*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

Jeep Wrangler 4.0 secondary ignition waveform

- Rutesic

-

Topic Author

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 0

I'm tracing some idle misfire on my Wrangler 1995. 4.0 automatic. Engine shakes a bit but I can't find out why. It is not constant like when I unplug injector from a single cylinder, it is more like random cylinders misfiring. Distributor, coil and wires are as per FSM and have only 4-5 thousand miles on them. Cap, rotor and plugs are brand new. I had some issues with crank sensor signal and I've finally managed to get it to a decent shape.

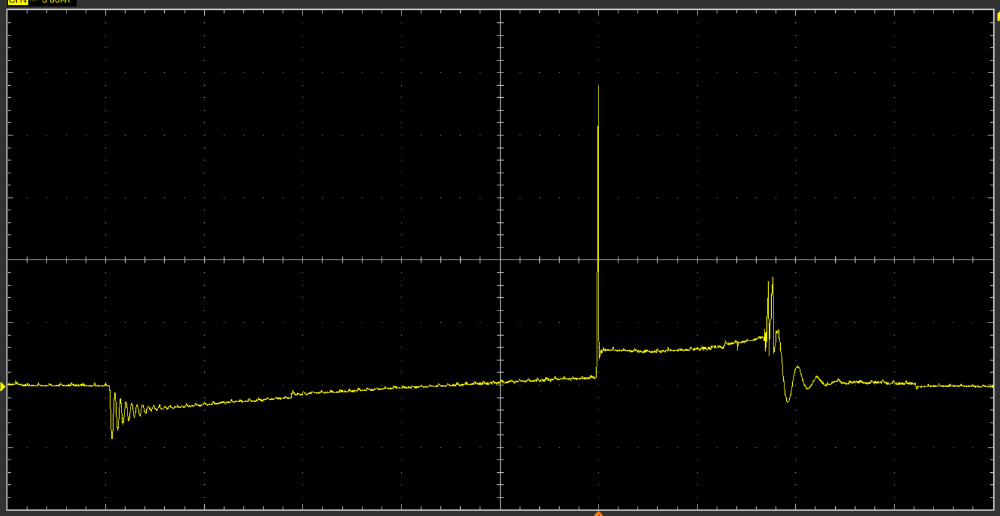

I need some help regarding secondary ignition waveform interpretation. Is the waveform from video below ok? I can see some weird peaks at the end of burn line, sometimes it is longer than 2ms, and firing voltage is sometimes as low as 6kV. Video is slowed down (you can slow it down further on youtube) and it shows all cylinders (153624 firing order). I don't have another probe to use it as a single cylinder trigger. Time scale is 1ms while voltage is set to 2kV.

Please Log in or Create an account to join the conversation.

- Rutesic

-

Topic Author

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 0

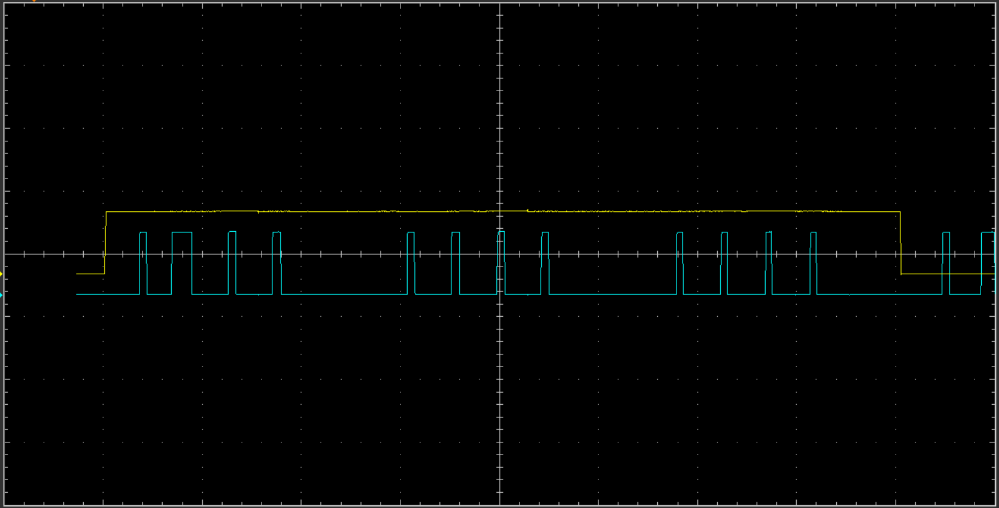

I have just seen that CPS signal is not ideal yet. Cam/Crank relation should be different, it seems like the crank signal is a bit moved to the left. I'm wondering if cam/crank out of sync and this longer second pulse on crank signal would cause misfire?

CPS scale is 10ms 5v

Please Log in or Create an account to join the conversation.

- VegasJAK

-

- Offline

- Platinum Member

-

- Silencing the Parts Cannon

- Posts: 566

- Thank you received: 140

cam crank out slightly... should be 50% at turn on-off.

"an open mind let's knowledge flow in and wisdom flow out for a man who has neither never listens to those who have both".

Please Log in or Create an account to join the conversation.

- chief eaglebear

-

- Offline

- Platinum Member

-

- Posts: 329

- Thank you received: 70

Please Log in or Create an account to join the conversation.

- John Curtis

-

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 111

Here’s some things to keep in mind.

ANYTHING that can slow the revolution if the engine can create a misfire. Any pulleys, a harmonic balancer shifting wobbling.

I don’t really feel it’s necessary to ask for current ramp. I do think you should scope spark and spark control. Also a relative compression test and secondary ignition as a sync (timing).

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

Please Log in or Create an account to join the conversation.

- Rutesic

-

Topic Author

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 0

Sorry but I don't understand what exactly should I scope here? Compare firing events to cam/crank sensor readings?John Curtis wrote: I do think you should scope spark and spark control.

John Curtis wrote: Also a relative compression test and secondary ignition as a sync (timing).

This engine was rebuilt 3k miles ago. As for the compression, I did test compression check with gauge and it was 150 -/+5 psi. Factory asks for 120-150psi. Considering this I guess there is no problem with intake valves or rings. But this test does not verify exaust valve condition (eg. if they open properly due to worn cam lobes). Could I verify this with relative compression test?

Please Log in or Create an account to join the conversation.

- John Curtis

-

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 111

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

Please Log in or Create an account to join the conversation.

- Rutesic

-

Topic Author

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 0

John Curtis wrote: You want to compare firing time with TDC using relative compression and ignition.

Will do, thank you. Regarding lean condition, do waveforms from that first video look like a little lean condition? I'm afraid if I have intake vacuum leak somewhere

Please Log in or Create an account to join the conversation.

- John Curtis

-

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 111

Rutesic wrote:

John Curtis wrote: You want to compare firing time with TDC using relative compression and ignition.

Will do, thank you. Regarding lean condition, do waveforms from that first video look like a little lean condition? I'm afraid if I have intake vacuum leak somewhere

I can definitely see how ScannerJohn is thinking that with the end of spark line but I think it may be okay but am not 100% positive. ScannerJohn may be positive and may be able to explain why it is lean (teaching us both). The end of spark to me looks like a typical ignition waveform, if it was drastically higher I would say for sure it is a lean issue. Personally I would use other data to help draw that conclusion since I am unsure of the waveform.

Try spraying some water all around your intake manifold and see if if the engine bogs down.

As far as intake valves, if you have a pressure transducer you would be able to see a valve problem. If you don’t, they’re pretty expensive and the next best thing might be to use a vacuum gauge. Valve train problems can cause at idle misfires that get better with RPM increase.

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1036

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- VegasJAK

-

- Offline

- Platinum Member

-

- Silencing the Parts Cannon

- Posts: 566

- Thank you received: 140

If its in only one cylinder check for leak at intake runner of that cylinder. If its all check for lean variables for a global lean.

The burn line looks pretty good, should be flat. As you can see, it has a slight rise when you have the spike at the tail. The spark fire voltage will rise high as well.

If you view the waveforms in a parade view you can compare each and if you can isolate #1 cylinder you can see which of the cylinder are having problems. Looks a little erratic.

Ignition waveform analysis is some heavy stuff but it gives a lot of insight. I'm still learning and studying.

I'm thinking you have a lean and ignition timing problems.

"an open mind let's knowledge flow in and wisdom flow out for a man who has neither never listens to those who have both".

Please Log in or Create an account to join the conversation.

- Tutti57

-

- Offline

- Platinum Member

-

- Posts: 1096

- Thank you received: 253

Nissan Technician

Please Log in or Create an account to join the conversation.

- Rutesic

-

Topic Author

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 0

Fuel trim is around +3% most of the time. Ok, so next step is to verify ignition timing and check for intake leaks.

I don't have pressure transducer. However, should I be able to check individual cylinders by doing dynamic (running) compression test with gauge? If I understand well that would show me if intake and exhaust valves are opening/sealing properly

Please Log in or Create an account to join the conversation.

- John Curtis

-

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 111

Rutesic wrote: Thank you all for tips.

Fuel trim is around +3% most of the time. Ok, so next step is to verify ignition timing and check for intake leaks.

I don't have pressure transducer. However, should I be able to check individual cylinders by doingcompression test with gauge? If I understand well that would show me if intake and exhaust valves are opening/sealing properly

When I’m dealing with drive ability problems and looking at fuel trims 10 is usually the safe number, however 6 is my tolerance for problem vehicles.

You’re going to want to do a leak down test. It’s different than compression testing in that you use a compressor to pressurize and it will show the amount of leak-down. You’ll have to figure out where it’s escaping from by listening to the exhaust, removing the oil cap, radiator cap or coolant reservoir, or air intake/throttle body.

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

Please Log in or Create an account to join the conversation.

- Rutesic

-

Topic Author

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 0

If not, I assume there are four options:

1. Ignition ( considering your responses there should not be any issues with this part)

2. Fuel delivery/injectors ( fuel pressure is around 30psi idle which is 1 psi below Chrysler spec)

3. Air leaks ( since fuel trim is 3% it should not be anything major)

4. Something sensor/ECU related

What bothers me are timing events. There is one pulse in crank signal that is a bit wider that all others. Could this one mess up spark/fuel timing enough to cause random engine shakes ?

Please Log in or Create an account to join the conversation.

- Rutesic

-

Topic Author

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 0

I don't have current clamp so I cranked the engine and scoped crank sensor and secondary lead. It seems that spark occurs between 3rd and 4th peak of each crank sensor signal group. There are no missing sparks or more than one spark per cylinder, so this seems to be consistent.

After that I took fuel pressure gauge and measured pressure on idle. This time it had 27-8 PSI on idle. Factory spec is 31 psi. If I snap throttle it will bounce up a bit - maybe 2-3 psi, and when I release throttle it would go to 26 and then climb to 27-8. Is this proper behavior?

I have also tried to sync cam/crank sensor, but it is impossible to do so with this distributor. I followed FSM - put harmonic balancer to TDC (0 mark), blocked distributor shaft from rotating with a pin, however when I put it back i can't screw it in - i need to remove pin and rotate it a couple of degrees. This is weird, only thing that comes to my mind is that the clamping slot is not correct on distributor or that harmonic balancer does not point to TDC properly.

Please Log in or Create an account to join the conversation.

- VegasJAK

-

- Offline

- Platinum Member

-

- Silencing the Parts Cannon

- Posts: 566

- Thank you received: 140

I looked at your secondary waveform... check for carbon tracking on the plugs and or plug boot. Also check to make sure EGR is closing all the way. Those waves are erratic, should be all the same. I sure would like to see the secondary in a parade form of all...

"an open mind let's knowledge flow in and wisdom flow out for a man who has neither never listens to those who have both".

Please Log in or Create an account to join the conversation.

- Rutesic

-

Topic Author

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 0

One thing I noticed is that misfire becomes more evident after engine is warmed up (but it could be more noticeable because of rpm drop). I have snap on MT2500 and temp sensor data seems to be correct (at most 90 deg celsius on fully warmed up engine, so I don't suspect bad coolant temp sensor). Spark advance that ECU calculates seems to fluctate between 12-14 degrees. However, sometimes it randomly bounces to 19-20. Engine was rebuilt - new timing chain and sprockets.

As for the fuel pressure, it rises to around 35-6 psi with regulator vacuum disconnected. Does this mean that regulator is OK? This is still below factory spec. Only thing that comes to my mind is either bad pump, fuel filter or something inside the tank that restricts fuel pressure?

I have tried to partially connect vacuum to regulator so that it makes 31psi in fuel rail, however I did not see any improvement on idle. Not sure if this is ok test since I got same extra air in intake manifold because of partially connected vacuum.

AFAIK, there is no EGR on 91-95 4.0 engines.

Please Log in or Create an account to join the conversation.