When to use impacts vs hand tools

- Tutti57

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1096

- Thank you received: 253

I got my but kicked today trying to get an A/F sensor out of a Titan manifold and ended up using my impact to get it out. Had some threads to clean up, but cripes was it in there and I got lucky.

I'm not just wondering about the bigger power applications. Even smaller stuff like 10mm with a 3/8" impact vs hand.

I'm trying to avoid breaking crap and there is so much speculation in the field on topics like this.

Nissan Technician

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

Now, not so much. Anything that's threaded into an insert that's potted in plastic I remove by hand. Intake manifold bolts and small stuff like that I feel out with a ratchet. If the first couple don't fight I use an air ratchet. I prefer air ratchet to an impact for 3/8ths fasteners. Less violent, more control.

I'm also a huge fan of oxy/acetalyne!

I don't spend a lot of time screwing around. If an oxygen sensor is giving me a rough go, the torch comes out without much reservation.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tutti57

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1096

- Thank you received: 253

I tend to break a lot of the smaller 10mm stuff using my m12 3/8" impact. I'm working on using better judgement there, ha. Damn rust belt.

I ended up using the torch and 1/2" impact on that 02 sensor. I've never done that before, used the big impact on an o2.

I tried heat and a 1/2" long ratchet with no luck, just as someone comes over to tell me, "whatever you do don't heat it up or it will gall the treads when it comes out."

These types of comments, do you ever really know what is going to work? I feel like you just keep trying different techniques until something works and that becomes the proper way, since it worked.

One note on breaking bolts loose - from what I gather, slowly applying more and more force is what usually breaks stuff rather than quick shocks, which is what impacts can be so effective. Correct?

It's like the industry of speculation!

Nissan Technician

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

It just takes time to find the finesse.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Fabian100

-

- Offline

- New Member

-

- Posts: 7

- Thank you received: 3

That will tell you when its time to break out the torch or the impact..

I've seen to many young techs turn a simple 1hr job into a all day thing becuse they snapped off a bolt head..

Remember the shop can only charge what the book says it takes for that job and they will only pay you that .. If you break a bolt that's on you.

Get it out no matter how long it takes but we only gonna pay you the 1 hour the book says it should of taken..

Do it again and you can roll your fancy shinny new Matco or Snap-on box out the door..

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

I would have been fired from or quit that place a long time ago!

Please don't take offense, this isn't a personal shot at you. I'm always amazed at the cultural difference between repair shops. I guess I'm just lucky to work for a guy who realises that shit happens.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Potanist

-

- Offline

- Banned

-

- Posts: 74

- Thank you received: 10

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

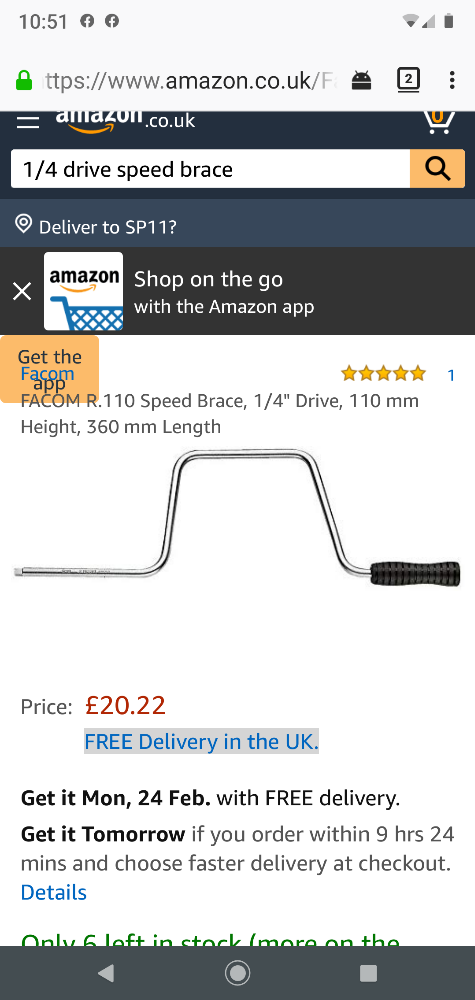

If assembling an engine the speed brace is again my tool of choice before torquing, especially for fitting cam carriers and covers and oil pans .

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

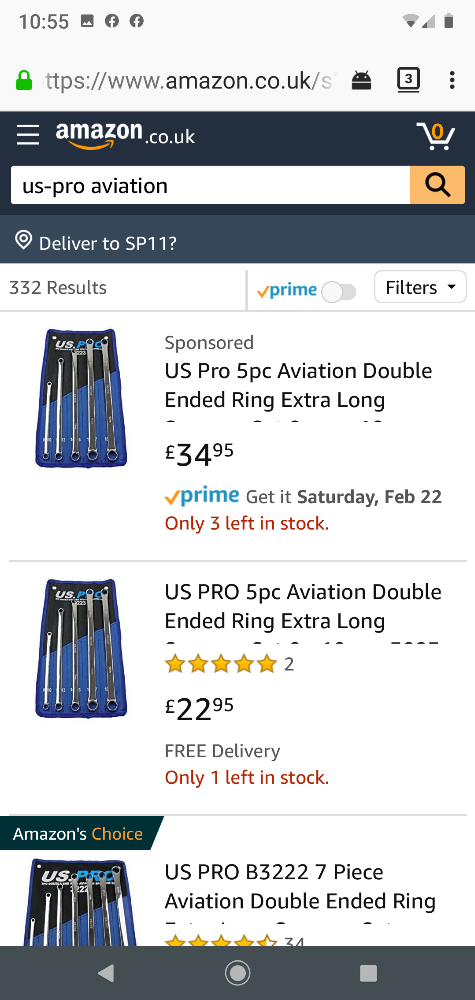

But must confess I now have a set of US-Pro extra long aviation wrenches that now have become my tool of choice for a lot of jobs.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

Tutti57 wrote: It's like the industry of speculation!

Ain't that the truth. :silly: Anecdotal evidence is about as good as it gets for us, unfortunately.

I see nothing wrong with the way you removed that O2, for what it's worth. Heat, no heat, impact, no impact, whatever. That sensor wasn't coming out cleanly no matter what you did.

There's a lot of those pitfalls in the industry.

Maybe I'm an animal? But I'll often use impacts in situations that I technically shouldn't. Whenever possible, I'll impact spark plugs out. Especially the 5.4L Triton engines. Reinstall by hand, obviously.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.