FIXED Really need help 2017 dodge caravan 3.6 with cylinder 2 misfire

- XsleepercellX

-

Topic Author

- Offline

- Senior Member

-

- Posts: 59

- Thank you received: 7

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4959

- Thank you received: 1111

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- XsleepercellX

-

Topic Author

- Offline

- Senior Member

-

- Posts: 59

- Thank you received: 7

Please Log in or Create an account to join the conversation.

- XsleepercellX

-

Topic Author

- Offline

- Senior Member

-

- Posts: 59

- Thank you received: 7

Please Log in or Create an account to join the conversation.

- XsleepercellX

-

Topic Author

- Offline

- Senior Member

-

- Posts: 59

- Thank you received: 7

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

When the ac-compressor engages the rpm are commanded slightly higher to compensate for the additional load on the engine. A wider opened throttle will affect intake manifold vacuum.

As you measured vacuum with a real gauge:

is the needle stable or does it flicker/bounce regularly while idling?

As you don't notice lack of power:

is the miss present at idle only?

If so it might be a valve(train) issue which is not uncommon on this engine as Noah already mentioned.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

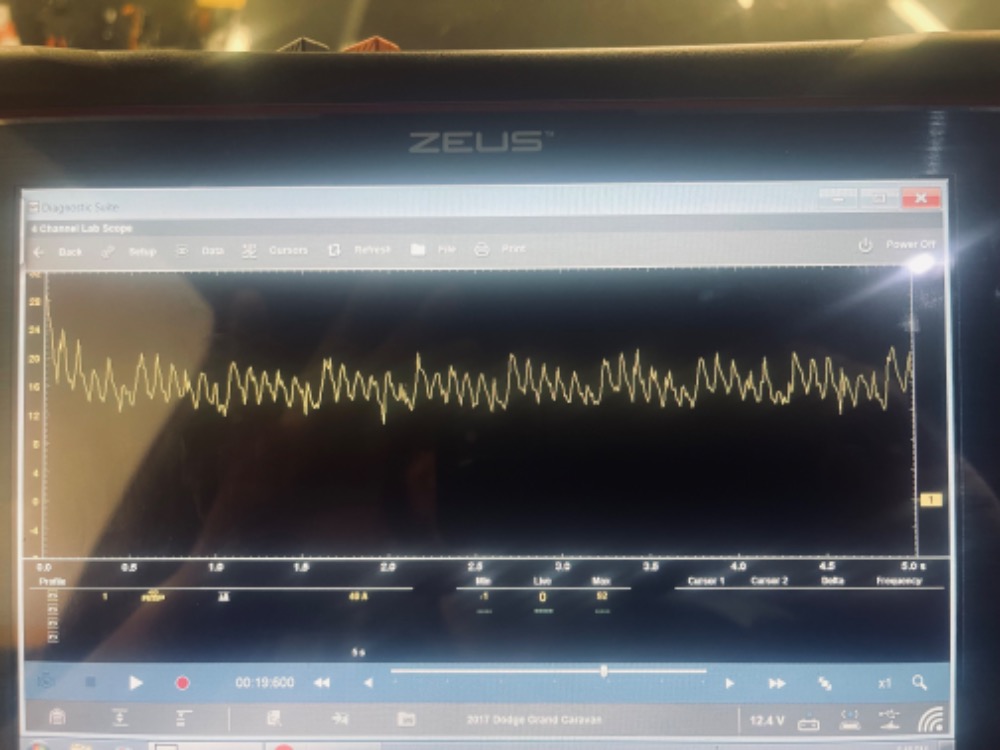

Not sure I did it on the greatest settings but any thoughts?

Definitely one low cylinder there. What probe were you using, and where was it connected?

I'd add a sync to your next capture so you can ID the low cylinder before pulling the intake again. Pick one of the rear bank coils and connect a backprobe to one of the coil control wires.

Valvetrain issues are indeed common on this engine, and usually shows up as a misfire at idle like you've described. Smoked cam followers and flat cam lobes are typical, but I've also seen leaking intake valves several times.

Please Log in or Create an account to join the conversation.

- XsleepercellX

-

Topic Author

- Offline

- Senior Member

-

- Posts: 59

- Thank you received: 7

Please Log in or Create an account to join the conversation.

- XsleepercellX

-

Topic Author

- Offline

- Senior Member

-

- Posts: 59

- Thank you received: 7

Here’s some info about how Chrysler detects misfires, anyone have any ideas on how to use this info in a diagnostic situation would be helpful. My thoughts are to pull the intake and spark plugs, get an actual compression reading in all cylinders and I’m also thinking I should pull the valve cover off and visually inspect the valves, valve springs, lifters, rockers and cam lobes for cylinder number two. Before pulling the cover though, if I do have low compression I’d add oil and recheck, if ok I’d do a leak down test and then from there depending on what I find, pull the cover and just inspect what I can visually… it’s not making a ton of noise so I don’t have high hopes it would be something easy like a bad lifter or rocker arm.. I’ve seen people just loosen the cam enough to pull the rocker arms out without messing with timing..

Please Log in or Create an account to join the conversation.

- XsleepercellX

-

Topic Author

- Offline

- Senior Member

-

- Posts: 59

- Thank you received: 7

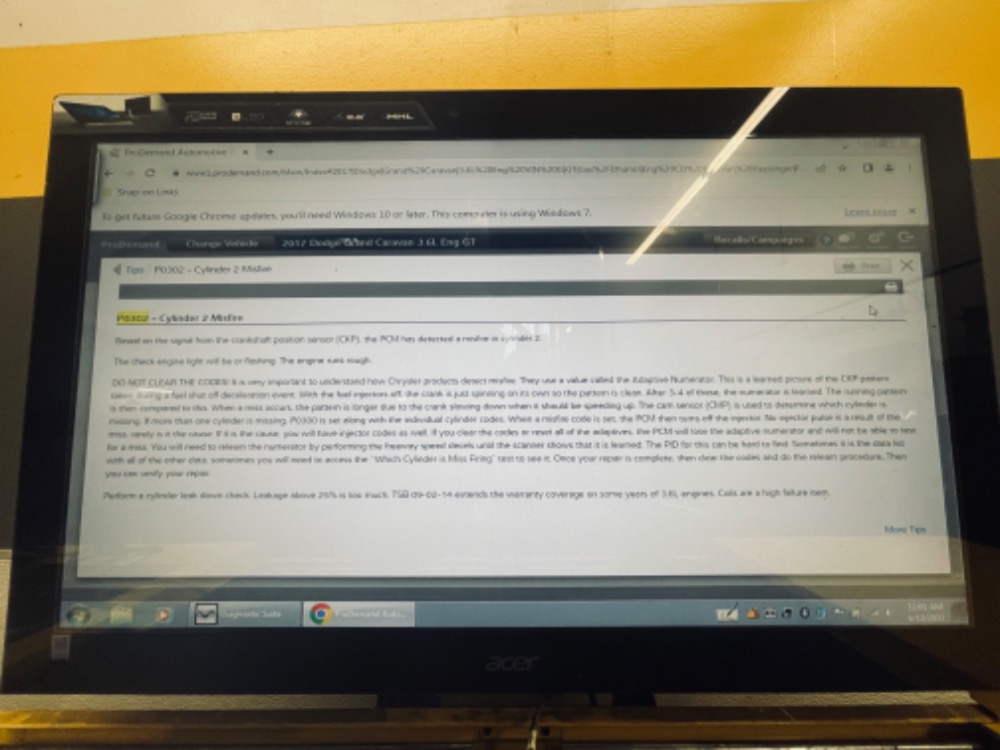

P0302

Based on the signal from the from ckp the pcm has detected a misfire in cylinder 2.

DO NOT CLEAR THE CODES! It is very important to understand how Chrysler products detect misfires. They use a value called the Adaptive Numerator. This is a learned picture of the ckp pattern taken during a fuel shutoff deceleration event. With the fuel injectors off, the crank is just spinning on its own so the pattern is clean. After 3-4 of these the numerator is learned. The running pattern is then compared to this. When a miss occurs, the pattern is longer due to the crank slowing down when it should be speeding up. The cam sensor is used to determine which cylinder is missing. If more than one cylinder is missing, p0300 is set along with the individual cylinder codes. When a misfire code is set, the pcm turns off the injector. No injector plus is a result of the miss, rarely is it the cause. If it is the cause , you will have injector codes as well. If you clear the codes or reset all the adaptives, the pcm will lose the adaptive numbers for and will not be able to test for a miss. You will need to relearn the numerator be performing the freeway speed decals until the scanner shows that it is learned. The pid for this can be hard to find. Sometimes it is in the data list with all the other data, sometimes you will need to access the “which cylinder is misfiring” test to see it. Once your repair is complete, then clear codes and do the relearn procedure. Then you can verify your repair.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4959

- Thank you received: 1111

I have pryed the rockers out and reinstalled without loosening the camshaft or timing, if that is the issue. At my shop, I have even seen them put a rocker in an engine that really should have gotten a camshaft. There was noticeable scoring of the lobe but misfire codes did not return and the customer is satisfied with the repair.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- XsleepercellX

-

Topic Author

- Offline

- Senior Member

-

- Posts: 59

- Thank you received: 7

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6064

- Thank you received: 1531

Ok, pulled the intake and did a compression test. All cylinders were @145-150 psi except cylinder number 2 which was right 100 psi and the spec is 100 psi.. I added some oil to the cylinder and the compression jumped up to 150 psi… Looks like it’s piston rings which sucks…. Not sure if the engine has to be pulled for this repair or if it’s doable from underneath just removing the oil pan, if anyone has experience with swapping out piston rings on this engine feel free to chime in and let me know. Thanks to everyone that pitched their ideas, it was all much appreciated..

Do a leak down on cylinder #2 anyway. I can't say that I've ever seen (or even heard of) a bad piston ring on a Pentastar engine before.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4959

- Thank you received: 1111

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- XsleepercellX

-

Topic Author

- Offline

- Senior Member

-

- Posts: 59

- Thank you received: 7

Please Log in or Create an account to join the conversation.

- Mechanic 350

-

- Offline

- Elite Member

-

- Posts: 312

- Thank you received: 15

how would I determine the firing order based on this capture?

how do I dissect this waveform?

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4959

- Thank you received: 1111

Without a sync from a coil firing event, you can't for sure. In hindsight, knowing that #2 is having lower compression, we can infer the low hump in the pattern is #2, then plug in the firing order from there.are you able to circle the wave capture and show me the misfires?

how would I determine the firing order based on this capture?

how do I dissect this waveform?

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Hardtopdr2

-

- Offline

- Platinum Member

-

- Posts: 852

- Thank you received: 150

Please Log in or Create an account to join the conversation.

- XsleepercellX

-

Topic Author

- Offline

- Senior Member

-

- Posts: 59

- Thank you received: 7

Please Log in or Create an account to join the conversation.