*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

'[--Cadillac XLR / Corvette roof pump

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

Fortunately for a few dollars I got a sub to Mitchell's "DIY" data for the car, not unsurprisingly non of the European ones have anything. It's very comprehensive and the Autel can read all of the roof PIDS.

Yesterday I think I found the root cause. Pulled the hydraulic pump out and it's motor is stuck solid. - Strangely it was working briefly/intermittently so with so many inputs needing to be right to get it to go it was not the first suspect. However commanding it from the scan tool I was getting an overcurrent warning. Bench tested and yep its locked rotor.

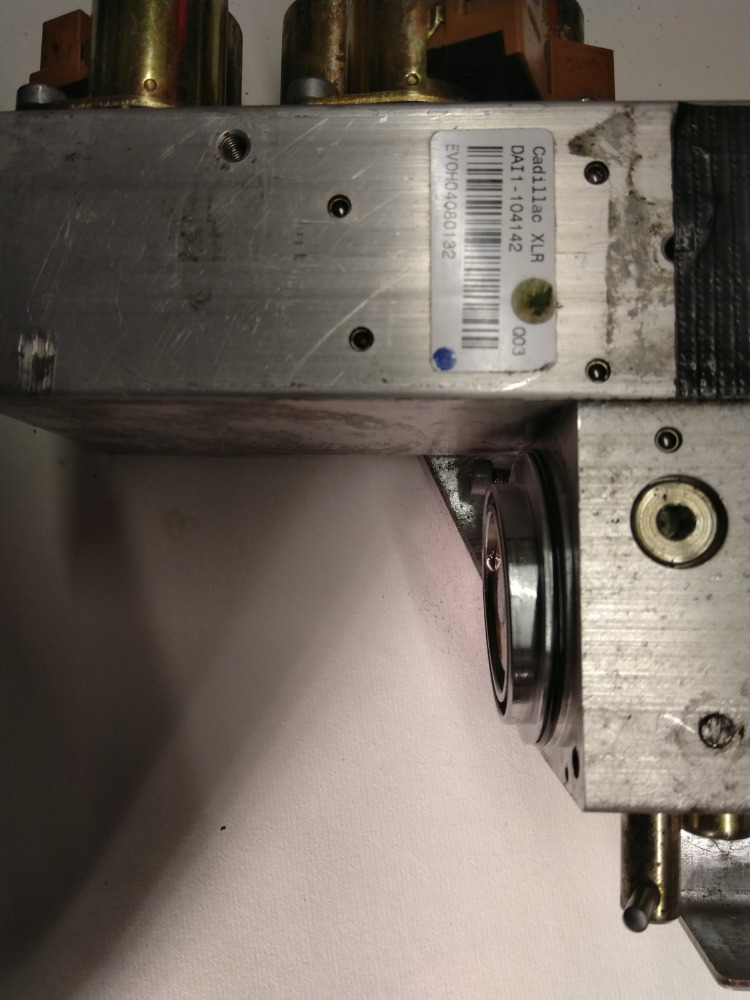

Pulled the motor off the pump and the motor has obviously been replaced very recently as it was shiny and new. However it looks like the re-assembly was a botch job as the bearing housing is not in square and I don't think the jiggly bits are all there. Motor runs perfectly off the pump. Solenoids ohm out the same, but 2/5 connections were bad.

Jaunty angle of bearing housing :ohmy:

Missing dowel

Has anyone got disassembly pics or an exploded diagram of the section in the pic. The bearing seems to be a guide for the dowel pins (only 2 came out, should be 3 I think!) that act as vanes.

I believe it is the same as the Corvette pump. Last resort I can send it off to "Top Hydraulics" for a re-build or swap out but that's $200 and weeks in shipping to start with (plus insuring a $1,500 part) even before their costs, so if it just needs to be put back in the right order with the missing part and I can press in that bearing square to the right depth then that would make the customer happy.

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Haven't been able to find a parts breakdown. 04 and up Saab 9-3 pumps look very similar on the pump and motor side. You could buy one of those used for cheap and dismantle it. Might even be able to rob parts from it. The 'vette C6 pump is an even closer match and I did find a UK based rebuilder of those.

roofmotors.co.uk/Chevrolet/chevrolet-cor...oof-pump-motor-unit-

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

Yes the long pin is a drive from the pump spider wheel, the 2-should -be-3 short dowels are in the off centre brass bush holes, they slide out from the centre into a groove in the body to act like vanes I think. They are kept in the groove by the bearing. As the bearing is not in straight I think it worked for a while before jamming.

My worry is that there are pieces that are not there or have been substituted - I think that might be the wrong bearing for example.

The Chevy one does not have enough solenoids - XKR has 5.

I will take a look at the Saab option.

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

The Saab unit looks more different but does appear to have the same type of pump. If I went that route it'd be as a relatively cheap way to find out what is supposed to be inside the pump and how it goes together. Any useable parts would be a bonus.

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

You're a star, thanks Matt!

EDIT of course Cadillac = GM = Saab, Vauxhall !

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

It's a radial piston pump. en.wikipedia.org/wiki/Radial_piston_pump which means that the bearing should be all the way in the recess for the pins to contact, however as it is stuck solid at an angle the wrong size bearing may have been used or there may be a circlip missing to hold it in place.

Saab pump on the way!

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

I am at a loss as to how the old bearing could be in like that and the motor still mounted as it was supposed to be pressed all the way in.

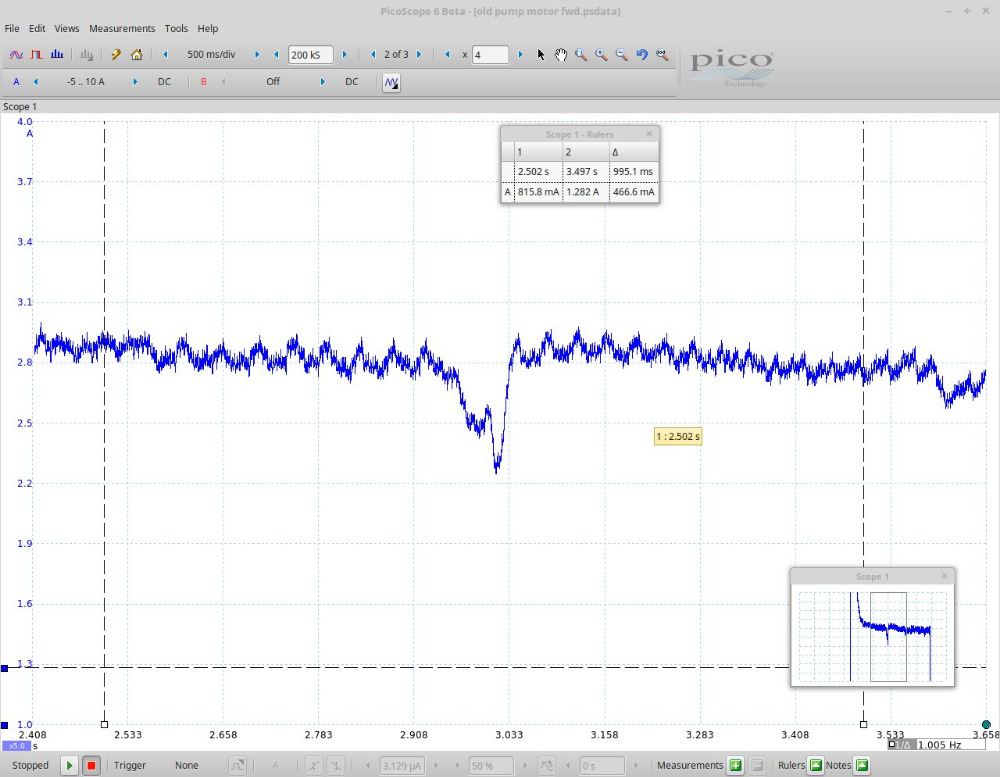

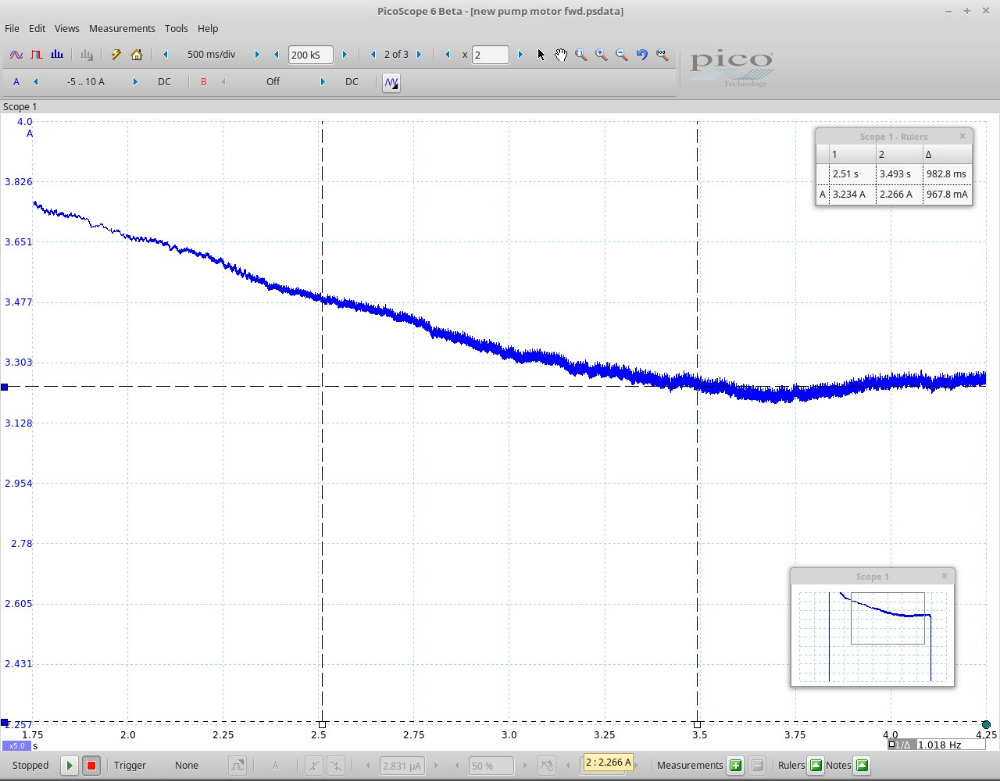

Though it was stuck really solid at the angle I am thinking maybe it came out when I disassembled it. Anyway, robbed the missing piston and I am going to swap the much higher quality motor over and put the scope on the old one (got to stay on forum topic after all!) as it is possible that it was the issue if it has a big dead spot.

Anyway with big ups to @Matt T looks like I will have a happy customer.

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

"New" on the car

Saab on the replacement

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

Technical question, Tech2win I beleive will work with any J2534-2 unit.

The XLR is CAN based diagnostics, but also has a class 2 line on the DLC. Anybody know if I use Tech2win to command a top re-learn on the FTC module that is on the class2 network if that command will go via CAN on the gateway or directly on the Class 2 pin - which would probably require using the GM-MDI

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

www.kvaser.com/about-can/can-standards/j2534/

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

These guys make the JLR approved VCI and this is their more general version.

www.diagnostic-associates.com/collection...-pass-thru-interface

the Tech2Win manual says

"...using the MDI or an ISO 22900 PDU API compliant device."

just trying to get something that is not pirated, has a justifiable cost and can be used for other manufacturers!

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

However with the car now having sat around a bit there is no response at all from the folding top switch so I can't do a calibration.

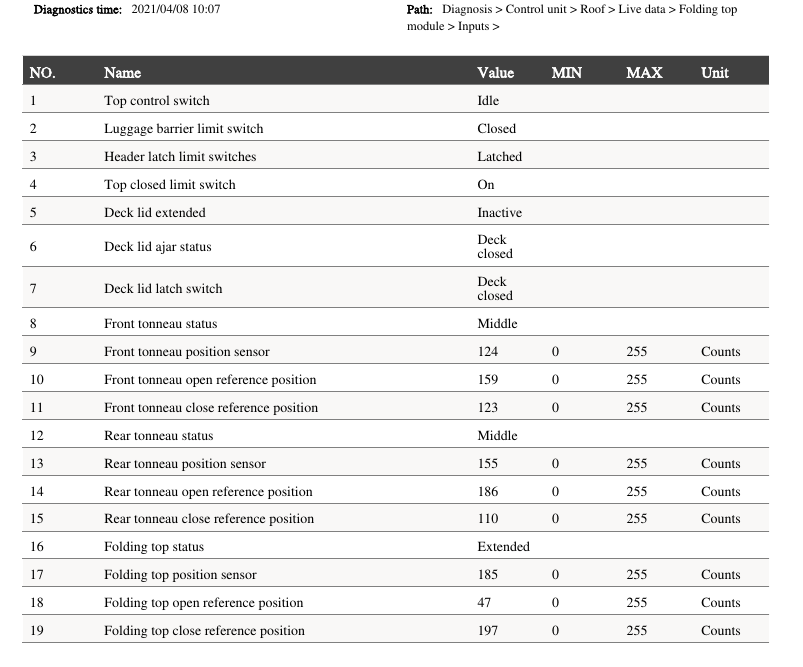

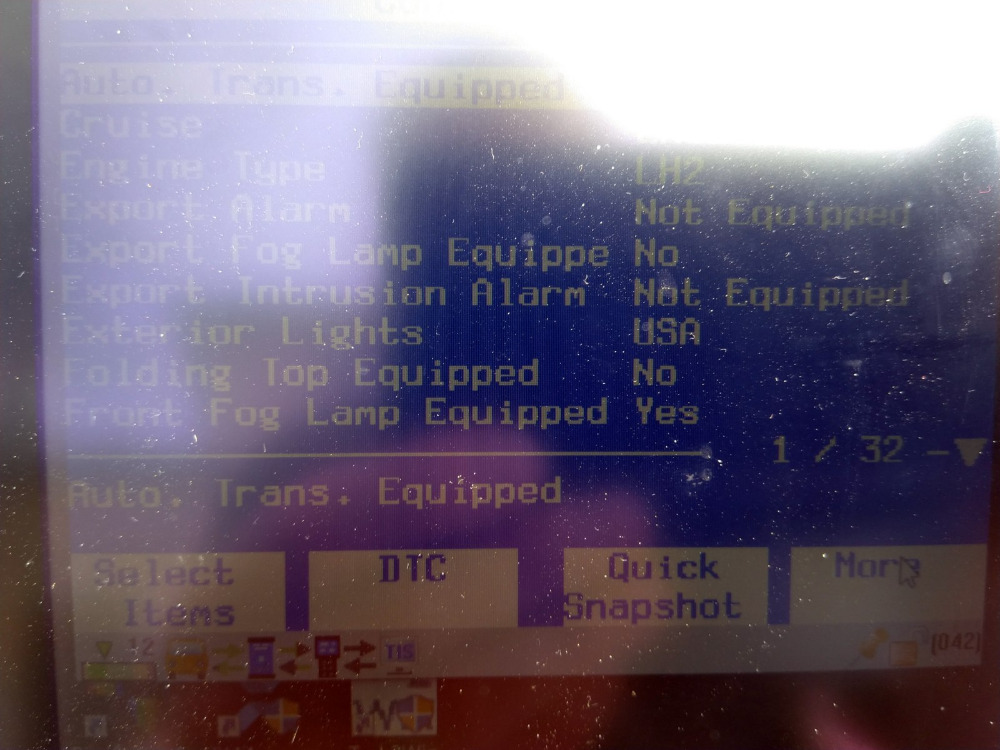

Have checked all the pre-requisites (windows showing normalised, in P, valet off, top extended and latched etc). The valet switch is connected via the HVAC module on the class 2 and so is the DLC so that's working. Pic of status before attempting to calibrate.

Obviously the 2 tonneaus are wrong - but that's why I need to run the calibration.

I can see the inputs, outputs and live data to the FTM so pretty sure that's working. However no reaction at all - first action should be an express window open (I guess commanded by the FTM on the Class 2 to the DDM and PDM . Also no reaction on the dash - the "top not secure" message is there but does not appear in reaction to the switch as previously it had.

The switch is connected to the FTM and I can see the switch when activated on the Tech2/Autel, I can command the solenoids and pump motor on the Autel via the FTM and they work (after I repaired the ground connection )

The Tech2 had flagged some non-comms on the class 2 and from splice pack investigation it looks like the RCDLR might be causing intermittent issues. I will disconnect that and see if any change. I can only think that it's a network issue

One real oddity on the T2W was the BCM configuration thinks it does not have a folding top. Which is odd as the car only came with one. Anyway it was working previously so putting that one aside.

Ideas on what I might be missing welcome.

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

Plug it in and we now have hydraulic trunk operation on the button that we did not have previously - however I still can not get either any response from the Top operation button (can see it pressed on scanner) and it will not calibrate either in Tech 2 or if I tell the Autel its an 05 I can run the re-learn from that (FTM is the latest version anyway). Autel says "data out of range" Tech2win says learn mode but still no button response (other than "top not secure on the IP" )

I went through the manual for calibration and still all the inputs read as ready to go - except the front tonneau position - but that is what the calibration is for. No codes in the FTM

Out of ideas!

Please Log in or Create an account to join the conversation.