2007 F150 5.4 Possible Low Fuel Pressure (NO ISSUE)

- graywave

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Adv. Diagnostics New Hampshire

- Posts: 302

- Thank you received: 80

I have an 2007 Ford F150 which has hesitation and misfire which was not brought here for this condition so the boss may not want me to put much more time into it. Though it has now spiked my curiosity. Ive been doing some tests to familiarize myself with fords FPDM fuel system. My knowledge is a little low on fords FPDM fuel system. I have a basic understanding of it.

Symptoms

Slightly Rough Idle - Some light misfires on all cylinders which I can only pick on the the cylinder contribution test on the scan tool.

Hesitation under WOT

NO DTCs for this. Only Generator fault code which could be a cause if voltage drops. Will check this tomorrow. Last voltage test I saw was 13.3v at idle

Scan Tool Diag

NOTE: Vacuum line connected to FRPS during pressure readings

- Fuel Rail Pressure Sensor PSI at idle: 37-39PSI

- Fuel Rail Pressure Sensor PSI at WOT: 37-39 PSI

- At some point, usually just as I let off the throttle at the end of my WOT run the FRPS will spike to 49 PSI

- Bank 1/2 Upstream O2 Sensors will NOT read rich during WOT until the FRPS reads 49 PSI. At that point O2s will be pegged rich. The initial instantaneous romp on the throttle, both Upstream and Downstream O2s will read full lean for a second till the truck starts accelerating.

Lab Scope Diag

FPDM Fault Return Signal Wire (PIN 30) and PCM to FPDM Control Signal Wire (PIN 62) probed at PCM

1. FPDM Return Fault Signal Wire: 50% at all times. (No Fault?)

2. PCM to FPDM Control Signal Starts at 86% and drops as load increases. Lowest I got was 67%. Now this confuses me as I was expecting this to be low and INCREASE. I am thinking that maybe I should be reading this the other way around. 86% on the labscope would be 14% command to the FPDM??? I didn't try swapping my leads around, thinking that possibly my NEG and POS lead on the scope should be swapped to get a different % or maybe that wouldn't matter.

Had very little time to look at this.

Basically I am a little new to this system to be honest. I'm used to looking for 50-60PSI but this system specs at much lower pressures. 28-35PSI KOER I think. I am wondering what ACTUAL fuel pressure should be under load and at idle. Depending on if I can put time into this issue, I'd like to T my fuel gauge into the system some place to get mechanical readings. I am not ruling out a bad FRPS.

I know these have huge common faults with the Fuel Pump Driver Module Corroding. Not sure if these symptoms line up with a bad FPDM

Thanks everyone!

Confirm what it's not, and fix what it is!

Please Log in or Create an account to join the conversation.

- graywave

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Adv. Diagnostics New Hampshire

- Posts: 302

- Thank you received: 80

Confirm what it's not, and fix what it is!

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6086

- Thank you received: 1537

- Fuel Rail Pressure Sensor PSI at idle: 37-39PSI

- Fuel Rail Pressure Sensor PSI at WOT: 37-39 PSI

- At some point, usually just as I let off the throttle at the end of my WOT run the FRPS will spike to 49 PSI

- Bank 1/2 Upstream O2 Sensors will NOT read rich during WOT until the FRPS reads 49 PSI. At that point O2s will be pegged rich. The initial instantaneous romp on the throttle, both Upstream and Downstream O2s will read full lean for a second till the truck starts accelerating.

The fuel pressure staying at 37-39 PSI, and spiking after a WOT run, is normal in my experience. The O2's also sound reasonable, as not every system will switch to open loop right away upon WOT application. How severe is this hesitation? :huh:

Lab Scope Diag

FPDM Fault Return Signal Wire (PIN 30) and PCM to FPDM Control Signal Wire (PIN 62) probed at PCM

1. FPDM Return Fault Signal Wire: 50% at all times. (No Fault?)

2. PCM to FPDM Control Signal Starts at 86% and drops as load increases. Lowest I got was 67%. Now this confuses me as I was expecting this to be low and INCREASE. I am thinking that maybe I should be reading this the other way around. 86% on the labscope would be 14% command to the FPDM??? I didn't try swapping my leads around, thinking that possibly my NEG and POS lead on the scope should be swapped to get a different % or maybe that wouldn't matter.

The FPDM return at 50% duty cycle is completely normal, no worries there. If the signal were at 0%, 25%, 75% or 100%, then the PCM would flag a FPDM code. There's more info about this circuit in here:

www.scannerdanner.com/forum/post-your-re...4ford-e450.html#8554

The PCM's command to the FPDM is weird... it's a 'halved' signal. :blink: When you saw 86%, you were actually looking at a 14% duty cycle, which equates to a 28% duty cycle of the fuel pump by the FPDM. Make sense? :lol: Your lowest reading of 67% was actually 43%, which equates to 86%, which is about as close to full fielding of the pump as the FPDM will get. I've never seen the command signal go over 50%.

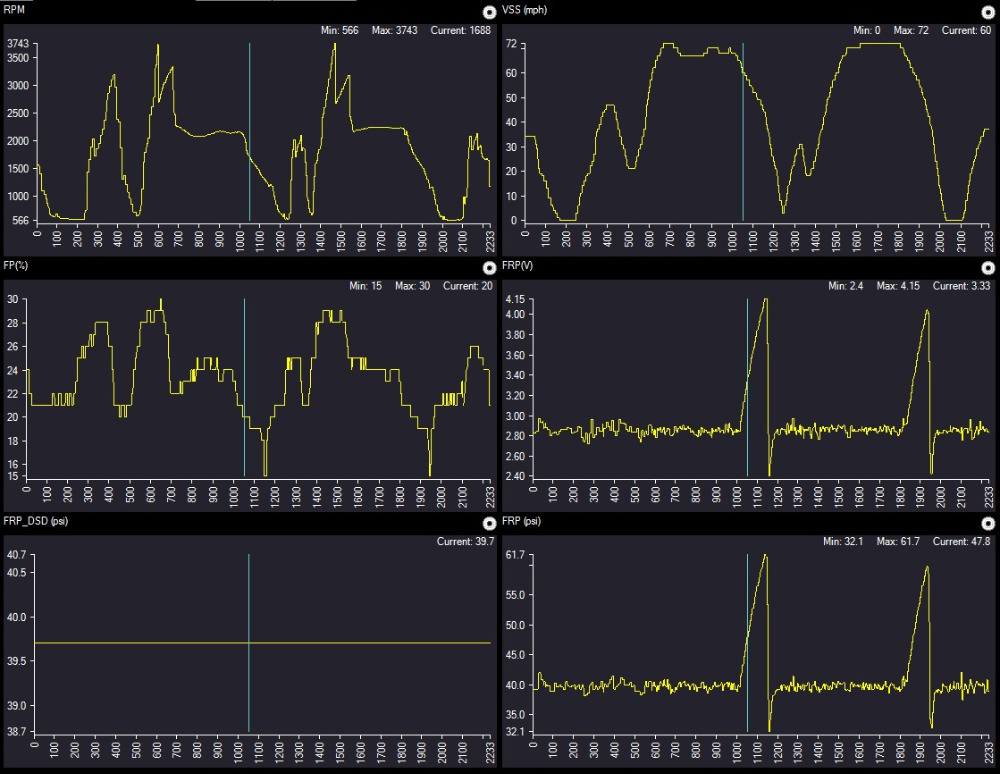

www.scanshare.io/share/rOyxN7DxDU201WIeEqbelQ

I am wondering what ACTUAL fuel pressure should be under load and at idle. Depending on if I can put time into this issue, I'd like to T my fuel gauge into the system some place to get mechanical readings. I am not ruling out a bad FRPS.

Your gauge will almost always show you HIGHER than the FRPS, because of the vacuum hose. If you disconnect the vacuum hose, then the gauge should match the gauge exactly. Why have the vacuum hose? Who knows. :silly:

Please Log in or Create an account to join the conversation.

- graywave

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Adv. Diagnostics New Hampshire

- Posts: 302

- Thank you received: 80

I can't remember exactly. I'd have to look since I think I saved the data. Friday I"ll look at the scan tool history.Tyler wrote: Hey graywave! What were you generator codes? 13.3V sounds a bit low for this system, since desired is usually 14V. P0622?

Hesitation was pretty bad, more intermittent than a constant hesitation which would also lead me away from the fuel pump or module. I did test the ignition coils and found a few cylinders with an open in the secondary at times. Current ramps looked great on all coils.The fuel pressure staying at 37-39 PSI, and spiking after a WOT run, is normal in my experience. The O2's also sound reasonable, as not every system will switch to open loop right away upon WOT application. How severe is this hesitation? :huh:

That all makes complete sense. That links has a bunch of info too. Thanks for sharing.The FPDM return at 50% duty cycle is completely normal, no worries there. If the signal were at 0%, 25%, 75% or 100%, then the PCM would flag a FPDM code. There's more info about this circuit in here:

www.scannerdanner.com/forum/post-your-re...4ford-e450.html#8554

The PCM's command to the FPDM is weird... it's a 'halved' signal. :blink: When you saw 86%, you were actually looking at a 14% duty cycle, which equates to a 28% duty cycle of the fuel pump by the FPDM. Make sense? :lol: Your lowest reading of 67% was actually 43%, which equates to 86%, which is about as close to full fielding of the pump as the FPDM will get. I've never seen the command signal go over 50%.

Your gauge will almost always show you HIGHER than the FRPS, because of the vacuum hose. If you disconnect the vacuum hose, then the gauge should match the gauge exactly. Why have the vacuum hose? Who knows. :silly:

Shouldn't the vacuum in the FRPS cause a high than normal pressure reading on the scanner? I figure the vacuum will pull the diaphragm up, same direction the fuel pressure would push it. The fuel pressure instantaneous spike at the end of my WOT run would make sense if the vacuum would create higher than normal readings. At the end of the WOT run when I snap the throttle shut, vacuum would spike and create that spike in the FRPS reading which then bleeds off as RPMs decrease and vacuum decreases. Reason I say this is the spike in pressure was not gradual, it was a straight line up even zoomed in on the scanner. I can't imagine the Fuel pump being able to raise the pressure 10psi so instantaneous by the module ramping voltage. Your thoughts?

I also read that the reason they measure fuel pressure referenced to manifold vacuum was to get the fuel pressure that is at the injectors....I am having a hard time wrapping my head around that.

Thank you!

Confirm what it's not, and fix what it is!

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6086

- Thank you received: 1537

I hadn't considered that the vacuum hose might be responsible for the pressure spikes after WOT. :blink: I always figured it was because the PCM cut injector pulse when I lifted off the throttle, and the fuel pump is suddenly deadheading against a rail that isn't flowing any fuel.

Please Log in or Create an account to join the conversation.

- graywave

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Adv. Diagnostics New Hampshire

- Posts: 302

- Thank you received: 80

I guess the only way to confirm that is to hook up a fuel pressure gauge. I suppose you could scope average voltage to the pump to watch the fluctuation, throttle input, FRPS Signal and a fuel injector to see what is happening too. Next time I have a ford I'll scope this out just because it might be easier than T'ing in a mechanic fuel pressure gauge or pressure transducer. Unless I run into an older ford with a schrader valve.

What is interesting is your FRP(V) waveform (well mine was on the scanner not the scope) is opposite of what mine looked like. On this truck the beginning of the spike was straight up and gradually decreased, yours looks like it gradually increased and decreased suddenly.

Confirm what it's not, and fix what it is!

Please Log in or Create an account to join the conversation.