*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

Strangeness with brand new A/C compressor

- photoshopman1972

-

Topic Author

- Offline

- New Member

-

- Posts: 2

- Thank you received: 0

I have an interesting one (to me anyways) and fair warning, it is a bit long winded but I feel that having the back story will maybe help lead me in a proper direction!

Ok, warning is given, let's begin.

The vehicle is an 1994 Chevrolet C1500 Silverado that was customized by Dixie Customs with the 5.7L engine.

I had put a fuel pump in it to get the truck to run again for the owner (who is disabled and elderly) after it had sat for over 5 years. On a recent trip to get the vehicle inspected, he noticed that the A/C did not function. Before I did anything including hooking up a set of gauges, I checked for leaks visually with a black light because I could tell by the low side port that some of the detection dye was added to the system.

All looked good until I got around the compressor. The front of the thing right behind the A/C clutch glowed a lot indicating that the compressor had a leak in that area.

The man who owned the truck then wanted for me to see if there was anything in it so I hooked up a set of gauges to it and of course, there was no refrigerant in the system.

Here is where I may get some flack but at the time I nor the owner knew we could use air (I'm having a devil of a time finding someplace in my area that will sell an nitrogen setup like Mr. Danner showed in his videos) to see if all was working so we did what anyone else would have done. Put in enough to get the compressor to engage. Yes, I could have jumped out the pressure switch but I did not think about that and neither did he.

Needless to say, the sounds that came out of this thing was horrible! The rattling sound sounds like an engine with very bad collapsed lifters. The high side needle also was bouncing all over the place so I could not get an accurate reading!

There was a pressure differential and the inside was starting to blow cold but the noise and the bouncing needle on the high side had me make the call on the compressor.

The compressor that had gone bad was an aftermarket and I did not replace the original one with this one. The owner had it done by his friend who has a shop. The owner did do mechanic work in his day but not a lot of A/C repair. He mainly did new installations. This will be important in a minute or so.

Continuing on... So a new compressor was ordered.

A few days later, the new one arrived and it did not come with any oil in it so I knew I had to add oil and rotate the compressor (and just not the belt pulley) to circulate the oil.

Here is where things start to get interesting. I could not exactly find the specifications online for how much to add back to the compressor online. I do not have a subscription to Mitchell or Alldata and our library does not have this information either. They may have a repair manual that I could've looked into but I did not think of that until now as I typed this post.

So I errored on the side of caution and put in 3oz of oil. Rotated the compressor a few times to get the oil moved around and installed the new unit.

Vacuumed down the system for over 30 min because the day was extremely muggy and we decided that the little bit extra time would help get rid of the moisture in the system.

Performed the leak down check for over 10 min and it held vacuum so we proceeded to recharge. I at the owners request did the charging of the system with vapor only! Yes doing it shade tree style did take a few moments before there was enough to get the compressor to run.

Started the engine and engaged the compressor. At first it did not have enough to keep the compressor running but as more went into the system, the compressor stayed on and it ran quiet and the high side needle was nice and steady!

It was good with us putting in two of the 12oz cans however the specification for this truck as well as what it stated on the accumulator/dehydrator was 32oz.

As I was adding the partial charge needed from the third can, the compressor started to rattle! Not as bad as the one we removed but still it went from quiet and happy to rattling and unhappy!

I also noticed that the high side needle started to bounce some as well!

I'm no A/C expert but I've never seen this happen! A compressor going from content and happy to unhappy when attempting to finish up the charge!

This has me scratching my head and here is where some of the back story and other issues have made this even more complicated for me.

1) My friend (the owner) believes that putting the system under the vacuum pulls the oil out of the system. The research that I was able to do states that it doesn't unless an recovery machine is used. I'm not too sure here. I could use some enlightenment here!

2) The owner being a bit older and the problem child compressor was replaced well over 5 years ago, could not remember if the compressor came pre charged or not nor could he remember if his friend did the do diligence to measure and replace the exact amount of oil in the compressor.

3) I ASS U MEd that the gauge set I was using to recharge the system HAD schrader valves in it! It does not! So even though I thought I was careful not to introduce any outside air during the can change, it could have happened! When I installed the custom one on their 55 Ford, I always checked and bled out the supply as well as the low side line to make sure I didn't introduce anything. I again ASS U MEd that this newer guage set had schrader valves and did not do this.

So with all of this said, here is the variables that I don't know.

Could there be air in the system that was accidentally introduced into the system? I'm thinking possibly there was! I'm not infallible to making a mistake.Remember here I did ASS U ME.

Could there be little to no oil in the system? Possible because the seals on the back of the compressor even though they did not glow when I initially looked at the vehicle, they weren't in the best of shape. Also the front of the compressor where the shaft seal is and some around where the face plate meets the side body had fairly substantial traces of oil around them and I could actually see the dye after I removed the compressor from the truck.

Could the system be still overfilled with oil? Again possible. I did not work on the vehicle when the compressor was changed originally and as we all know, there is no dipstick to check oil level here. Supposedly according to the internet, there is a sight glass on the back of the compressor in which you can see the oil in the compressor. Looking down at this sight glass, I cannot see any level so I'm not sure here. Also there is no traditional sight glass like on some of the other systems in which you can look into the system unless it is the one on the back of the compressor. Again not sure.

Could it be over charged with refrigerant? Possible but unlikely. We were using the 12oz cans and I got 2 plus about a half of the third one in when the "party" started. The only way that it could be overcharged is if the cans themselves were over filled. I feel that this hypothesis is highly unlikely!

Could the old unit sent some of it's part numbers into the system when it failed? Possible again. We only elected to replace the compressor and did not check anything else. It sure took a while for the shrapnel to reach the compressor though. I looked into the lines right by the compressor and looked a little inside the old one and I didn't see anything but who knows! Remember while I was adding the refrigerant, I am having to warm the cans up to get the pressures up high enough for the vehicle to draw in the vapor. The compressor was running for quite a while before the noise started.

There is no bad smells or smoke coming from the compressor while it is running and when I checked the compressor for temperatures with an infrared thermometer (I know, not extremely accurate), the temps were around 180 degrees. IMHO not too terribly hot.

So the question I have with what is known, what can cause a compressor that was just as happy as happy can be to all of a sudden become a working noise maker?

The compressor seems to be quieter when it cools off some but not much quieter.

Any thoughts will be most appreciated at this point and time! I apologize for the length for the post however I feel that some of the info may help with this and lead us to an answer!

Thank you.

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2122

- Thank you received: 709

That is a pretty safe bet. So far, so good.So I errored on the side of caution and put in 3oz of oil. Rotated the compressor a few times to get the oil moved around and installed the new unit.

Even longer would be appropriate for an "extremely muggy" day.Vacuumed down the system for over 30 min because the day was extremely muggy and we decided that the little bit extra time would help get rid of the moisture in the system.

Even with a machine, oil recovery is minuscule. The lack of air flow cannot overcome gravity. (Try to suck an ounce of oil out of the bottom of a glass bottle, without tipping the bottle. )1) My friend (the owner) believes that putting the system under the vacuum pulls the oil out of the system. The research that I was able to do states that it doesn't unless an recovery machine is used. I'm not too sure here. I could use some enlightenment here!

Anything is possible but, you will have to answer that question. Without being there for the process, it is hard for anyone else to know.Could there be air in the system that was accidentally introduced into the system? I'm thinking possibly there was! I'm not infallible to making a mistake.Remember here I did ASS U ME.

Not knowing the history of this problem, it is very possible that the system is lacking oil. The best thing to do would be to disconnect all line connections and use a chemical AC solvent/flush the flush the entire system. Then, add the appropriate amount of oil to each component.Could there be little to no oil in the system?

I suppose, it is possible that there is too much oil but, I would say that is unlikely. If you want to be sure, flush the entire system and add the proper amount of oil to each component.Could the system be still overfilled with oil? Again possible. I did not work on the vehicle when the compressor was changed originally and as we all know, there is no dipstick to check oil level here. Supposedly according to the internet, there is a sight glass on the back of the compressor in which you can see the oil in the compressor. Looking down at this sight glass, I cannot see any level so I'm not sure here. Also there is no traditional sight glass like on some of the other systems in which you can look into the system unless it is the one on the back of the compressor. Again not sure.

I agree that that is unlikely.Could it be over charged with refrigerant?

YES!Could the old unit sent some of it's part numbers into the system when it failed?

Whenever you replace an AC compressor, especially due to a catastrophic compressor failure, in addition to flushing all of the lines, it is important to replace the Condenser and the expansion valve or orifice tube, as well. Any fragments that left the compressor can/will possibly/eventually return to the compressor.

A lack of oil, foreign debris from the last compressor, or a factory defect.So the question I have with what is known, what can cause a compressor that was just as happy as happy can be to all of a sudden become a working noise maker?

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- photoshopman1972

-

Topic Author

- Offline

- New Member

-

- Posts: 2

- Thank you received: 0

I was thinking the same on the oil but the man does not understand the concept. I will still do my best to get him to understand. May take a while but I do attempt.

The air question I thought I explained in my original post but I will restate. I ASS U MEd that the guages had schrader valves in them. I did not find out till later that they did not so I did that bad word again and thought that there would be no air that could've got to the system however I should've bled out the line each can change but I didn't.

Like you, I do not know the full history of this vehicle. I got called in second hand on it. The front of the old compressor like I stated before had a bunch of oil on the front of it behind the clutch so the hypothesis of low oil is seeming to be more and more likely.

I agree the only way to do this correctly is to flush and go again.

I do not know if it is a defect or what. All I know is that the system seemed happy until I attempted to install the rest of the charge.

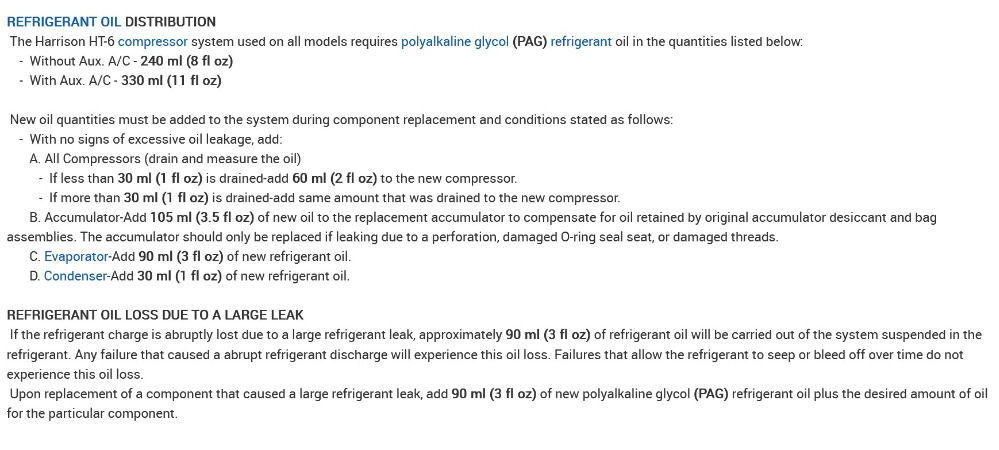

Thank you for your insight and the pic talking about the oil. That is helpful. Now I get to have a headache for the rest of the day dealing with GM about this.

I will see about obtaining a kit to replace the compressor, dryer, orface tube and condenser especially if I go looking into it and see any metal anywhere when the other compressor decided to leave the party.

Again I couldn't look at the condition of the oil before. The old compressor didn't have any in it! I even let the compressor sit on the hose side for over 30 min and not a drop came out.

Again thank you for your time in this. I will do some more research and see what I can do. It still looks like a new compressor is in the future!

Please Log in or Create an account to join the conversation.