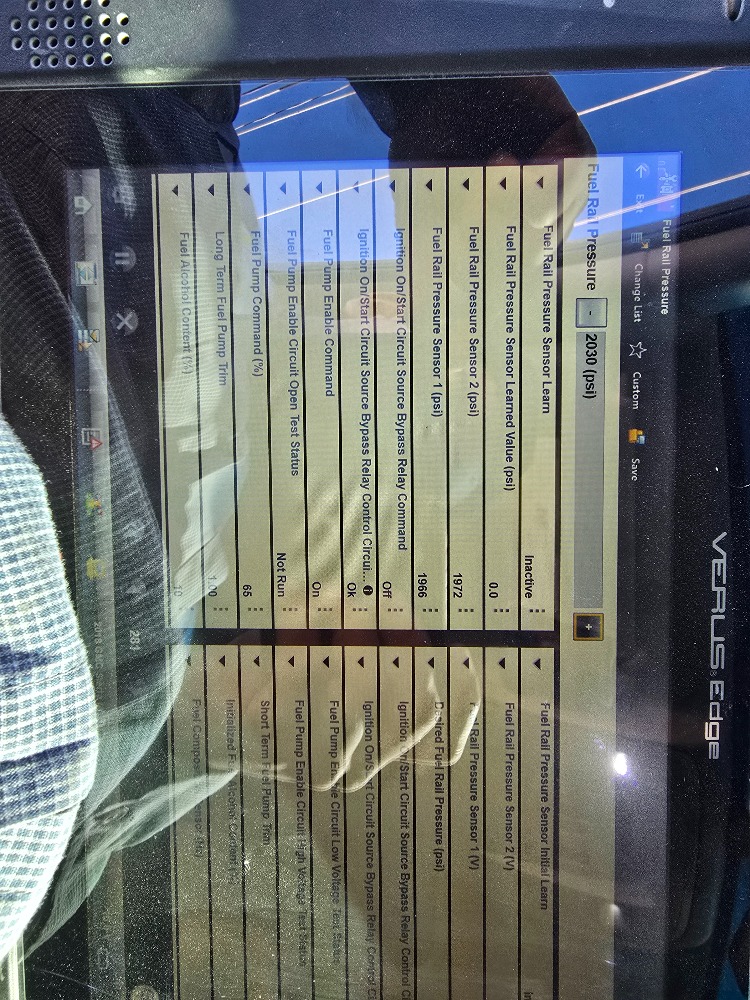

2018 GMC Sierra Wont read fuel rail pressure sensor signal

- Christian9000

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- ferris48

-

- Offline

- Premium Member

-

- Posts: 129

- Thank you received: 47

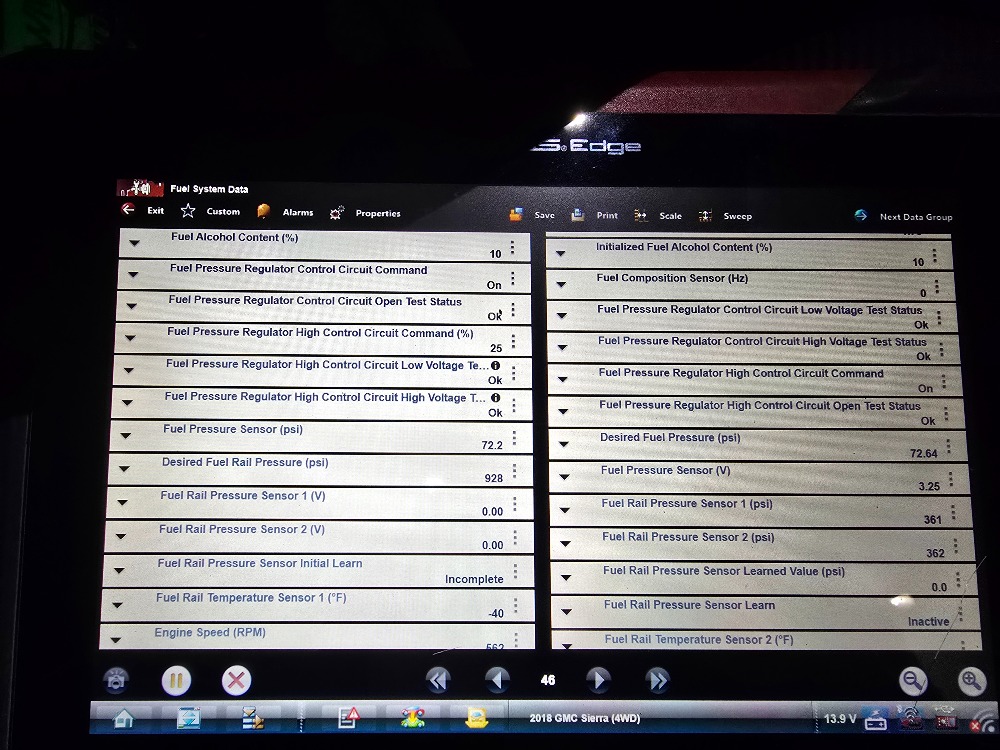

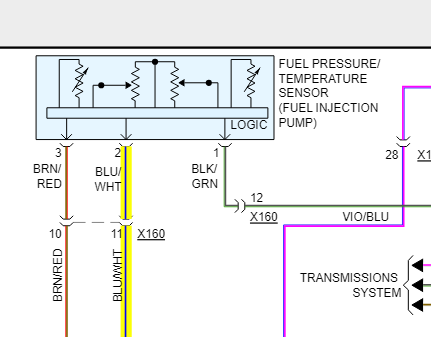

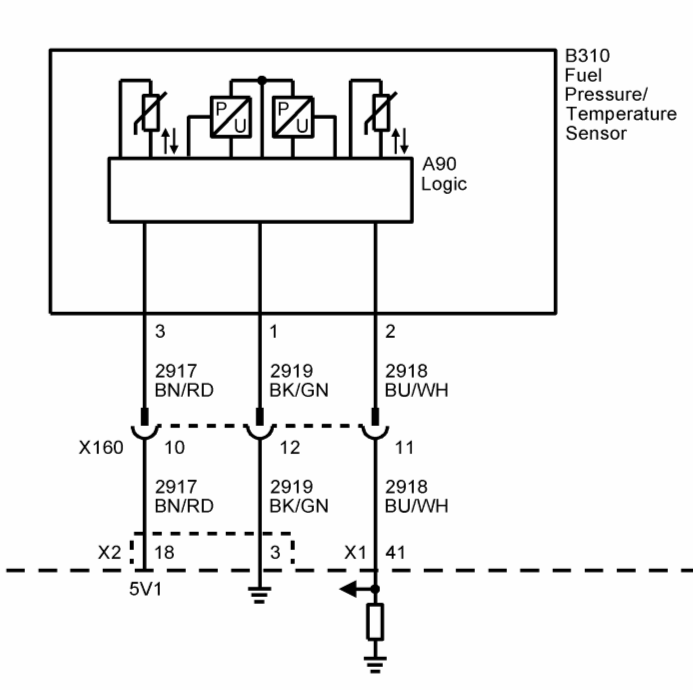

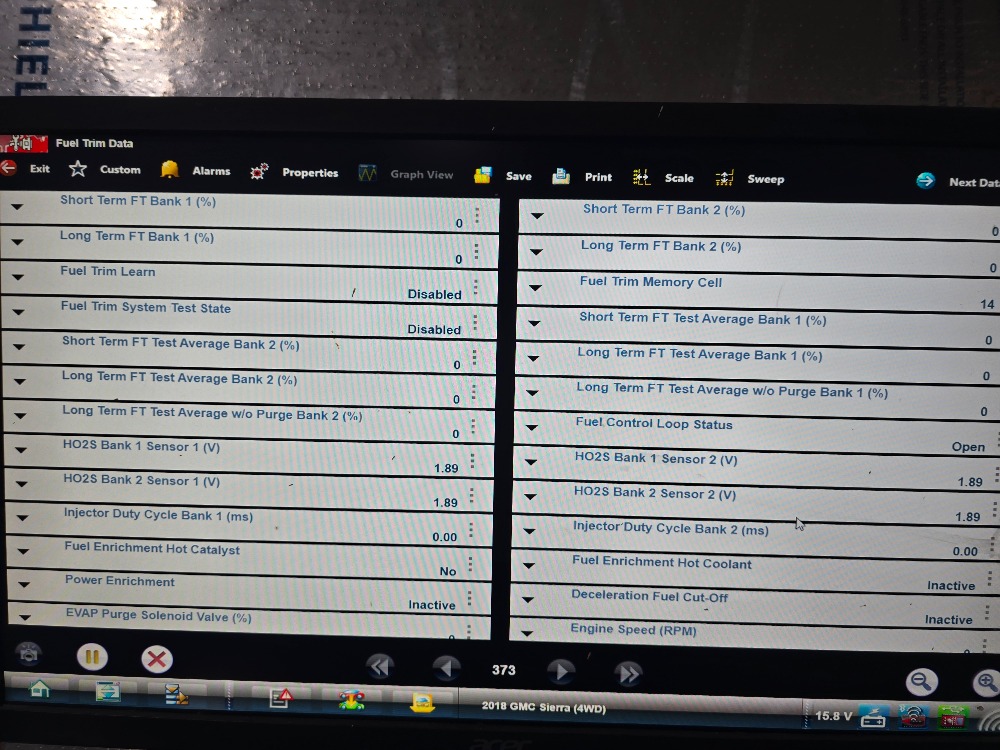

Identifix testing procedure states the signal wire should have 5 volts with it disconnected.The fuel rail pressure sensor transmits fuel pressure and temperature information by serial data using the Society of Automotive Engineers (SAE) J2716 Single Edge Nibble Transmission (SENT) protocol. The fuel rail pressure sensor internal microprocessor allows 4 separate sensor outputs from one 3 wire sensor. The ECM supplies the fuel rail pressure sensor with a 5 V reference circuit, a low reference circuit, and an asynchronous signal/serial data circuit. The asynchronous signal means communication is only going from the fuel rail pressure sensor to the ECM. The ECM decodes the serial data signal into separate voltages which are displayed on a scan tool as the voltage inputs from the Fuel Temperature Sensor, Fuel Rail Pressure Sensor and Fuel Rail Pressure Sensor 2.

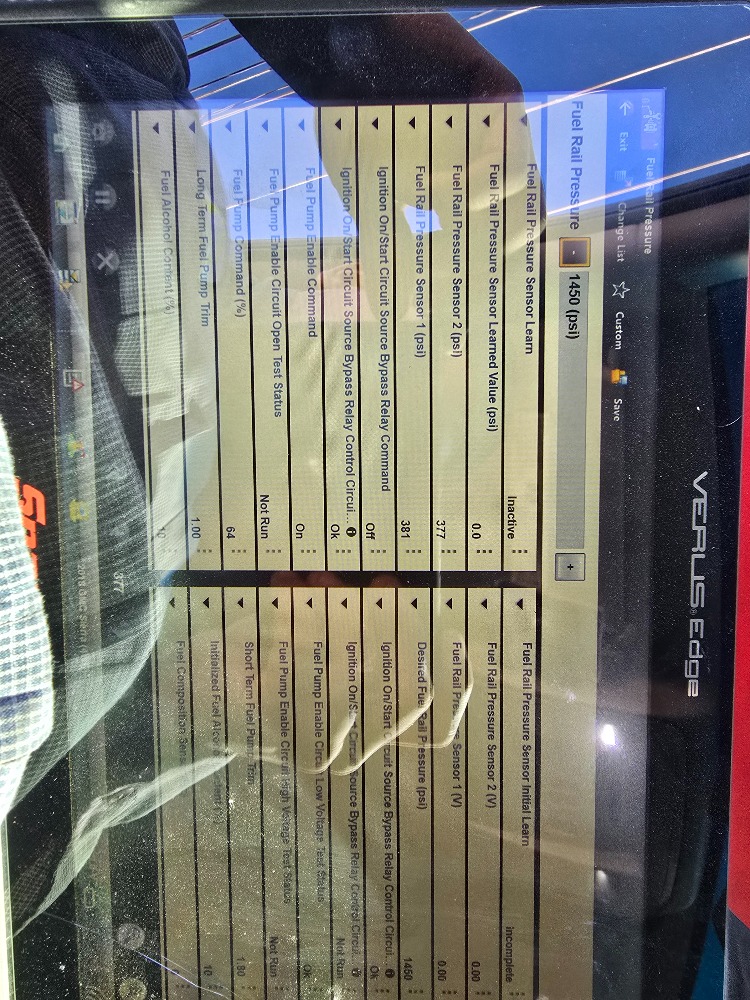

Service info says an open, shorted to ground or shorted to voltage signal wire will show 95,058 PSI. It also says the high pressure system is protected by a relief valve in the pump that prevents the pressure from exceeding 21.5 MPa (3,118 PSI). It stands to reason the pressure is not really going that high otherwise the pump relief valve would be screaming at you.

The fact that this PSI value changes when you unplug it and you don't have any codes for this fuel rail pressure/temperature sensor kinda makes me want to look away from it but it doesn't hurt to check it anyway.

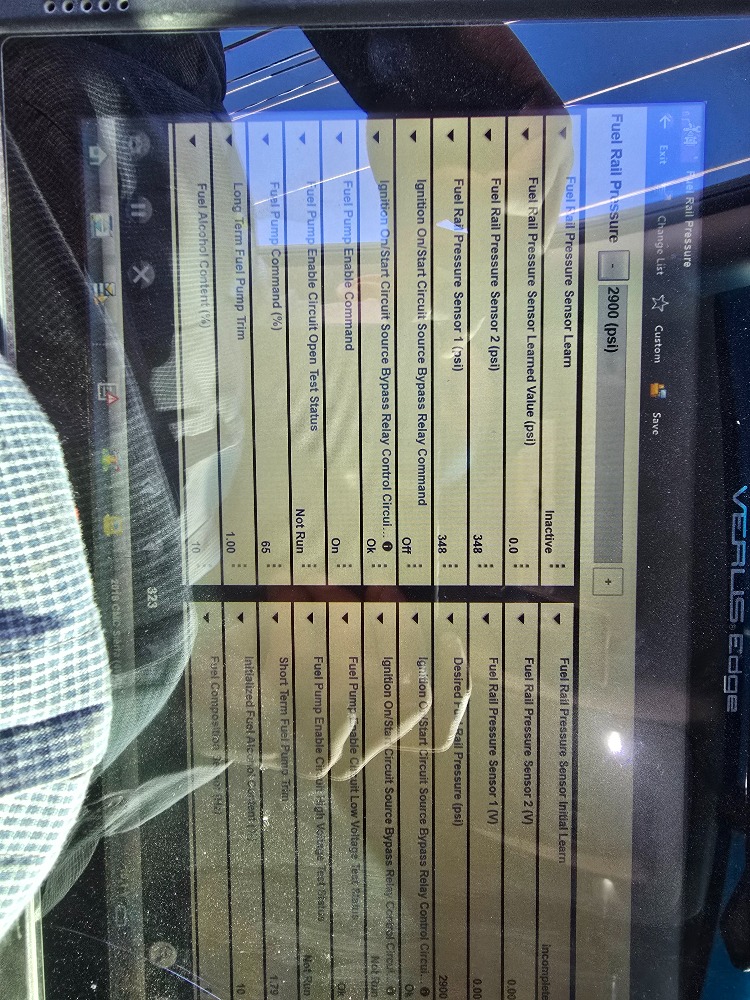

Is the 361 PSI reporting vs the commanded 928 PSI real? Check this value in generic obd2, kill the low psi fuel pump and watch the engine die - does the 361 PSI drop down? I believe there's a command to depressurize the high side pressure as well you can use.

See static.nhtsa.gov/odi/tsbs/2019/MC-10162136-9999.pdf

You don't mention you have timing codes and service info says this pump runs off a 3 lobed cam so timing is important for this "internal solenoid-controlled valve." Was the cam lobe checked for damage?A quick test to see if the fuel pressure sensor is the concern:

Note : If the engine is warm/hot heat will expand the fuel in the system causing the pressure to stay up. The engine will continue to run much longer and the sensor value will not go to zero.

- Engine must be cold!

- Set up GDS/MDI

- Navigate to Fuel System Depressurize

- Engine at idle – depressurize fuel system

- Fuel pressure sensor value should drop to Zero and engine will stall

- Suspect sensors will not drop to zero but rather the engine will stall and the sensor will still read 30-40 PSI

Please Log in or Create an account to join the conversation.

- Christian9000

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- ferris48

-

- Offline

- Premium Member

-

- Posts: 129

- Thank you received: 47

There is another test described in service info called the "Fuel System Pressure Test" which does the following: "This device control is used to charge the fuel rail on a high pressure direct injection system before completing the assembly of the engine in order to check for fuel leaks. This feature will allow the technician to inspect the fuel system for leaks after servicing the fuel system or after any other service procedure that required disconnection or removal of fuel system components. The starter relay is commanded on to crank the engine. Spark (SIDI) and fuel injection are inhibited to prevent the engine from starting. The high pressure fuel pump/regulator(s) are controlled to ensure maximum fuel system pressure is achieved while the engine is cranking and fuel pressure maintained after the engine stops rotating ."

Please Log in or Create an account to join the conversation.

- Christian9000

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- ferris48

-

- Offline

- Premium Member

-

- Posts: 129

- Thank you received: 47

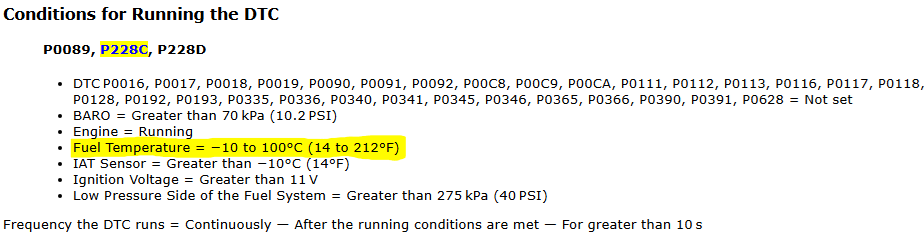

I don't know why the fuel temperature is showing -40 degrees F because then it wouldn't run the P228C check if that was true.do you think that a fuel leak would cause the data from the sensor not to show?

Keeping it simple, the high pressure pump can't produce the high pressure or there's a leak somewhere.

Please Log in or Create an account to join the conversation.

- Christian9000

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6063

- Thank you received: 1531

About the fuel rail pressure sensor and temperature voltages - those PIDs may be invalid. From service info regarding the B310 Fuel Pressure Temperature Sensor:

In other words, the sensor doesn't generate a normal analog sensor signal, therefore there's no voltage value to display.The control module uses the fuel rail pressure sensor to constantly adjust the high pressure fuel pump's feed rate so that the ideal pressure is permanently maintained in the high pressure section (between the high pressure fuel pump and the injectors) by means of a closed loop control. The fuel rail pressure sensor transmits fuel pressure and temperature information via serial data to the control module K20. The sensor's internal microprocessor allows 4 separate sensor outputs from one 3 wire sensor.

It doesn't help that previous versions of the L83 engine actually DID have a fuel rail pressure sensor with two analog outputs. Your Snap-On scanner may be incorrectly displaying those PIDs because it uses the same PID list for both versions.

Please Log in or Create an account to join the conversation.

- Christian9000

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- ferris48

-

- Offline

- Premium Member

-

- Posts: 129

- Thank you received: 47

Now I'm inclined to check the low pressure side. Check for fuel volume and verify with a gauge. This problem is present at idle, so no need to drive it around with a gauge on the window I think.We are currently in our 4th pump from Orreylis.

Please Log in or Create an account to join the conversation.

- Christian9000

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6063

- Thank you received: 1531

We are currently in our 4th pump from Orreylis.

...

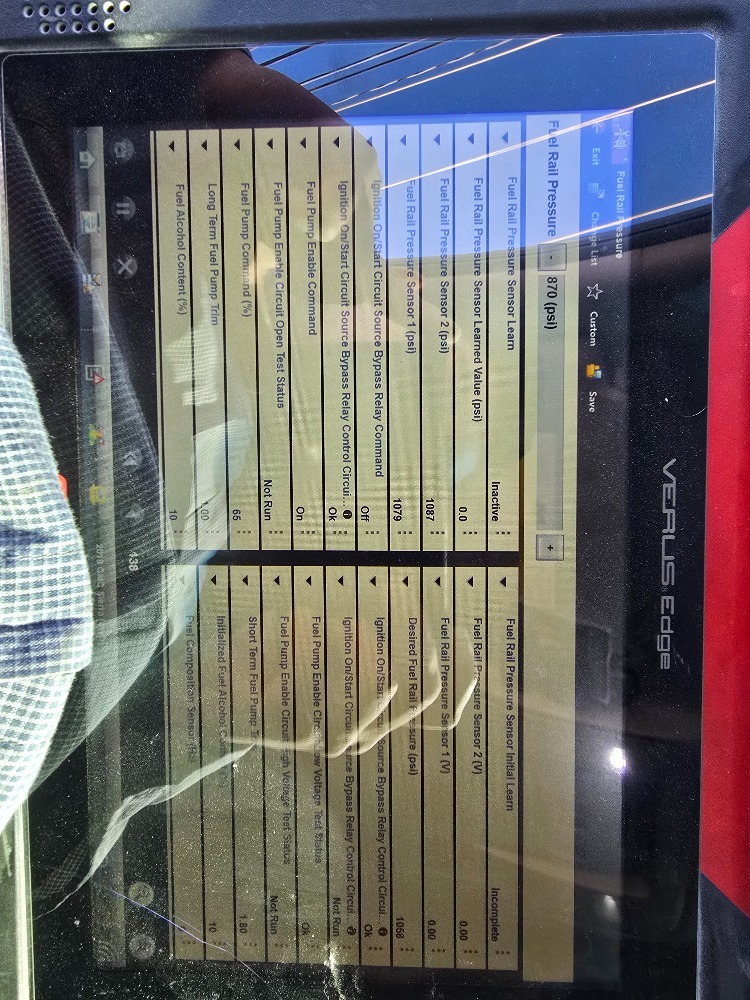

i was commandind the pressure to be at 2400 psi( only ever reached about 2000psi never any higher) i started hearing a wine, kind of like a supercharger wine, and then a pop. Pressure hasnt gone up since. My guess it that i blew the pump, furthermore, now there is a slight ticking sound on the top end. I hear it under the intake. Im going to remove it once again and check.

Time for an OE pump. GM's are never quite happy with aftermarket for one reason or another, in my experience. If the intake is coming back off again, you might as well make certain that the fifth pump is solid.

Please Log in or Create an account to join the conversation.

- Christian9000

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- ferris48

-

- Offline

- Premium Member

-

- Posts: 129

- Thank you received: 47

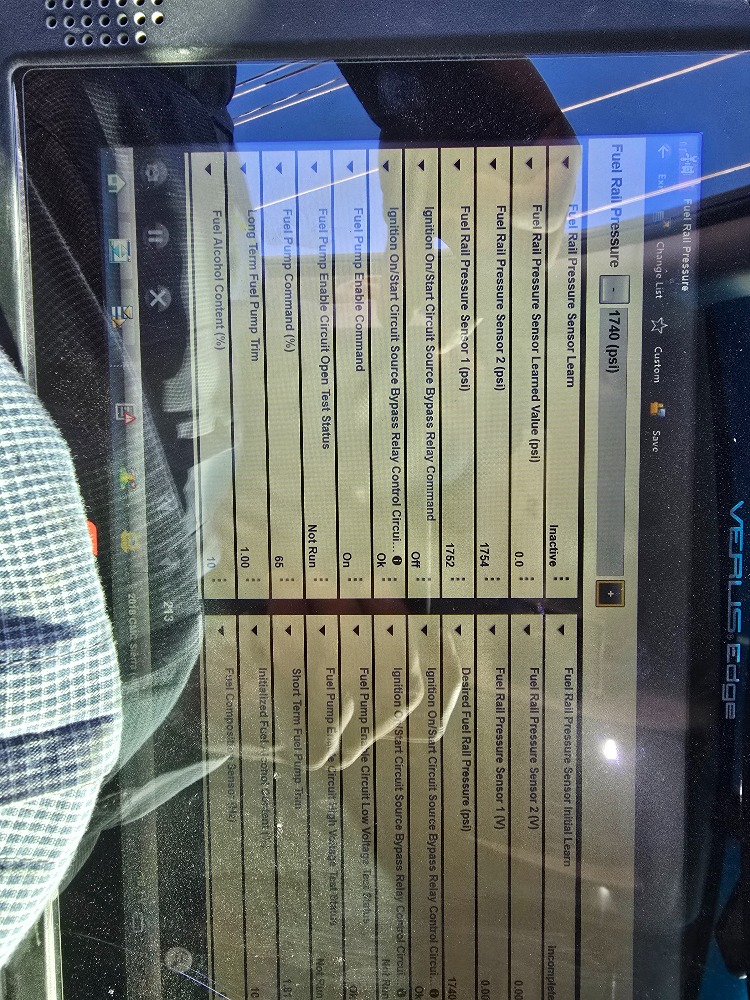

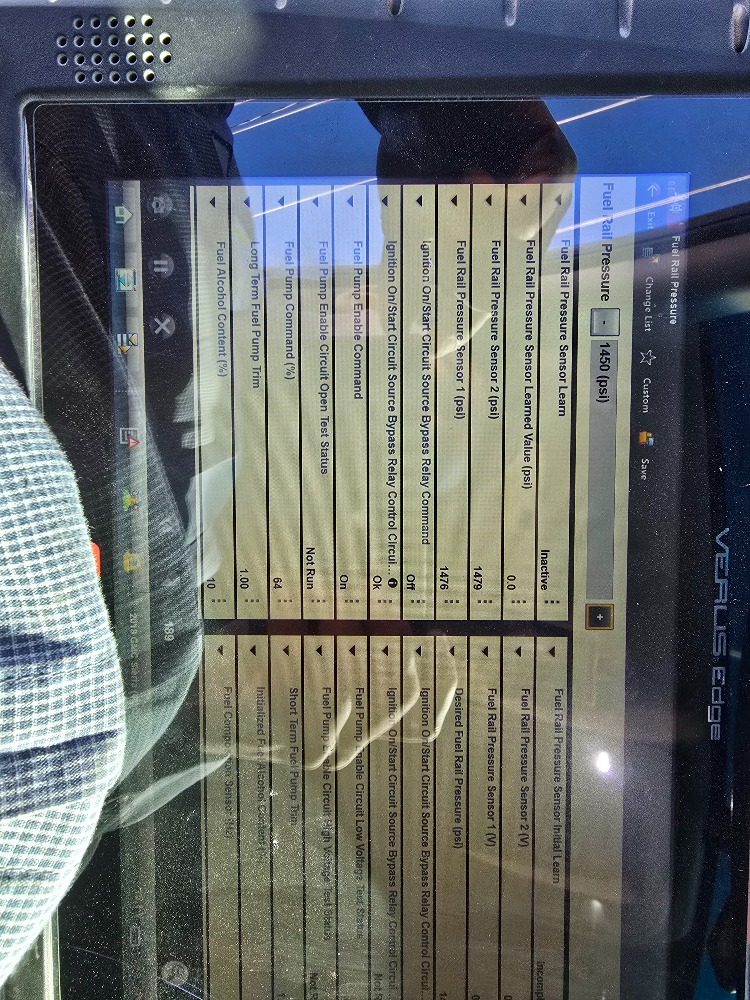

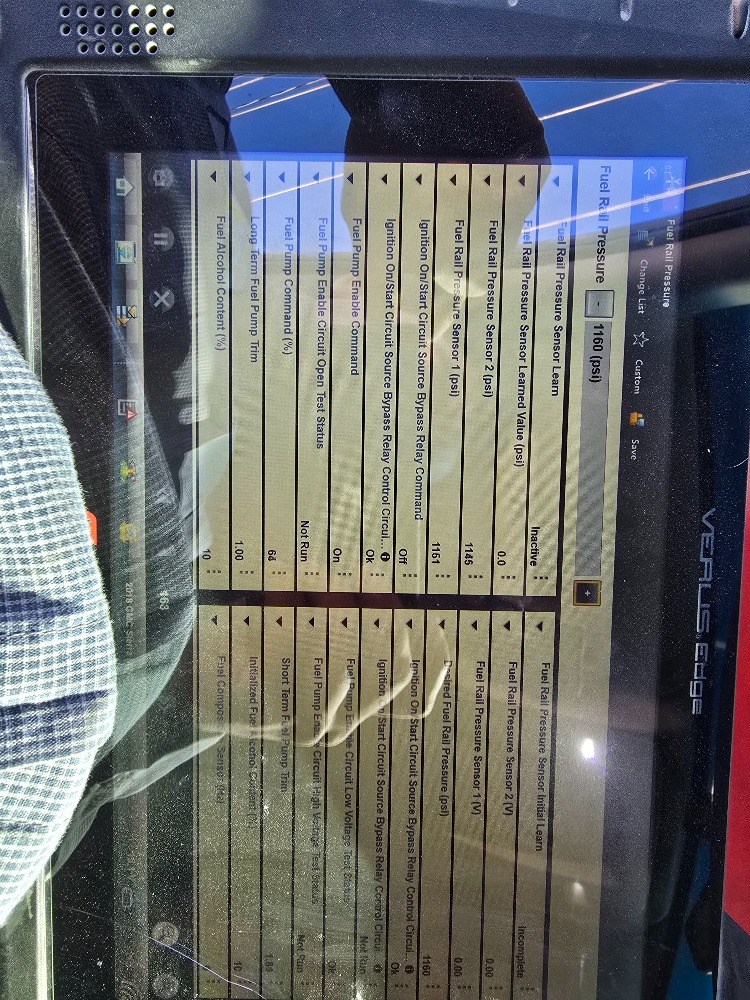

If the computer's not throwing a code about the temp don't worry about it. Fuel rail sensor R&R makes no mention of a learn procedure, so I'd ignore that learn pid showing inactive too.it still doesnt read the fuel rail temperature or the voltage. It keeps saying that the fuel rail pressure sensor learn is inactive. Any ideas on what it could be?

Did you install a new pump?

Please Log in or Create an account to join the conversation.

- Christian9000

-

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.