Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

BMW E46 316i P2177 Lean off idle

- marijn8888

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

5 years 1 month ago #27748

by marijn8888

BMW E46 316i P2177 Lean off idle was created by marijn8888

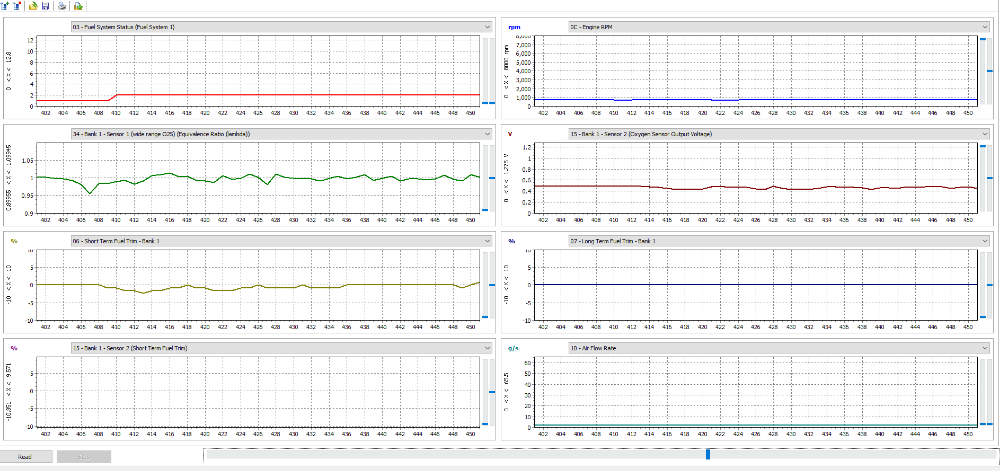

Hi everyone, I could use some help with my bmw 3-series touring. It has the 1.8 4-cylinder N46B18 engine in it. Some time ago it threw an engine light, with P2177 code. The code description is 'Fuel mixture too lean off idle'. There are no performance issues whatsoever, no rough running or loss of power or anything like that. First I reset the code, and I drove for a few days, maybe even a week without the light coming back on. It lit up again on a long highway drive, while on cruise control. I reset it once more, and again it took some time to come back on. Here is a screenshot from the error code in INPA:

As you can see in the freeze frame data, the code set at least 16 times since the engine light was on. All three times that are shown, the engine was between 2000-3000 rpm, and the fuel trim was high each time the code set(24%-25.5%-35.25%).

A little info on the setup in this car, as most of you are probably not familiar with the 4 cylinder engines since it wasn't sold in the US. The fuel system uses two oxygen sensors, one upstream and one downstream. The upstream sensor is a wideband sensor, the downstream is narrow-band. This engine also has the valvetronic system in it, which uses variable valve lift to control airflow into the engine.

Yesterday I did some first checks, mostly trying to figure out how the software that I am using works. I am using Scanmaster ELM, with a 20 euro ELM327 OBD2-scanner. The available data pids are very limited, but at least it shows me the fuel trims and oxygen sensor data. I am new to this, so I spend some time with it yesterday but forgot to save any of the recorded data. A first look at the data showed that the long term fuel trim was at 24% at idle, while the short term was around 0%. The MAF showed an airflow of around 2,0-2,2 g/s. I am not sure whether this is a plausible value, there is very limited info on these engines online. Therefore I assumed this was correct and carried on. When revving the engine to about 3000 rpm, the short term trim raised to around 20% as well. The long term trim didn't change at all. The first checks that I did were to determine whether I should trust the oxygen sensors. I pulled the oil dipstick tube to create a vacuum leak, and saw immediate response from the upstream sensor. Then I sprayed some break clean in the intake to create a rich condition, and again the upstream o2 reacted.

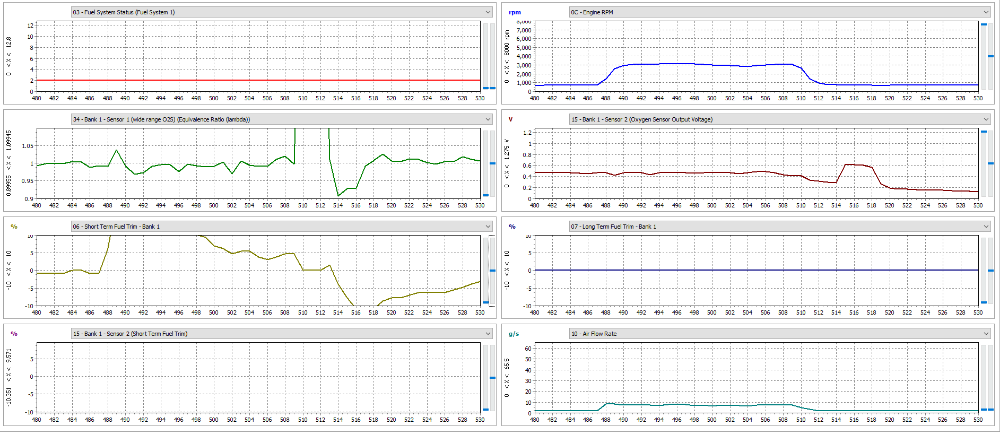

Today I connected my laptop with a K+DCAN cable, and started playing around with BMW's oem software INPA. It's not very user friendly, but I found the same values here as in Scanmaster ELM. I played around a little, and ended up resetting the fuel adaptations, to see if it made any difference. In how the engine ran. I didn't notice any difference, no roughness at idle or at higher rpms. I then switched to Scanmaster again, because it's easier to use and has graphing view. Today I did manage to save the data. Here is a screenshot of the data when the engines goes into closed loop, after I reset the fuel adaptations:

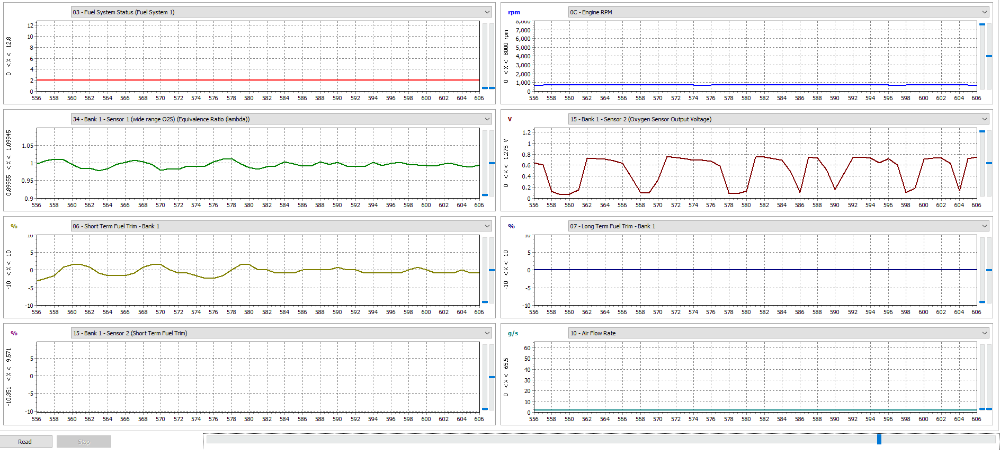

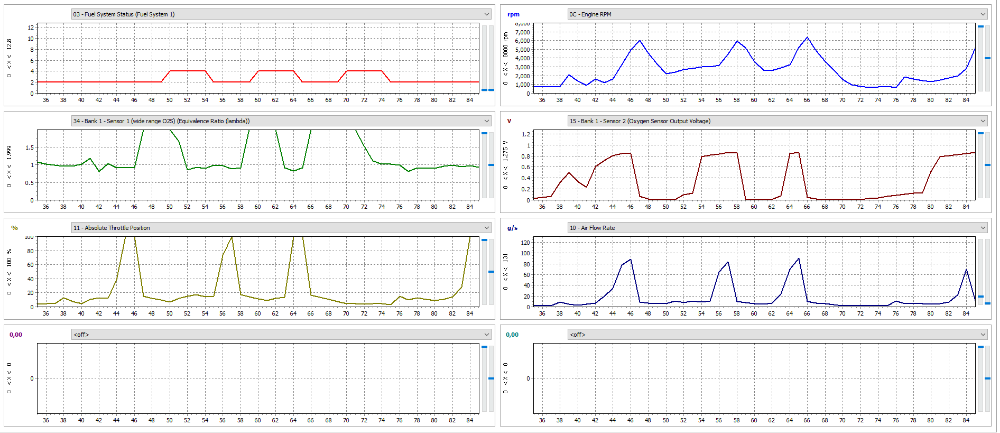

The value for fuel system status changes from 1 to 2 when the system goes into closed loop. The lambda value shows a little rich right after it goes into closed loop, but evens out quickly. Also the short term trim stays around 0. Now I revved up the engine to about 3000rpm:

Now the short term fuel trim shoots up to around 20%, then slowly comes back down again while the engine is still revved up. I then let it idle for a bit, and made another screenshot of the data:

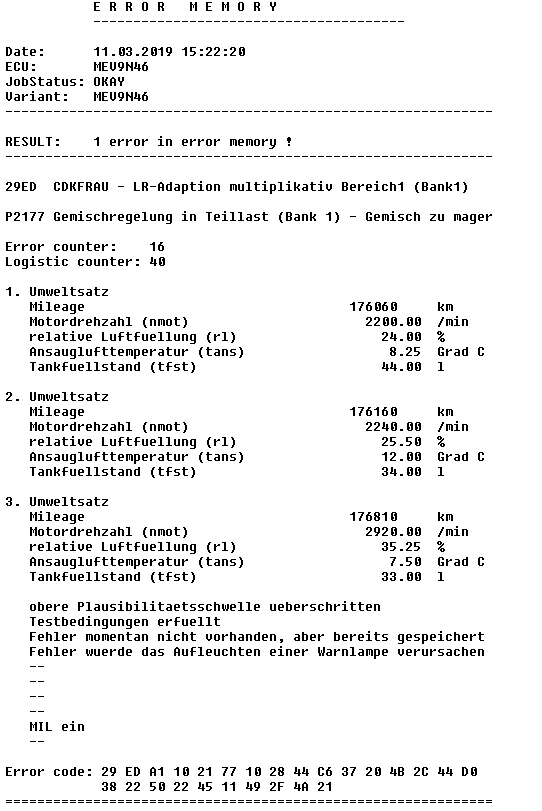

Both fuel trims are around 0%. The downstream O2 is switching between rich and lean, but I believe that is normal. I would like to hear your opinion on what to do next. I made a list of probable causes of the lean condition, and my thoughts on them. Feel free to leave a comment to let me know what you think!

Vacuum leak:

Today the lean condition was only present at higher rpms. Yesterday the long term fuel trim was at 24%, also at idle, but today I didn't see anything in the oxygen sensor data that points to a lean condition at low rpms. I'm not sure whether to trust the long term trim data pid, because I haven't seen it change except when I reset the adaptation values. Assuming that the lean condition is not present at idle, would point away from a vacuum leak. However, since this car has variable valve lift, and therefore no throttle plate to restrict the airflow, the amount of vacuum in the intake is very limited at idle. Could the lean condition at higher rpms be the cause of a vacuum leak? I think the leak would have to be very substantial to show up at high rpms, which would cause the engine to run rough or even misfire at idle. When I pulled the oil dipstick tube to create a vacuum leak, the engine did start running rough. I could do a smoke test on the intake, but I will have to fabricate my own diy smoke machine first.

Fuel delivery:

I am not very suspicious of a fuel delivery issue, since the engine has no performance issues. Even accelerating at full throttle, the car does not show any hesitation or loss of power whatsoever.

Under reporting MAF:

I don't know the normal g/s of this engine type. 2 g/s seems a bit low at idle. At 3000rpm, the MAF reported around 8,0 g/s. Yesterday I checked in my friends car, he also has an E46 touring but with the M54B22 engine in it. In that 320i, the MAF reported 3.6 g/s at idle. Do you guys think that the MAF could be a problem? I already disassembled the air filter housing to take a closer look at it, but it didn't seem dirty. I'm also hesitant to clean it or fiddle around with it, since it's a 400 euro part.

Exhaust leak:

I have read some stories where exhaust leaks can cause lean codes. However, i would think that I would hear it if there was an exhaust leak. I already checked briefly under the car, but as far as I could see there weren't any cracks or holes in the exhaust pipe. I wasn't able to look at the exhaust manifold from underneath, since the subframe and some other components were blocking my view.

I'm very curious to hear what you guys think I should do next. I think my first move will be to do a smoke test on the intake. Maybe I should also buy a fuel pressure gauge to check the rail pressure.

Thanks in advance for helping me! Best regards from the Netherlands!

Marijn

As you can see in the freeze frame data, the code set at least 16 times since the engine light was on. All three times that are shown, the engine was between 2000-3000 rpm, and the fuel trim was high each time the code set(24%-25.5%-35.25%).

A little info on the setup in this car, as most of you are probably not familiar with the 4 cylinder engines since it wasn't sold in the US. The fuel system uses two oxygen sensors, one upstream and one downstream. The upstream sensor is a wideband sensor, the downstream is narrow-band. This engine also has the valvetronic system in it, which uses variable valve lift to control airflow into the engine.

Yesterday I did some first checks, mostly trying to figure out how the software that I am using works. I am using Scanmaster ELM, with a 20 euro ELM327 OBD2-scanner. The available data pids are very limited, but at least it shows me the fuel trims and oxygen sensor data. I am new to this, so I spend some time with it yesterday but forgot to save any of the recorded data. A first look at the data showed that the long term fuel trim was at 24% at idle, while the short term was around 0%. The MAF showed an airflow of around 2,0-2,2 g/s. I am not sure whether this is a plausible value, there is very limited info on these engines online. Therefore I assumed this was correct and carried on. When revving the engine to about 3000 rpm, the short term trim raised to around 20% as well. The long term trim didn't change at all. The first checks that I did were to determine whether I should trust the oxygen sensors. I pulled the oil dipstick tube to create a vacuum leak, and saw immediate response from the upstream sensor. Then I sprayed some break clean in the intake to create a rich condition, and again the upstream o2 reacted.

Today I connected my laptop with a K+DCAN cable, and started playing around with BMW's oem software INPA. It's not very user friendly, but I found the same values here as in Scanmaster ELM. I played around a little, and ended up resetting the fuel adaptations, to see if it made any difference. In how the engine ran. I didn't notice any difference, no roughness at idle or at higher rpms. I then switched to Scanmaster again, because it's easier to use and has graphing view. Today I did manage to save the data. Here is a screenshot of the data when the engines goes into closed loop, after I reset the fuel adaptations:

The value for fuel system status changes from 1 to 2 when the system goes into closed loop. The lambda value shows a little rich right after it goes into closed loop, but evens out quickly. Also the short term trim stays around 0. Now I revved up the engine to about 3000rpm:

Now the short term fuel trim shoots up to around 20%, then slowly comes back down again while the engine is still revved up. I then let it idle for a bit, and made another screenshot of the data:

Both fuel trims are around 0%. The downstream O2 is switching between rich and lean, but I believe that is normal. I would like to hear your opinion on what to do next. I made a list of probable causes of the lean condition, and my thoughts on them. Feel free to leave a comment to let me know what you think!

Vacuum leak:

Today the lean condition was only present at higher rpms. Yesterday the long term fuel trim was at 24%, also at idle, but today I didn't see anything in the oxygen sensor data that points to a lean condition at low rpms. I'm not sure whether to trust the long term trim data pid, because I haven't seen it change except when I reset the adaptation values. Assuming that the lean condition is not present at idle, would point away from a vacuum leak. However, since this car has variable valve lift, and therefore no throttle plate to restrict the airflow, the amount of vacuum in the intake is very limited at idle. Could the lean condition at higher rpms be the cause of a vacuum leak? I think the leak would have to be very substantial to show up at high rpms, which would cause the engine to run rough or even misfire at idle. When I pulled the oil dipstick tube to create a vacuum leak, the engine did start running rough. I could do a smoke test on the intake, but I will have to fabricate my own diy smoke machine first.

Fuel delivery:

I am not very suspicious of a fuel delivery issue, since the engine has no performance issues. Even accelerating at full throttle, the car does not show any hesitation or loss of power whatsoever.

Under reporting MAF:

I don't know the normal g/s of this engine type. 2 g/s seems a bit low at idle. At 3000rpm, the MAF reported around 8,0 g/s. Yesterday I checked in my friends car, he also has an E46 touring but with the M54B22 engine in it. In that 320i, the MAF reported 3.6 g/s at idle. Do you guys think that the MAF could be a problem? I already disassembled the air filter housing to take a closer look at it, but it didn't seem dirty. I'm also hesitant to clean it or fiddle around with it, since it's a 400 euro part.

Exhaust leak:

I have read some stories where exhaust leaks can cause lean codes. However, i would think that I would hear it if there was an exhaust leak. I already checked briefly under the car, but as far as I could see there weren't any cracks or holes in the exhaust pipe. I wasn't able to look at the exhaust manifold from underneath, since the subframe and some other components were blocking my view.

I'm very curious to hear what you guys think I should do next. I think my first move will be to do a smoke test on the intake. Maybe I should also buy a fuel pressure gauge to check the rail pressure.

Thanks in advance for helping me! Best regards from the Netherlands!

Marijn

Please Log in or Create an account to join the conversation.

5 years 1 month ago #27753

by guafa

Replied by guafa on topic BMW E46 316i P2177 Lean off idle

Hi marijn8888,

Have you seen any change in STFT at idle (and closed loop)?

That seems like LTFT just appear suddenly. My understand is you first should see any STFT increasing, which then is recorded in LTFT memory. It is possible you can't see STFT changes, because these happend while you are driving and under specific conditions (like PCM is telling you).

Have you seen any change in STFT at idle (and closed loop)?

That seems like LTFT just appear suddenly. My understand is you first should see any STFT increasing, which then is recorded in LTFT memory. It is possible you can't see STFT changes, because these happend while you are driving and under specific conditions (like PCM is telling you).

Please Log in or Create an account to join the conversation.

- marijn8888

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

5 years 1 month ago #27758

by marijn8888

Replied by marijn8888 on topic BMW E46 316i P2177 Lean off idle

At idle the STFT is fluctuating between -5% and 5%. The LTFT stays at 0%. It is best visible in the last screenshot that I posted, where the STFT is the yellow line. I agree that the LTFT may only adapt during driving conditions, or after more drive cycles. After doing some more research, I think I am going for MAF issues first. I will do a wide open throttle test tomorrow, to see if the bank 1 sensor stays lean under load.

Please Log in or Create an account to join the conversation.

5 years 1 month ago - 5 years 1 month ago #27761

by guafa

Replied by guafa on topic BMW E46 316i P2177 Lean off idle

I would say a fluctuation between +/- 5% is not enough to later store 24 - 35% in LTFT (in my experience with other cars).

I agree with you. Check fist MAF, because numbers are low. I did some calculations and i would expect at 3000 revs. A bigger number.

Use formula Pv = nRT (with your local values) and D=m/v to know the air density. Then with engine size, engine volumetric eficiency and revs, you can estimate the amount of air (g/s).

Is your engine turbocharged? If yes, numbers are very low.

I agree with you. Check fist MAF, because numbers are low. I did some calculations and i would expect at 3000 revs. A bigger number.

Use formula Pv = nRT (with your local values) and D=m/v to know the air density. Then with engine size, engine volumetric eficiency and revs, you can estimate the amount of air (g/s).

Is your engine turbocharged? If yes, numbers are very low.

Last edit: 5 years 1 month ago by guafa.

Please Log in or Create an account to join the conversation.

- marijn8888

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

5 years 1 month ago #27831

by marijn8888

Replied by marijn8888 on topic BMW E46 316i P2177 Lean off idle

All right so yesterday I got around to doing some wide open throttle tests. Here is a screenshot of the data:

It is difficult to judge the outcome, because the refresh rate of the scan tool is very low. I'm not sure if I caught the peaks in airflow with these measurements. However, what is clear in these graphs is that the engine runs very lean during these wide open throttle test. If we look at the first wot-run for instance(frame 44-50), the lambda value of sensor 1 is pegged lean. Also sensor 2 indicates lean, but with a slight delay. I think it is clear that I have a fuel delivery issue. I haven't measured the fuel pressure since I don't have a fuel pressure gauge, but I will order one.

I also did some research on the mass air flow sensor that is in this car. It is not a common hot-wire sensor, but this system uses a hot-film sensor. From what I understand, this is able to calculate airflow more accurately. I found some information on it on the Auslogic-website:

us.autologic.com/news/hot-film-mass-5-hfm5-air-flow-sensors

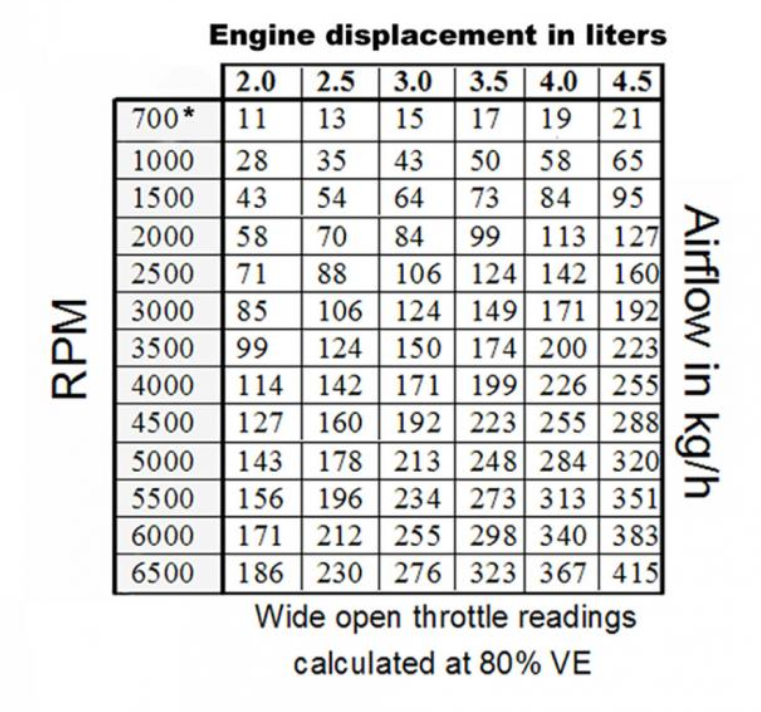

This sensor looks exactly like the one that is in my car. Does anyone know if it is possible to clean such a sensor? On this website I found the following table:

If we compare these with the values reported in my wide open throttle tests, I would think my mass air flow sensor is underreporting. According to this table, a 2.0 liter engine (mine is 1. should consume far more than 100g/s if you get above 4000rpm. In my tests however, it didn't report any value above 90 g/s. I'm very hesitant whether I should condemn this air flow sensor just yet, because I don't feel like I have done any conclusive tests. On the other hand, I don't really have the equipment to perform further diagnosis. I'm considering picking up a second hand sensor from the junkyard, to see if it makes any difference. But before I do that, does anyone have any tips on what to do next?

should consume far more than 100g/s if you get above 4000rpm. In my tests however, it didn't report any value above 90 g/s. I'm very hesitant whether I should condemn this air flow sensor just yet, because I don't feel like I have done any conclusive tests. On the other hand, I don't really have the equipment to perform further diagnosis. I'm considering picking up a second hand sensor from the junkyard, to see if it makes any difference. But before I do that, does anyone have any tips on what to do next?

It is difficult to judge the outcome, because the refresh rate of the scan tool is very low. I'm not sure if I caught the peaks in airflow with these measurements. However, what is clear in these graphs is that the engine runs very lean during these wide open throttle test. If we look at the first wot-run for instance(frame 44-50), the lambda value of sensor 1 is pegged lean. Also sensor 2 indicates lean, but with a slight delay. I think it is clear that I have a fuel delivery issue. I haven't measured the fuel pressure since I don't have a fuel pressure gauge, but I will order one.

I also did some research on the mass air flow sensor that is in this car. It is not a common hot-wire sensor, but this system uses a hot-film sensor. From what I understand, this is able to calculate airflow more accurately. I found some information on it on the Auslogic-website:

us.autologic.com/news/hot-film-mass-5-hfm5-air-flow-sensors

This sensor looks exactly like the one that is in my car. Does anyone know if it is possible to clean such a sensor? On this website I found the following table:

If we compare these with the values reported in my wide open throttle tests, I would think my mass air flow sensor is underreporting. According to this table, a 2.0 liter engine (mine is 1.

Please Log in or Create an account to join the conversation.

5 years 1 month ago #27849

by guafa

Replied by guafa on topic BMW E46 316i P2177 Lean off idle

Hi marijn,

Try to clean Maf sensor with carburetor cleaner and a soft brush (be very gently).

There is a scannerdanner video related "dirty MAF sensor case study"

Try to clean Maf sensor with carburetor cleaner and a soft brush (be very gently).

There is a scannerdanner video related "dirty MAF sensor case study"

Please Log in or Create an account to join the conversation.

5 years 1 month ago #27850

by guafa

Replied by guafa on topic BMW E46 316i P2177 Lean off idle

I would also check for a good sensor ground (ground voltage less than 100mV) and noises (transient peaks less than sensor power voltage).

Please Log in or Create an account to join the conversation.

- marijn8888

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

5 years 1 month ago #27851

by marijn8888

Replied by marijn8888 on topic BMW E46 316i P2177 Lean off idle

I took the sensor out, to see if I could clean it. This sensor is a hot film type and the actual hot film part is embedded completely into a plastic housing. Therefore I don't think it's possible to clean this style MAF's. I also read on some other forums that you can actually damage the hot film if you spray it with any kind of cleaner.

Please Log in or Create an account to join the conversation.

5 years 1 month ago #27852

by guafa

Replied by guafa on topic BMW E46 316i P2177 Lean off idle

According to sensor response you posted, the higher voltage signal, the more g/s you have. That also means you don't have any frecuency in output sensor signal.

How good at electronics are you? If you change reference sensor ground, you could expect a higher output signal.

Remember talk is cheap for me, then you have to be sure of what you are doing.

On the other hand. The idea of a second hand sensor, sounds good for me.

How good at electronics are you? If you change reference sensor ground, you could expect a higher output signal.

Remember talk is cheap for me, then you have to be sure of what you are doing.

On the other hand. The idea of a second hand sensor, sounds good for me.

Please Log in or Create an account to join the conversation.

Time to create page: 0.244 seconds