Crank no start

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

First is spark. Pick an easy ignition coil to get to, pull it out of the cylinder head but leave it electrically connected. Use your test light connected to B- and use it to test for spark out of the ignition coil while someone else cranks the engine. Vary the air gap to see how much spark you can get out of the coil, if any.

Second is injection pulse. Check for power by unplugging an injector and carefully probing one pin with the test light connected to B-. Again, have someone else crank the engine. If one pin doesn't light up, try the other. One pin should light brightly during cranking.

Doing these checks while cranking the engine is important. This Jeep uses an ASD relay system, meaning that the coils and injectors only get power once the PCM has seen a valid engine speed signal. Checking for power with the key on will tell you nothing.

If you find one of the injector pins lights up during cranking with the test light connected to B-, switch to B+ and do the same thing. Engine cranking, one pin or the other should pulse faintly.

Knowing if there's spark, injection pulse and power to the injectors will help us put you in the right diagnostic direction.

Please Log in or Create an account to join the conversation.

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

While engine cranking I got no spark to ignition coil. I also got no pulse to the injector.

So the engine is cranking but it appears the ASD relay might not be powering up as Tyler mentioned. The PCM provides a ground to the ASD relay if it sees an RPM signal.

If you have a scan tool now is a good time to verify the RPM signal in graphing mode while the engine is cranking. You should hit 150+ rpm.

Does the scan tool detect an RPM signal?

If there is a signal we head towards the ASD Relay, if not, we head towards the Crank sensor input.

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

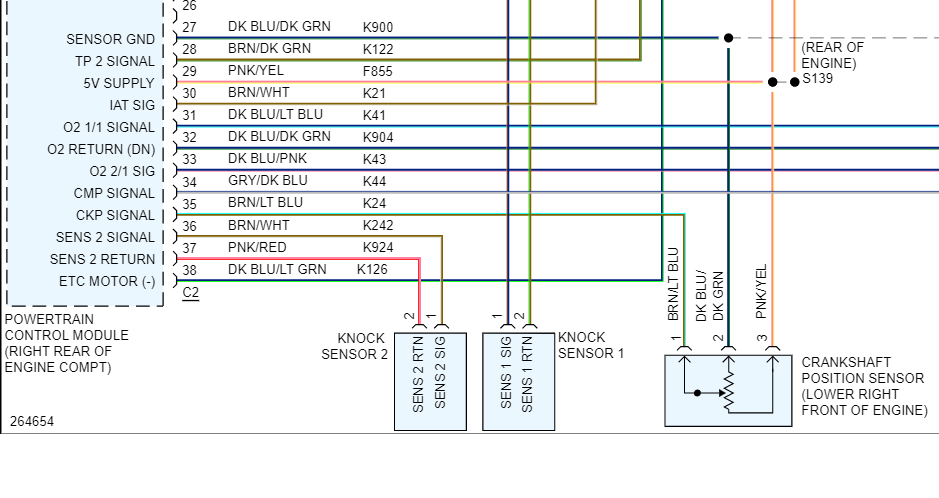

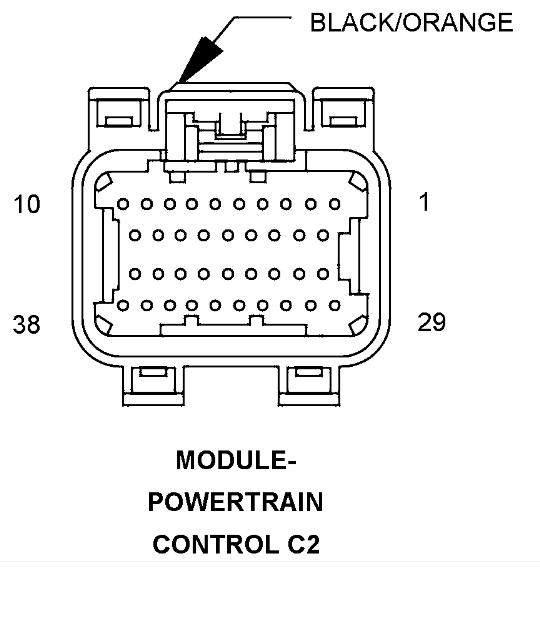

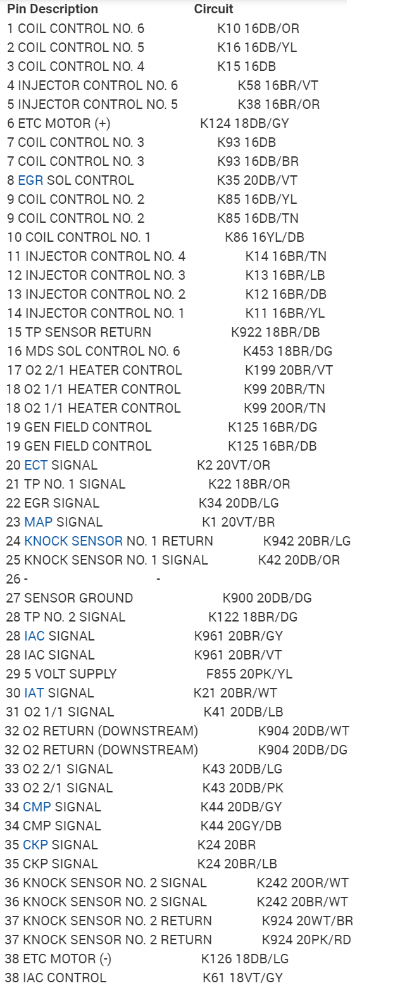

I would be checking for a crank signal next using a scope at Pin 35, Connector C2 (orange) PCM. Should be a 5v square wave. A DVOM will show you an average voltage maybe 2.2v cranking.

Just because the sensor is "new", doesn't mean it's good. You might have a wiring issue.

Have any codes come up during all this?

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

This video will help you immensely:

Here is the sensor wiring diagram;

Should also mention you can backprobe the 3-wire pigtial at Pin 3 and jumper (with a test lamp) with repeated slight taps to the signal wire pin 1 to see if you produce an rpm on the scan tool. This will certainly verify a bad sensor. But Do this test after confirming the 5v ref, the ground are intact.

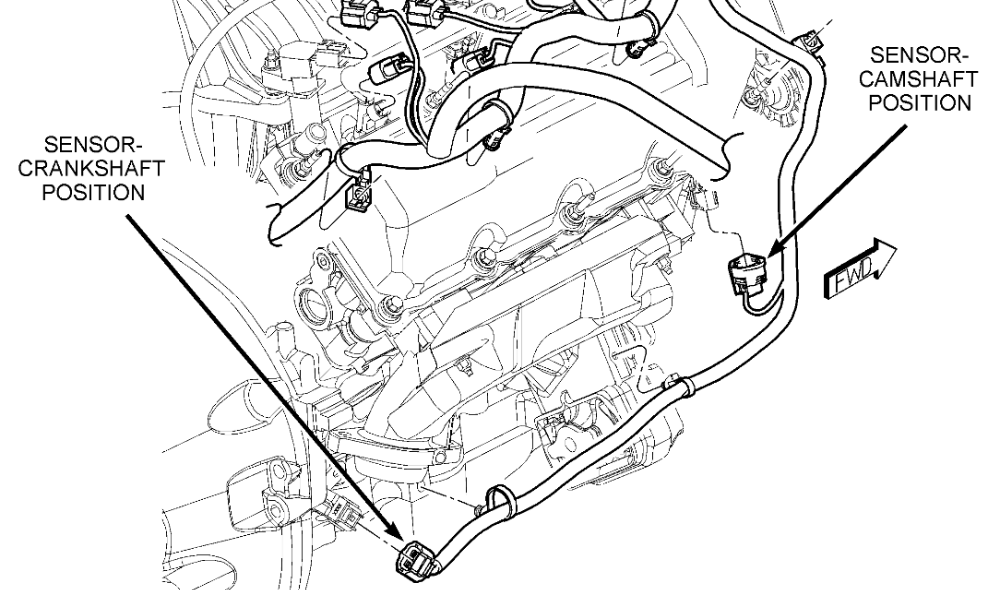

Here is it's location;

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

While it is unplugged, what is the voltage on the signal wire? (Key-ON). If it is 5v, tap the signal repeatedly to ground. If it is 0v, tap it up to 5v from the 5v reference wire while observing for rpm.

If this doesn't produce an RPM on the tool, the signal wire might be OPEN. You'll have to do the tap test at the PCM.

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

To be clear, do you have 5 v on the signal wire (PIN 1) at the sensor unplugged? Because you stated there is 5v at the PCM C2 Pin 35.

If you do:

At the sensor unplugged, use the test light and repeatedly short pins 1 and 2 to bring down the voltage, do you have RPM?

If you don't there is an open between the Sensor Pigtail and the PCM.

In between these tests you should be cycling the key to re-initiate the PCM. Or clear codes, because unplugging the CKP with the key-on should set a code.

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Just verify the sensor ground is good, test lamp to B+ and touch pin 2, lamp should light.

And with a volmeter to bat negative while cranking test pin 3, voltage should remain stable.

The signal wire integrity is good because of you trying to pull down the circuit and activating relay ( probably the ASD relay which powers the Coils and Injectors). You could test that theory, do the tap test while seeing if they power up with a test lamp!!!!)

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Ted1984

-

Topic Author

- Offline

- New Member

-

- Posts: 13

- Thank you received: 4

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Key-on, look for the little solid red circle on the instrument cluster (Lower left maybe for that year), after about 2 seconds it should go out.

If it doesn't, the engine will crank and only run for 2 seconds.

Sounds like your crank sensor may be ok for now, but you got some KEY/SKREEM/SECURITY issues.

Never stop Learning.

Please Log in or Create an account to join the conversation.