tree version.

I'll post up what I learn...

Please Log in or Create an account to join the conversation.

Time to create page: 0.303 seconds