*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

GM EVAP vent solenoid

- superfragl

-

Topic Author

- Offline

- New Member

-

- Posts: 4

- Thank you received: 4

Trying to understand what`s wrong here..

2003 Chevy Silverado 1500 4.3.

Recently had CEL on with code P0446.

Hooked up HPTuners and did a few observations:

- Fuel tank pressure sensor works. 1.3V initial, if I open the purge valve it goes up.

- Previous item tells me that Purge valve works as well.

- Evap vent valve is showing always as Closed??? Turn ignition on, start engine - no change - still shows closed.

If I run a command to open the vent valve - it starts showing as Open, but I see no change in pressure. I hear the valve click, however.

When I drive, the tank pressure sensor voltage can go as high as 3.8V.

I opened the purge valve at idle and built some vacuum in the EVAP system, then I closed the purge valve and opened Vent valve and nothing happened - the vacuum was still there... Which tells that the vent valve is stuck closed, or the tube is clogged, but what confuses me is that the valve is showing closed all the time...

What do you folks think?

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6039

- Thank you received: 1518

Before we go too far, would you mind rechecking that Fuel Tank Pressure sensor reading? With no vacuum or pressure present, the PID should show 1.5V or near enough. Just want to make darn sure you're not looking at a skewed sensor.

I see this code very often in my area, with GM trucks that spend the majority of their lives on dirt roads. The P0446 code description can vary depending on the scanner, but I've always seen something along the lines of "Vent System Performance". This bit of testing you did right here was crucial:

I opened the purge valve at idle and built some vacuum in the EVAP system, then I closed the purge valve and opened Vent valve and nothing happened - the vacuum was still there...

It's possible that the vent valve is stuck closed, but it's even more likely that you're looking at a restriction in either the charcoal canister or the vent valve tubing. Either one will prevent the vent system from breathing correctly, hence the code. Known good systems can relieve the vacuum in a system almost instantly.

The way to tell if you have a canister or vent problem is simple. Find the charcoal canister, and disconnect the large hose that goes from the canister to the vent valve. Start the engine and open the purge valve wide open while watching the FTP sensor. If you can achieve more than 1" of water, there's still a restriction. If you can't, the problem lies in the vent valve or it's tubing. While you have the vent tube off, look in the tube for dirt/debris. If there's a noticeable amount of dirt, it's likely the charcoal canister has inhaled too much of it.

This problem is so common, GM has a TSB for it. Note the 'I' in the TSB#. That means it's been revised nine times. :lol:

Hooked up HPTuners and did a few observations:

I'm not familiar with HPTuners - can you post some screenshots? If it's doing bidirectional testing, then it's obviously capable.

Please Log in or Create an account to join the conversation.

- superfragl

-

Topic Author

- Offline

- New Member

-

- Posts: 4

- Thank you received: 4

I rechecked the log file and looks like the initial FTP vas 1.4 V and when I shut off the engine it slowly returned to that value, so looks like the FTP sensor is working properly.

I agree that most likely there is a restriction in the vent valve related components. What got me confused is that the vent valve always shows CLOSED, even though its default state should be open. Whether it is closed or not - I do not know, but I will confirm it. I plan on checking the EVAP system this weekend - I will pull the vent valve and operate it out of the vehicle.

HPTuners has two components - PCM editor (edits all parameter, like ignition tables, fuel tables, transmission shift points, etc.) and Scanner (this is where you can read live data and send special commands). It is fully customizable.

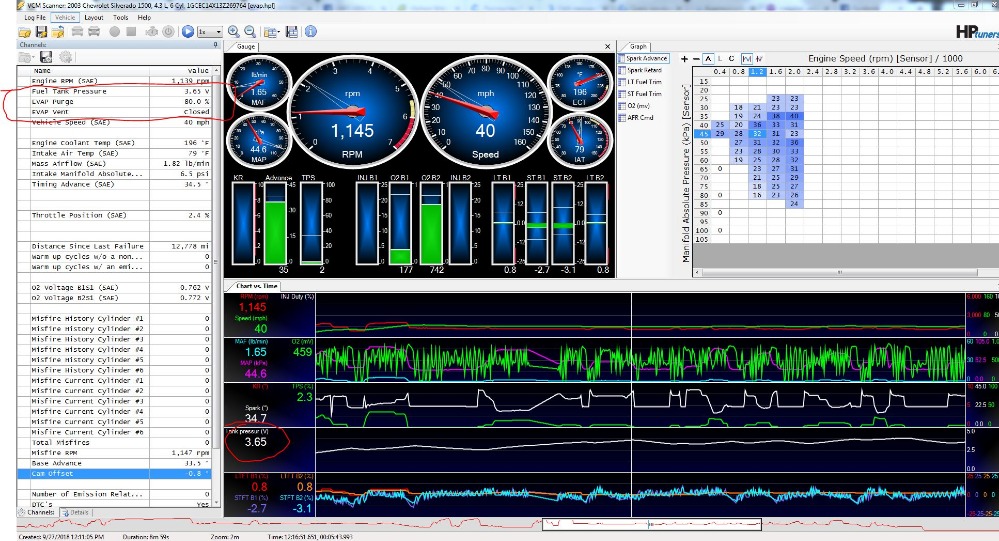

On the screenshot below I highlighted the data I have added for EVAP testing, I also added the TPS chart on the right bottom side.

Please Log in or Create an account to join the conversation.

- Bealio

-

- Offline

- New Member

-

- Posts: 3

- Thank you received: 1

Is the scanner software bugging out and somehow commanding the PCM to energize the vent coils ALL the time?

PCM provides the ground for the vent valve. Use a multi-meter or test light and see If you detect a ground on the white wire with scanner software connected. How about with the scanner software disconnected?

Please Log in or Create an account to join the conversation.

- superfragl

-

Topic Author

- Offline

- New Member

-

- Posts: 4

- Thank you received: 4

I will test for ground this weekend and will report back. Thanks!

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6039

- Thank you received: 1518

Definitely let us know what you find!

Please Log in or Create an account to join the conversation.

- superfragl

-

Topic Author

- Offline

- New Member

-

- Posts: 4

- Thank you received: 4

First of all, the vent solenoid being closed all the time was just the incorrect interpretation by software (I already submitted the bug to tech support). It was actually open all the time and I confirmed this with test light.

Next I took off the vent valve and found it to be sticking in closed position.

And last - I checked the air flow through the vapor canister and and I felt like it is somewhat restricted. With the vent valve off, engine running and purge valve open - there was still vacuum building up in the system. I was not sure if it is normal or not so I went to the autoparts store and asked to take a look at the new canister - I tried blowing air into vent port and there was no restriction at all.

After replacing the canister and the vent valve everything works the way it is supposed to - once I open the vent valve - the pressure drops to atmospheric within a few seconds. If I purge the air and seal the system - the vacuum stays there and the value does not change at all.

Thank you all for your help!

Very nice forum and very nice folks!

Please Log in or Create an account to join the conversation.

- John Clark

-

- Offline

- Premium Member

-

- Posts: 139

- Thank you received: 46

I recently had a 2001 Tahoe 5.3 with an evap leak code. With the smoke machine I quickly found a leaky hose at a hose clamp and repaired the leak. However, during my troubleshooting I found that when I filled the system with smoke (using a Redline Smoke Pro) that the vent valve would not open with the scan tool. If I let the pressure out of the system it would open. If the vent valve was open I could easily close it and pressurize the system but it wouldn't open until first depressurized. Since these vent valves fail all the time I recommended replacing the valve, which I did. However, I found the same thing with the new valve.

Is this normal when testing these GM vent valves with a smoke machine? The very low pressure of the smoke machine is enough to prevent proper opening of the valve?

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6039

- Thank you received: 1518

superfragl wrote: After replacing the canister and the vent valve everything works the way it is supposed to - once I open the vent valve - the pressure drops to atmospheric within a few seconds. If I purge the air and seal the system - the vacuum stays there and the value does not change at all.

Thank you all for your help!

Very nice forum and very nice folks!

Nice.

Just for my info, with the vent valve open and the purge valve wide open, how much vacuum can you generate in the tank? Mostly interested to see if my 1" of water rule holds true.

John Clark wrote: Is this normal when testing these GM vent valves with a smoke machine? The very low pressure of the smoke machine is enough to prevent proper opening of the valve?

I can't say I've run into that.

Which scan tool were you using? I have run into issues with my Modis Ultra when running the Purge/Seal functional test. It'll purge, it'll seal, but it won't open the vent valve again until I exit the test. :silly: If you were using the vent valve function by itself, then disregard.

Please Log in or Create an account to join the conversation.

- John Clark

-

- Offline

- Premium Member

-

- Posts: 139

- Thank you received: 46

Tyler wrote:

John Clark wrote: Is this normal when testing these GM vent valves with a smoke machine? The very low pressure of the smoke machine is enough to prevent proper opening of the valve?

I can't say I've run into that.As far as I can remember, I've always been able to release smoke machine pressure with the vent valve. I thought about a vent valve installed backwards, but I don't think that's possible on this design.

Which scan tool were you using? I have run into issues with my Modis Ultra when running the Purge/Seal functional test. It'll purge, it'll seal, but it won't open the vent valve again until I exit the test. :silly: If you were using the vent valve function by itself, then disregard.

I was using the Autel DS708. I don't recall if I was using the purge and seal menu...I'm pretty sure I was just using the vent valve control only. I've used the purge and seal menu on the Autel and it has always worked normally on GM. It was showing open and close on the tool but it wouldn't let the smoke out until I let the pressure off of it. It was quite odd and I've not seen anyone talk about it anywhere. The truck hasn't been back since (been a few months) so it's obviously working normally.

Please Log in or Create an account to join the conversation.