What'd I miss? In-cylinder capture

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

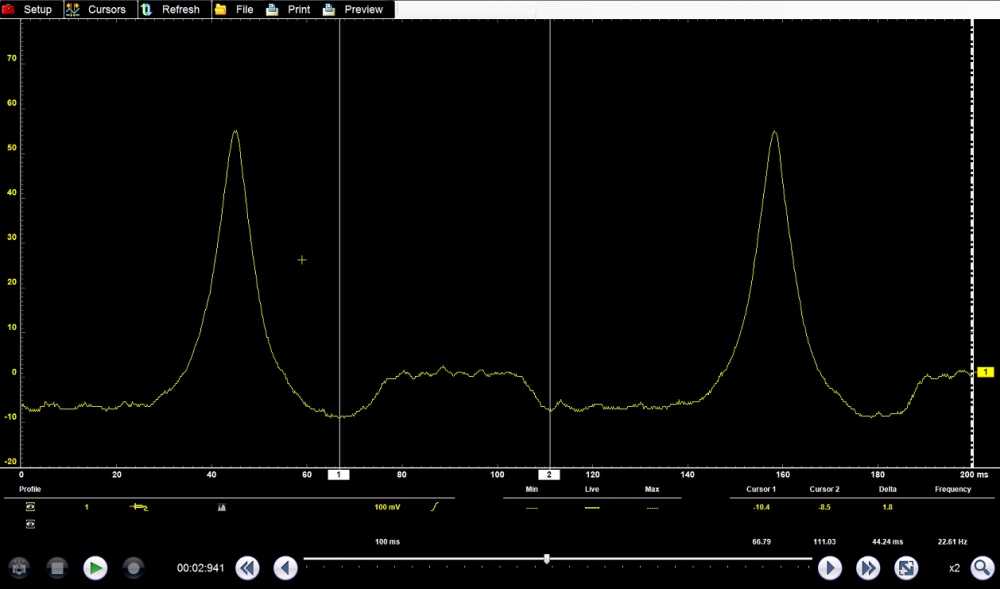

2011 Ford Escape, much like the last case. Audible compression problem, obvious misfire, relative compression points to #2. Here's the running in-cylinder capture:

This cylinder has a leaking exhaust valve, confirmed with a leak down test. 95% leakage. My question to you is, was the leaking valve obvious in the in-cylinder capture? My understanding says that, if there's a leaking exhaust valve, that the decompression pocket vacuum level (cursor #1) will be weaker than the intake stroke vacuum level (cursor #2). But this one is exactly the opposite. :blink:

Welcoming all questions/comments! Please feel free to comment even if you don't feel comfy with in-cylinder captures. We're all here to learn from each other.

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

I also looked through any captures I had and found nothing similar.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- SniperDan

-

- Offline

- Senior Member

-

- Posts: 78

- Thank you received: 28

"Without data, you are just another person with an opinion."

~W. Edwards Deming

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

First consider an in-cylinder test on a healthy cylinder. The cylinder is filled durring the induction stroke by air at inlet manifold pressure (ie partial vacuum), and durring the compression stroke it is compressed to 80 psi or so above atmospheric pressure. As the valves are sealing effectively the mass/weight of air trapped in the cylinder reamains unchanged.

On the expansion stroke the piston the air trapped in cylinder expands back to very close to the original volume and pressure.

On engine with a leaking exhaust valve more air will leak out durring the compression stroke than in will be drawn back into the cylnder via the exhast valve leak durring the expansion stroke. The mass/weight of air trapped in the cylinder will be less than if valves sealed perefectly so unless the exhaust valve leak is huge the pressure at the end of the expansion stroke must be lower than end of the exhaust stroke.

Camshaft timing, dwell and overlap will also effect the depth of the pressure pocket.

It would be interesting to have an in-cylinder cranking compression test on this engine as I would expect the compression-expansion towers to not be symetrical and show a noticeable lean to the right.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

Andy.MacFadyen wrote: On engine with a leaking exhaust valve more air will leak out durring the compression stroke than in will be drawn back into the cylnder via the exhast valve leak durring the expansion stroke. The mass/weight of air trapped in the cylinder will be less than if valves sealed perefectly so unless the exhaust valve leak is huge the pressure at the end of the expansion stroke must be lower than end of the exhaust stroke.

This is what I was thinking, sir, but your explanation makes way more sense.

My rough math equates 1 PSI of pressure to 2 inHg of vacuum, so the reading of -10.4 PSI at the end of the decompression stroke equates to over 20" inHg. That tends to say good sealing, right? But I know this isn't the case.

It would be interesting to have an in-cylinder cranking compression test on this engine as I would expect the compression-expansion towers to not be symetrical and show a noticeable lean to the right.

*sigh* I actually did a cranking capture, but forgot to save the waveform. :blush: I was looking for a leaning compression tower, too, but didn't see one... It *was* Friday at 4:30 PM, so maybe I wasn't looking as carefully as I should have. :lol:

On Monday, I'll grab a running capture of a known good cylinder, as well as cranking captures on #2 AND a known good.

Please Log in or Create an account to join the conversation.

- Dylan

-

- Offline

- Moderator

-

- Belgium, Europe

- Posts: 1461

- Thank you received: 327

Analyzing these waveforms is not that simple

I'd like to add 2 videos for other members and guests who are following along. It's real basic stuff but hey gotta start somewhere

Motor Age:

PicoScope:

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

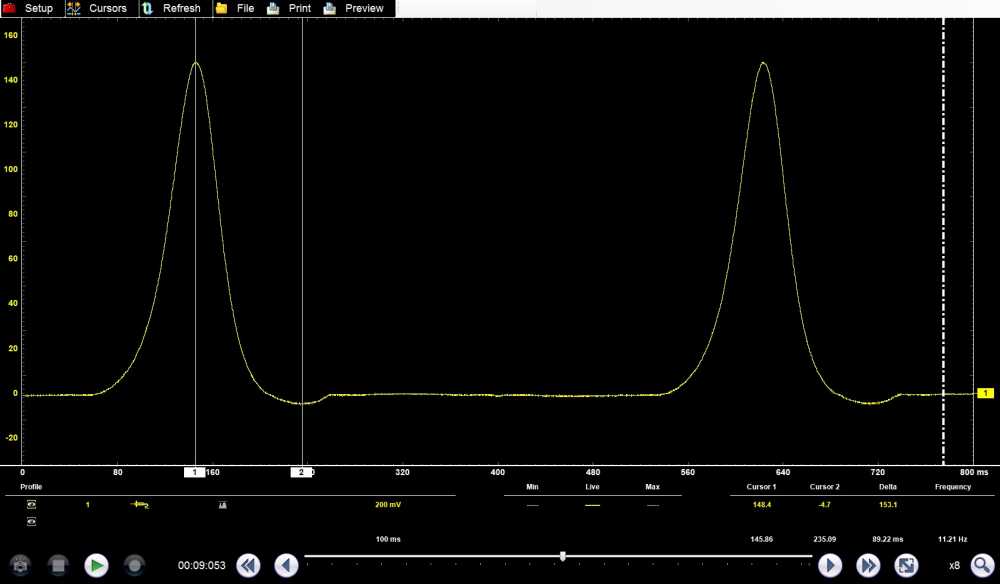

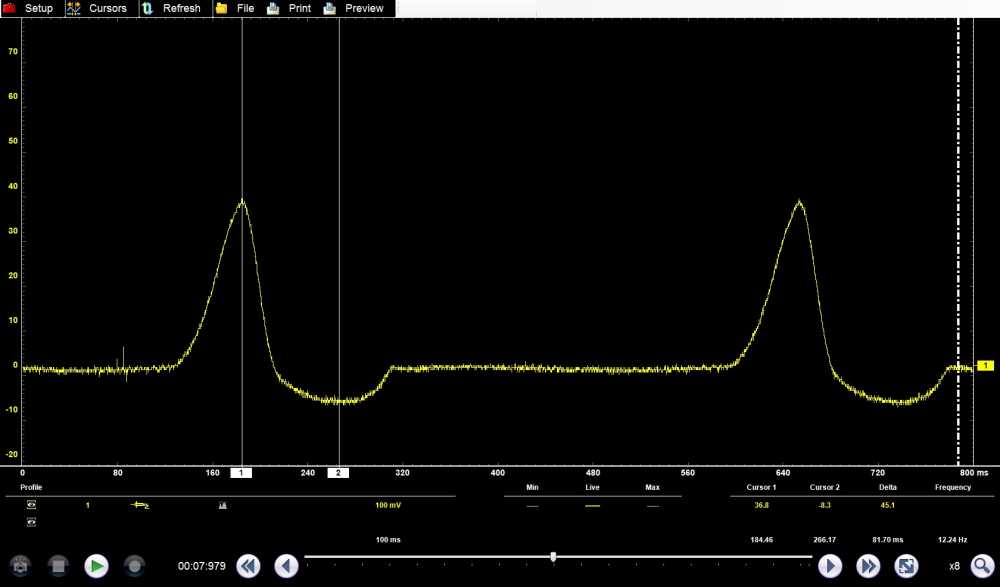

So Andy pointed out that a cranking capture would be more likely to reveal a leaking cylinder, evidenced by a 'leaning', asymmetric compression tower. He's absolutely right, so I went and grabbed cranking captures on the bad #2 cylinder, and a known good #1 for reference.

FYI, keep an eye out on the scaling. All the readings on #1 exceeded the 100mV scale on my Modis, so I had to change between cylinders. The conversion is 1mV/1 PSI.

#1 (good) cranking:

#2 (bad) cranking:

And there it is! Nothing symmetric about that #2 compression tower... The low peak compression matches what I saw on the relative compression.

Here's where it gets weird. I retook the running capture on #2, and #1 for reference.

#1 (good) running:

#2 (bad) running:

Something I hadn't noticed before - the running compression is higher than the static compression on #2. How does that work? :blink: :lol:

My (very rough) explanation: Because the engine speed is lower during cranking, the leaking exhaust valve essentially has more time under compression to leak. Once the engine is running, the cylinder events happen much faster, and the leaking valve has less time under compression. Does this make sense, or is this BS? :lol: I really don't have a solid answer here. Please feel free to comment!

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

Thinking about it if you try to push air or any gas too fast through a very narrow gap because the air flow speed increases and goes supersonic. Supersonic shock waves form which "choke" the gap increasing the ressistance to flow which slows the air down.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

Andy.MacFadyen wrote: I think you have nailed it -- longer time under compression more air leaks out.

Thinking about it if you try to push air or any gas too fast through a very narrow gap because the air flow speed increases and goes supersonic. Supersonic shock waves form which "choke" the gap increasing the ressistance to flow which slows the air down.

Sweet! It's always cool when there's a scientific explanation for something you know intuitively.

So the head is coming off this one. I'll be sure to update when I get a look at the valves.

Please Log in or Create an account to join the conversation.

- Dylan

-

- Offline

- Moderator

-

- Belgium, Europe

- Posts: 1461

- Thank you received: 327

So the head is coming off this one. I'll be sure to update when I get a look at the valves.

Can't wait

Here's a case study video from SD Premium where Paul shows different captures and explains them, using his Pico with pressure transducer:

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

I knew I'd find an exhaust valve problem because of the leak down test. What really blew me away was how much compression this thing was still generating despite the leak. :ohmy: I went back over the captures, and I still don't think the answer was very forthcoming. The leaking cylinder was still able to draw 16" inHg during cranking, and showed 18" on decompression when running. Very confusing.

Honestly, I think this is when a FirstLook sensor or similar would have been valuable. Couple the FLS in the exhaust with an ignition sync, use an overlay, and I'd have my answer. Either I need more experience with the in-cylinder transducer, or in-cylinder wasn't the tool for the job.

Please Log in or Create an account to join the conversation.