Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

2023 Silverado 2.7L Turbo with a misfire P0300 and P050D

- brianmstoltzfus

-

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 4

3 months 6 days ago #92278

by brianmstoltzfus

2023 Silverado 2.7L Turbo with a misfire P0300 and P050D was created by brianmstoltzfus

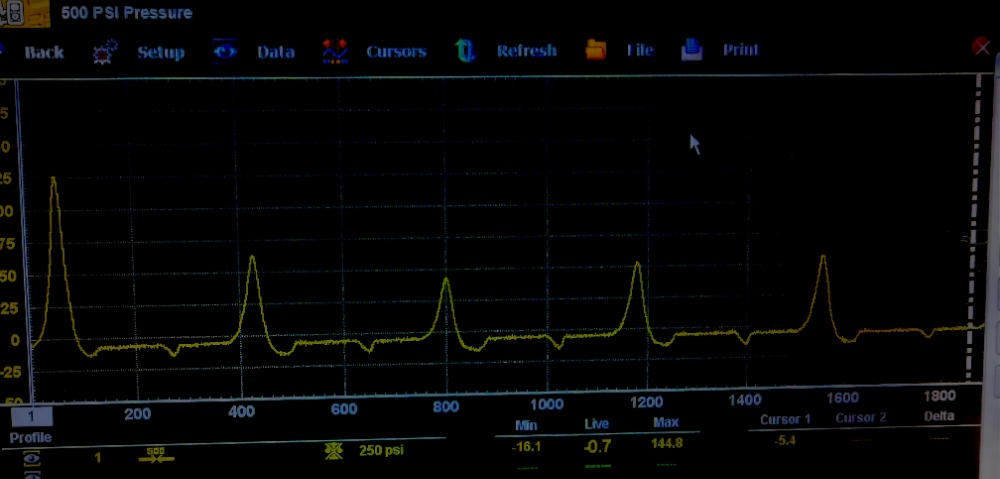

Hi I have this 23 Silverado with a 2.7L in my shop. It has 128000 miles and came in with P0300 and P050D. Cyl 2 is misfiring steadily but not quite a complete miss. The check engine light was not flashing. Relative compression test showed cyl 2 has low compression at least every few engine rotations. Leak-down is only 8% at TDC and 100 psi. Attached are the compression waveforms while cranking. One is zoomed out and the other is closer. I am not familiar enough with compression waveforms to look at this and know exactly what the problem is but what I did notice is the pattern of high then low compression continues to repeat itself but is not completely identical. This engine is equipped with sliding camshaft valve lift. Any help is appreciated! Thanks.

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

Less

More

- Posts: 2129

- Thank you received: 715

3 months 6 days ago #92279

by Chad

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Replied by Chad on topic 2023 Silverado 2.7L Turbo with a misfire P0300 and P050D

That compression pattern makes me suspect a valve sealing issue.

Valves spin/rotate, a little bit, as they open and close. This pattern makes me think that there is a carbon build-up, or some other valve to valve-seat surface-to-surface sealing issue with one of the valves. As the valve rotates, the mating surface with the valve and valve-seat is changing. The repeating pattern is the valve completing a 360° rotation, sealing well in some strokes, rotating a bit and not sealing so well in other strokes, then completing a revolution and sealing well, again.

If you have a pulse sensor, watch for the same "roller-coaster" pattern the intake and exhaust as you crank.

An articulating bore-scope/inspection camera inserted into the cylinder through the spark plug hole might reveal some texture on the valve seats.

Valves spin/rotate, a little bit, as they open and close. This pattern makes me think that there is a carbon build-up, or some other valve to valve-seat surface-to-surface sealing issue with one of the valves. As the valve rotates, the mating surface with the valve and valve-seat is changing. The repeating pattern is the valve completing a 360° rotation, sealing well in some strokes, rotating a bit and not sealing so well in other strokes, then completing a revolution and sealing well, again.

If you have a pulse sensor, watch for the same "roller-coaster" pattern the intake and exhaust as you crank.

An articulating bore-scope/inspection camera inserted into the cylinder through the spark plug hole might reveal some texture on the valve seats.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

Less

More

- Posts: 6063

- Thank you received: 1531

3 months 4 days ago #92285

by Tyler

Replied by Tyler on topic 2023 Silverado 2.7L Turbo with a misfire P0300 and P050D

Heads up, PIP5847B may help:

static.nhtsa.gov/odi/tsbs/2023/MC-10247363-9999.pdf

Thank you for posting the compression waveform. I'm going to (cautiously) disagree with Chad and say that there's a valve lift issue, not a sealing issue. I find that this 'dip' after where the intake valve should have opened is often an indication of an intake lift/duration problem. Cam lobe, follower, lifter, whatever. Could be wrong - I've never seen an in-cylinder on an engine with the sliding camshaft system.

May be time to take an oil sample, pull the oil filter and see how much metal is floating around in the engine...

static.nhtsa.gov/odi/tsbs/2023/MC-10247363-9999.pdf

Thank you for posting the compression waveform. I'm going to (cautiously) disagree with Chad and say that there's a valve lift issue, not a sealing issue. I find that this 'dip' after where the intake valve should have opened is often an indication of an intake lift/duration problem. Cam lobe, follower, lifter, whatever. Could be wrong - I've never seen an in-cylinder on an engine with the sliding camshaft system.

May be time to take an oil sample, pull the oil filter and see how much metal is floating around in the engine...

The following user(s) said Thank You: Chad

Please Log in or Create an account to join the conversation.

Time to create page: 0.268 seconds