1995 Ford Ranger 4.0 V6, XLT 4x4- no spark

- kvforte

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 12

Parts Replaced so far:

crankshaft sensor

camshaft synchronizer & sensor

PCM

Vehicle has factory non-chip key anti-theft system.

Test results:

50/50 test- no start.(starter fluid sprayed into intake.)

in-line spark tester- no spark while cranking.

injector has 12 volts- key on, but no pulse while cranking.

fuel pump- primes with key on.

Coil- 12 volts key on, drops to 10 while cranking.

CEL- on with key on, goes off for approx 3 seconds while cranking then comes back on.

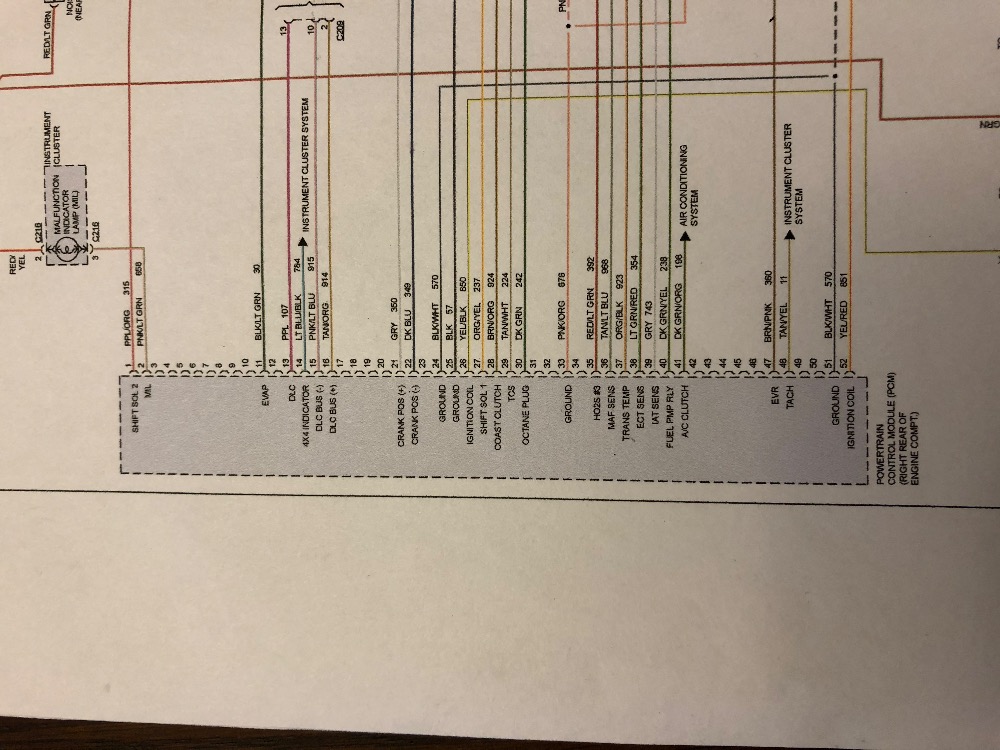

RPM monitor- reads 186 rpms while cranking, then drops to zero in about 3 seconds. RPM measurement is from OBD device. (Onboard tach doesn’t move.)

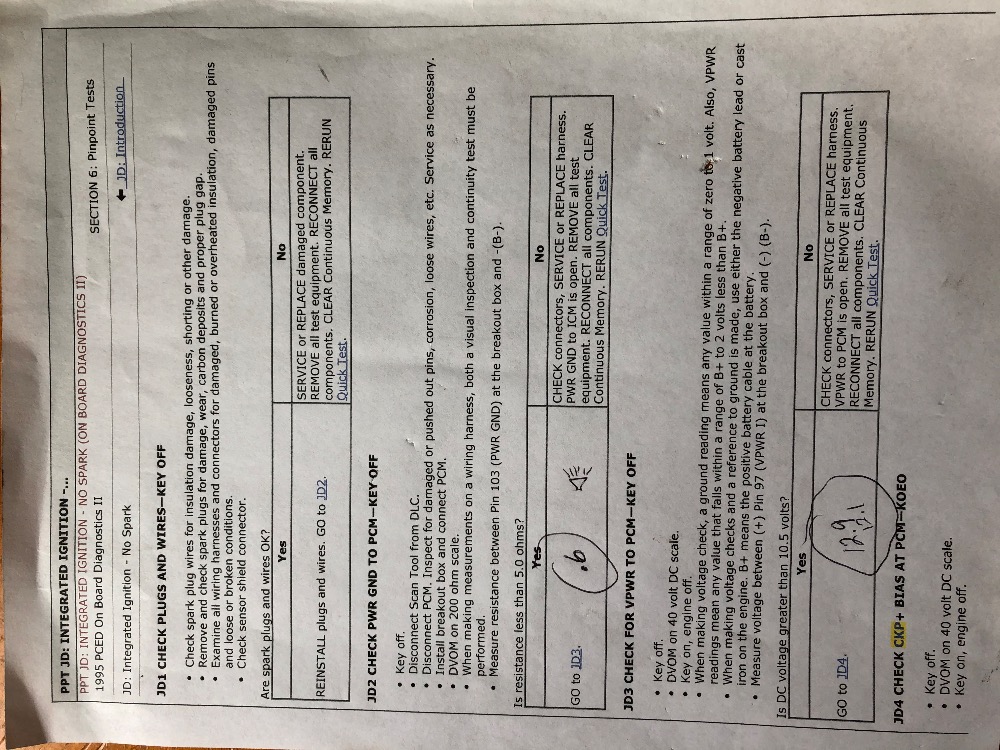

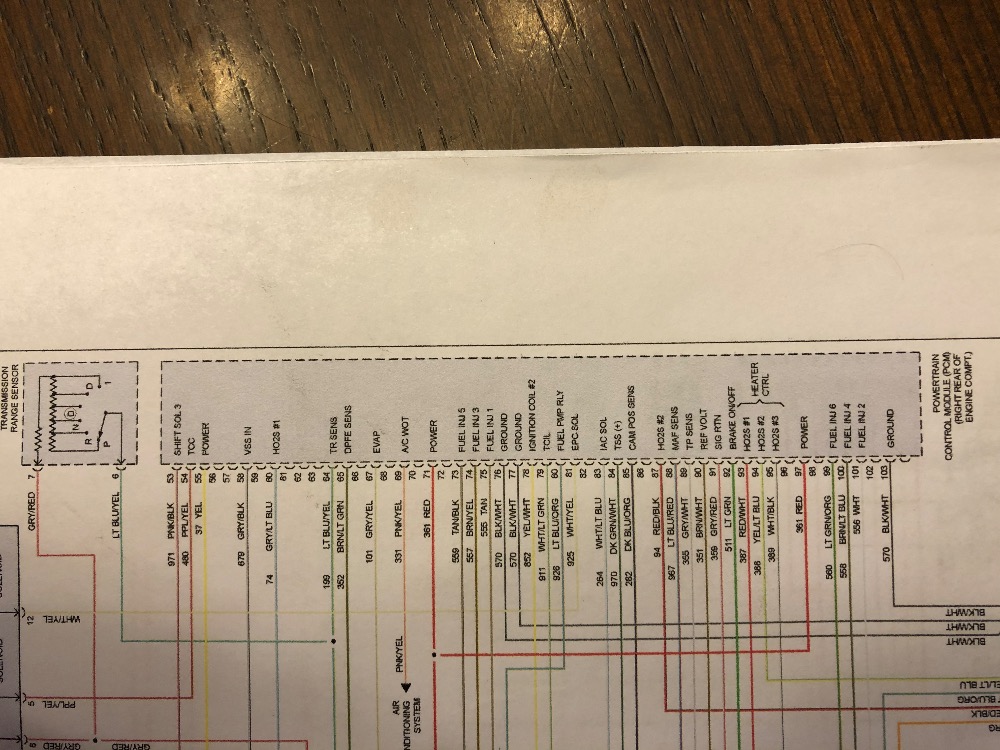

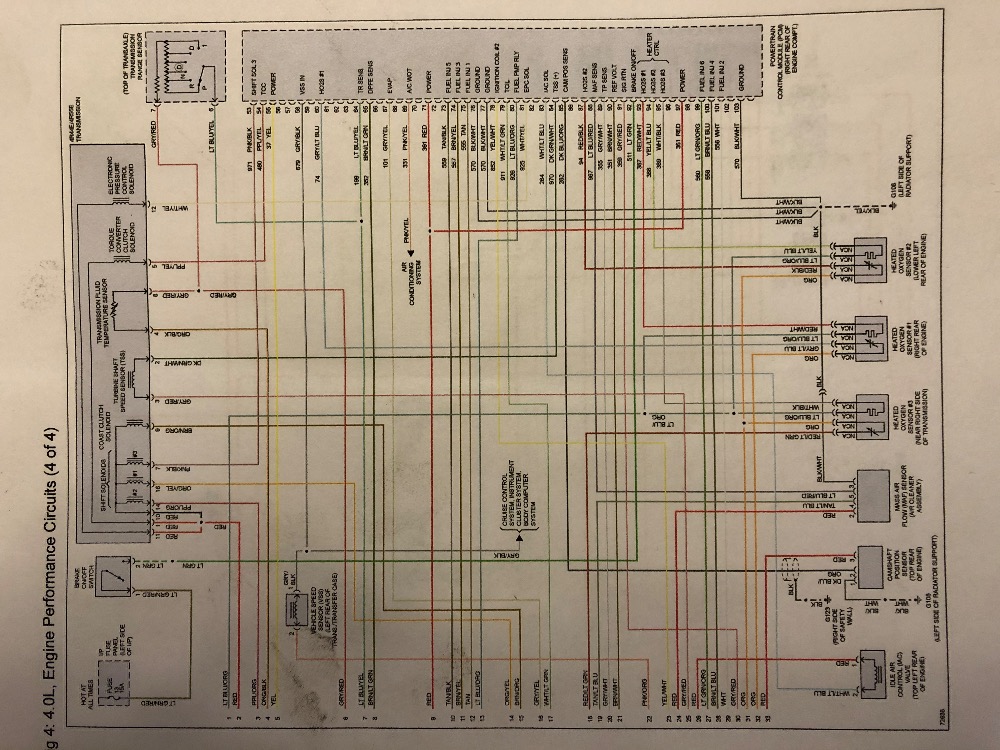

PCM pin 103 to B- has .6 ohms key off.

PCM pin 97 to B- has 12.1 volts key on.

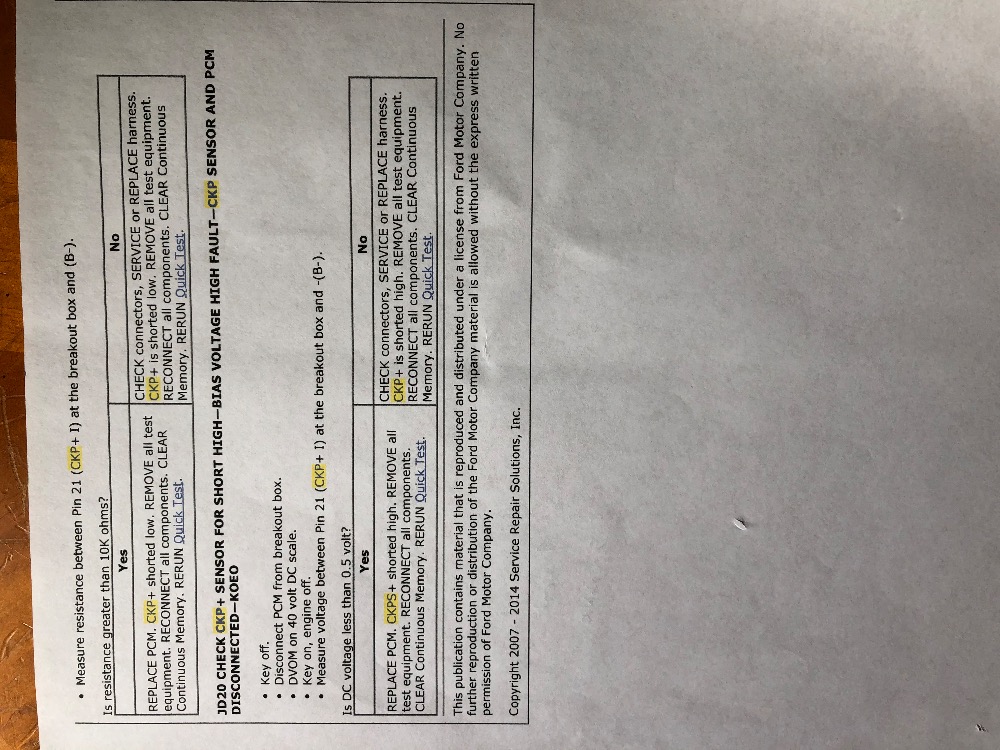

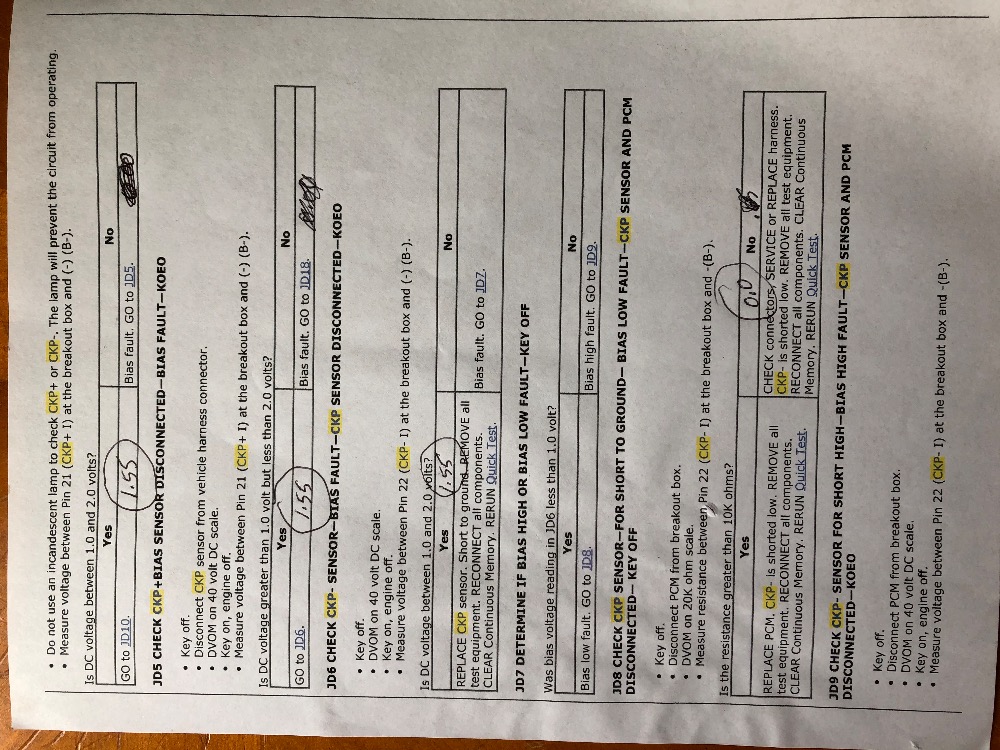

CKP pin 21 to B- has 1.55 volts DC key on.

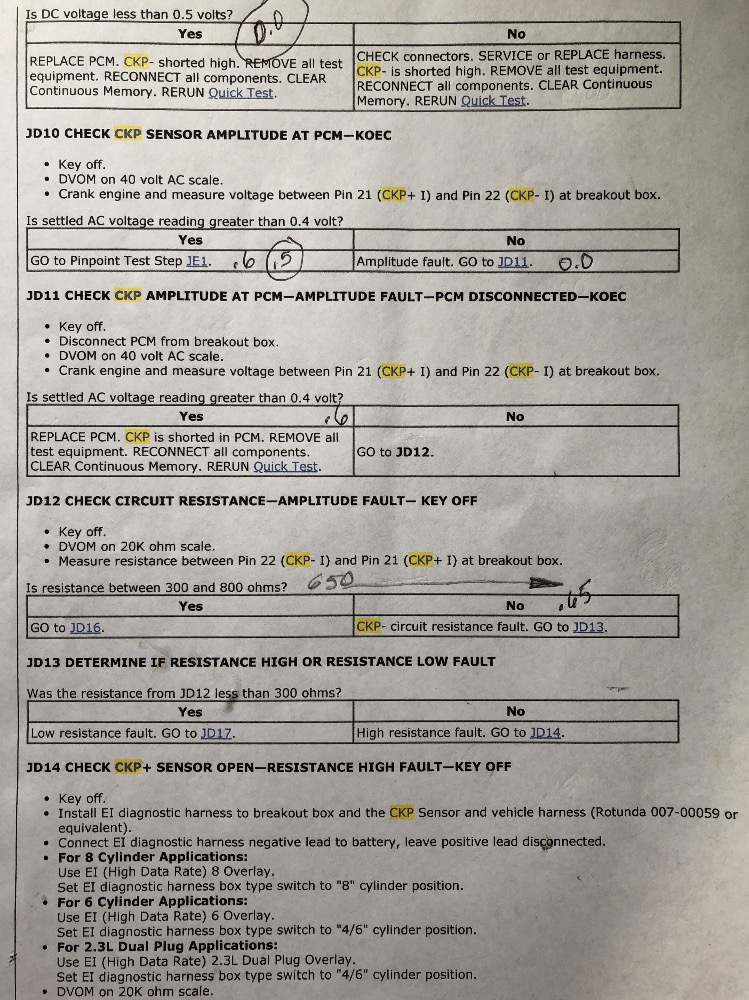

pins 21 & 22 at PCM -has .5 AC volts while cranking.

CKP at sensor - .5 AC volts while cranking.

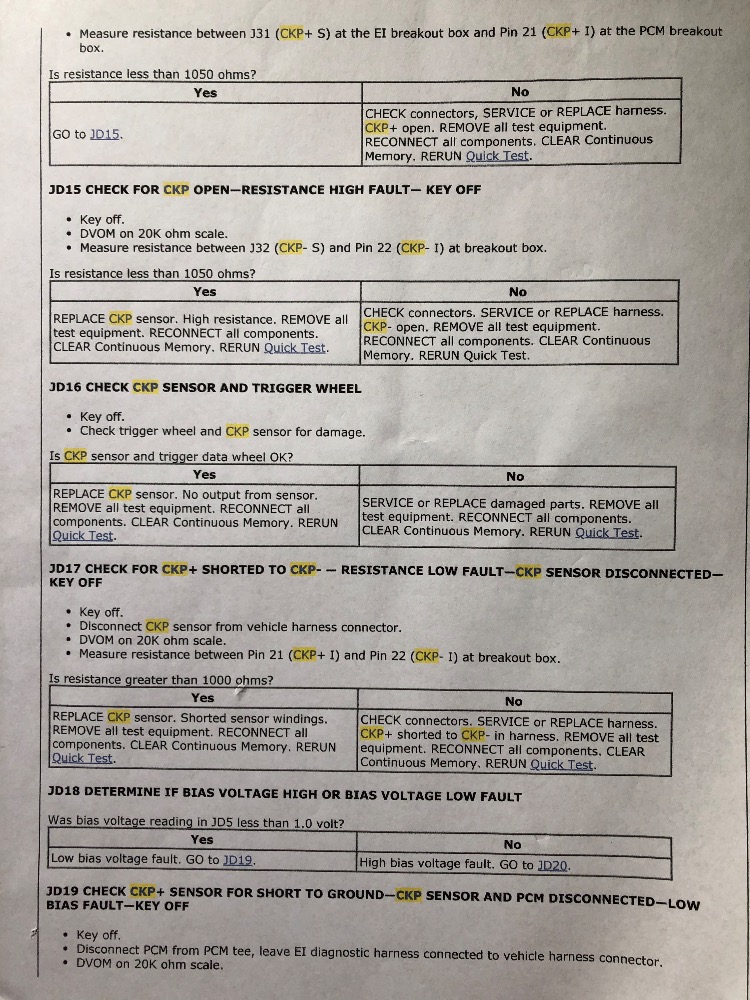

CKP at sensor - 660 ohms resistance.

Tone ring visual inspection looks normal.

As stated about already replace crankshaft sensor, PCM, Coil Pack, and camshaft synchronizer w/sensor. Not sure what else it could be?

Please Log in or Create an account to join the conversation.

- John Curtis

-

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 111

A couple things. You need to make sure the PCM has powers and grounds. (Does check engine light come on for a few seconds during initial key on?)

Just realized you checked this.

How much voltage drop is happening during crank?

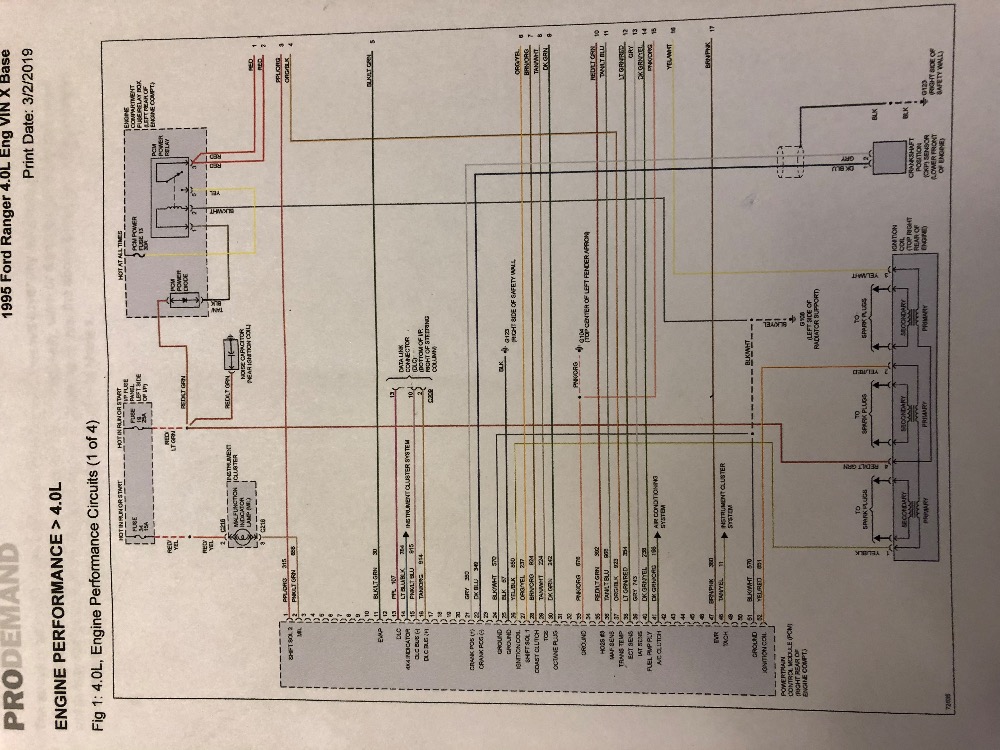

You need to verify crank signal is getting to the PCM.

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

Please Log in or Create an account to join the conversation.

- kvforte

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 12

Thanks for your help, I’ve been working on this truck for several months when time allows. Getting a little hopeless.

Please Log in or Create an account to join the conversation.

- Cheryl

-

- Offline

- Platinum Member

-

- Posts: 1214

- Thank you received: 215

Please Log in or Create an account to join the conversation.

- kvforte

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 12

Please Log in or Create an account to join the conversation.

- kvforte

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 12

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

kvforte wrote: I have 11.5V with key on at red wire on coil pack. I assume the other three wires at coil pack harness are grounds that the PCM used to fire the coil. When testing each of these along with the battery positive, the test bulb will only light up very dim. Is this correct?

I'm sorry, I'm not following this part well...

Are you saying that with the test light connected to battery positive that while cranking the engine the yellow/xxx wires light dimly?

That would suggest good coil control. It happens so quickly that it's never grounded long enough to light the bulb very brightly.

Or, are you saying that with the test light connected to battery negative that all 4 wires on the coil light the test lamp dimly with the key on and engine off?

That would indicate a voltage drop on the coil feed circuit.

Sorry for the confusion on my part

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- kvforte

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 12

Shouldn’t these three wires be grounded completely while key is on but not cranking? Then the PCM would cut/uncut the ground to each along with the timing as the engine cranks.

Also, just for good measure I tested the crankshaft sensor signal again. Got .4 AC volts at the sensor and at the PCM while cranking. Is this enough signal to tell the PCM to fire the coil?

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

I'm not sure about the test light for that test, doesn't sound right. I would think that it should not light at all, but I suppose it could be finding a ground path through the pcm?

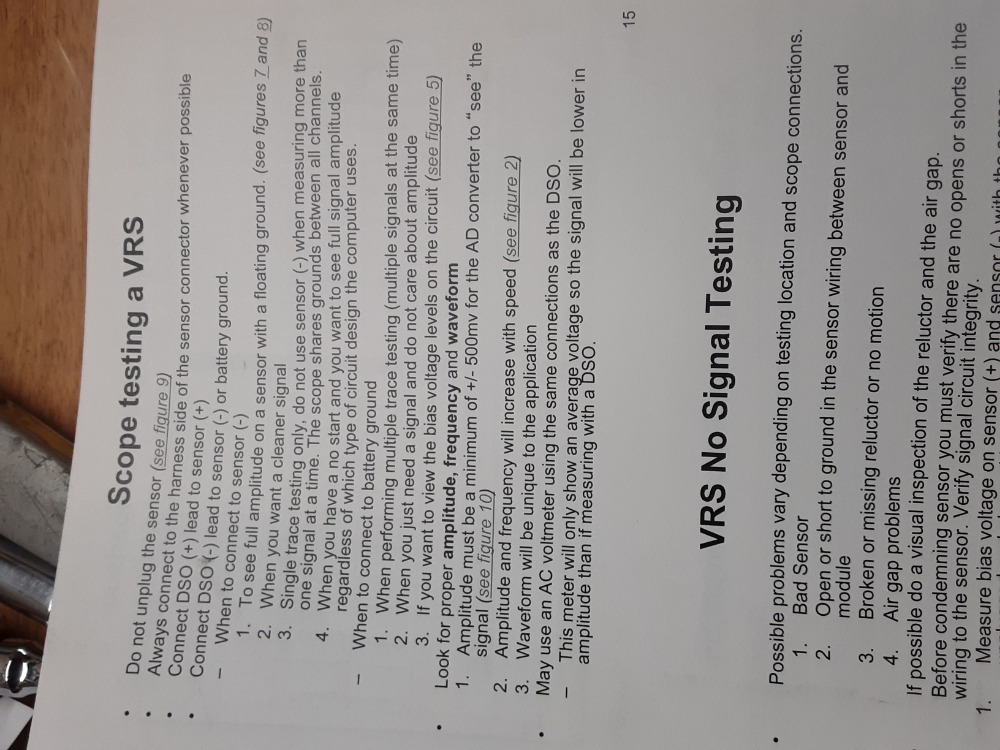

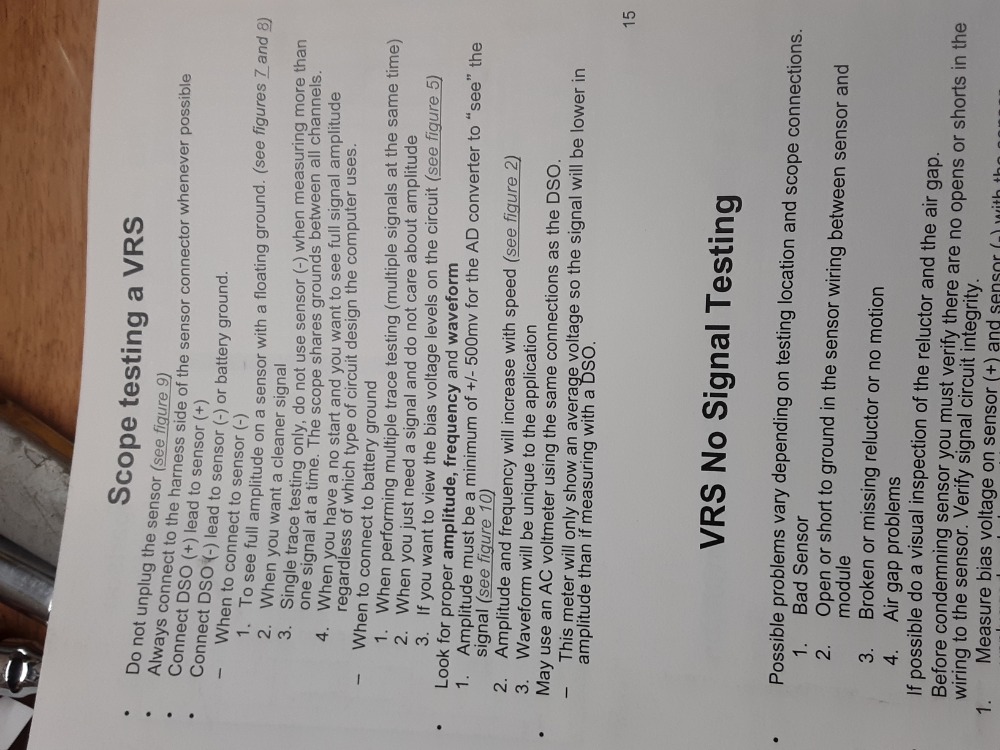

As far as .4vAC on the crank sensor, I think that should be sufficient. I've never checked one with a meter, but according to the Engine Performance and Diagnostics book: pg15 21-8,

"Amplitude must be a minimum of +/- 500mv for the AD converter to "see" the signal."

So your .4v (400mv) is course enough for me to think it's working, remembering that a voltmeter gives you an average reading. So at an average of 400mv, I would assume that when viewed on the scope that the signal is likely crossing that 500mv threshold.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- kvforte

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 12

When harness is disconnected with key on red wire has 11.5volts, and the other three have .02volts.

Any ideas what else could be causing the no spark?

Please Log in or Create an account to join the conversation.

- kvforte

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 12

Please Log in or Create an account to join the conversation.

- stioc

-

- Offline

- New Member

-

- Posts: 16

- Thank you received: 17

When the RPM reads zero is the crank sensor still sending the .4v?

Please Log in or Create an account to join the conversation.

- kvforte

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 12

Is the spark and injector pulse related? I’m just wondering if there could be an issue in the fuel system that is causing the computer to shut down the spark.

If feel like the computer has to be killing the RPM signal after the 3 seconds. Because it will do it exactly the same every time as long as the key is turned to the off position before cranking. However, I guess the crankshaft signal could be getting shorted out. I’ll check voltage after RPM loss tomorrow.

Thanks

Please Log in or Create an account to join the conversation.

- kvforte

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 12

Maybe one of the crankshaft sensor wires is shorted somewhere? Thought?

Please Log in or Create an account to join the conversation.

- stioc

-

- Offline

- New Member

-

- Posts: 16

- Thank you received: 17

kvforte wrote: Looks like the crankshaft ACVolts signal is dropping at the same time the RPM’s go to zero on the OBD scanner (after about seconds of cranking).

Maybe one of the crankshaft sensor wires is shorted somewhere? Thought?

I would suspect a bad crank sensor first especially if it's aftermarket. If you still have it I would put the old CKP sensor back on and see if it's also dropping out so quickly. If it shows the same exact behavior then I'd chase the wiring possibility or some other reason.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

I like Juergen's suggestion about polarity, especially if you had to repair the connector when you changed the sensor.

check out this Ford crank sensor video:

While cranking the engine on your Ford, the CEL should go out as long as the PCM is receiving the crank signal. You say it goes out but then returns just as the RPM stops displaying. This seems to confirm a crank sensor signal dropping out. Possibly an air gap issue. Do you get maybe one or two spark events during the first couple seconds of cranking?

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- kvforte

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 12

Please Log in or Create an account to join the conversation.

- stioc

-

- Offline

- New Member

-

- Posts: 16

- Thank you received: 17

Please Log in or Create an account to join the conversation.

- kvforte

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 12

Please Log in or Create an account to join the conversation.