2000 BMW 320i P0170, P0173 and intermittent misfire codes on all cylinders

- szgonik

-

Topic Author

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

The car isn't registered and wasn't driven for about 18 months except for some test runs I did recently on temporary license plates. I'm working on it as a hobby in my spare time. And my spare time is limited as well as funds I don't have a lift and also most of the stuff I do I do it for the first time so I have to learn a lot along the way. So that's way it takes unusually long for me to fix something on the car.

About 6 months ago I removed the intake manifold and replaced pretty much every seal, o-ring, vacuum hose and vacuum cap there was. I had all the injectors professionally refurbished (cleaned, tested for proper flow and spray pattern, new o-rings, new filters). Throttle body and idle air control valve were also professionally cleaned. I cleaned the intake manifold, opened, cleaned and inspected the CCV valve diaphragm which didn't show any signs of damage. I also installed a new air filter. I put everything together and the car started instantly without any trouble and was idling smoother than ever before. But I noticed smoke coming from the exhaust headers and loud exhaust leak sound from that area. The car stood outside for so long the exhaust headers rusted through. The other issue I had was the brake lines started to leak too because of rust. So at that point I couldn't drive the car and all I can say is at that point it idled smoothly for a few minutes and had no trouble starting.

And it took me another 6 months to sort that out. :blush:

The brake lines are routed above the fuel tank and they were leaking right around the fuel tank area so I dropped the fuel tank. Before I reinstalled the tank I also replaced the fuel filter. To be able to disconnect and reconnect the brake lines at the ABS unit I also removed the airbox, MAF and intake boots before the throttle body.

As for the headers I decided to use a different design. Catalytic converters on these engines are located on the exhaust headers. I've always hated this design. It's supposed to be more environment friendly because cats heat up faster but I believe they also make temperatures in the engine bay higher and are so annoying to remove and install because bulky cats are blocking access to header nuts. Same BMW models but on RHD markets have "more common" catalyst location on the middle exhaust section because there's no space for them in the engine bay because steering column would be in the way. So I sourced 2nd hand exhaust headers from a RHD car and bought a new middle exhaust section with cats. The headers came with used O2 sensors installed. As my previous O2 sensors were too slow reacting and had too short wires to reach below the car I I kept the "new" ones.

Now for the first start of the day the car would start but stall immediately. After one ore more tries it will start but idle erratically and stall. After a few more tries it would manage to idle with RPM jumping all over the place. Then after a few minutes of running it would idle fine.

My first thought was it had to be a fuel delivery issue. As I dropped and installed the tank there was about 1/4 of fuel so I thought some debree might have been lifted from the bottom of the tank and plugged the fuel delivery or STH like that. I measured the fuel pressure and it seems fine. AFAIK these engines run on constant fuel pressure of 3.5 bar regardless of engine load. It takes 2 prime pulses to raise the pressure to about 3.6 to 3.7 bar which is still in manufacturers specs. While cranking the pressure gauge needle wiggles just a bit and than stays rock steady during entire RPM range all the way up to WOT and redline.

Anyway I thought maybe the car just had to adapt to the recent changes of exhaust system and O2 sensors. So I bought temporary license plates and went on a few hour test drive that included mostly country roads and highways. After a few miles of driving the engine light came on and the codes I read were P0170 and P1730. Both codes mean fuel trim malfunction for Bank 1 and 2. No info on being rich or lean. So I monitored some live data which was kind of hard because the software I use doesn't have logging capability and it's impossible to drive and look at the screen all the time. But I threw my eye on it now and then. At idle the fuel trims seem almost perfect. Both front O2 sensors cycle between lean and rich voltage. But WOT makes them go super lean. As for the downstream O2's they seam to be fixed lean most of the time some time one or the other will start cycling a bit up and down and then go fixed lean again, but they won't show constant rich as they're supposed to. I also did some stops and let the engine idle for a few minutes and on a few occasions I got a bit unsteady idle and misfire. And it also threw codes for misfires at different times for all the cylinders.

After the test run I also think the car isn't as fast as it's supposed to be. I'd say it accelerates a bit slower than it should. But it's not drastically slow. It's normally driveable and it reached speeds of above 100mph easily. The fuel consumption also seemed normal, didn't notice it being obviously too high or too low.

I removed downstream O2 sensors and they had a kind of "whiteish" color which I believe it confirms they're indeed lean most of the time and aren't "lieing". Before I installed them they were dark colored.

So from what I learned watching Paul's lessons this definitely doesn't look a vacuum leak as fuel trims at idle look perfect and they're crap as soon as partial load starts. Taking into account my injectors were professionally refurbished and tested and I believe my fuel pressure readings are fine too it shouldn't be fuel delivery issue.

Paul also mentioned a case where torn intake boot between MAF and throttle body caused similar behavior. I just recently installed that boot and it's certainly not cracked. I even tested by spraying water around that area just in case it wouldn't sit itself properly. No change in idle at all. And I had that boot torn a few years ago on this car. It would start and idle fine and throw no codes, just the car would feel much slower. It was not even close to the symptoms it has now.

So it points to the MAF right? or not

As I mentioned this car also runs on LPG so I have secondary fuel source to rule out gasoline delivery problems. I filled the LPG tank and as I switched to LPG O2 sensors suddenly began to behave as they're supposed to. STFT's went negative. O2's cycle up and down and go full rich at WOT I even measured them with oscilloscope and they cycle a bit faster than 2 Hz so they seem to be in good condition. The downstream O2's stay at about 0.8V most of the time which might be a bit on the high side but I believe it's fine.

So with another fuel source it runs fine, so is it fuel delivery issue afterall?

And now I'm running in circles every idea I come up to has a counter idea that makes it implausible.

1. Bad MAF? Before removing it to access the ABS unit the car was starting and idling fine with it. I find it hard to believe it broke by itself just by sitting unmounted for a few months. And on LPG the car runs fine if it was the MAF that wouldn't be the case. The only explanation would be that MAF was already on the way out when LPG system was installed. It was installed only about 20k miles ago. So the LPG ECU might have been calibrated during leaner conditions already and that's why fuel trims are rich enough running on LPG. I also checked papers from the last two emission tests I passed and both tests showed the measured lambda value a bit on the lean side. If I get it right lambda value at the tip of exhaust should be slightly rich not lean.

Another thing that points to MAF is if I disconnect it the engine doesn't stall on cold starts at all it idles at a bit higher RPM for a few seconds then it drops to normal idle speed and stays there steadily. It runs a bit rough but it runs. But again I think disconnected MAF causes ECU to richen the fuel mixture so it might as well mask the real problem. I found that out after my temporary license plates expired so I'm not allowed to drive it on public roads now to watch the fuel trims during normal driving conditions and my driveway is not even long enough to make a single 1st WOT run.

And it's a hot film type MAF not that wire with resistor type. Manufacturer states cleaning is unnecessary because sensor itself is hot enough all the time it just burns any contamination. Paul doesn't recommend cleaning these types of sensors either. And I've never heard or read of someone that had success with cleaning their MAFs on these vehicles. Except for the ones which used oiled air filters and their MAFs got contaminated by the oil. So trying cleaning it before replacing probably won't do any good.

2. Thinking the car history something must have screwed up when dropping the fuel tank. At least it would make more sense than MAF going so much worse than before just buy waiting in a box to be reinstalled. On the other hand fuel tank had to be tumbled and wiggled a lot to unmount and install without a lift and all the fuel lines and fuel pump had to be disconnected. So fuel delivery system was the one I messed the most with before troubles began. It's just I can't seem to measure anything wrong with it. Might it be tank EVAP system could be screwed up? I'm not very familiar on how exactly it works. Could something with it go bad when I dropped the tank that would cause lean conditions at engine load?

3. The other thing that was changed is the exhaust. But I can't find a good idea on how it could cause these conditions. Second hand headers might be leaking somewhere but there's no visual smoke or obvious exhaust leak sound. I guess if it messed up the fuel trims so badly it would probably have to be large enough leak to be very obvious and easy to spot. And again why LPG wouldn't mind the exhaust leaks. The middle exhaust section with cats is new but some cheap brand. Probably not as perfect flow as original and cats probably aren't as efficient for the price but still I have no idea how cheap exhaust could be the culprit.

4. These cars are notorious for CCV valve failure. And it's known to cause misfire at cold starts. Either one of the vacuum hoses to the valve cracks or the diaphragm tears. But as I stated I checked the diaphragm as I had the intake apart and I also replaced 3 of the 4 hoses, one of them looked fine. And also if the diaphragm was torn there would be strong vacuum under the valve cover but as I remove the oil cup there's almost no suction at it just as I think it's supposed to be.

5. Cold misfire and stalling might also be cracked or warped valve cover. I'm not completely sure it seals perfectly but I sprayed it with water when cold and there was absolutely no change in engine sound. Even if it doesn't seal 100% I doubt it can introduce such a major leak to throw those codes and it would be a vacuum leak and fuel trims don't behave like there was one.

6. Ignition coils. They don't look to be in best shape. There can be some whitish deposit seen on the housings which could be result of slight arcing. But I guess these wouldn't cause lean conditions at loads but rather rich.

7. Maybe I'm wrong and these cars aren't supposed to run on fixed fuel pressure. The thing is manufacturer documents say so. Many people on different BMW forums believe so while some don't. I watched every possible video of this or similar type of engine but everybody seems to measure fuel pressure just at idle where it sits at same pressure as mine. I remember seeing only one video of someone revving the engine and the pressure stayed the same as mine does. The fuel pressure regulator on this engine is mounted on the end of the fuel rail and looks exactly like vacuum regulated ones on the outside. It has a nipple where a "vacuum" hose connects to. But that hose isn't connected to the manifold vacuum but to the CCV valve. BMW states it's only there in case diaphragm leaks the fuel will leak to the CCV valve and be sucked to the intake manifold rather than being vented to the atmosphere. As I disconnect that hose from the regulator there's absolutely no change in fuel pressure. I also don't feel any suction at all at the hose. And I'm not the only there's several cases like this some guys even measured vacuum on that hose and it was almost none on their cars. So I'm pretty confident the regulator works as it's supposed to but can't claim I'm 100% positive.

Excuse me for this incredibly long post wasn't planning on it to be that long but I guess it's an unusual problem I didn't know how to describe with a few sentences.

So I'm open to suggestions from the experienced. What to troubleshoot next to make the diagnosis as short as possible. Should I look into something I missed? What steps to do to definitely condemn or exclude the MAF. At the prices of new MAF I'd really hate to guess and be the parts changer. I'm particularly interested in that EVAP purge system too. Say if the hose from the tank to the purge valve leaked I suppose it might cause stalling on first start of the day since purge valve probably opens at the startup to consume the evaporated gas and would suck air in. But not sure if it could affect usual driving conditions.

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Please Log in or Create an account to join the conversation.

- szgonik

-

Topic Author

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

So there is fresh fuel in the tank but symptoms stay the same.

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

As you stated it runs fine with LPG on but you have rich codes for gasoline. This makes me wonder if the LPG is fully closing off when running gas or if it has some issue with the fuel curve. I am not sure how they set up the LPG computer to switch back to the gas ecu when gas is turned on but it might be somewhere within that area. some pics and diagrams would be helpful to diagose this one

Please Log in or Create an account to join the conversation.

- szgonik

-

Topic Author

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

LPG system has low mileage and is still under warranty. And I can hear the valve on the tank click as I switch to gas. And even if it was slightly leaking wouldn't that cause rich conditions not lean?

I'll try to do some pictures. The Scanmaster XL software I used for the test run doesn't have logging capabilities and it's not even possible to scroll back the graphs so what you see live is what you get. I should have recorder video of it but didn't think of that. I'm trying to find more suitable software. I tried ScanXL professional it looked very promising but for some reason it wouldn't plot the graphs or log data even though it has those functionalities. But it would show live data numbers in the graph window so it can read the PID's.

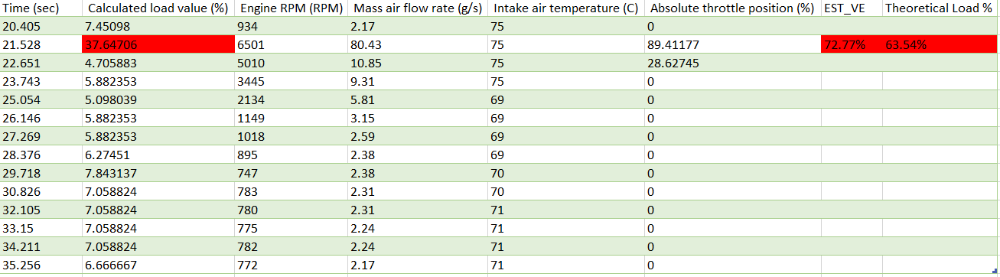

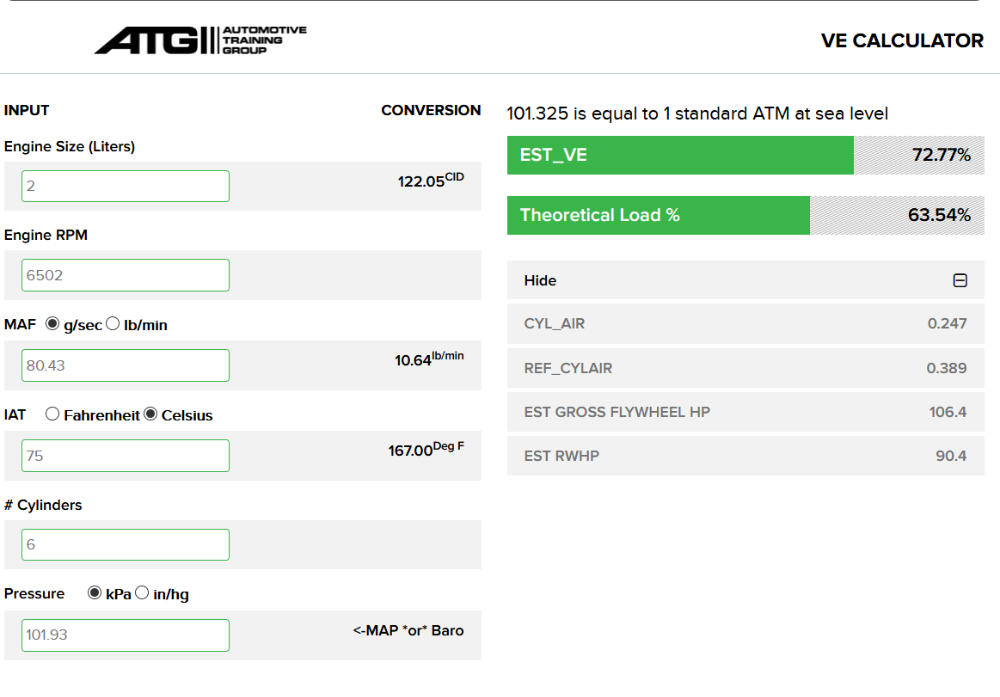

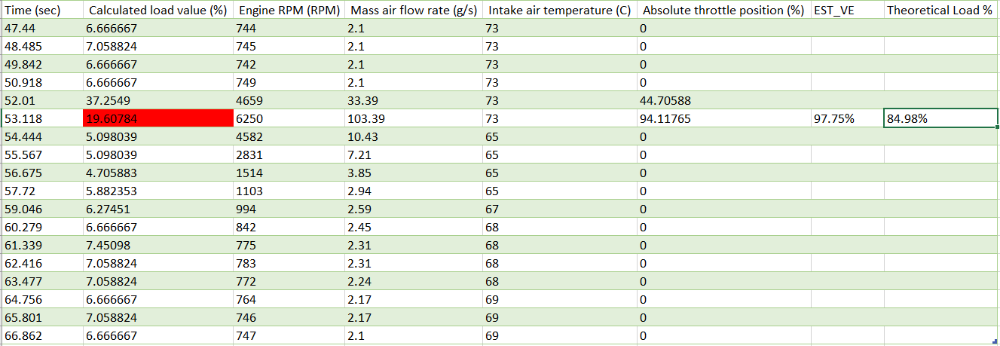

Today I was trying OBDwiz but it's so inaccurate it's of no use. I was trying to capture WOT snap data to throw them into a VE calculator.

The graphs aren't synchronized. See how how the MAF one is about 2s lagging behind the RPM one for example. There's no printed min or max values and no measuring tools to tell the peak numbers.

So I had to run background data logging. But it isn't synchronized with graphs. These certainly aren't the same peak numbers as pictured on the graphs.

And as I put those logged numbers into VE calculator I get bad results.

And it's impossible to tell wether the graphed or the logged data is wrong but possibly both are. Could someone suggest Windows software that works with ELM327 USB cable and is exact at logging data, plotting graphs, has the ability to scroll graphs back and has some measuring tools or at least a cursor and that also displays min and max values in graph windows?

I also scoped a WOT snap test but I'm just starting to learn to use the scope and couldn't find a way to freeze the picture and make a screenshot. But the waveform shape looked exactly as it's supposed to. It had that initial spike and it hit a just above 4V max. voltage. So at least the scope shows my MAF being probably fine. At least if I relate it to the Paul's videos.

So I'm thinking about those "vented to atmosphere" words Matt used. TBH until now I always thought bad fuel was probably myth. It's not the first car I had sitting for a long time. And no other car ever had fuel problems because of it. But none of those cars had the tank dropped resting on the driveshaft for a month of two with filler neck hose disconnected. So lots of "the good" stuff might have evaporated through that opening leaving just the bad stuff.

I did some googleing on it don't know if I can trust what I read but when gas evaporates it's supposed to turn into some brown gunk that could plug up fuel delivery system including the injectors and that it may cause wrong fuel level gauge reading.

Now my first post was way too long but I still omitted some details that might be important so I'm sorry but this one will be long too. The exact story is I knew I dropped the tank with about 1/4 gas in it because the fuel level gauge said so. When reinstalling it I heard some fluid clunking in and I'd say it felt heavier as if it were empty. But after reinstallation the faul gauge was showing almost empty and low gas light was lit on the dash. I thought it was because of the fuel tank design. The tank is divided in two sections each has it's own fuel level sending unit and the gauge in some way calculates the total gas in both sections. I was thinking it must be because all of the gas flew into one of the sections while I was wiggling it around to get it back into place and it just messed up the reading. But what if that wasn't the case but were because of gunked up gas.

That day car wouldn't start at all a couple of times it almost felt like it would start but it wouldn't. So I thought it was probably because most of the fuel has flown to the left section and fuel pump is installed in the right one. So next day I added 5l (about 5quarts?) of fuel as I didn't have larger fuel can than that. The fuel gauge would rise a bit but low gas light was still lit. And it should have gone out after adding those 5l unless the tank was empty to the last drop which it wasn't for sure. After several tries the car would finally start but stall immediately. Then after a few more tries it would idle a bit and stall. So the next day I added another 5l of gas. Now the low gas light went out and the fuel level gauge rised and seemed to be accurate. I didn't exactly count but I'd say it took less time for it to start then the day before and after every stall it ran a bit longer before than started to idle erratically and as it warmed up a bit it began to idle fine. The next day I got a larger 20l can and added 25l of gas. But didn't notice any obvious changes in how it started and ran than the day before. So that's when I got it topped up at the gas station and vent on that long test drive to empty the tank until it was just about 3l left in it.

So I'm not sure if this gunked up fuel is a myth or true. But if it were true I encountered a supposed symptom of fuel gauge reading wrong. Wouldn't it also be possible for it to gunk up my injectors before that gunk was diluted enough by the fresh gas. I honestly have no idea but if it was true it might be my problem.

Has someone encountered gunked up fuel before, could it gunk up because of the tank sitting with filler neck disconnected for abouth a month or two, could it really mess up injector flow in such a short time of running on gunk?

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

If it was p0171, p0174 those are lean trouble codes which would support what you just said.

Please Log in or Create an account to join the conversation.

- szgonik

-

Topic Author

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

P0172 and P0175 are the rich ones

P0170 and P0173 are trim malfunction codes that I believe can be rich or lean, and my conditions are lean for sure.

But I'm not sure why it threw those codes rather than the P0171 and P0174.

Maybe P0171 means that the bank is too lean but ECU's still able to compensate while P0170's so bad that it can't compensate anymore? Don't know.

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

A vacuum leak (common spots are vacuum tubing around engine) one specifically is the crank case vent tubing cracking behind the alternator under oil filter housing right below a "t" in the tubing on driverside. a smoke test should find this quickly by smoking through the oil fill cap and as well as you should do the intake system as well. Which from what I re-read you replaced most of them.

bad front o2 sensors, I would try forcing it rich with carb cleaner or propane to see if they respond. Also just in general see if you may have fully connected all fuel injector connectors not fully seated in.

Plugged/restricted fuel injectors (yes I have ran into varnished gas it sucks but typically it takes a while to go bad.) Also small critters mice and squirrels get into places so if tank was open a while i would say drop the tank and open it up and look. Since their nesting material can plug the prefilter in the tank

fuel pressure regulator ... the fuel pressure should stay steady in the fuel rail put a pressure gauge on it and see if pressure drops while running.

Edited :

Maf sensor under reporting g/s (idle should read 3.5-5 g/s, 2500 rpm should read ~90g/s) which from the graph you put up that looks like it's under reporting.

Also in your VE chart you will want to check you numbers i believe the m52 is a 2.8 liter and the rpm in chart was 6501...

With VE being low you probably want to check compression cause that is pretty low.

Please Log in or Create an account to join the conversation.

- szgonik

-

Topic Author

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

O2 sensors behave fine on LPG so I don't think they're bad. LPG is mixture of propane and butane too so basically I am adding propane when running on LPG.

Before I dropped the fuel tank and replaced the exhaust system the car started without any issues so I must have connected the injectors right. But I might pull the injector rail anyway to visually inspect the injectors for some obvious signs of dirt.

Would mice really make a nest in a tank that has 1/4 of gas in it? I guess they wouldn't be stupid enough to go suffocate or drown down there? I'd imagine smell of gas wouldn't attract animals but rather deter them. But I might pull the fuel pump and take a look at it and inspect contents of the tank through the opening. But I guess I'll remove the fuel filter first to check for signs of gunk on the rear connection. As it's the least work.

Fuel pressure is steady at about 3.6 - 3.7 bar across entire RPM range. Manufacturers specs are 3.5 +/- 0.2 bar so it checks OK.

My engine indeed is a 2.0l but those were never sold in the US. It has lower stroke and bore diameter than the 2.8l engine but every other part under the hood including all the intake parts and MAF. So my MAF should definitely read lower at idle than the 2.8l. I just can't say how much lower should it be. If it were directly proportional I guess it should read about 2.6 g/s but. That would indeed make the reading low. But I'm not sure about that. And new MF is a 400€ part so it's hard to decide for a new one without firm evidence.

And I'm taking those higher than idle measurements with a big grain of salt. I posted those images to show how inexact is the software I used. Graph shows about 100 g/s peak value while the log recorded only 80 g/s. And also the RPM graph was plotted 2s ahead of the airflow graph. I have more log screenshots. I could have posted this one as well:

This one has excellent VE, but calculated load is much worse. I think it's just the diagnostic software doesn't synchronize time frames accurately and makes VE calculations all over the place which makes it useless to gather VE data. So I have to find better software to be able to test the VE properly.

The other important thing to consider is I did the measurements with car standing still so that may have influenced air flow at higher than idle RPM significantly. There's a valve that changes length of intake runners on the intake manifold, both camshafts have variable timing controlled by the ECU and I believe at WOT even idle air control valve opens all the way to let more air in. It's very possible ECU doesn't activate some of those systems if the car isn't moving and I imagine that would have large impact on the airflow.

I never had compression checked but at some point in time while doing the work on the car I did a leakdown test. I measured it while the engine was cold because I had the intake removed already so couldn't warm it up, so the piston rings wouldn't seal as good as on a worm engine. But all the cylinders passed the test anyway with like new engine specs. IIRC they were leaking only about 2% each and all of them at the piston rings. Which a kind of makes sense because the engine was cold. Unless my cheap leak down gauge is waaaay off the engine should be in excellent condition.

Please Log in or Create an account to join the conversation.

- szgonik

-

Topic Author

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

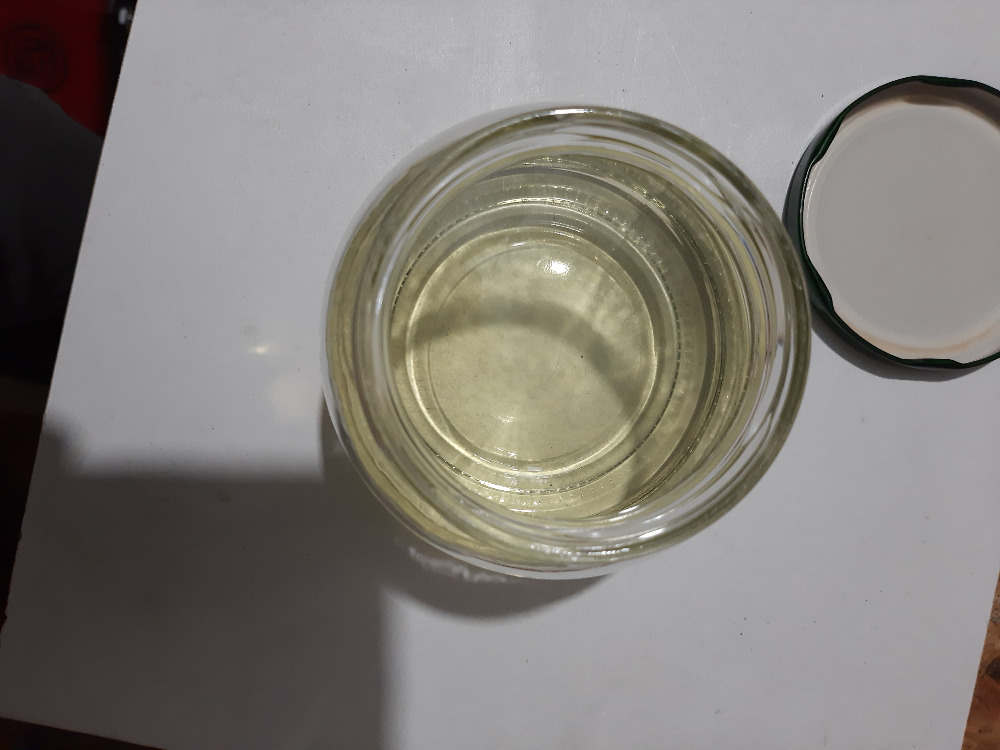

There's no signs of any brown varnish, gum slime or anything like that.

It can't bee seen well because it's impossible to make good photos of tank internals. There's a few small particles at the the bottom but I guess that would be normal for an old high mileage car, right?

It took some fuel samples from the bottom of the tank and let it set for a while. No particles were found settled at the bottom of the jar.

I also disconnected inlet hose to the fuel filter and drained the gas out. It was also clear without any particles. No signs of brown deposits in side the inlet nipple.

I seems fuel delivery system wasn't fouled by bad gas if it's clean up to the filter it can't be worse from the filter onwards.

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

Assuming it isn't a stale fuel or diesel in the tank issue. You are looking at a fuel delivery issue if it were my job I would start by checking fuel pressure and delivery volume.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- szgonik

-

Topic Author

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

With pressure built up to 3.5 bar I start the car but it stalls. Then I disconnect MAF. With MAF disconnected idle RPM is higher but much steadier. With MAF reconnected it doesn't stall but it has trouble keeping RPM high enough not to stall. At 3:25 I add a bit throttle and there's some loud clunking which sounds almost like mechanical noise but I was told even bad misfire could cause such awful sounds so not sure what this sound is? Ignore that noise that starts at 3:33 it's not the car but a train passing by at the most inappropriate moment. After the engine warms up a little the idle becomes steadier.

I let the engine idle to fully warm up to test the fuel pressure and volume because I don't fill comfortable revving cold engines. Idle pressure is at 3.6 bar. In the video it might look a bit higher because of angle of the camera but it's not. Pressure gauge stays steady at 3.6 bar during entire RPM range and during throttle snap.

The injectors were cleaned and tested by professionals and car wasn't driven at all since then except for a few minutes of idling. So I find it hard to believe they would plug up in literally a few minutes of idling. Visual inspection of fuel tank internals and fuel filter didn't reveal anything strange going on in there. Pressure and delivery volume look fine. I find it very unlikely the problems would be related to fuel delivery issues. But I don't have much experience so maybe I might be wrong.

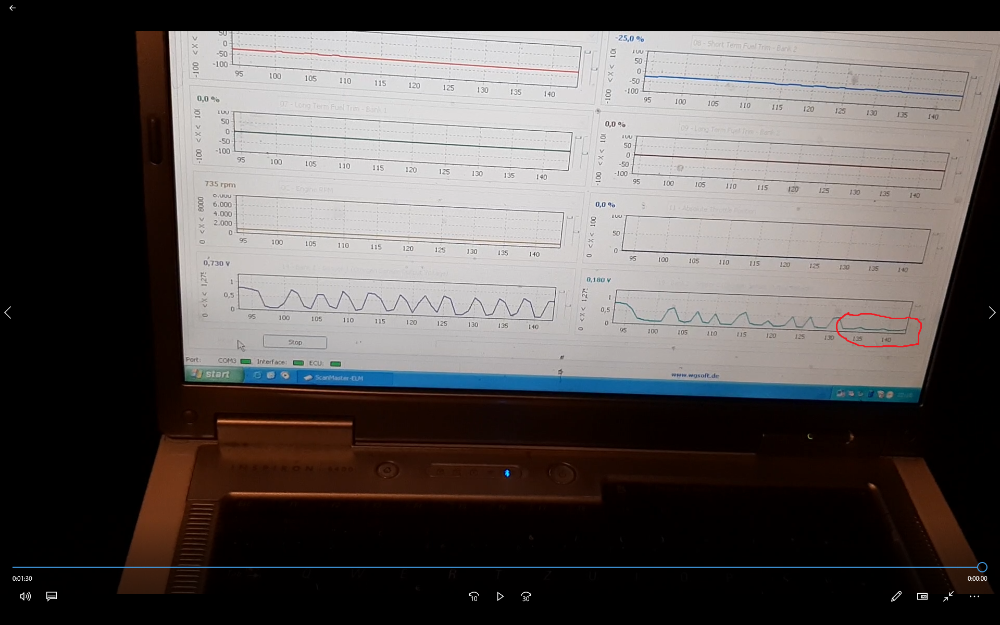

Next video shows some scan data on warm engine. Idle STFT are perfect and O2 sensors switching between rich and lean. It all seems fine. But notice as I raise the RPM just a bit (to about 1700 - 1800 RPM) both O2 sensors go full lean before they catch up. Next I do WOT and they go full lean again.

What I find strange in this video and subsequent videos is the throttle position graph shows only almost unnoticable reaction at frame 54 as it should go fully up. The other software I used had trouble graphing this PID too. But the values in log file did record changes in this value. Strange maybe for some reason generic OBD2 software can't interpret throttle position PID or it might really be a TPS issue as Hardtopdr2 suggested. I should definitely check what's going on with TPS.

Next video. Around frame 74 I switch to LPG. O2's go full rich and STFT's go full negative. O2's then start to switch between lean and rich STFT's are still way too negative. And between frames 130 and 135 bank2 O2 goes fully lean but ECU keeps leaning out the mixture on that bank with -24% STFT. I've never seen this happen with this O2 sensor so far. Oh my this reminds me more and more of that Scanner Danner Kia Rio video. Seems like scan data "behaves" inconsistently sometimes for no reason.

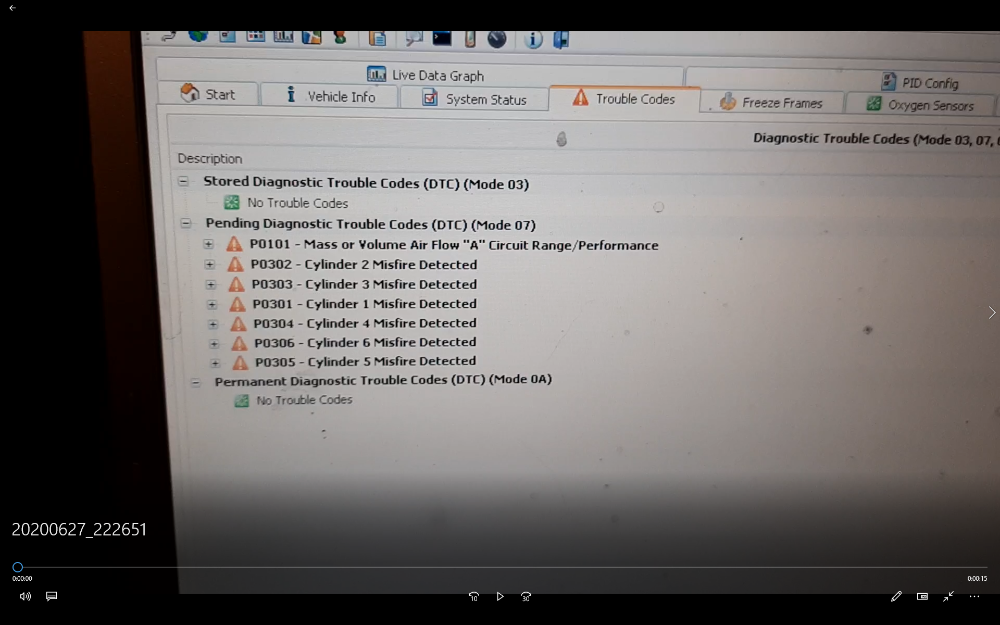

Reading the error codes after. Ignore the P0101 as it was caused by me unplugging the MAF. P0170 and P0173 aren't there because they won't appear while the car's standing still. They tend to appear after a few miles of driving. There' also no freeze frame data for the misfire codes as I guess freeze frames aren't stored while the codes are pending.

Please Log in or Create an account to join the conversation.

- szgonik

-

Topic Author

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

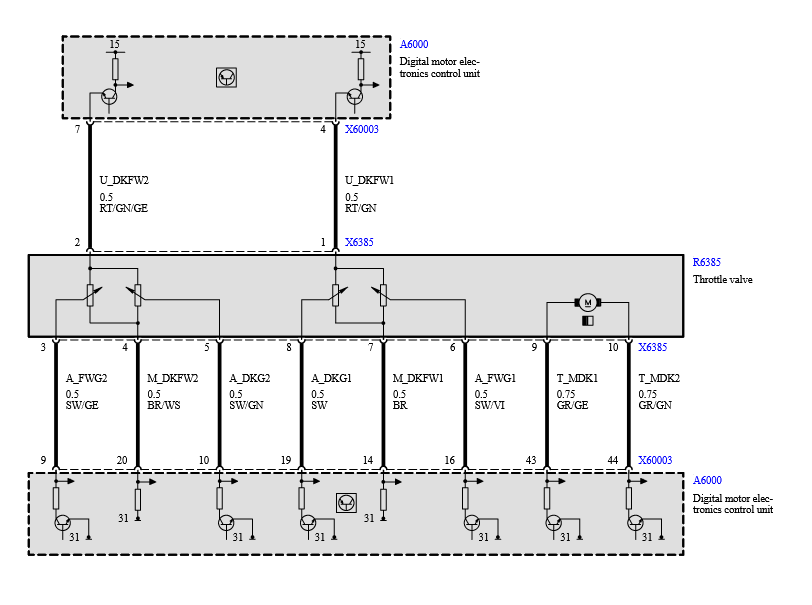

2nd switch is supposed to be there for redundancy in case one of them fails. And it would make sense ECU compared those switches and throw a code if their values were off.

I also checked throttle plate and potentiometer angles with BMW specific software.

They're not completely synchronized which I'm not sure is normal behavior or not. But it confirms ECU can read throttle position values and it must be generic OBD2 I used in those videos I posted before that can't read that PID properly. And it also confirms there are no glitches while slowly depressing and releasing the pedal. According to BMW Technical documentation the throttle plate with pedal fully depressed should be at 80° - 84° angle. Mine is a bit low and it could be easily adjusted by turning the stop screw under the pedal. But I won't do it for now. As I don't want to introduce another variable into the troubleshooting process.

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

Please Log in or Create an account to join the conversation.

- szgonik

-

Topic Author

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

I know aftermarket part replacements for this of MAF won't work properly. Only BMW branded will work for sure and there's a good chance Siemens VDO would work too because they make them for BMW but I'm not sure I would take a risk with with the Siemens one as exactly same part number is used on Hyundai Sonata and Kia Carnival so it's hard to believe such different cars would need exactly same calibration. There's also a Scanner Danner video on Kia Rio with a sensor looking exactly like mine. He replaced it with a cheap aftermarket one. It's just another confirmation that there's no aftermarket replacement for this type of Siemens made sensors. And that aftermarket sensor caused the live data to do some funky stuff that made him think the O2 sensor might be bad too. But it wasn't. It gave even him a tough time but at the end genuine MAF solved it.

At the end of that video I posted above - live data running on LPG there's something funky happening too. Bank O2 goes fully lean. That sensor might be bad but what bothers me is STFT stays at -25%. Why wouldn't the ECU react with rich command as the sensor clearly reports lean. How much funkier can it get? Can someone find an explanation for this?

I don't have a lot of experience so it's hard to make a call and condemn such expensive part but I think there's quite some evidence that points to the MAF.

Pros:

1. Stalling and erratic idle at cold start. At this time O2 sensors aren't heated yet so the car runs in open loop ignoring O2 signals and MAF is the main sensor it relies on. Disconnecting it makes the car idle steadier and not stalling. After 3 minutes or so the car would idle fine even with MAF connected which could be explained by entering closed loop mode and the main sensors to rely on are the O2. I have to investigated further if entering closed loop and steady idle start at the same time.

2. Considering fuel delivery issue is very unlikely STFT's behave exactly as an under reporting MAF. At idle the trims are fine at higher RPM they're lean. Besides torn intake boots before the throttle plate I can't think of any other reason that would cause such fuel trims.

3. Bank2 O2 sensor showed funky behavior I can't explained. I really have to carefully rewatch that part of the video when he was thinking about O2 sensor being bad. And compare it to what my Bank O2 did.

4. I've seen a video where the car with almost same type of engine behaves exactly like mine on startup. And it was the MAF.

Cons:

1. Disconnecting the MAF's supposed to make car running rich which could richen the lean conditions enough to mask the problem. I have to investigate further on this one by collecting some live data with MAF disconnected and comparing it to data with MAF connected.

2. O2 live data seems to be much better running on LPG which suggests it might steel be fuel delivery problem.

3. It seems very unlikely a MAF would go bad in a few months waiting to be reinstalled in the car. While I replaced complete exhaust and dropped the fuel tank. So it seems much more likely something would be wrong with those two. But I have no idea why. I've proved fuel pressure and volume are fine. I've checked the tank for varnish. And it's very unlikely to be the injectors. I can't detect any obvious exhaust leaks. Could minor exhaust leaks that don't produce any exhaust leak sounds and visible smoke be large enough to cause such bad lean conditions? I find this very unlikely too but don't have experience with that.

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

Please Log in or Create an account to join the conversation.

- szgonik

-

Topic Author

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

Please Log in or Create an account to join the conversation.