[FIXED]P0400 Code and My First DIY Troubleshooting

- Charles Acosta

-

Topic Author

- Offline

- Senior Member

-

- Posts: 79

- Thank you received: 13

One of the codes was the P0400. After doing some research the EGRC Solenoid Valve is grounded (On) by the ECM, the plunger will move to block vacuum to the EGR valve when the following conditions occur:

1) Low engine coolant temperature

2) Engine starting

3) Engine stopped

4) Engine idling

5) Excessively high engine coolant temperature

6) Low vehicle speed

With the KOER I remove the hose from the EGR valve and felt vacuum . i thought this was odd since the solenoid should be energized. Putting that aside for now I applied vacuum to EGR valve and the engine stalled so I know the passage ways are clear. I focused on the EGR solenoid next. I know its ground side switched so with the KOEO, solenoid plugged in, using a VOM, I had 13v feed but .225mv on the control side when I know it should be 13v when there is no voltage drop.

So here is my first question. Am I correct into thinking that the driver for the solenoid is not ON until engine is running? With KOEO doing voltage measurement the driver is OFF? If so I suspected a short to ground.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6063

- Thank you received: 1531

So here is my first question. Am I correct into thinking that the driver for the solenoid is not ON until engine is running? With KOEO doing voltage measurement the driver is OFF? If so I suspected a short to ground.

I think you're correct in your thinking that the driver is likely off (not energizing the solenoid) with the key on, but should be with the engine running to prevent unwanted EGR operation.

Your voltage readings KOEO could suggest a short to ground in the control wire, but that would result in the solenoid being energized all the time. If that were true, then you SHOULDN'T have felt vacuum at the EGR valve. Could be that the solenoid is mechanically stuck, but we can get to that later.

To me, it's more likely that you're looking at a failed EGR solenoid, likely high resistance. That'd explain your voltage readings, and why you're getting vacuum at the EGR valve at idle. There's lots of ways to test for this, but the easiest would probably be the good ol' test light. Here's a great ScannerDanner video demonstrating this, if you haven't seen it already:

He's testing an EVAP solenoid in the video, but the procedures are identical. You won't have bidirectional control, but you can get the driver to activate by starting the engine. Please feel free to ask questions if you're unsure of this test!

The EGR solenoid aside, I'm curious - if you felt vacuum at the EGR valve at idle, then was the valve open at idle all the time? If my memory serves, these systems employ some kind of mechanical transducer that works off of exhaust backpressure. Am I thinking about this right? Could be way off, lol.

Please Log in or Create an account to join the conversation.

- Charles Acosta

-

Topic Author

- Offline

- Senior Member

-

- Posts: 79

- Thank you received: 13

According to AlldataDIY the solenoid when energized moves the plunger to stop vacuum during any of those 6 conditions i mentioned earlier. When I revved up the engine the was more vacuum.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6063

- Thank you received: 1531

tribal599 wrote: Used a incandescent test light, it didn't light but with a LED test light it did.

Just so I'm clear here, you had the control wire at the EGR solenoid backprobed, key off, and your test lights connected to B+? The LED test light lighting does suggest a short, but the incandescent should have lit, too. This EGR solenoid definitely requires more current than the 10mA the LED test light draws (probably 150mA or more), so I don't believe that the driver is shorted.

tribal599 wrote: DVOM red lead to positive battery and black lead to control wire and I read system voltage.

Really not trying to be critical of you here, but having your DVOM connected in this way can make your readings confusing. If I understand correctly, then your DVOM will indicate battery voltage when connected to ground. It's not WRONG to use your meter this way, but it makes keeping your results straight tough for guys like me.

According to AlldataDIY the solenoid when energized moves the plunger to stop vacuum during any of those 6 conditions i mentioned earlier. When I revved up the engine the was more vacuum.

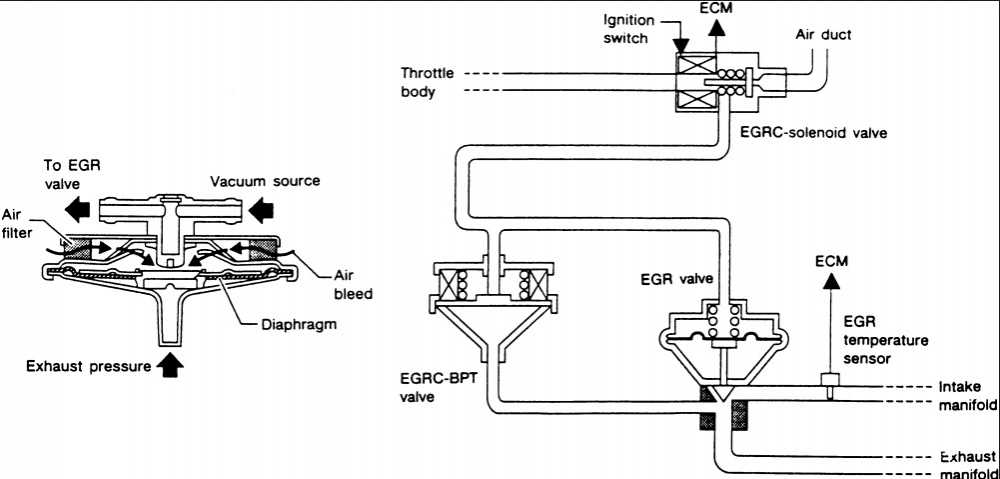

This makes sense to me, given my understanding of these backpressure transducer systems. For anyone else following along, here's a diagram I found on Google Images that pretty well shows how this system works:

If you would, try doing a few tests for me:

1.) Connect your incandescent test light between B+ and the EGR solenoid control wire. Observe during KOEO, KOER, 2500 RPM steady and during a throttle snap. If the light goes out and comes on at various times, then I would argue that the computer driver is NOT shorted.

2.) Disconnect the rubber hose at the EGR backpressure transducer that comes from the exhaust (where it says EGRC-BPT valve in the diagram). Check for carbon buildup in the hose, or in the rubber nipple at the backpressure transducer. If those are clear, start the engine and check for exhaust out of the hose.

I'll be honest, that last one is a hunch based on previous experience. A '96 Sentra with the same code kicked my butt a few years ago, and ended up finding a plugged hose at that location. AFTER I'd replaced the backpressure transducer for no reason :blush:

Please Log in or Create an account to join the conversation.

- Charles Acosta

-

Topic Author

- Offline

- Senior Member

-

- Posts: 79

- Thank you received: 13

Tyler wrote: Hey sir, thanks for getting back to fast!

tribal599 wrote: Used a incandescent test light, it didn't light but with a LED test light it did.

Just so I'm clear here, you had the control wire at the EGR solenoid backprobed, key off, and your test lights connected to B+? The LED test light lighting does suggest a short, but the incandescent should have lit, too. This EGR solenoid definitely requires more current than the 10mA the LED test light draws (probably 150mA or more), so I don't believe that the driver is shorted.

When I had the solenoid unplugged, test light to B+ and control wire the incandescent didn't light but with the connector plugged in, the incandescent did light. The video you posted for me (thanks BTW!) it showed the connector still plugged to the solenoid.

When I disconnected the ECM I got 12 volts on the control side and on the ECM with KOEO when I didn't at first with the ECM connected.

When it comes to 0 volts on the control side with the driver commanded off, is the test light the only way to go? If I didn't have a test light, wouldn't the voltage reading I took the way I described it confirm a shorted driver?

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6063

- Thank you received: 1531

tribal599 wrote: When I had the solenoid unplugged, test light to B+ and control wire the incandescent didn't light but with the connector plugged in, the incandescent did light.

If you did this test with the key off, then it's possible that the incandescent test light was finding a ground back through the power feed, fuse box, and other circuits. It's the same reason a test light connected to B+ will light when hooked to the power feed wire of a fuel pump - the test light can find enough of a ground through the pump motor to light brightly. It doesn't mean that the pump or wiring is shorted. This is why short-to-ground testing with a test light CAN be tricky.

When it comes to 0 volts on the control side with the driver commanded off, is the test light the only way to go? If I didn't have a test light, wouldn't the voltage reading I took the way I described it confirm a shorted driver?

Maybe not the best way, but the most definitive way. The 0V reading at the solenoid control wire with the driver off can also be from an open solenoid. The test light is important because it makes it easy to distinguish between the two. Engine running, 0V on the control wire, and the test light does NOT light represents an open solenoid.

I have run into shorted ground side drivers before, and the thing about them is that they can't choose when they're shorted. If they're shorted, then they're shorted all the time, even with the key off. Thus, if you connect an incandescent test light from B+ to the solenoid control wire, key out of the ignition, and it doesn't light, then the driver isn't shorted.

Thinking now, I should have suggested that test earlier, sorry :lol:

Please Log in or Create an account to join the conversation.

- Charles Acosta

-

Topic Author

- Offline

- Senior Member

-

- Posts: 79

- Thank you received: 13

Please Log in or Create an account to join the conversation.

- Charles Acosta

-

Topic Author

- Offline

- Senior Member

-

- Posts: 79

- Thank you received: 13

In my first post the one of the conditions for the solenoid to energize and block vacuum is with a stopped engine. Does this mean with just the key on or when you turn off the engine?

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

I would try a less technical approach on this one. One of the tests all data has you perform is with KOEO, to disconnect and reconnect the valve. You should be able to hear the operation of the valve as you do so. This tells me that the pcm is supposed to be grounding the solenoid with just the key on.

So it seems like the circuit is intactWith the KOEO Incandescent test light from B+ to control wire, plugged in or unplugged, the test light lit. I disconnected the ECM, unplugged solenoid, with KOEO test light did NOT light. At the same time checked control side voltage and it was 13 volts. Put the ECM back in and repeated test and the test light lit and O volts on the control side.

I'm not sure of the location or connections to the valve, but if possible, I would disconnect both vacuum hoses from the solenoid and try to blow each way through the valve while disconnecting and reconnecting the solenoid. If you can always blow air through it both ways (even a little) while activating and deactivating the solenoid, she's junk. I think that's what you're going to find based on the fact that you observed vacuum on that line while at idle.

The system appears to monitor flow with a thermistor, I suspect it's reading higher than expected temperature at idle due to the valve hanging open (mechanically), hence the P0400.

Did you do a ground to ground volt drop measurement on the control wire? I apologize if you did and I missed it.

Basically put your negative lead on the negative terminal of the battery and measure voltage on the ground side of the solenoid circuit with the circuit activated. KOEO should be fine for this test based on the description I have from all data.

I'm not implying that you don't know how to do a volt drop test, just putting it out there for anyone reading along.

You could also manually energize it with a power probe or jumper wire with it disconnected from the circuit now that you know which pin is power and which is ground (which I don't think is critical in this case anyway, but better safe than sorry), and then try blowing through it both ways, on and off.

If the solenoid checks out OK, we can follow another path, but I've got a hunch it's not sealing.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Charles Acosta

-

Topic Author

- Offline

- Senior Member

-

- Posts: 79

- Thank you received: 13

I had the engine running and disconnected the hose to the egg valve. I felt a very slight vacuum but definitely not enoght to make the egr opened.

When I revved the engine I felt more vacuum.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

You could prove it by checking fuel trim at idle. I'd expect slightly positive trims at idle, maybe a pending lean code. That's kind of mouse hunting with a machine gun though.

I'd try to stay focused on what we do know. That is that at idle, no vacuum should be present to the egr valve. We also know the valve opens based on the increased vacuum you noted, which verifies circuit integrity. We also know the egr passages are clear and the valve functions based on your manual bypass (good move BTW). That doesn't leave a whole lot to be setting your p0400. Either there's egr flow when there shouldn't be (which I think is the case), not enough flow when there should be, or a lying egr temperature sensor.

The solenoid does all the work and is exposed to the harshest conditions, so that puts it at the top of the suspects list in my book. Plus it's letting vacuum through when there should be none. I would make sure it seals and flows outside of the circuit before getting tangled up in the logic of the circuity.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

.One of the codes was the P0400. After doing some research the EGRC Solenoid Valve is grounded (On) by the ECM, the plunger will move to block vacuum to the EGR valve when the following conditions occur:

1) Low engine coolant temperature

2) Engine starting

3) Engine stopped

4) Engine idling

5) Excessively high engine coolant temperature

6) Low vehicle speed

With the KOER

Engine stopped would be koeo, so the solenoid would be closed, or activated.

Low vehicle speed with koer could explain the results observed during the snap throttle test where the test light remained lit.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Charles Acosta

-

Topic Author

- Offline

- Senior Member

-

- Posts: 79

- Thank you received: 13

I disconnected the three hoses to the EGR solenoid and ran compress air to the port A fitting to check air passage ways. Did the test as described and found that with the solenoid energized ports A and B had good flow but with no power to solenoid ports A and C air flow was a little weaker. The weaker side goes to the EGR and BPT valves. Maybe the vacuum is not strong enough to open the EGR valve. Connected the hoses back together and put my fingers under the valve and can feel some of the diaphragm moving as I throttle the engine but doing this for the first time I cant really judge a good from weak diaphragm movement.I know when I press up hard enough I can make the engine stall.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Charles Acosta

-

Topic Author

- Offline

- Senior Member

-

- Posts: 79

- Thank you received: 13

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Charles Acosta

-

Topic Author

- Offline

- Senior Member

-

- Posts: 79

- Thank you received: 13

Please Log in or Create an account to join the conversation.

- Charles Acosta

-

Topic Author

- Offline

- Senior Member

-

- Posts: 79

- Thank you received: 13

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6063

- Thank you received: 1531

So, had someone worked on the EGR solenoid before you? Or, were the hoses themselves faulty?

Please Log in or Create an account to join the conversation.

- Charles Acosta

-

Topic Author

- Offline

- Senior Member

-

- Posts: 79

- Thank you received: 13

Please Log in or Create an account to join the conversation.

.png)

.png)

-2.png)

.png)

.png)

.png)