2002 Chevy Trailblazer 4.2L: Lean to Rich Sensor Threshold Voltage (Constant)

- frankiep77

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

Problem 1: Sometimes after it is warmed up, when I come to a stop, the idle drops but it usually catches itself. Occasionally it will stall. I notice this more when I go from drive to reverse to back into my driveway.

Problem 2: Within the past month or so, I am smelling gas fumes.

Problem 3: I am noticing it cranking a little more to start.

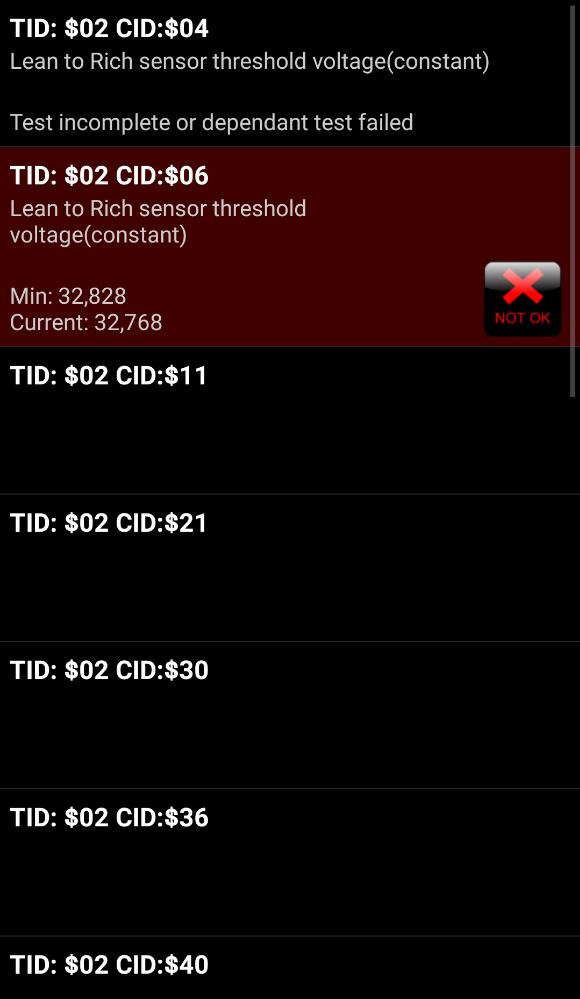

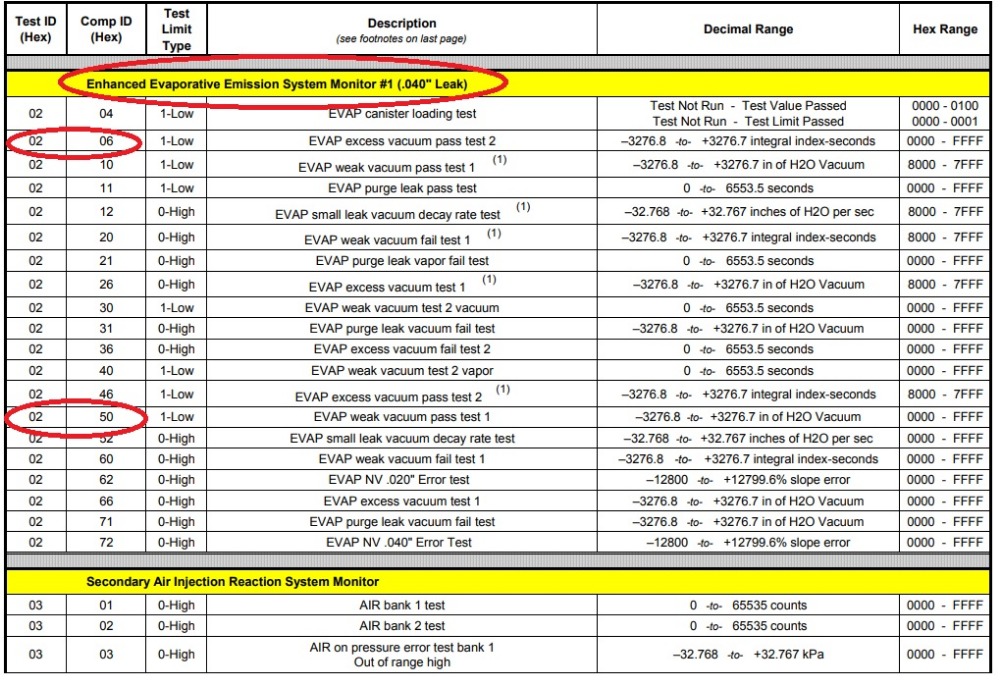

Problem 4: TID: $02 CID: $06 Lean to Rich sensor threshold voltage (constant)

Problem 5: TID: $02 CID: $50 Lean to Rich sensor threshold voltage (constant)

I inspected for vacuum leaks to no avail. I did check my fuel pressure and it was within spec 48-54 psi. The fuel pressure regulator has a hose connected to the air resonator. I do not notice any vacuum from this port. My understanding of the fuel pressure regulator function is at idle there should be more vacuum applied to the regulator so that the diaphragm allows less restriction for return. When I manually apply vacuum to the regulator, the measured fuel pressure drops so I assume the fuel pressure regulator is working properly even though there is no noticeable vacuum applied.

The CEL is not active with any codes. I am hoping these are all related to the same fix. Attached are some screen shots I gathered from Torque Pro. Any help would be greatly appreciated.

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2137

- Thank you received: 718

frankiep77 wrote: The fuel pressure regulator has a hose connected to the air resonator. I do not notice any vacuum from this port................My understanding of the fuel pressure regulator function is at idle there should be more vacuum applied to the regulator so that the diaphragm allows less restriction for return. When I manually apply vacuum to the regulator, the measured fuel pressure drops so I assume the fuel pressure regulator is working properly even though there is no noticeable vacuum applied.

Make sure the hose is connected to a vacuum source.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- graywave

-

- Offline

- Elite Member

-

- Adv. Diagnostics New Hampshire

- Posts: 302

- Thank you received: 80

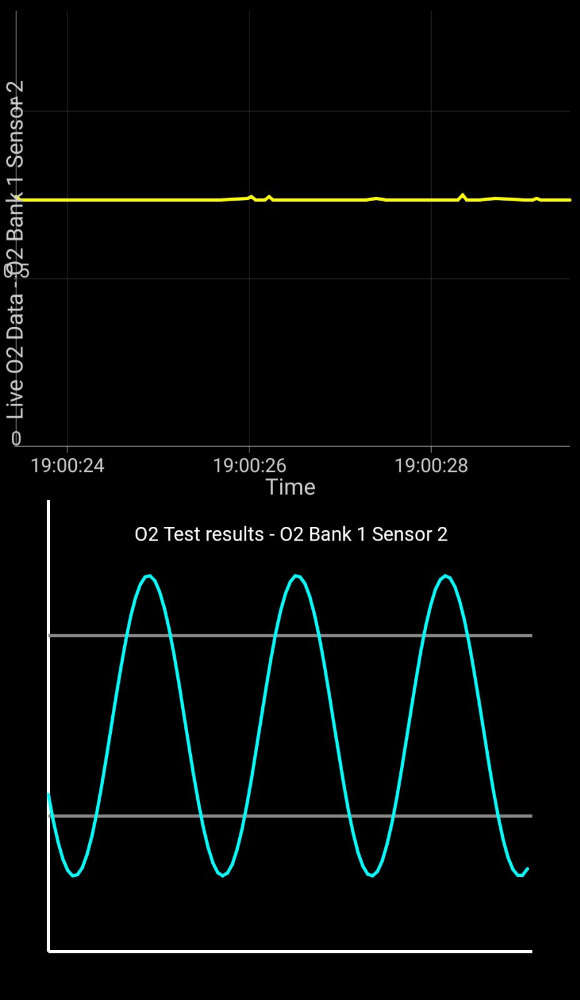

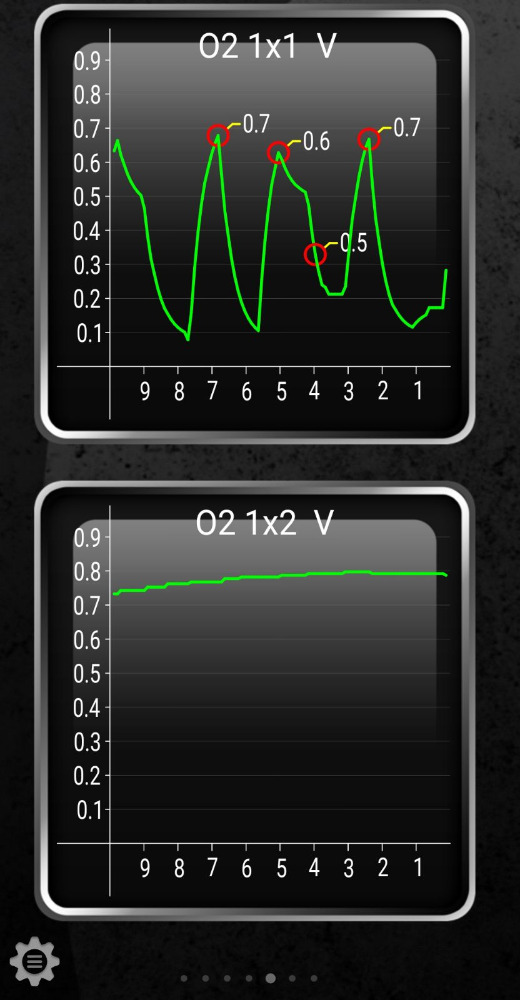

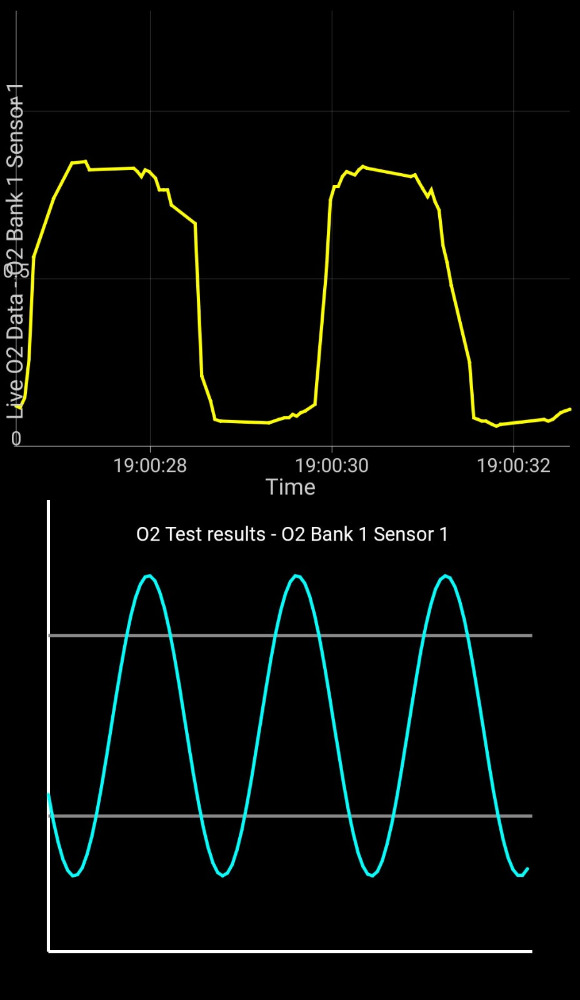

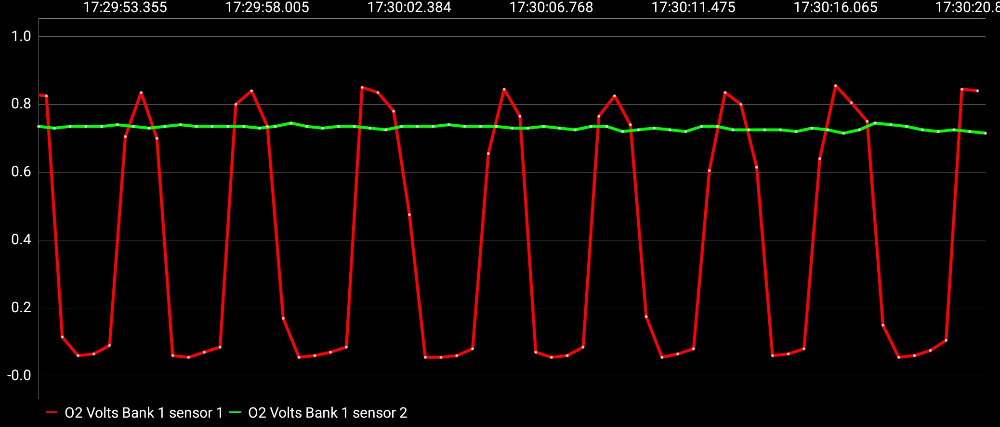

you will see sensor 2 dance around when your on and off the throttle. Sensor 1 should switch from around .1 or 100mv to .8 or 800mv. The high and low point is different from one sensor to another. Some will go as low as 10mv and as high as 950mv. Some will go as low as 150mv to 780mv. All depends on the sensor, the manufacture and other variables we won't know. As long as its switching from low to high usually indicates a functional sensor. There are variables to that such as the sensor switching to slow.

Those blue AC Sine wave looking waveforms you posted are only in a perfect magical world where everything is perfect. You won't see perfect AC Sine looking waveforms like that from an o2 sensor. Its fairly rare. Some do some don't

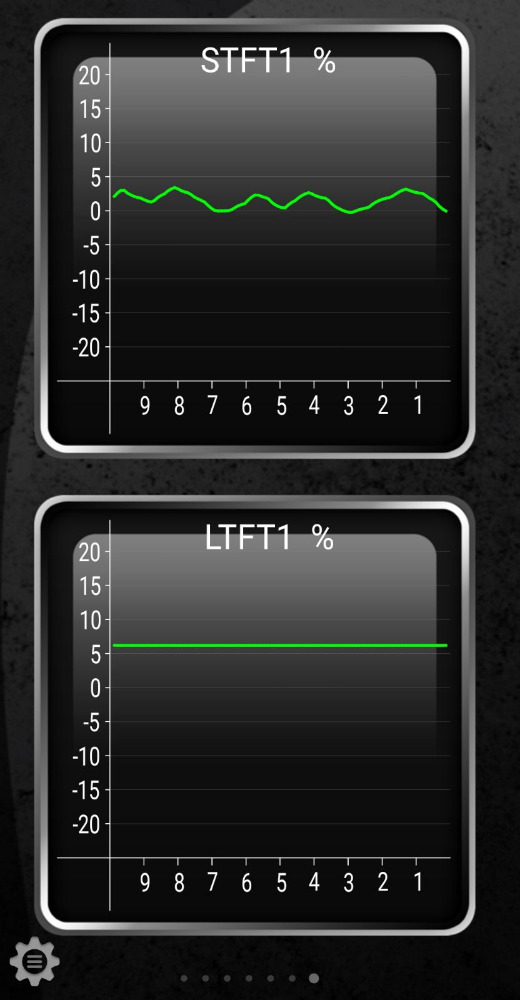

Those fuel trims look good too if those are at idle. Looks like its adding from 6-10% fuel. I usually like seeing less than 6% total but they say 10% and under is OK. Some PCMs won't trigger fuel trim related codes until they reach 30%! Is there only 1 upstream sensor on these engines?

Confirm what it's not, and fix what it is!

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6073

- Thank you received: 1535

Problem 2: Within the past month or so, I am smelling gas fumes.

Problem 3: I am noticing it cranking a little more to start.

Wondering if these are related. :blink: Maybe do a visual inspection on the fuel tank and lines, if you haven't already.

If you've still got the fuel pressure tester available, maybe watch the key off pressure after idling? Looking for an excessive rate of drop. ALL systems will depressurize after long enough, but a leaking check valve will be evident. That'd account for the long-er crank time.

Problem 4: TID: $02 CID: $06 Lean to Rich sensor threshold voltage (constant)

Problem 5: TID: $02 CID: $50 Lean to Rich sensor threshold voltage (constant)

Did these tests fail, or have yet to run? Does the O2 Sensor monitor show complete?

Please Log in or Create an account to join the conversation.

- frankiep77

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

I was thinking the same thing but this is the original design. Shouldn't there be vacuum at this port on the resonator at idle?

Please Log in or Create an account to join the conversation.

- chief eaglebear

-

- Offline

- Platinum Member

-

- Posts: 334

- Thank you received: 70

Please Log in or Create an account to join the conversation.

- frankiep77

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

graywave wrote: At a quick glimps your O2s are working. Sensor 2 should be a constant voltage at idle above .7v or over 700mv. Little less can be had without issues, such as 600mv but less than that and you possibly run into cat performance issues.

you will see sensor 2 dance around when your on and off the throttle. Sensor 1 should switch from around .1 or 100mv to .8 or 800mv. The high and low point is different from one sensor to another. Some will go as low as 10mv and as high as 950mv. Some will go as low as 150mv to 780mv. All depends on the sensor, the manufacture and other variables we won't know. As long as its switching from low to high usually indicates a functional sensor. There are variables to that such as the sensor switching to slow.

Those blue AC Sine wave looking waveforms you posted are only in a perfect magical world where everything is perfect. You won't see perfect AC Sine looking waveforms like that from an o2 sensor. Its fairly rare. Some do some don't

Those fuel trims look good too if those are at idle. Looks like its adding from 6-10% fuel. I usually like seeing less than 6% total but they say 10% and under is OK. Some PCMs won't trigger fuel trim related codes until they reach 30%! Is there only 1 upstream sensor on these engines?

Yes, I believe those perfect blue sine waves are an example that Torque Pro gives for comparison to the actual. A better scan tool with faster response time might produce smoother results but these provide the general idea. This engine is an inline 6 with only one upstream sensor.

Attached are screenshots I took today at idle. Still learning how to use this Torgue Pro App but the graphs are pretty consistent with what I submitted previously. I wasn't sure if those were taken at idle.

Please Log in or Create an account to join the conversation.

- frankiep77

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

Tyler wrote:

Problem 2: Within the past month or so, I am smelling gas fumes.

Problem 3: I am noticing it cranking a little more to start.

Wondering if these are related. :blink: Maybe do a visual inspection on the fuel tank and lines, if you haven't already.

If you've still got the fuel pressure tester available, maybe watch the key off pressure after idling? Looking for an excessive rate of drop. ALL systems will depressurize after long enough, but a leaking check valve will be evident. That'd account for the long-er crank time.

Problem 4: TID: $02 CID: $06 Lean to Rich sensor threshold voltage (constant)

Problem 5: TID: $02 CID: $50 Lean to Rich sensor threshold voltage (constant)

Did these tests fail, or have yet to run? Does the O2 Sensor monitor show complete?

I will crawl under this weekend and give another visual as I retest the pressure looking for the excessive rate of drop as you suggested.

Attached are the screenshots of the test results.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6073

- Thank you received: 1535

gsi.ext.gm.com/gmspo/mode6/pdf/GM%20Clas...0data%20final_dm.pdf

The TID descriptions in Torque are wrong.

Please Log in or Create an account to join the conversation.

- frankiep77

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- frankiep77

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

Static pressure, pre-start with key on: 46 psi

Running at idle with and then without the fuel pressure regulator hose connected to the air resonator: 52 psi unchanged

With the fuel pressure regulator hose connected to the test vacuum port (which is -19 psi at idle): 44 psi

Attached is a graph of the fuel pressure vs. time after shutdown.

It loses about 4 psi over the first 8 minutes then has a much steeper decline over the next 16 minutes. How long should the pressure hold?

Please Log in or Create an account to join the conversation.

- Cbj

-

- Offline

- New Member

-

- Posts: 1

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- frankiep77

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 1

Still troubleshooting the rpm drop issue. Recently my alternator failed so I thought that might have been the issue but after the new one was installed, I still have the same problem. The engine bogs down at idle when there is a severe power draw or when the power steering is stressed. I've cleaned the throttle body several times to no avail. I am wondering if I have a bad ground or the throttle body is just on it's way out. Occasionally I notice the rpm drop when coming to a stop also so could be vacuum related also.

Please Log in or Create an account to join the conversation.