Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

[FIXED] 1996 Jeep 4.0L Misfire, Engine Cut, Stalling, Tach Bounces. Case Study

- graywave

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Adv. Diagnostics New Hampshire

Less

More

- Posts: 302

- Thank you received: 79

6 years 11 months ago - 6 years 11 months ago #23343

by graywave

Confirm what it's not, and fix what it is!

[FIXED] 1996 Jeep 4.0L Misfire, Engine Cut, Stalling, Tach Bounces. Case Study was created by graywave

Hi Guys,

First...YES this is confirmed repaired. haha, I learned my lesson on the sprinter van I posted about.

Vehicle. 1996 Jeep Grand Cherokee 4.0L (146K Miles)

Symptoms

Runs like CRAP. There ya have it fellas.

- Misfires

- Engine Cut out

- Stalling

- Backfiring in exhaust

- Tachometer bounces and reads much higher at times when engine speed decreases in rpm. Gets ya thinking.

- Problem happens regardless of throttle

Parts cannon was shot at this by the shop I work at. The original diagnosis by another tech was a bad crank position sensor

1. Crank Sensor

2. Cam Sensor

3. Distributor

4. Ignition Coil

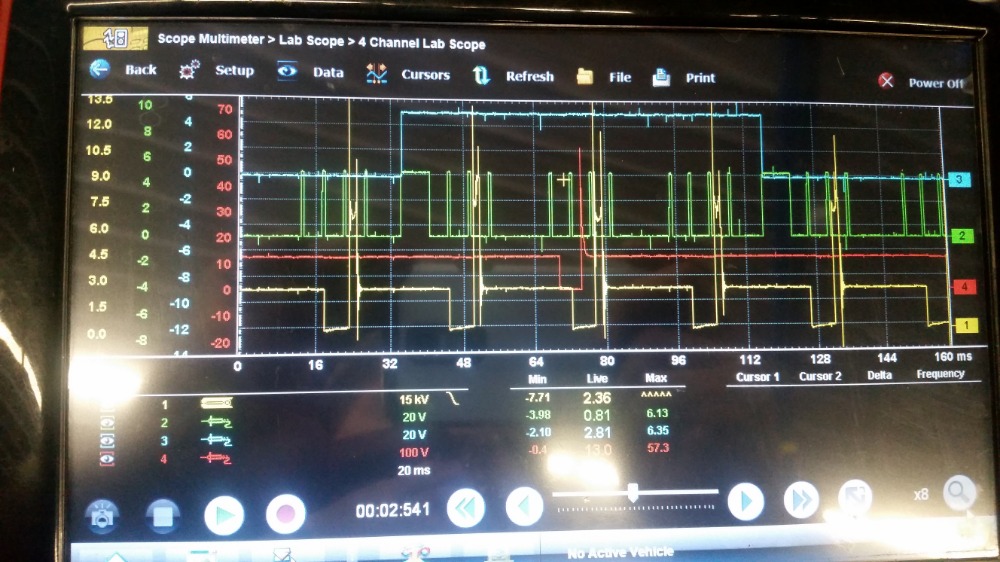

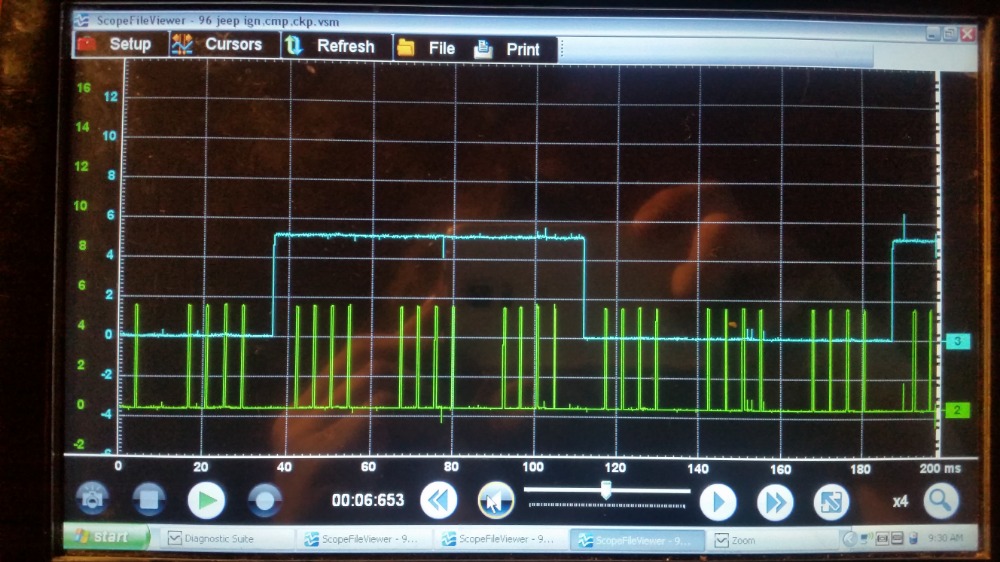

After couple weeks they asked me to look at it finally. My first thought was to grab, Crank, Cam, #1 Inj and Ignition Coil Primary so I could see what this engine is doing and how the PCM is controlling everything. Looking at PCM Inputs and Outputs at the same time. So thats what I did. Here is what I saw after a few minutes. This confirmed diagnosis took 10 minutes to point me at the tone ring on the back of the flywheel.

Note the large square wave in the crank signal (Green)

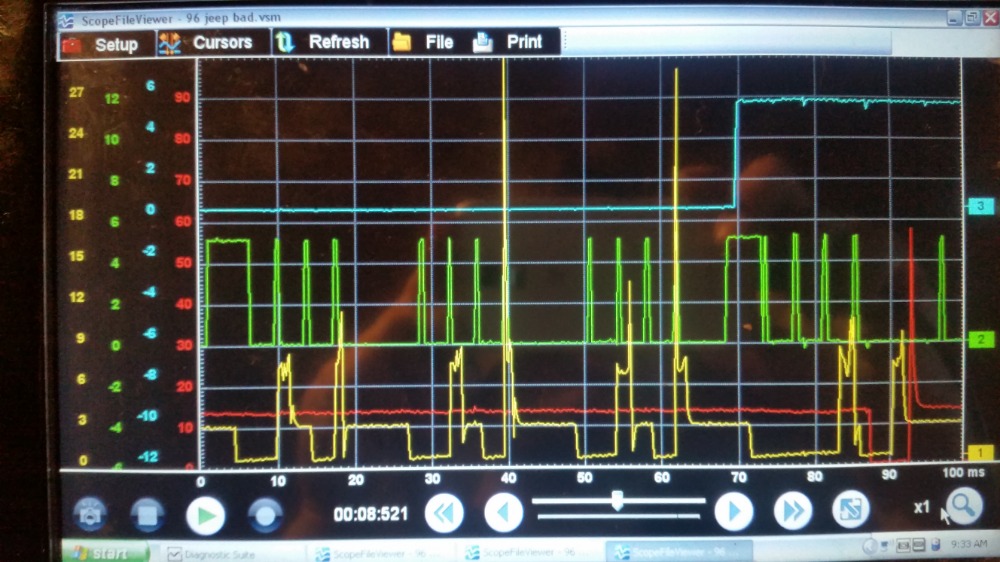

After the vehicle got warm the PCM started firing the coil during times it never should have and started firing the injectors at the wrong times. This started happening after the large sqaure wave would break into 2 square waves so there would now be 5 square waves.

Some more pictures

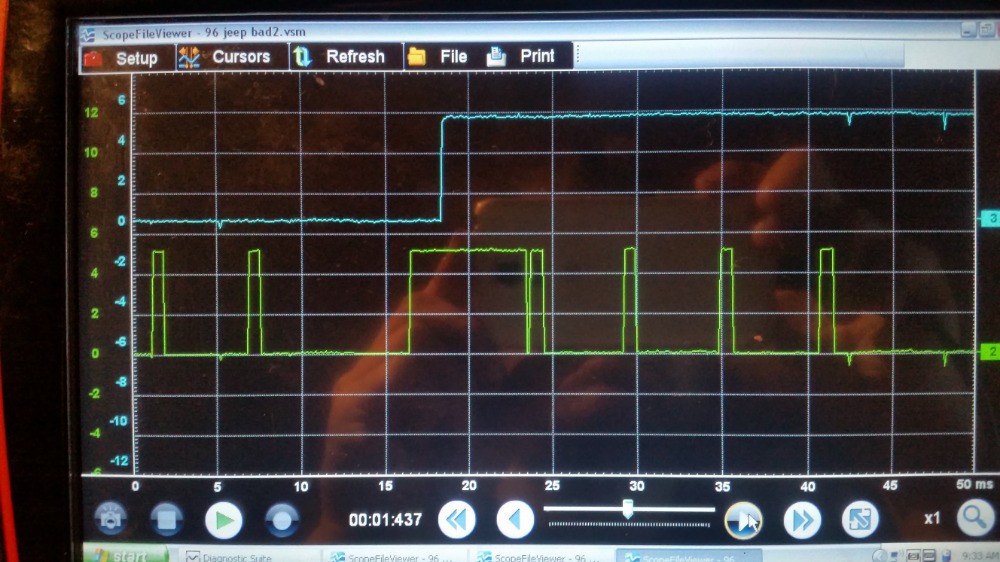

I was able to use the Oscilloscope to find the EXACT location on this tone ring that the crank sensor was having a hard time picking up and mark it with a marker. By eye, it looked fine but I bet had I use a dial indicator, I bet it was slightly out of round and was to far away from the crank sensor for any "Aftermarket" crank sensor to read. Basically during an "all metal no window" portion of this tone ring which the crank sensor should have pulled this signal down to ground, the ckp sensor did not....the magnet was not strong enough to react to the metal area so as far as the PCM was concerned, there was a really large window.

If I loosened the crank sensor and pushed down on it to get it closer to the flywheel, while the flywheel was in that correct position, I could get that crank sensor to trigger and pull the 5v ref signal to ground. Unfortunately just pushing down on the crank sensor and tightening the bolt was not the fix.

After arguing with the boss about it, he insisted it was the PCM still and that my diagnosis was wrong so he made a case with Identifix and they told him the same thing. Though only to suggest using a factory sensor. I had thought about that but also though the original sensor which was removed was factory and I push the idea to the side and was suggesting to replace the flywheel.

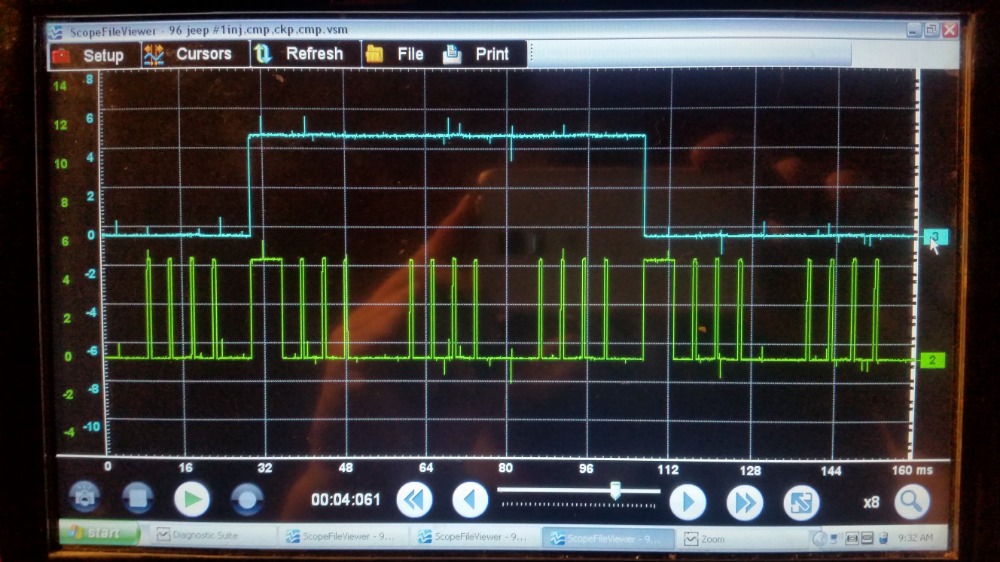

The Fix was replacing the aftermarket crank sensor with a Factory OEM crank sensor. If that didn't cure it, we would have needed to replace the flywheel.

Crank & Cam waveform after sensor replacement.

First...YES this is confirmed repaired. haha, I learned my lesson on the sprinter van I posted about.

Vehicle. 1996 Jeep Grand Cherokee 4.0L (146K Miles)

Symptoms

Runs like CRAP. There ya have it fellas.

- Misfires

- Engine Cut out

- Stalling

- Backfiring in exhaust

- Tachometer bounces and reads much higher at times when engine speed decreases in rpm. Gets ya thinking.

- Problem happens regardless of throttle

Parts cannon was shot at this by the shop I work at. The original diagnosis by another tech was a bad crank position sensor

1. Crank Sensor

2. Cam Sensor

3. Distributor

4. Ignition Coil

After couple weeks they asked me to look at it finally. My first thought was to grab, Crank, Cam, #1 Inj and Ignition Coil Primary so I could see what this engine is doing and how the PCM is controlling everything. Looking at PCM Inputs and Outputs at the same time. So thats what I did. Here is what I saw after a few minutes. This confirmed diagnosis took 10 minutes to point me at the tone ring on the back of the flywheel.

Note the large square wave in the crank signal (Green)

After the vehicle got warm the PCM started firing the coil during times it never should have and started firing the injectors at the wrong times. This started happening after the large sqaure wave would break into 2 square waves so there would now be 5 square waves.

Some more pictures

I was able to use the Oscilloscope to find the EXACT location on this tone ring that the crank sensor was having a hard time picking up and mark it with a marker. By eye, it looked fine but I bet had I use a dial indicator, I bet it was slightly out of round and was to far away from the crank sensor for any "Aftermarket" crank sensor to read. Basically during an "all metal no window" portion of this tone ring which the crank sensor should have pulled this signal down to ground, the ckp sensor did not....the magnet was not strong enough to react to the metal area so as far as the PCM was concerned, there was a really large window.

If I loosened the crank sensor and pushed down on it to get it closer to the flywheel, while the flywheel was in that correct position, I could get that crank sensor to trigger and pull the 5v ref signal to ground. Unfortunately just pushing down on the crank sensor and tightening the bolt was not the fix.

After arguing with the boss about it, he insisted it was the PCM still and that my diagnosis was wrong so he made a case with Identifix and they told him the same thing. Though only to suggest using a factory sensor. I had thought about that but also though the original sensor which was removed was factory and I push the idea to the side and was suggesting to replace the flywheel.

The Fix was replacing the aftermarket crank sensor with a Factory OEM crank sensor. If that didn't cure it, we would have needed to replace the flywheel.

Crank & Cam waveform after sensor replacement.

Confirm what it's not, and fix what it is!

Last edit: 6 years 11 months ago by graywave.

The following user(s) said Thank You: Noah, goldwing2000

Please Log in or Create an account to join the conversation.

Time to create page: 0.301 seconds