Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

1998 jeep Cherokee loss of Crank Signal

- Wmridaho19

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

11 months 1 week ago #80775

by Wmridaho19

1998 jeep Cherokee loss of Crank Signal was created by Wmridaho19

So I have a 1998 jeep Cherokee with a 4.0L and the automatic Asian trans.

When I first started working on the vehicle, the symptoms were it would run pretty good for the first 15 minutes and then would start to randomly misfire.

The codes that it had were a

P0700

P1391

Trans codes

P1745

I checked the signal on the distributor pick up sensor and felt it was week so I replaced that. No change to performance.

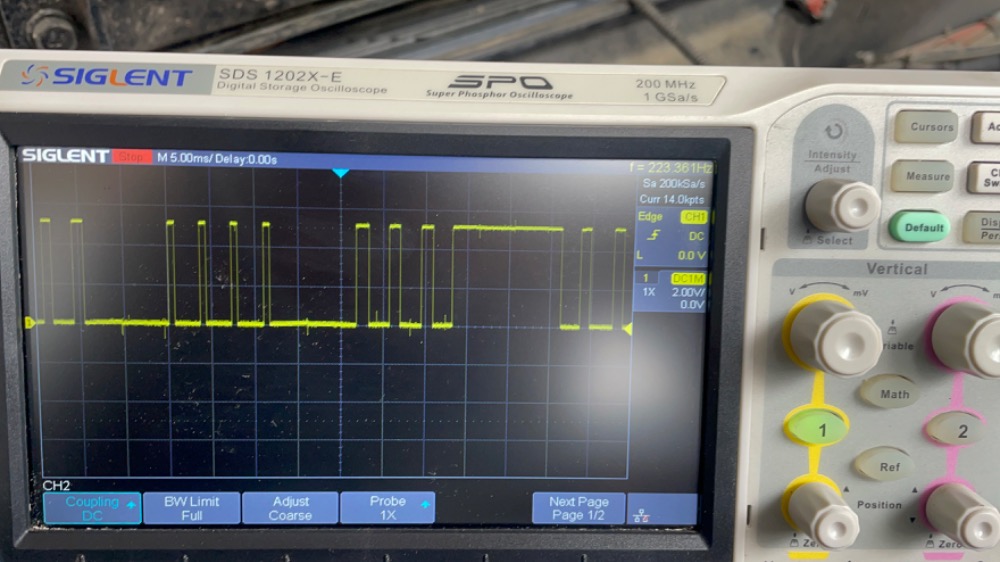

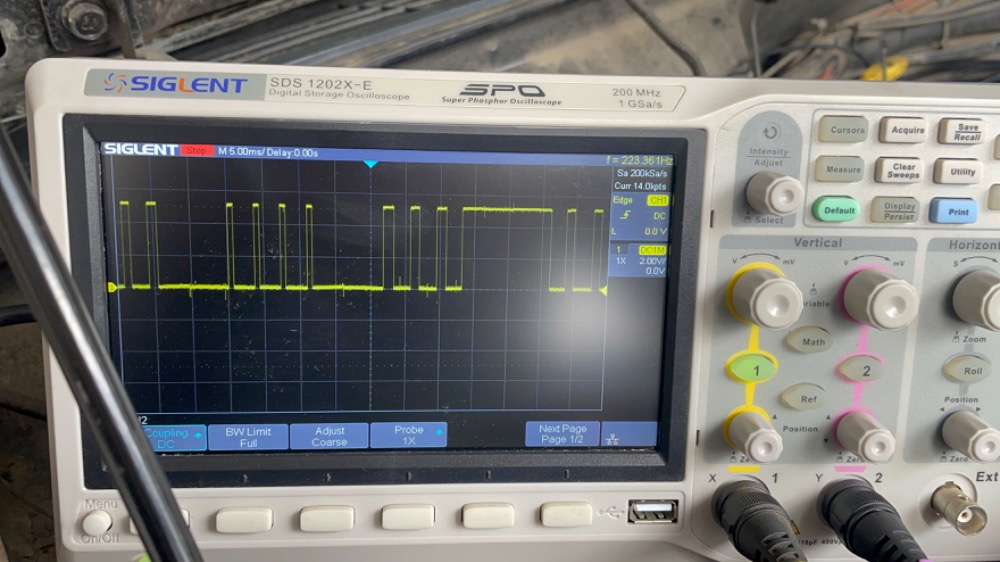

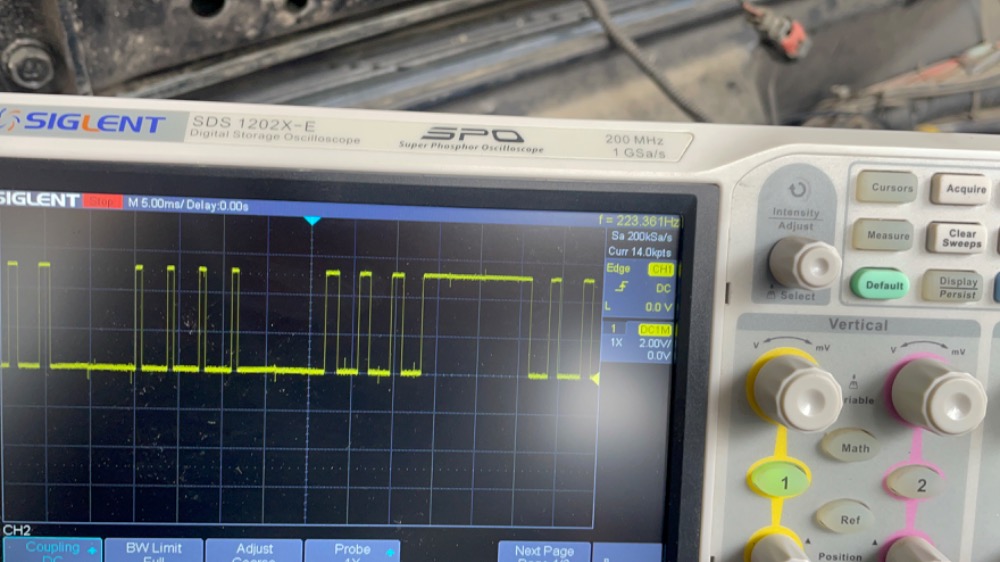

At this time, I didn’t have my scope customer purchased a new crank position sensor which I installed. When the new sensor was installed, the performance was worse. It would immediately start skipping, Or barely start. I installed the old sensor which was a new replacement about a year ago. Performance went back to original would run for 15 minutes or so, and then start missing and stumbling. At this time I thought we just had a bad new crank position sensor issue. OEM Mopar sensors are not available and I have not had any luck finding one. So I tried multiple sensors from multiple parts houses. None of them improved the problem. So I finally got access to my scope and scope the crank signal, and it is definitely not a proper signal. So In doing more research on the issue with not being able to source an OEM crank position sensor. I found a lot of talk about using an NTK brand of sensor which I ordered, but also did not improve the performance.

I have attached some pictures of the scope signals, any help on, this, would be appreciated

Thanks Joseph

When I first started working on the vehicle, the symptoms were it would run pretty good for the first 15 minutes and then would start to randomly misfire.

The codes that it had were a

P0700

P1391

Trans codes

P1745

I checked the signal on the distributor pick up sensor and felt it was week so I replaced that. No change to performance.

At this time, I didn’t have my scope customer purchased a new crank position sensor which I installed. When the new sensor was installed, the performance was worse. It would immediately start skipping, Or barely start. I installed the old sensor which was a new replacement about a year ago. Performance went back to original would run for 15 minutes or so, and then start missing and stumbling. At this time I thought we just had a bad new crank position sensor issue. OEM Mopar sensors are not available and I have not had any luck finding one. So I tried multiple sensors from multiple parts houses. None of them improved the problem. So I finally got access to my scope and scope the crank signal, and it is definitely not a proper signal. So In doing more research on the issue with not being able to source an OEM crank position sensor. I found a lot of talk about using an NTK brand of sensor which I ordered, but also did not improve the performance.

I have attached some pictures of the scope signals, any help on, this, would be appreciated

Thanks Joseph

Please Log in or Create an account to join the conversation.

- ferris48

-

- Offline

- Premium Member

-

Less

More

- Posts: 129

- Thank you received: 47

11 months 1 week ago #80997

by ferris48

Replied by ferris48 on topic 1998 jeep Cherokee loss of Crank Signal

Put more time on the screen does this pattern repeat? Before the fat tower shows up, the tower gets slightly thicker. It could be because the engine slowed down but not sure.

If the pattern repeats, use a borescope to inspect the slots on the flexplate.

My understanding is when a flywheel/flex plate slot passes the crankshaft position sensor magnet, output voltage of the Hall Effect sensor goes high (5 volts). When the metal between the slots is aligned with sensor, output voltage goes low.

My big fat guess is there's a physical dent on the flexplate trigger wheel and the crank sensor voltage goes high (I'm looking at that fat single tower in the photo) because the gap between sensor and metal is too great.

If the pattern repeats, use a borescope to inspect the slots on the flexplate.

My understanding is when a flywheel/flex plate slot passes the crankshaft position sensor magnet, output voltage of the Hall Effect sensor goes high (5 volts). When the metal between the slots is aligned with sensor, output voltage goes low.

My big fat guess is there's a physical dent on the flexplate trigger wheel and the crank sensor voltage goes high (I'm looking at that fat single tower in the photo) because the gap between sensor and metal is too great.

Please Log in or Create an account to join the conversation.

- Wmridaho19

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

11 months 1 week ago #81279

by Wmridaho19

Replied by Wmridaho19 on topic 1998 jeep Cherokee loss of Crank Signal

Yes the pattern repeats pretty steady but a bit random. We thought we did have an issue with the flex plate so I had already replaced the flex plate with a brand new one.

Please Log in or Create an account to join the conversation.

- Monde

-

- Offline

- Elite Member

-

Less

More

- Posts: 220

- Thank you received: 43

11 months 1 week ago #81281

by Monde

Assuming is never a good thing.

Replied by Monde on topic 1998 jeep Cherokee loss of Crank Signal

Put more time on the screen does this pattern repeat? Before the fat tower shows up, the tower gets slightly thicker. It could be because the engine slowed down but not sure.

If the pattern repeats, use a borescope to inspect the slots on the flexplate.

My understanding is when a flywheel/flex plate slot passes the crankshaft position sensor magnet, output voltage of the Hall Effect sensor goes high (5 volts). When the metal between the slots is aligned with sensor, output voltage goes low.

My big fat guess is there's a physical dent on the flexplate trigger wheel and the crank sensor voltage goes high (I'm looking at that fat single tower in the photo) because the gap between sensor and metal is too great.

The sensor may be too weak to pull the 5v ref to ground or you may lose the ground at that time. You may have to monitor the ground as well to see if it does not drop when you have the big square wave.

Assuming is never a good thing.

Please Log in or Create an account to join the conversation.

Time to create page: 0.363 seconds