*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

2000 Jeep Grand Cherokee 4.0 Mystery misfire?

- Idunno123

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

Regardless, 2000 jeep grand cherokee 4.0, I am trying DESPERATELY to figure out this mystery knock on an engine that has a lot of sentimental value to me. It'll run and start great, but after about 5 or so seconds, it'll start this really irregular knock that'll hit about every 6 someodd seconds and be strong enough to feel in the drivers seat. and it gets worse as the engine gets warmer, but never bad enough to throw codes. But It's not throwing any codes? But when I backprobe the signal circuit (cheap hantec), it's a REALLY weird waveform? Grounds are good, wires are good going to the PCM, but I had a really weird issue I discovered that I don't know if it messed up the PCM?

Basically, the previous owner was an idiot who spliced in a ground on the wire going between the ASD and the coil pack (even though that circuit was fine...), and I realized that for the past good bit of running, the engine had 14 live volts going through it. Could that have messed something up in the PCM maybe? I havn't backprobed the 5v circuit yet but I think I should to be sure?

I'm seriously running out of ideas and I'm loosing my marbles so I'd appreciate any help

and before anyone recommends just changing the Crank sensor, I already did, it had an OEM chrystler one that worked great until my flywheel/torque converter started knocking on the plate. Ever since then this WEIRD misfire started and won't go away, even when I switched out the chrystler one for replacement chrystler ones I had on standby, or switched in standard brand backup ones.

Please Log in or Create an account to join the conversation.

- Cheryl

-

- Offline

- Platinum Member

-

- Posts: 1214

- Thank you received: 215

Please Log in or Create an account to join the conversation.

- Idunno123

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

Is there any situations of an improperly installed torque converter or flex plate causing knocking? I've taken off the inspection plate and it's not moving back and forth when it runs, I can't flex the plate with a small pry bar from any angle, it SEEMS like a good flex plate and torque converter combo, except for this mystery knock? and slight vibrations I can feel when I put it into gear, or when I take it out of gear; However, it's not pinging like a broken flex plate that's the same sound regardless of anything. This will vibrate/ping HARD for a second or two (nearly shake the car almost, can hear it hitting the inspection plate), then slowly adjust itself to not making a noise at all?

There was a while ago that my dumb friend tried to tighten the crank sensor bolt down with a 1/2 rachet and we had to helicoil it? Could that maybe be doing something? The bolt will torque to the 15 someodd ft-lbs it requires so I wouldn't think the crank sensor could wiggle around or move?

Sorry if this sounds like me listing random repairs I've done, I'm really up a creek without a paddle here, all my family members are basically carb guys and part swappers so I really don't know ANYTHING here,

Please Log in or Create an account to join the conversation.

- Idunno123

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

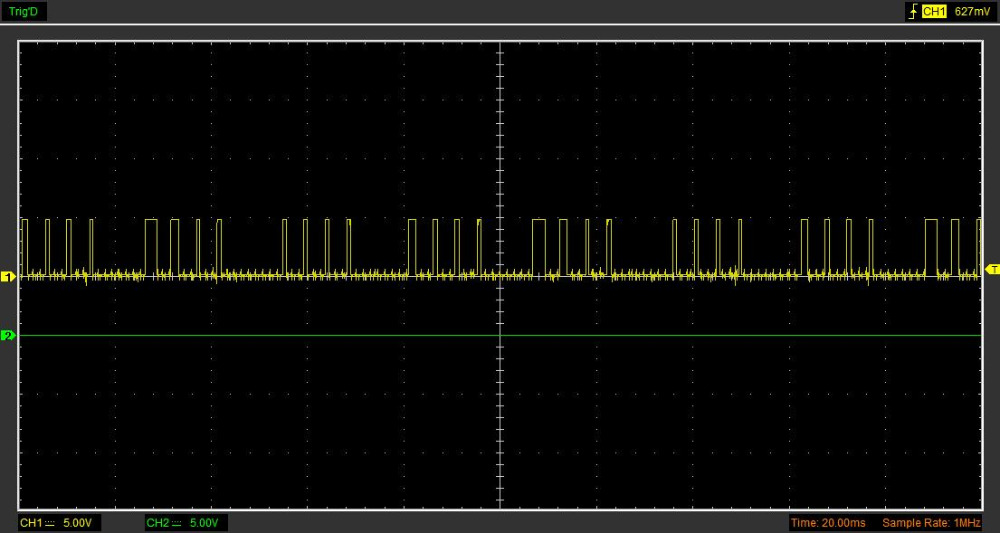

I think you have an issue with your trigger wheel. The square waves have random different sizes in them it looks like. Might be a cracked flex plate

Is there anything that I could be checking on the trigger wheel? I can see it from the bottom of the car when I remove the inspection plate, and it doesn't seem to be bent or cracked or anything other than what it should look like? It doesn't wiggle back and forth when I turn the engine, and I can't see any scuff marks on the crank sensor when I remove it to inspect it either?

I saw an old forum post a few months back when I started searching about someone finding a notch in their trigger wheel BENT in and it was causing a misfire, but the pictures they had looked like someone ran over the flywheel on accident or something; that was a visible BEND, and mine looks perfectly fine compared to that? But then again, I know the air gap is pretty small, so I'd wager that a small bends can cause issues, i dunno

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

The knock itself is the sound of a misfire or is it more of a mechanical contact/hammering noise. If so, does it originate in the bell housing area?

Did you do the mentioned repairs personally or were there more 'stupid friends' involved?

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

I think you have an issue with your trigger wheel. The square waves have random different sizes in them it looks like. Might be a cracked flex plate

That looks like a repeating pattern to me. There is a wide pulse every 360* which looks like a sync. But I don't think this application has a CKP sync.

I'd be taking a real close look at flexplate target slots. And flexplate radial runout. Feeling for mechanical tightness while barring the engine over.

Please Log in or Create an account to join the conversation.

- Idunno123

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

Jeep has been running good for abt 3 months now, the engine is NOT knocking under ANY circumstance (feels great in cabin), I (unknowingly) have the ASD wire-spliced in grounded connection connected (live voltage going through engine), and we're out driving one day,

--It's been having this mechanical contact go on every now and then when the engine gets warmed up, not bad, but a hum of something vibrating slightly too much at best, and then it would go away when not under load, replaced engine and trans mounts to no fix, and shrugged it off

--We're going uphill one day, hum gets progressively worse, worse, WORSE, WORSE, then BANG; CLANG, CLANG, CLANG sound entire time the engine is running even off load, get it home, it's the flexplate/torque converter, you can put your hand on the inspection plate and feel it hit on the other side, and you can also apply pressure and hear the CLANG get worse

--I drop the transmission, replace the flexplate/torque converter combo, replace the inspection plate and the metal shield between the engine and bellhousing because they both have such a massive GOUGE in them (but none of the torque converter bolts were loose when I removed them? just marred), get everything torqued and bolted back up with no issues I could really notice until I couldn't really pull the torque converter all the way snug to the flexplate? I actually had to get longer bolts from ace to help "wiggle" it closer so the OEM Flexplate/TQ bolts could thread and pull it closed the rest of the way, torqued to 15ft-lbs with orange threadlock and the special Flexplate-to-TQ bolts from the same car at the junkyard

I performed this ENTIRE repair, start to finish there, new mopar crank sensor (old mopar sensor that fixed previous misses got lost in a garage relocation, fml)

Ever since I performed this repair, it's been missing. Not enough to throw a code like I said, but enough to jutter every few seconds and shake the cabin,

I checked EVERYTHING I could think of it being, fuel pressures good, injectors switched and good, cylinder pressures good (it is less than 500 miles old, brand new engine rebuilt at home by me and my grandpa, he's passed now so don't ask if he can answer any questions on the rebuild), new spark plugs, it got a new computer with the original rebuild;

the ONLY thing that was suspicious was the coil pack, which measured (I think) 20~k ohms btwn cylinders 2/5 and 3/4, but like 2 Million OHMS btwn 1/6, so I replaced that and it fixed nothing? It didn't even get better or worse

Oh, and I also found the DUMB ground connection that was spliced into the ASD+->Coil pack circuit that had live voltage going through the engine the entire time, but hasn't caused any issues connected or disconnected?

The misfire did get worse when I switched the ASD and TCM relays... But I'm kindof broke rn and waiting to get new relays, and this jeep isn't a daily

Side note: Dumb fried was coming by one day to pick me up to hangout, he stripped the crank sensor bolt with an impact rachet trying to "guess" when it was ran down trying to be helpful, that was his first and last help to anything before we just stopped to go hangout, I got it helicoiled after a week or so of trying to find a way to do it without dropping the transmission again

TL;DR

Engine was missing hella abt 2 years ago post initial rebuild, gpa/machinist of the rebuild passes, I replaced ckp and computer and it ran great for abt 6 months other than a building flywheel vibration/break, then 100% broke flexplate, fixed, and has been missing ever since, regardless of mopar vs standard brand crank sensor or any repairs

That's my whole diagnosis/repair story up to this moment!

Please Log in or Create an account to join the conversation.

- Idunno123

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

I'd be taking a real close look at flexplate target slots. And flexplate radial runout. Feeling for mechanical tightness while barring the engine over.

I measured the radial runout from the starter gear/ring (was that correct to do? Should I measure along the flywheel area?) a few days ago, it didn't have any noticable runout until 2 distinct points where it had btwn 0.020"-0.030" (it didn't fluctuate, that's just my guesstimate since it was a few days ago, was 100% more than 0.020" though), and dipped back down to zero after about an 1/8 of a rotation? looking at all the video's on youtube, that seems to be excessive? and also weird, as per usual with this project, lmao. I'm honestly not sure, I have no experience so please correct me if that's acceptable

Should I be looking at a new flexplate? Or would something about the flexplate/TQ mating make it bend so bad in certain spots? Or perhaps correlated with the difficulty I had with pulling the Torque Converter flush with the flexplate? Should I redo remeasure the radial runout to get a more precise measurement?

I'm going to disconnect the torque converter tomorrow, push it back, and see if the results are the same

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4914

- Thank you received: 1098

This sounds like bad news to me. If the converter bolts that belong in the converter couldn't reach, then something went together wrong, or the wrong parts were used.

I understand the flex plate was broken, but why did the converter also get changed?

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Idunno123

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

"I understand the flex plate was broken, but why did the converter also get changed?

The torque converter was changed as well because during the first repair, replacing just the flexplate didn't stop the vibration or even deter it.

So I dropped the transmission again, replaced the Torque Converter, and the vibration finally stopped; but the knock also started

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

The torque converter was changed as well because during the first repair, replacing just the flexplate didn't stop the vibration or even deter it.

So I dropped the transmission again, replaced the Torque Converter, and the vibration finally stopped; but the knock also started)

I strongly suggest to revisit that torque converter and it's installation.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Idunno123

-

Topic Author

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

Is there anything I should be checking in particular other than the TQ nub/crank slot clearance? What's good tolerances for something that should be free-fitting but snug?

Sorry if any of my questions have been foolish, I changed oil and brakes before this project jeep, and it was supposed to be a learning experience and it's turned into quite a lot more learning than I ever anticipated

Side note: It's going to be about 5 degree's for a week where I live, so I'll have to get back to you guys when I drop the transmission in a week or so

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4914

- Thank you received: 1098

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.