'14 Golf 2.0L TDI CJA Crank No Starty

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6083

- Thank you received: 1537

I've added the VCDS code scan, but here are the highlights:

Address 01: Engine (CJA) Labels: 03L-906-022-CBE.clb

Part No SW: 03L 997 030 D HW: 03L 907 309 AA

Component: R4 2.0l TDI G000SG 9983

Revision: 12H16--- Serial number:

Coding: 0050072

Shop #: WSC 09060 003 1048576

VCID: 2F2E00CEBEB1EEF766-807A

VINID: 9E69DE74745A1959C000000310D6C350B3

2 Faults Found:

011174 - NOx Emissions Exceeded

P2BA6 - 000 - SCR Catalyst Malfunction - MIL ON

Freeze Frame:

Fault Status: 11100000

Fault Priority: 2

Fault Frequency: 1

Reset counter: 255

Mileage: 180749 km

Time Indication: 0

Date: 2016.10.28

Time: 22:23:18

Freeze Frame:

RPM: 0 /min

Speed: 0.0 km/h

Load: 0.0 %

Pressure: 955.9 mbar

Temperature: 24.3°C

Mass Air / Rev.: 1100.0 mg/str

Temperature: 40.5°C

006744 - NOx Catalyst

P1A58 - 000 - Regeneration Required

Freeze Frame:

Fault Status: 01100000

Fault Priority: 6

Fault Frequency: 4

Reset counter: 255

Mileage: 180749 km

Time Indication: 0

Date: 2016.10.28

Time: 22:23:18

Freeze Frame:

RPM: 0 /min

Speed: 0.0 km/h

Load: 0.0 %

Pressure: 955.9 mbar

Temperature: 24.3°C

Mass Air / Rev.: 1100.0 mg/str

Temperature: 40.5°C

Readiness: 1 1 0 1 1

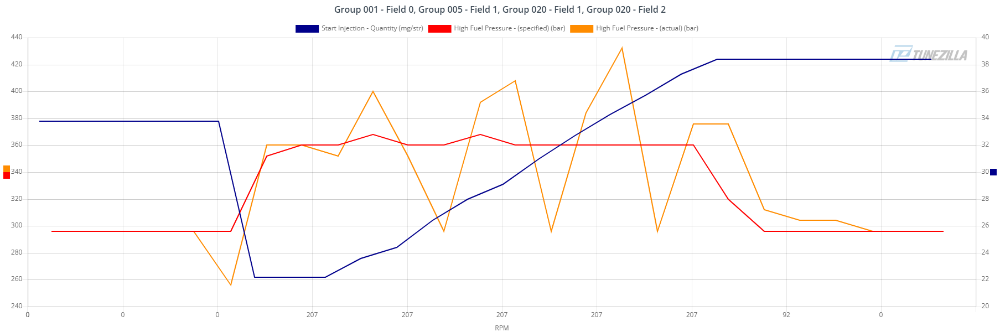

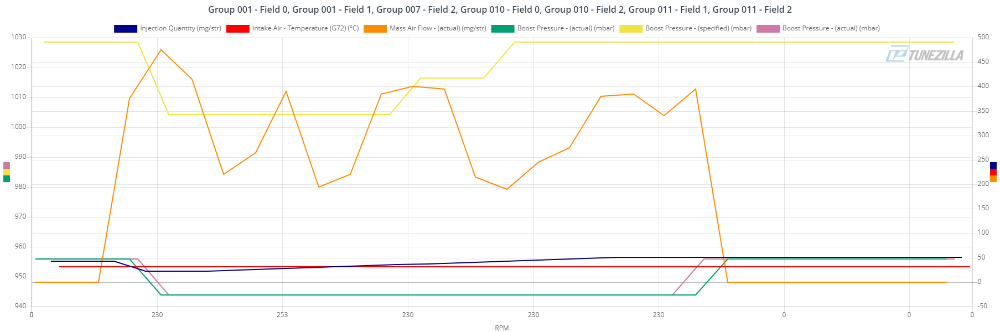

I'm told that the SCR codes are old news and have been ignored for awhile. :lol: Anyway, since I've seen high pressure fuel pump failures on these previously, my first check was rail pressure. It was disappointingly good:

Rail pressure may be a bit erratic, but it's there. 207 RPM cranking speed isn't spectacular, I know, but the battery was dead when I got to it.

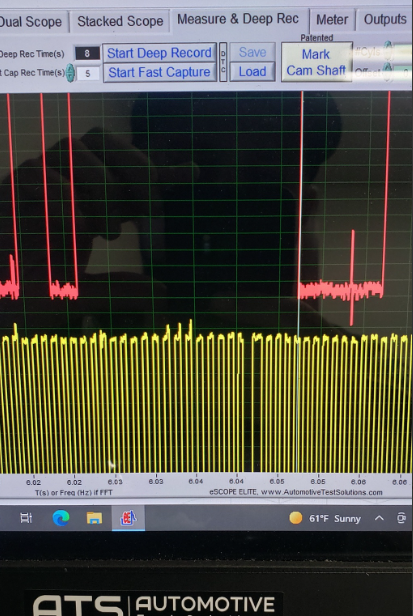

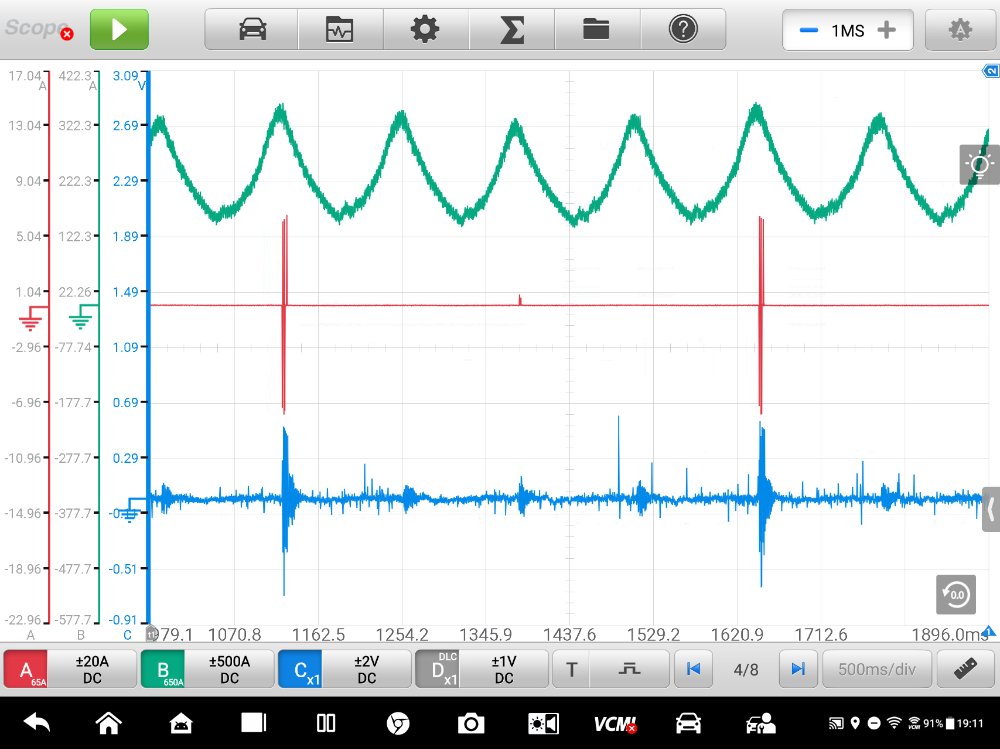

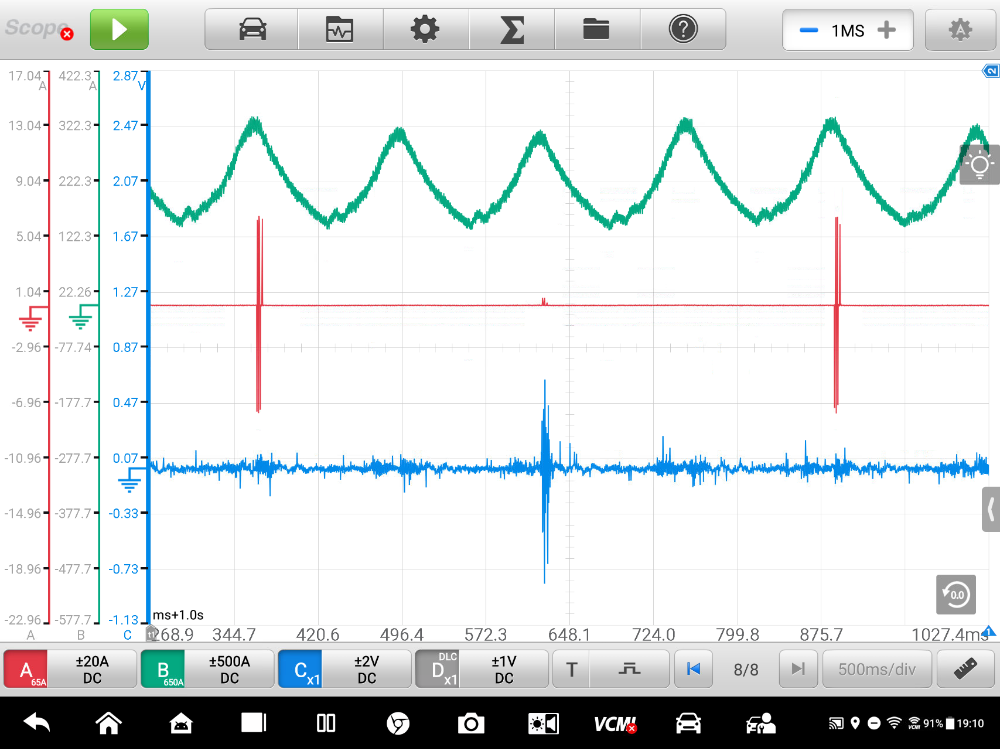

I move on to possible mechanical/breathing issues. I take a cam crank waveform with a current probe on the #1 injector:

This appears good compared to the (only) known good I could dig up:

diag.net/msg/m1qyflnr89ke721kzzflmoqgoo

Swing and a miss. SCR codes stored - Maybe it's got a massive exhaust restriction? So I pull the upstream NOX sensor. No improvement.

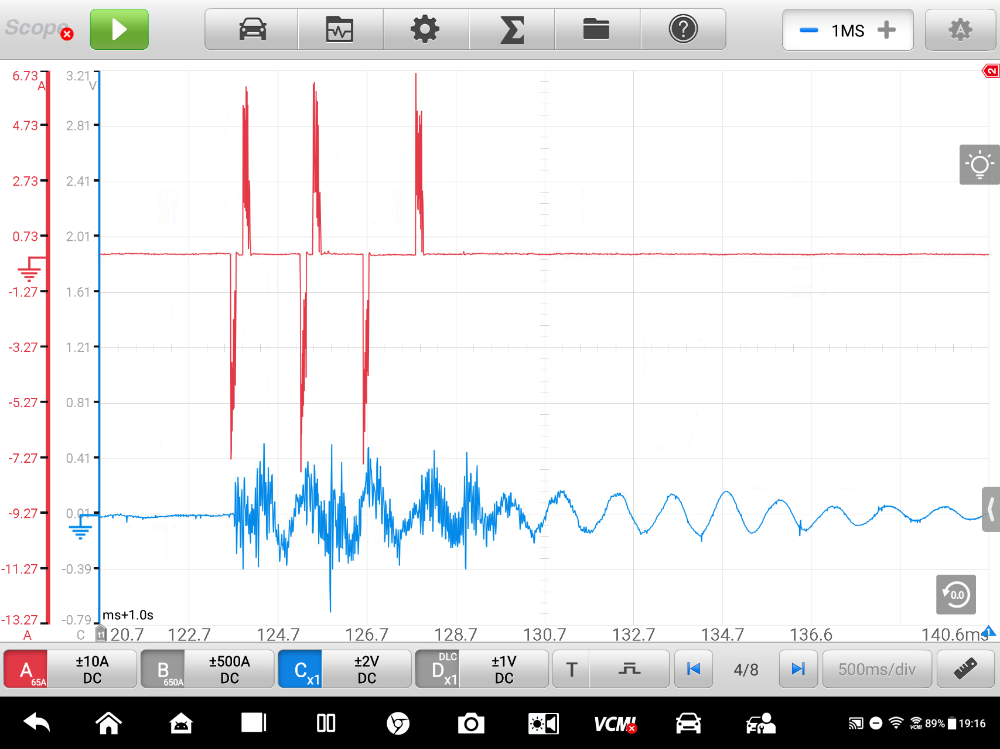

Thinking maybe there's an intake restriction, I watch the boost and MAF sensors during a crank:

A slight vacuum on the boost sensor, and some activity on the MAF. It's trying, I guess? I don't normally watch these PIDs on diesels during a crank. :silly:

Desperate, I pull the intake tubing off. Still no improvement. But I do notice what seems like an excessive amount of diesel fumes coming OUT of the intake during cranking. :huh:

What am I missing? As usual, any thoughts, ideas or WAGs are welcome!

Please Log in or Create an account to join the conversation.

- derekoliveira

-

- Offline

- Senior Member

-

- Posts: 72

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6083

- Thank you received: 1537

If throttle body won t open for any reason is not possible to start engine?!

You mean the J338 Throttle Valve Control Module?

I suppose so? :huh: Usually that throttle valve defaults to 100% open until EGR flow is commanded... I'll have a look at the indicated scan tool position on Monday.

Forgot to mention in the opening post that I did take a fuel sample and found clean diesel.

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6083

- Thank you received: 1537

The gentleman and scholar known as Juergen suggested using a piezo sensor on the injector rail to confirm that the injectors are actually opening. Solid idea.

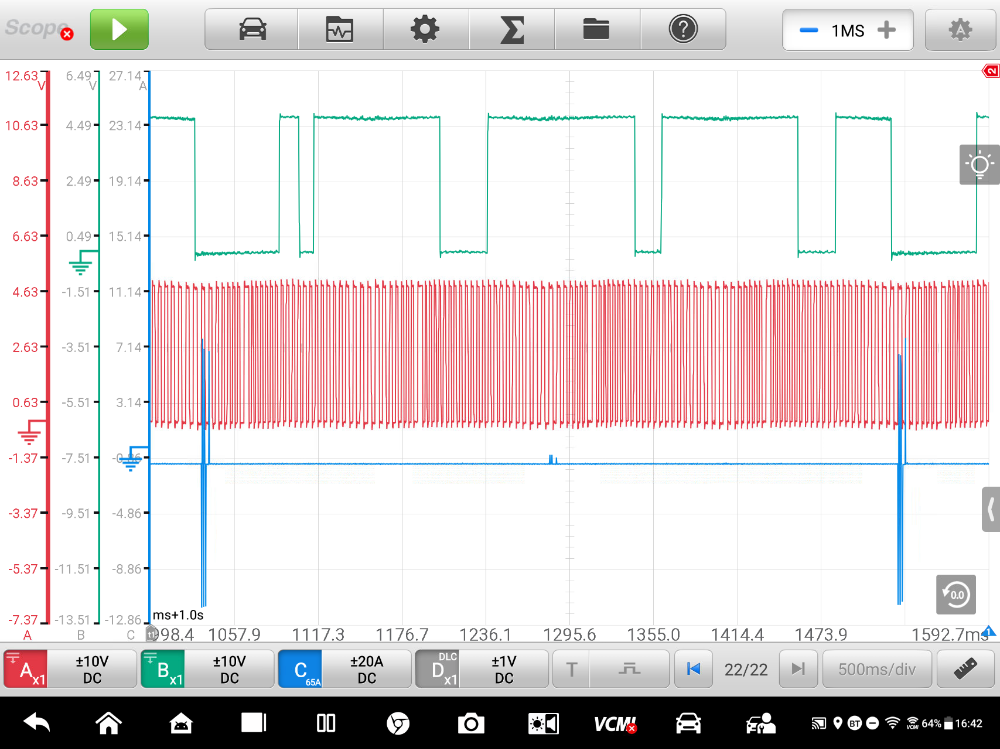

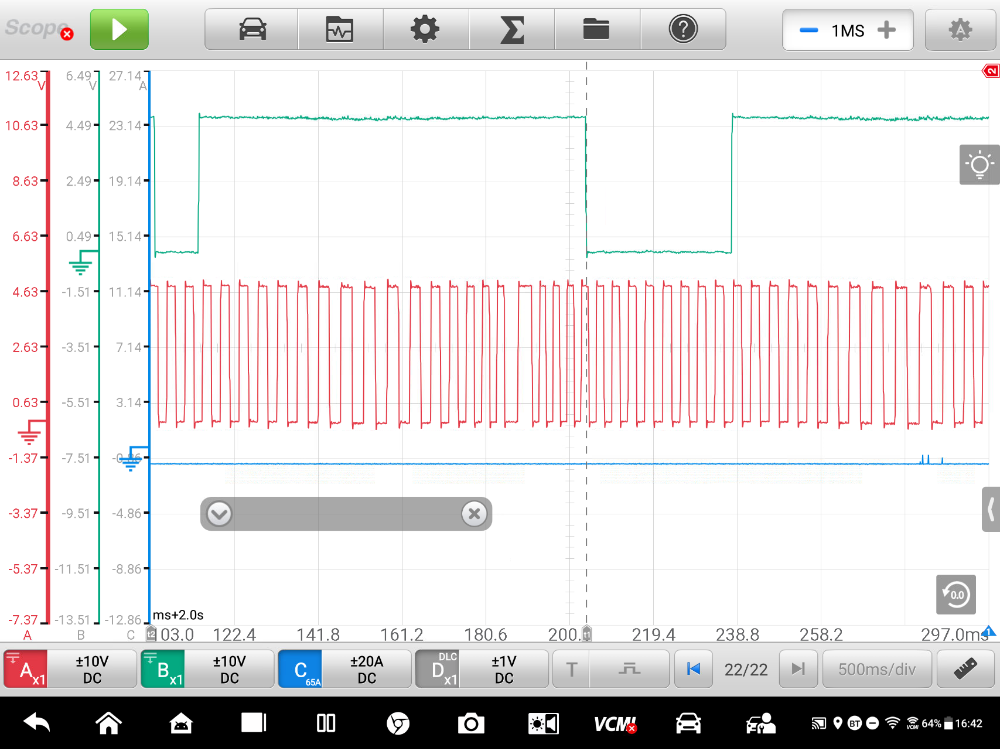

Relative compression in green, #1 injector current in red, piezo sensor on the #1 line in blue:

Same for the #4 line:

The #2 and #3 look similar. I was pleasantly surprised at the amount of detail that can be seen in the injector operation with the injector current and the piezo sensor:

Cool waveforms aside, this was ultimately a dead end. :silly: Rail pressure is there, injectors are opening.

Taking derekoliveira's suggestion, I did check the G338 Throttle Body Control Module. During Output Control and Basic Settings, the throttle does open and close as designed. Still a good suggestion.

What else are we missing? Another technician suggested pulling the boost hose off at the throttle body, just for giggles. I explained why I didn't suspect an intake restriction (the boost sensor during a crank), but what do we have to lose? It starts. :lol:

So where is the intake restriction? It might have something to do with this:

That compressor wheel is locked solid. I also found this in one of the boost hoses:

Oh no.

Anyway, I'll update this one if we end up fixing it.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

This is an excellent example for showing the value of following a "game play", your persistence payed off.

The turbine wheel looks like it came off the shaft at some point and then got stuck because of a binding bearing??

There are these shiny marks on the blades.... apparently all in the same spot on each blade where they were scrubbing against a foreign oject/the housing.

Anyhow, this MUST have caused really heavy noise on its way out I'd believe.:blink:

p.s.

I see you using that Autel scope solo much

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.