Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

2004 Chevy Classic Trying to repair alternator

- Stinky

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 10

- Thank you received: 0

2 years 10 months ago - 2 years 10 months ago #60378

by Stinky

2004 Chevy Classic Trying to repair alternator was created by Stinky

2.2L

Valeo alt

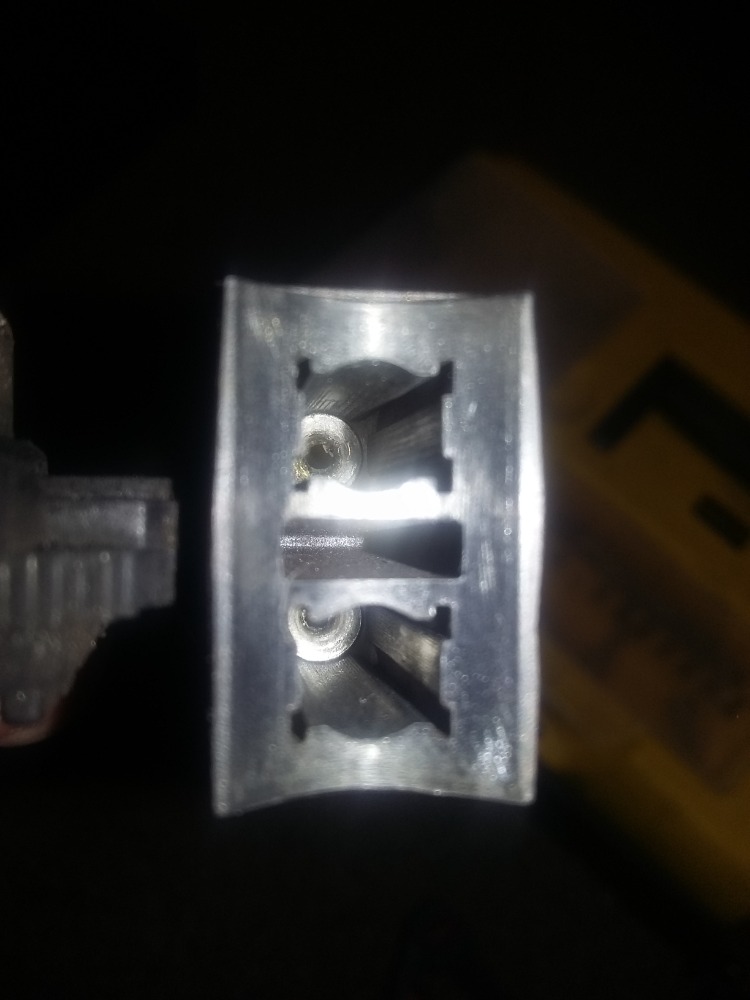

I took the dead alternator out of this car and took it apart. The first thing I noticed when I removed the voltage regulator was the tip of one of the brushes was dull and black, it obviously wasn't making contact with the slip ring. The problem seemed to be a sticky or dirty spring or the channel it sits in because contact was made again when I reseated the regulator. I bench tested it and it does work now, the brushes are obviously very worn though and need to be replaced before I put it back on the car.

The problem is I'm not sure if the brushes themselves are servicable. Are there any brushes for this alternator available anywhere or do I just have to replace the regulator?

Valeo alt

I took the dead alternator out of this car and took it apart. The first thing I noticed when I removed the voltage regulator was the tip of one of the brushes was dull and black, it obviously wasn't making contact with the slip ring. The problem seemed to be a sticky or dirty spring or the channel it sits in because contact was made again when I reseated the regulator. I bench tested it and it does work now, the brushes are obviously very worn though and need to be replaced before I put it back on the car.

The problem is I'm not sure if the brushes themselves are servicable. Are there any brushes for this alternator available anywhere or do I just have to replace the regulator?

Last edit: 2 years 10 months ago by Stinky.

Please Log in or Create an account to join the conversation.

- Stinky

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 10

- Thank you received: 0

2 years 10 months ago #60395

by Stinky

Replied by Stinky on topic 2004 Chevy Classic Trying to repair alternator

I contacted support for maniac electric motors and they directed me here. I went ahead and ordered them.

www.maniacelectricmotors.com/7308105b.html

As far as removing the old brushes I used a wire wheel attachment on a rotary tool to clean up the backside where the solder goes then applied heat. They popped right out being under spring tension. Then I used a drum sanding bit to bring it down to be flush with the plastic. Switched the tip from a chisel to a pointed tip and opened the hole where the leads pull through. I cleaned out the channel where the springs go to make sure they don't stick again.

As far as removing the old brushes I used a wire wheel attachment on a rotary tool to clean up the backside where the solder goes then applied heat. They popped right out being under spring tension. Then I used a drum sanding bit to bring it down to be flush with the plastic. Switched the tip from a chisel to a pointed tip and opened the hole where the leads pull through. I cleaned out the channel where the springs go to make sure they don't stick again.

Please Log in or Create an account to join the conversation.

- MarkBeck101

-

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 2

2 years 9 months ago #60836

by MarkBeck101

Replied by MarkBeck101 on topic 2004 Chevy Classic Trying to repair alternator

Only real men, unless stinky is a woman, repair their own alternators. In the old days we had shops in my town that would rebuild alternators, a real man's job. Times were simpler than. When alternator repair was looked up to, and was well lots of fun.

So with the rebuild you want replace the diode / regulator pack, clean up the slip rings, and as you stated replace the brushes, not to mention new bearing or bushings as needed (don't forget to lubricate). But, the question about brushes is very common, and the trick is to make the curve of the brush match the curve of the slip ring.

If you talk to the pros, once everything is working you really have to validate that the rotating assembly is balanced while putting out near full field as my memory recalls. This is where the simple spin-tron would be used, or just attached it to a bench an see if it vibrates, or just put it back on the car and see if it vibrates. But, if it vibrates you have to get it balanced.

When you buy the brushes new they may or may not match the slip ring diameter (in my experience they never do). If not, you would have to grind the brushes to match the slip rings. They actually make grinding tools for this that has a very nice fixture, but you can make your own, by basically putting emery cloth around a hole saw of about the same diameter as the slip ring and using a drill make a smooth curve while taking off as little of the brush material as possible.

So with the rebuild you want replace the diode / regulator pack, clean up the slip rings, and as you stated replace the brushes, not to mention new bearing or bushings as needed (don't forget to lubricate). But, the question about brushes is very common, and the trick is to make the curve of the brush match the curve of the slip ring.

If you talk to the pros, once everything is working you really have to validate that the rotating assembly is balanced while putting out near full field as my memory recalls. This is where the simple spin-tron would be used, or just attached it to a bench an see if it vibrates, or just put it back on the car and see if it vibrates. But, if it vibrates you have to get it balanced.

When you buy the brushes new they may or may not match the slip ring diameter (in my experience they never do). If not, you would have to grind the brushes to match the slip rings. They actually make grinding tools for this that has a very nice fixture, but you can make your own, by basically putting emery cloth around a hole saw of about the same diameter as the slip ring and using a drill make a smooth curve while taking off as little of the brush material as possible.

Please Log in or Create an account to join the conversation.

Time to create page: 0.274 seconds