Intermittent loss of 5v reference signal

- SK

-

Topic Author

- Offline

- Senior Member

-

- Posts: 42

- Thank you received: 8

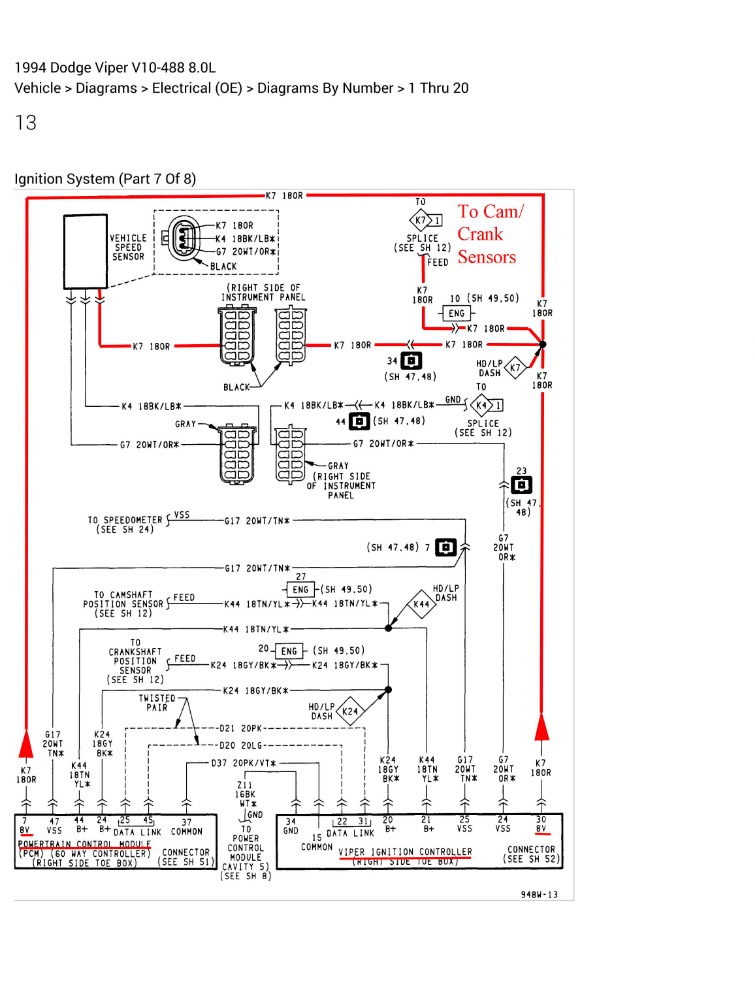

The 5v reference signal powers the camshaft, crankshaft, and vehicle speed sensor (VSS); I suspect a short in one of the sensors, but my question is how to rule out each of the three sensors under this type of failure condition. I could just change out all three sensors, and hope for the best, but I really want to learn how to isolate a bad sensor under these conditions.

Any ideas?

Please Log in or Create an account to join the conversation.

- MrMike

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

First- Dont go throwing money at parts unless you know for sure what the problem is and never assume- I did plenty of push ups in the military for using that word.

Im new here too but this is what I would do to have a good clue that the wiring is good- you may want to write your findings down- (I recommend using backprobe pins on your meter for all the testing except measuring resistance of the sensor, but you could if you wanted to.

1. Backprobe the 5V Ref wire at the PCM harness connector already plugged into the PCM. (KOEO)

2. Disconnect harness from PCM that has the 5V Ref, Signal and Ground(Return) wires to the sensors in question

3. Measure continuity from PCM wire harness appropriate sockets to the sensors 5V Ref, Signal and Ground (Return) wires at your sensors- wiggle the wires when you do this too. Pay attention to any spice connection, as this is where they are connected and sometimes have poor connection. (No power applied to circuit when measuring continuity or you could blow your meter up).

4. At this point, you should have a good idea about the wire(s) integrity

5. Now plug the PCM harness back in and (KOEO)- measure DC Volts on each 5V Ref, Signal and Ground (Return) at the sensors connectors and make sure they are to specs with manufacturer recommendations.

(Remember when checking a sensor ground, you should have no more than 0.01V)

If all of the above looks good, you can check the resistance of the sensors and compare to specs to rule out the sensor.

Like I said- write everything down as you go- after this, you should be able to narrow down what the issue is and guide you to any further testing. Im learning as well and I would recommend watching the Scanner Danner videos on Circuit Integrity. Paul is easy to understand in his videos. They are a wealth of information as well as the techs here. Remember, the above testing is only the start in most cases to help steer you in the right direction. Good Luck

"The object of war is not to die for your country but to make the other bastard die for his"

Please Log in or Create an account to join the conversation.

- MrMike

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

"The object of war is not to die for your country but to make the other bastard die for his"

Please Log in or Create an account to join the conversation.

- SK

-

Topic Author

- Offline

- Senior Member

-

- Posts: 42

- Thank you received: 8

I've finished chapters 1 though 16 (+ scope videos) on Paul's premium channel, and his book will be here on Monday.

I also learned (from further review) that there are two 8v reference signal sources; the PCM and the ignition control module (ICM). Perhaps Chrysler designed it this way so that if one 8v power supply fails, the other module provides a continuous backup 8v source. This design also provides another clue to the cause of the signal dropping out ... what are the odds that the 8v power supplies in the PCM and ICM are failing at the exact same time? On the other hand, a short in any sensor (cam, crank, or VSS) or wiring will cause the circuit to drop to zero volts. So far, all the wiring looks good, and I don't see any harness damage on visible contact points.

The owner has already changed the cam sensor, so he wants to change both the crank and vehicle speed sensors. I could monitor mA draw on the crank and vss signal wires individually to isolate which sensor is shorting out, but the owner is tired of dealing with the problem. And, getting an amp probe on the VSS signal wire is really not possible due to the location of the sensor and the location of the wiring harness.

Please Log in or Create an account to join the conversation.

- MrMike

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

This sounds like its been a serious PIA- I'm just a retired DYI'r that keeps our cars running and I help out my neighbors down the road. We live way out in the sticks. Im trying to buy some diagnostic stuff from time to time- So far Ive got a good DMM, PCM safe test light, small amp clamp and a few other things. Im not sure, but Chrysler and Dodge seem to have more electrical gremlins than others? I have to copy and paste something I sent to AndyMacFayden in here about my 2010 Dodge Ram 1500 and when you have time you could read it and let me know what you think. Remember; I dont have much experience in all this.

Thanks, in advance

MrMike

"The object of war is not to die for your country but to make the other bastard die for his"

Please Log in or Create an account to join the conversation.

- MrMike

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

2010 Dodge Ram 1500 (5.7) HEMI

A few months back, I was having intermittent starting issues- meaning that sometimes the truck would start right up and other times, I would have to keep the key turned to run/start for anywhere between 15-45 seconds before it would start? I checked the Batt(+) cable going to starter and was getting proper available voltage to the starter. Also verified the Batt terminals/clamps were clean like newborns baby butt. When it would start and Id drive a small distance and turn the truck off, it would not start again, but would if I hooked up jumper cables? I checked Batt volts and was reading around 12.6V. I was getting the "Red Lightning Bolt" on the dash, so I hooked up my scanner (Autel MaxiSys) and got a code P0123 or bad throttle body. I researched this before I even new Scanner Danner existed and everything says to replace the throttle body. I replaced the throttle body (I know) and same thing. Then people say its the WIN (wireless ignition node) which is not wireless because it has a small 12 pin connector on back with just 8 wires. I took off the WIN ignition key box and opened it up- the small contact arms looked good, so I went ahead a got a q-tip with rubbing alcohol to clean what I could just to be on the safe side- still no difference. Out of curiosity one day, I got under the truck and had the wife turn key to run- No power at starter solenoid? I Ohm'd out the Yellow/Grey wire from starter relay- it was good. I also bench tested the relay with a 9V battery- it was fine-(clicking). I have since torn apart the dash and cleaned up any grounds I could find to include engine and chassis grounds. My next step is to check the starter relay sockets in the TIPM to see if they check out. Also, if Im not getting the volts to the starter solenoid, Im thinking it could be the Neutral/Safety switch which Dodge calls the Transmission Range Selector which I have not tested yet. I dont want to assume anything because I did push ups years ago in the military for using that word.

Im somewhat stumped but am convinced it is probably something very simple. I have the complete wiring diagram from Mitchell and also a downloaded "Shop Manual" supposedly the dealerships use. The shop manual stated that after replacing a throttle body, use a scan tool to do a TPS/Throttle Body Re-learn but my Autel scanner does not have this function.

Update: I started checking continuity and their is an OL between MAP Sensor 5V Ref and PCM (weather has been bad and I have not looked for the break yet)

I need some guidance on this please. Any info/recommendations you could give would be greatly appreciated.

Thank You Sir, in advance-

MrMike

"The object of war is not to die for your country but to make the other bastard die for his"

Please Log in or Create an account to join the conversation.

- SK

-

Topic Author

- Offline

- Senior Member

-

- Posts: 42

- Thank you received: 8

Please Log in or Create an account to join the conversation.

- SK

-

Topic Author

- Offline

- Senior Member

-

- Posts: 42

- Thank you received: 8

SK- Heres whats going on with my truck

2010 Dodge Ram 1500 (5.7) HEMI

A few months back, I was having intermittent starting issues- meaning that sometimes the truck would start right up and other times, I would have to keep the key turned to run/start for anywhere between 15-45 seconds before it would start? I checked the Batt(+) cable going to starter and was getting proper available voltage to the starter. Also verified the Batt terminals/clamps were clean like newborns baby butt. When it would start and Id drive a small distance and turn the truck off, it would not start again, but would if I hooked up jumper cables? I checked Batt volts and was reading around 12.6V. I was getting the "Red Lightning Bolt" on the dash, so I hooked up my scanner (Autel MaxiSys) and got a code P0123 or bad throttle body. I researched this before I even new Scanner Danner existed and everything says to replace the throttle body. I replaced the throttle body (I know) and same thing. Then people say its the WIN (wireless ignition node) which is not wireless because it has a small 12 pin connector on back with just 8 wires. I took off the WIN ignition key box and opened it up- the small contact arms looked good, so I went ahead a got a q-tip with rubbing alcohol to clean what I could just to be on the safe side- still no difference. Out of curiosity one day, I got under the truck and had the wife turn key to run- No power at starter solenoid? I Ohm'd out the Yellow/Grey wire from starter relay- it was good. I also bench tested the relay with a 9V battery- it was fine-(clicking). I have since torn apart the dash and cleaned up any grounds I could find to include engine and chassis grounds. My next step is to check the starter relay sockets in the TIPM to see if they check out. Also, if Im not getting the volts to the starter solenoid, Im thinking it could be the Neutral/Safety switch which Dodge calls the Transmission Range Selector which I have not tested yet. I dont want to assume anything because I did push ups years ago in the military for using that word.

Im somewhat stumped but am convinced it is probably something very simple. I have the complete wiring diagram from Mitchell and also a downloaded "Shop Manual" supposedly the dealerships use. The shop manual stated that after replacing a throttle body, use a scan tool to do a TPS/Throttle Body Re-learn but my Autel scanner does not have this function.

Update: I started checking continuity and their is an OL between MAP Sensor 5V Ref and PCM (weather has been bad and I have not looked for the break yet)

I need some guidance on this please. Any info/recommendations you could give would be greatly appreciated.

Thank You Sir, in advance-

MrMike

Mike, the my first step would be to have the battery bench checked. What is the rated cranking amperage of the battery, and what is your test result?

Please Log in or Create an account to join the conversation.

- MrMike

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

Man, you had that whole mess just from the wire from sensor? Thats crazy-

As far as my battery goes, Im pretty sure its good. I only have a DMM to test, but feel confident the battery is good. Earlier today, I cut back the tape and wire loom at my MAP. The 5V Ref wire is yellow with a blue striper. This wire goes from the sensor to a splice in which 2 wires come out of the splice. One of the two wires goes to another sensor and the other wire should go to the PCM. Im kind of at a standstill now until my wire piercing probes arrive. I dont want to rush it and start stabbing into wires either. When the probes arrive, Ill be able to pinpoint it. So, its a wait situation.

"The object of war is not to die for your country but to make the other bastard die for his"

Please Log in or Create an account to join the conversation.

- SK

-

Topic Author

- Offline

- Senior Member

-

- Posts: 42

- Thank you received: 8

A Colonel in the USAF once told a group of maintainers "Hope is not a maintenance strategy." Likewise, "pretty sure" is not "for sure." Get the battery checked. Voltage without amperage is useless. Imagine that silly feeling when you spend all your time chasing wiring and spending a lot of money on parts when somebody comes up and tells you "Hey! Your battery is down to 100 amps."

Please Log in or Create an account to join the conversation.

- MrMike

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

"The object of war is not to die for your country but to make the other bastard die for his"

Please Log in or Create an account to join the conversation.

- SK

-

Topic Author

- Offline

- Senior Member

-

- Posts: 42

- Thank you received: 8

In this case the sensor would only fail when it was hot ... 1+ hour of driving, so a bench test of a could sensor wouldn't work.

Since there is no real way to isolate an intermittent short to ground in this sensor, we simply chose the crank sensor (since the camshaft sensor had already been replaced), and rolled the dice. If that didn't fix it, we were going to change the vehicle speed sensor next. Based on where the sensor lives, I told the owner he should just make it part of his maintenance routine and change the sensor every 40K miles.

Please Log in or Create an account to join the conversation.

- MrMike

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

"The object of war is not to die for your country but to make the other bastard die for his"

Please Log in or Create an account to join the conversation.

- SK

-

Topic Author

- Offline

- Senior Member

-

- Posts: 42

- Thank you received: 8

I spoke with my local Snap On dealer and he said the scope Paul uses in many of his videos (Verus Pro) is no longer supported, so there will be no more updates for that tool. He suggested (if I was buying a used on on eBay) that the Verus Edge would be good. But, even used, those things are expensive!!!

Please Log in or Create an account to join the conversation.

- MrMike

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

"The object of war is not to die for your country but to make the other bastard die for his"

Please Log in or Create an account to join the conversation.

- SK

-

Topic Author

- Offline

- Senior Member

-

- Posts: 42

- Thank you received: 8

Yep, shop on the property, but looking to build a bigger one with a lift. At least I got the AC installed and insulated the garage doors.

I got this scope from Amazon; it's not a Snap-On, but it didn't have a Snap-On price either! The techniques Paul teaches work with this scope too.

www.amazon.com/dp/B07M9JJ6ZH?psc=1&ref=p...dt_b_product_details

Oh ... it's Jerry-rigging: www.grammarphobia.com/blog/2019/12/jerry-rigged.html

Sounds like the folks in your area (fixing those cars) also work in the Georgia Pacific lumber mill.

Please Log in or Create an account to join the conversation.

- MrMike

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 4

"The object of war is not to die for your country but to make the other bastard die for his"

Please Log in or Create an account to join the conversation.