*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

SOS. Stranded...with serious Ford 6.8 Misfire mystery

- Ocelot

-

Topic Author

- Offline

- New Member

-

- Posts: 3

- Thank you received: 0

Engine compression checked out A-OK before I left her stranded so figured it was worth the effort to diagnose and bring her home..

BUT!!!!!

I arrived to find someone decided to hack my engine wiring harness. All connectors for coil packs and injectors were gone! That's bad omen #2. I managed to score a full wiring diagram and I did manage to get some generic ends to solder into the engine harness for coils and injectors, but had to do some serious guessing as to which side of the coils and injectors the common feed and signal wires went to. The diagrams I have do not specify.

Help question # 1.

Does anyone have a Triton V10 that could take a quick peek at their harness and tell me which wire is which on the coils and injectors. Right now I have signal wires (different color for each coil) going to left side of the coil connector and power wire (all the same color for all coils) on right side. For injector connectors I have signal wires going to right side of injector plug (different color for each injector ) and power wire (all same color) going to left side of connector). Maybe it does not matter, but I want it done right. The truck does run now, but with the same bad miss it had before the harness hack. I pulled connectors off the coils and injectors one at a time while running and some give an obvious added misfire.... but with a couple cylinders the engine reaction is barely noticeable (if at all). With V-10 I know it can be tricky. I am getting power to all injectors and all coils, and I am getting pulse signals to all coils and injectors from PCM when I check with a test light while running.

Sadly, I only have a basic hand held code reader with me. I am getting code 0113 (high voltage) but so far that's it. It shakes bad at idle far more than I would expect for one bad coil. Per the code, I tested the IAT on the bench (it does have expected voltage drop with a temp change and ohms seem ok cold) but once again, I had to rewire the sensor connector as that was hacked off too. GRRRRRR... I need to know if it matters which side of the sensor the wires go to and which wire goes where on that two pin plug. It's a guessing game for me.

Thats help question #2 Can someone tell me what color wire goes where on that IAT sensor? On 1999 F250 It's easy to see for a quick peek. Referencing color of wire in relation to the clip on the connector would tell me how to orient my wires.

Last question. If I have good compression and have all new coils, all new plugs, good vacuum hoses and new PCV valve (a known issues with this year truck) and I still get bad misfires, what else do I look for? I am running out of time and would sure like to get this truck across the border before it ends up totally stripped. The only thing left I can think of is injectors. Today I paid $75 for the one and only injector this side of the border (took a week to get it) and installed it in the cylinder that showed the least reaction when pulling coil connection to see if that helped. It didn't seem to make any difference at all. I pulled all injectors and bench tested them and they did open and close when energized and they did spray well when pressurized with a simple spray can / adapter and then energized.

If you have a Triton V-10 and managed to subdue your own engine misfire demons in the past I would love to hear from you. I have to get this truck home and I have a week left to sort it out with limited tools. 7 mules and a lot of rope is looking really nice right about now.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6042

- Thank you received: 1519

Help question # 1.

Does anyone have a Triton V10 that could take a quick peek at their harness and tell me which wire is which on the coils and injectors.

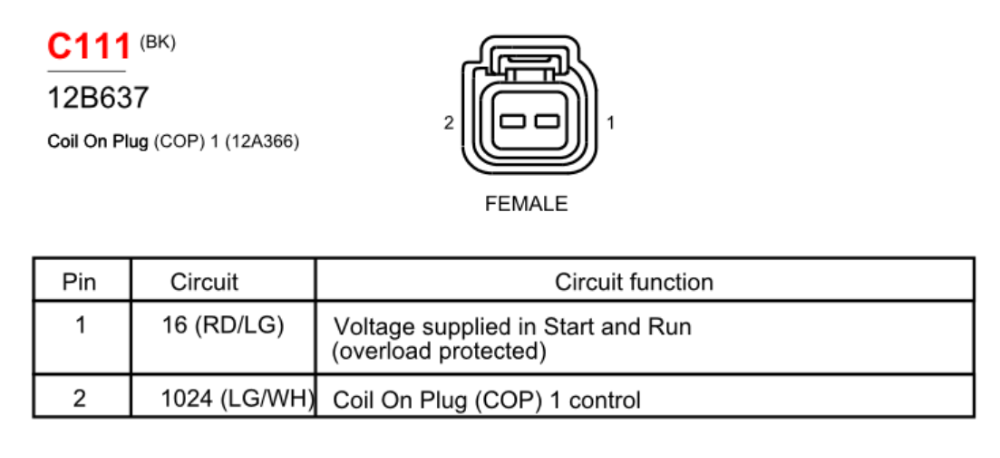

I don't have a V10 around to take a peek at, but I was able to dig up some service info that might help. '99 service info doesn't have pictures of the ignition coil connectors, but '05 does (which has better service info). '99 also doesn't note pin location in connectors smaller than six pins.

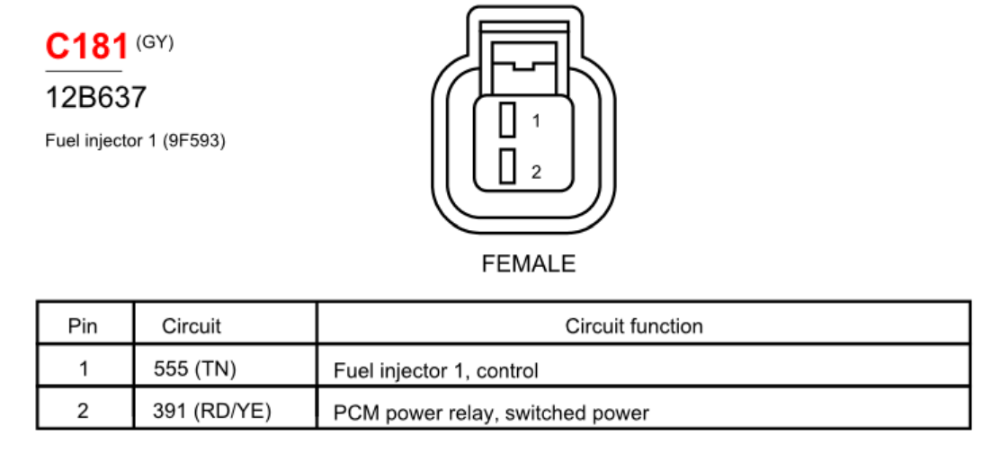

And here's one for the fuel injector:

Both pictures are viewed with the female connector terminals facing you, like so:

Maybe it does not matter, but I want it done right.

In the case of the ignition coils, at least, it truly does matter. I've seen backwards wired coils produce just enough spark at idle, but can't keep up under load. Injectors, I don't think it would matter, but best not to find out.

Depending on the replacement ignition coil, you might find a convenient 'B+' marking on the coil itself:

Thats help question #2 Can someone tell me what color wire goes where on that IAT sensor?

I couldn't find a fancy connector photo in service info, unfortunately. Newer 6.8's switched to an integrated MAF/IAT combo.

But I can say pretty confidently that pin location does NOT matter on thermistors like this IAT. Go eenie-meenie-minie-mo, hook it up and send it. Or, just leave the sensor disconnected and fix it when you get across the border. The IAT doesn't have that much weight in the fuel control calculation, and won't cause a severe misfire like you're experiencing.

Last question. If I have good compression and have all new coils, all new plugs, good vacuum hoses and new PCV valve (a known issues with this year truck) and I still get bad misfires, what else do I look for? I am running out of time and would sure like to get this truck across the border before it ends up totally stripped.

I'd back up a bit and repeat your cylinder balance test. Do it a few times if you have to - picking out a single cylinder miss on a V10 can definitely be a bit tricky.

Once you're sure which cylinders have contribution problems, look for common denominators. All on the same bank? Ends of the fuel rails? Speaking of, can you test for fuel pressure or take a fuel sample?

Will your code reader show scan data? That'd allow you to see fuel trims, and verify your IAT is working correctly.

Please Log in or Create an account to join the conversation.

- Ocelot

-

Topic Author

- Offline

- New Member

-

- Posts: 3

- Thank you received: 0

This is great.. Thanks so much for your effort and time. Just what I was looking for. I spent hours looking over videos and photos for anything that would give me a clue as to wire positions. I'm going to get at it again today by double checking all connections to make sure wiring is correct, then I'm going to clear all codes and start fresh. Let it run a while to collect any codes and see what comes up.

When I arrived tank was on empty so I put in 60 liters of fresh fuel so I know thats good to go. It's a plastic tank so hopefully no rust /crud. I will pump out some fuel through the rails and look for any water as well. Although the miss was there even before I had to leave it, so probably not a water issue. Can't hurt to check. Sadly, I have no way to check fuel pressure. I will say that once I shut it down and let it sit 10-15 minutes before lifting fuel rail there is still plenty of fuel which is under some pressure. So not likely an injector hanging open.

Using a test light I do seem to get consistent trigger pulses to injectors and coils but I am wondering, could the PCU be faulty and sending a weak or randomly missing signal that could create the constant heavy miss? Without a full scan tool I don't know how else I could check each coil / injector for performance under compression or load. I have not worked on many Fords and this is my first V10 deep diagnosis, though I suppose V8 and V 10 is not any different aside from two more of everything to go wrong. I sure am learning a lot so not all is lost. Thanks for the tips. I will get at at and see how it goes.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6042

- Thank you received: 1519

Sadly, I have no way to check fuel pressure. I will say that once I shut it down and let it sit 10-15 minutes before lifting fuel rail there is still plenty of fuel which is under some pressure. So not likely an injector hanging open.

Good enough for now.

Using a test light I do seem to get consistent trigger pulses to injectors and coils but I am wondering, could the PCU be faulty and sending a weak or randomly missing signal that could create the constant heavy miss?

Incandescent or LED test light?

If you've got power and control at each coil/injector with a test light, then I'd suspect you're not fighting a PCM problem. Generally, the PCM drivers either work, or they don't.

Without a full scan tool I don't know how else I could check each coil / injector for performance under compression or load.

For ignition coils, you can always pull a coil out of the cylinder head, leave it connected electrically and start the engine. Connect your test light to B- and use the tip on the spark plug boot to check for spark strength. Change the air gap to get the longest spark possible out of the coil. 1/2" minimum, 3/4" is better.

Please Log in or Create an account to join the conversation.

- Ocelot

-

Topic Author

- Offline

- New Member

-

- Posts: 3

- Thank you received: 0

BTW.. I am using an incandescent test light. Looked for noid light but not going to happen down here.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4914

- Thank you received: 1098

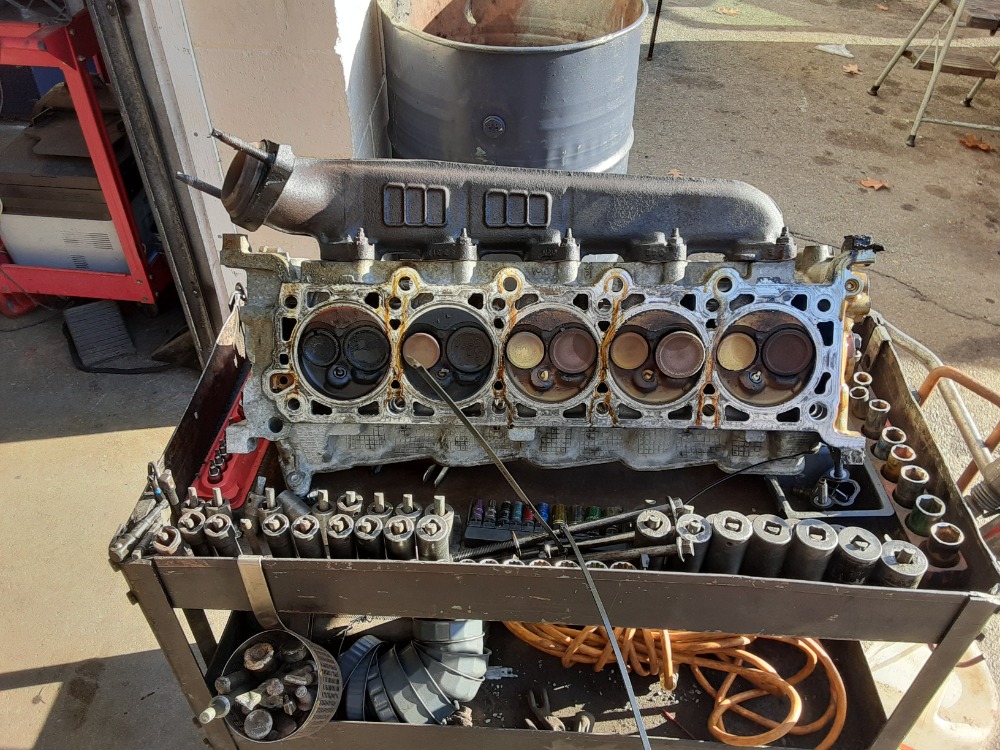

(This is a company vehicle on site if you need and comparative data.)

Compression test and leak down proved exhaust valve.

A compression test may be worth while before going too deep.

If you suspect injectors leaking, with a fuel pressure gauge on the test port, cycle the fuel pump, then turn the key off and see how long pressure holds.

It will drop, but a rapid, near instant drop points to something leaking.

The

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.