*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

2003 Silverado 6.0 NO spark or injector pulse, has cam and crank signals, no rpm

- b4ctrooper

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Bought a 2003 2500HD6.0 4WD rustbucket for the engine and trans. Sat for years not running. Cranks no start. No spark, no injector pulse (noid light flashes occasionally). Had a P0335 code. Found some broken harness wires going to the crank sensor so I ran new wires from the PCM to the sensor and new plug. Did the FSM troubleshooting for that code, crank sensor needs replacing. Crank sensor replaced TWICE! Still no start. NO cranking RPM on my hp tuners scanner.

Disabled the VATS with HP Tuners

2 new crank sensors

Bat+ at the injectors

Bat+ at the coils, and ground is good

Ran an extra ground from the engine harness to the battery negative (these trucks have ground issues)

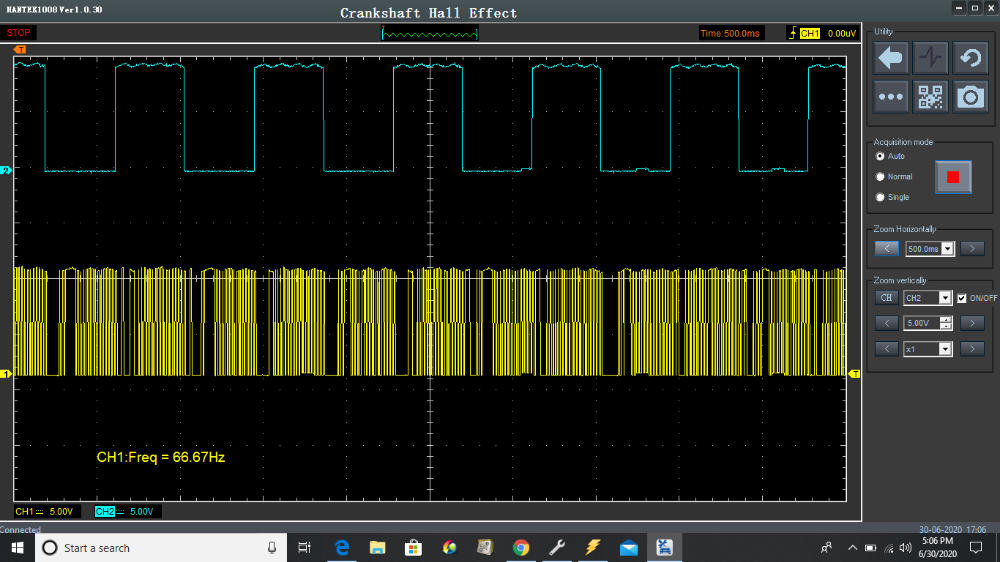

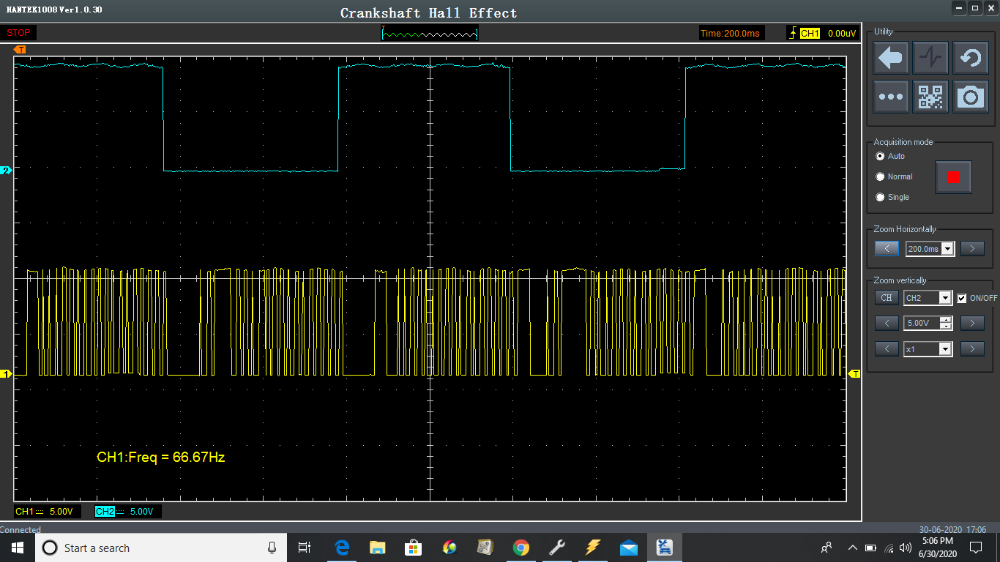

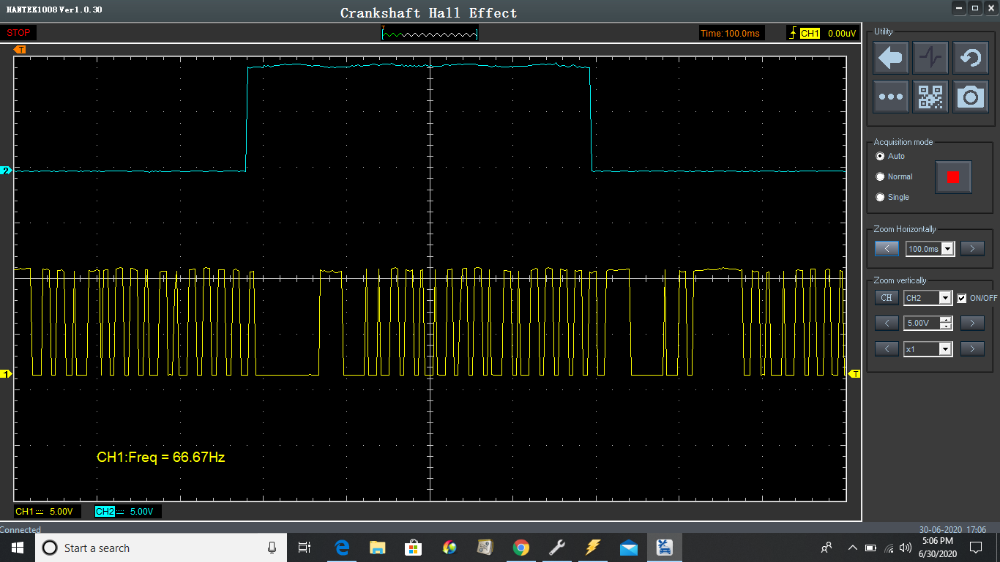

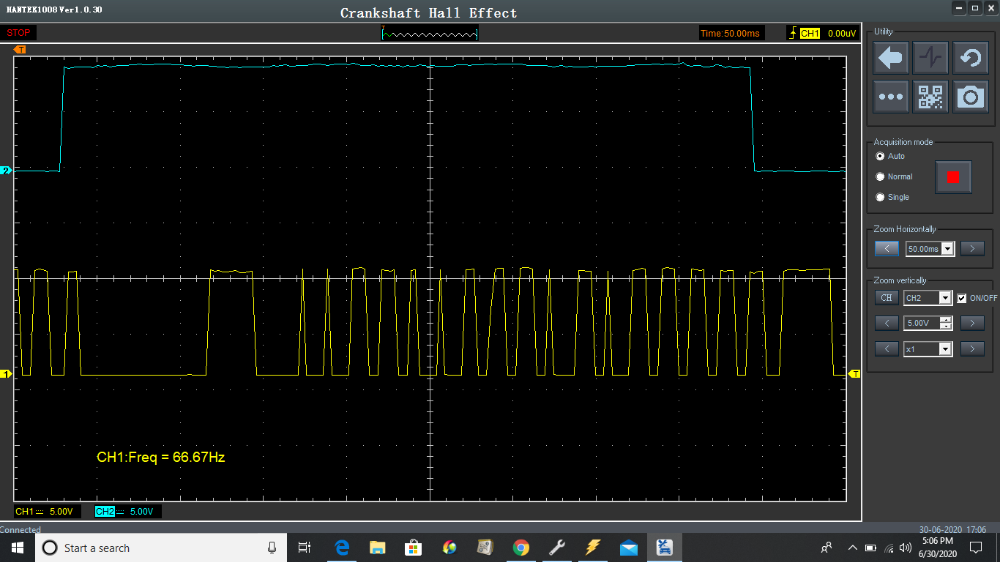

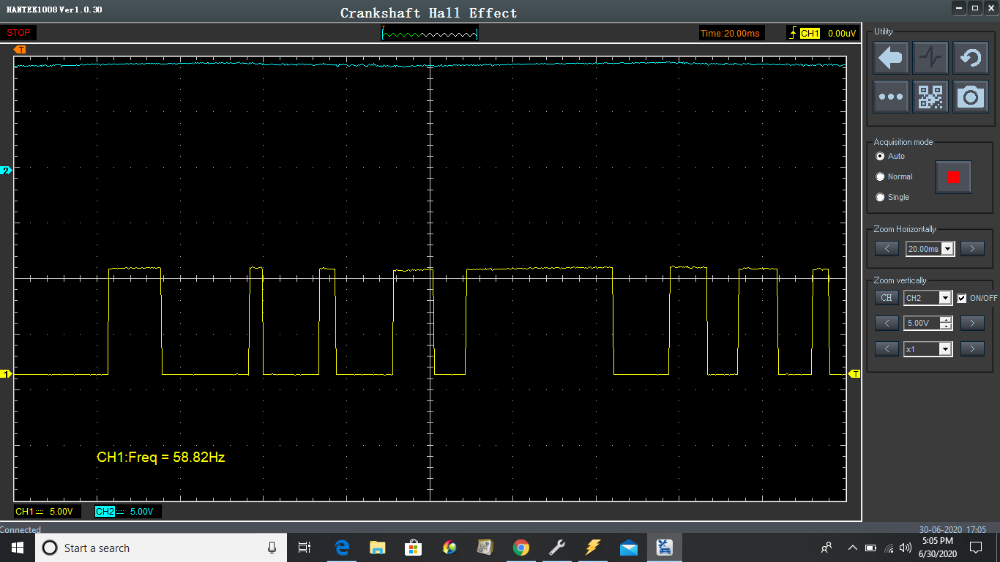

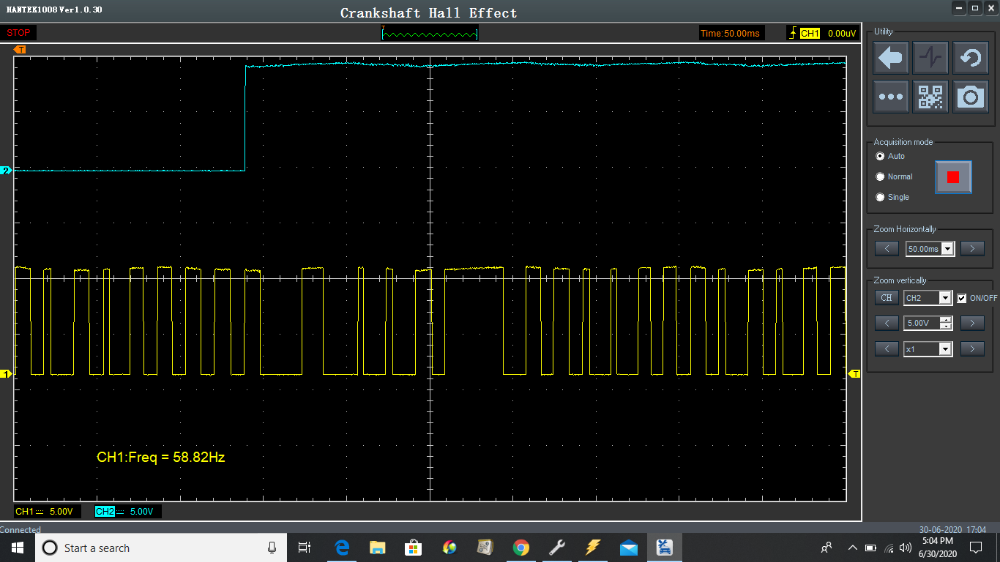

Purchased an oscilloscope to test this thing. I have a wave form on both my crank and cam sensors (T pinned at the PCM), no rpm shown. I am a noob, so all I can say is there is a waveform. It looks consistent.

I have an extra unlocked pcm from a 5.3 Avalanche, swapped that in, no start

Any suggestions on what I should look at next? Having a crank and cam signal shouldn't I at least get an rpm reading?

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6039

- Thank you received: 1518

If you disconnect the crank sensor completely, will it start?

Please Log in or Create an account to join the conversation.

- b4ctrooper

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- b4ctrooper

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Cheryl

-

- Offline

- Platinum Member

-

- Posts: 1214

- Thank you received: 215

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Cheryl wrote: Can you get mom and max Voltages on the cam and crank sensors?? I can’t tell if it’s pulling it all the way to ground.

The channel markers on the left are 0 V with the hantek software. He's set at 5 V/div so the waveforms are topping out at around 10 V.

Please Log in or Create an account to join the conversation.

- Cheryl

-

- Offline

- Platinum Member

-

- Posts: 1214

- Thank you received: 215

Please Log in or Create an account to join the conversation.

- b4ctrooper

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6039

- Thank you received: 1518

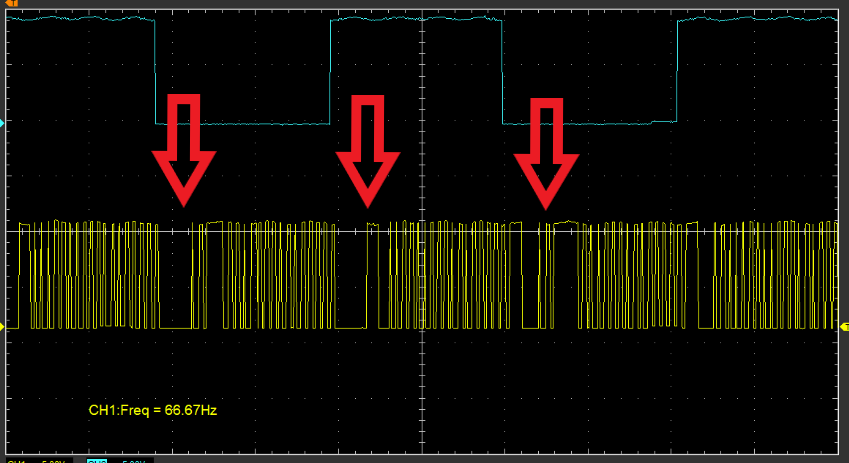

As you can probably guess, these shouldn't be here. :silly: The fact that it happens once every crankshaft revolution suggests a possible reluctor runout or metalurgy problem. Too regular to be a shorted wire, IMO. Happens too fast to be a shorted CMP.

The CMP waveform looks great, so there's still a good chance this thing will start if you disconnect the CKP. If it were me working on this truck, I'd either pull the CKP again and use a borescope to inspect the CKP reluctor, or pull the oil pan and inspect for damage.

Please Log in or Create an account to join the conversation.

- Cheryl

-

- Offline

- Platinum Member

-

- Posts: 1214

- Thank you received: 215

Please Log in or Create an account to join the conversation.

- b4ctrooper

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- b4ctrooper

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

I have been wondering that myself. After seeing Tylers last post, I think the sensor may have a dead spot in its' reading. Maybe that would not let it read each revolution? Pure speculation but it is the best reason I can come up with having all the info before me. I thought the waveform looked strange. Since it's consistent, the reluctor ring is very suspicious.Cheryl wrote: Wouldn’t he still get somewhat of a rpm on the scanner?? He said it stays at 0. Just a guess though.

Please Log in or Create an account to join the conversation.

- b4ctrooper

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- b4ctrooper

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Went back to the truck today and watched the scope while turning the crank by hand looking at the cam sensor. I had a rough idea where the bad reading spot was by looking at the cam signal. Looked at the crank reluctor ring in that area, nothing appeared bad.

I then scraped and cleaned the block where the sensor sits figuring it may not be totally flush as this is rusty (appears to have been the issue). Put the first new sensor back in (maybe the second was defective), and it was a total flatline. Brand new no good.

Put the second new sensor in, crank and the spark tester lit up! Injector has pulse. I got it to kick on starting fluid, but it is backfiring out of the throttle body. At least I have something now. Thank you for your input, that definitely helped keep the gears in motion.

Please Log in or Create an account to join the conversation.