A place to discuss hardware/software and diagnostic procedures

Home build In-Cylinder Pressure Build Details

- Andy.MacFadyen

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 3353

- Thank you received: 1037

8 years 11 months ago - 8 years 11 months ago #6566

by Andy.MacFadyen

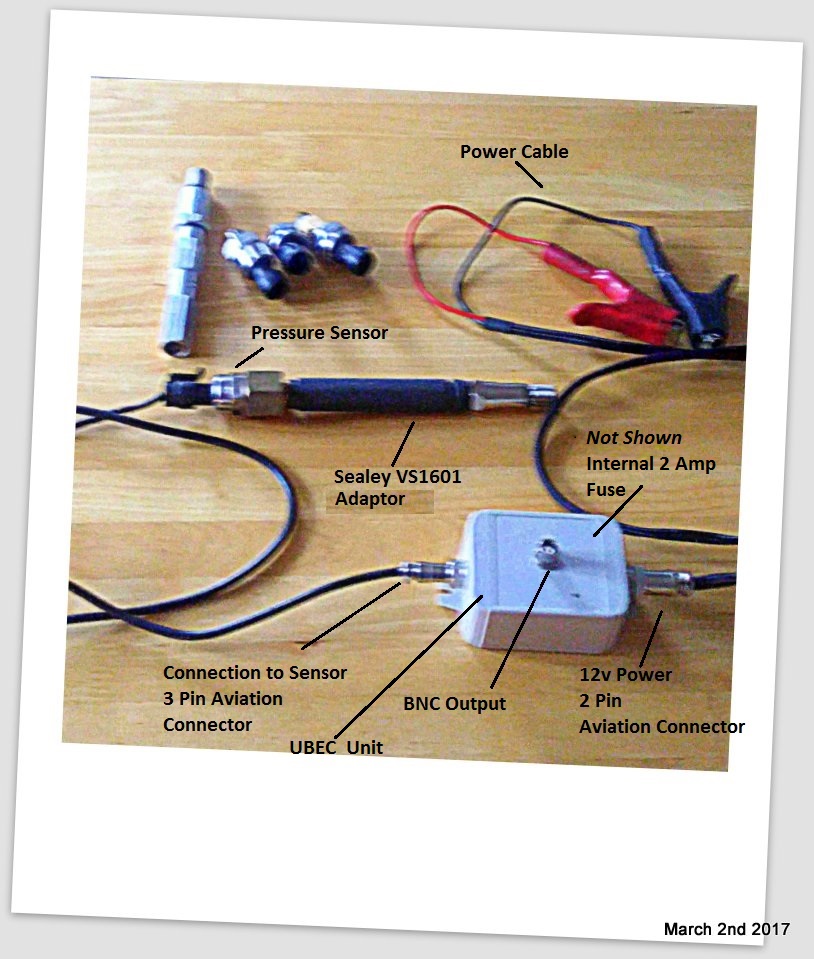

In-cylinder pressure tester build details.

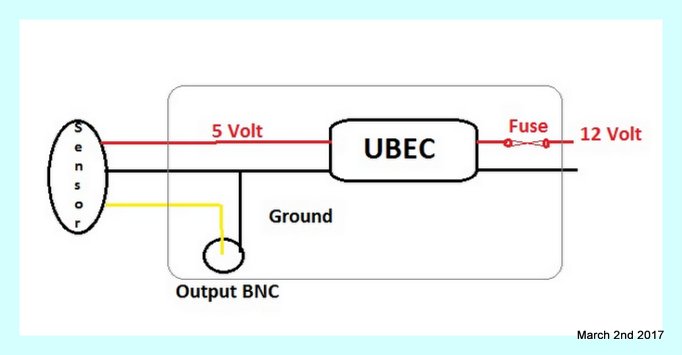

The pressure sensor is a very low cost item purchased from eBay it requires a clean 5 voltage.

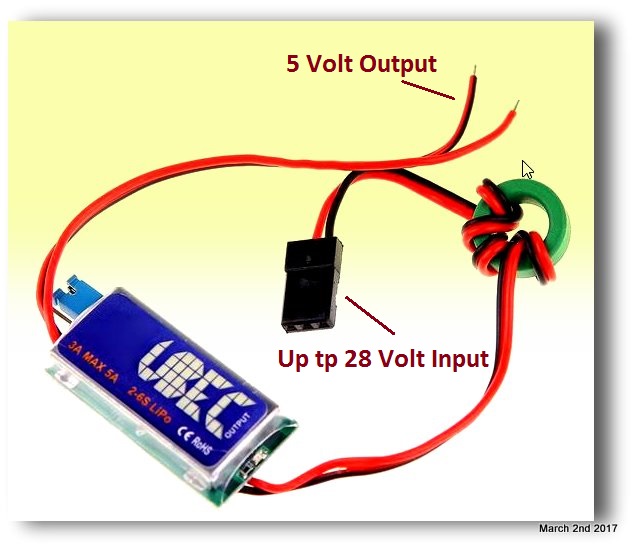

The 5 volt supply connsists of a 5 Volt UBEC bought from ebay

A UBEC is a very low cost device mainly used by model aircraft and drone builders and can be found very cheaply on eBay. The input supply can be anywhere from 7v to 28.8 volts DC so it can run from any normal car or heavy truck battery.

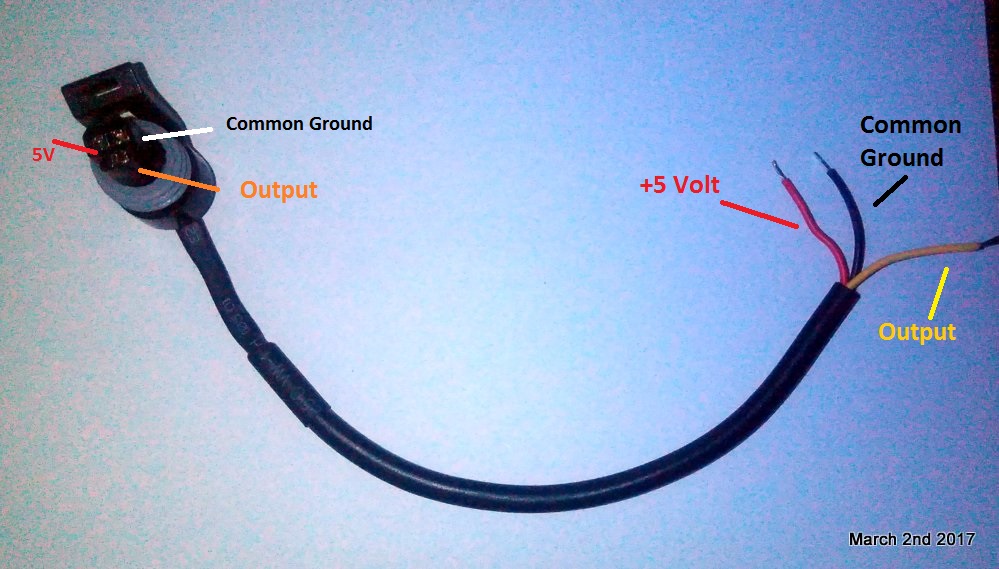

This is a typical wiring tail connection supplied with a pressure sensor.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Home build In-Cylinder Pressure Build Details was created by Andy.MacFadyen

In-cylinder pressure tester build details.

The pressure sensor is a very low cost item purchased from eBay it requires a clean 5 voltage.

The 5 volt supply connsists of a 5 Volt UBEC bought from ebay

A UBEC is a very low cost device mainly used by model aircraft and drone builders and can be found very cheaply on eBay. The input supply can be anywhere from 7v to 28.8 volts DC so it can run from any normal car or heavy truck battery.

This is a typical wiring tail connection supplied with a pressure sensor.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Last edit: 8 years 11 months ago by Andy.MacFadyen.

The following user(s) said Thank You: Noah, Chad, soptea

Please Log in or Create an account to join the conversation.

- Ben

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1097

- Thank you received: 215

8 years 11 months ago #6574

by Ben

Replied by Ben on topic Re:Home build In-Cylinder Pressure Build Details

Nice build . Is that your capture? I've been considering building 1 of these. I seen a while ago someone used one of of the ports on his modis to power the 5v transducer and I've been wondering if there's any 5v power output on any of the pins on my modis ultra to do this. I hate to have another set of wires going to the battery . I guess I'll have to sit down with the dvom and start testing the pins on my scanner to find out I may not have any other choices but to use external power supply...

Sent from my SM-N920P using Tapatalk

Sent from my SM-N920P using Tapatalk

Please Log in or Create an account to join the conversation.

- Ro-longo

-

- Offline

- Elite Member

-

- North Salt Lake, Utah

Less

More

- Posts: 168

- Thank you received: 43

8 years 11 months ago #6590

by Ro-longo

"Silver bullets are for killing Werewolves, not fixing Cars." -Rob Longoria-

Replied by Ro-longo on topic Home build In-Cylinder Pressure Build Details

Do you have any links for the pressure sensors, I picked on up on ebay a while back and the signal I got was very poor.

"Silver bullets are for killing Werewolves, not fixing Cars." -Rob Longoria-

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 3353

- Thank you received: 1037

8 years 11 months ago - 8 years 11 months ago #6592

by Andy.MacFadyen

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Replied by Andy.MacFadyen on topic Home build In-Cylinder Pressure Build Details

I know where you coming from

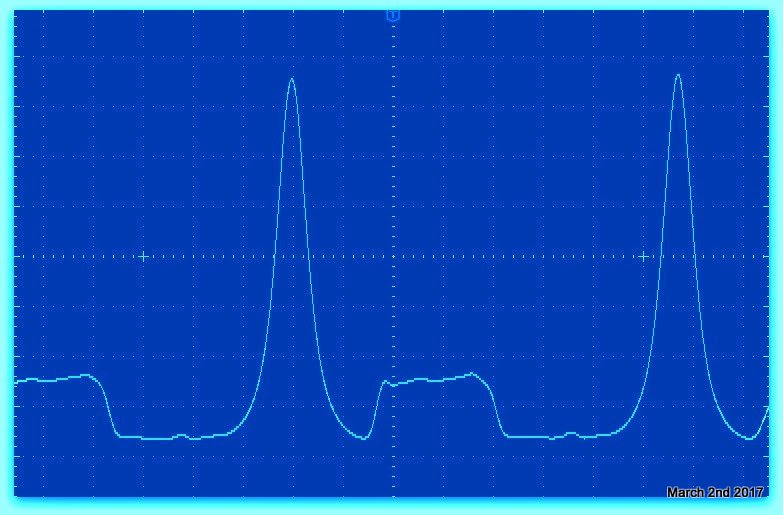

The important thing is to choose the pressure sensor with the most suitable range.

The sensors are listed in units of mpa, the most suitable for compression testing of petrol/gasoline engines are rated at 1.25 mpa and 2.5 mpa.

1.25 mpa is 12.5 bar roughly 180 psi

2.5 mpa is 25 bar roughly 360 psi

Cranking compression pressures on gasoline engines can be as high as 220 psi and some GDI engines may be higher. But more typically expect 160 to 180 psi on good cylinder in service engine. Also these sensors a rated to withstand a substantial over range pressure so a 1.25 mpa sensor would be OK although a 2.5 mpa sensor also gives very good resuls.

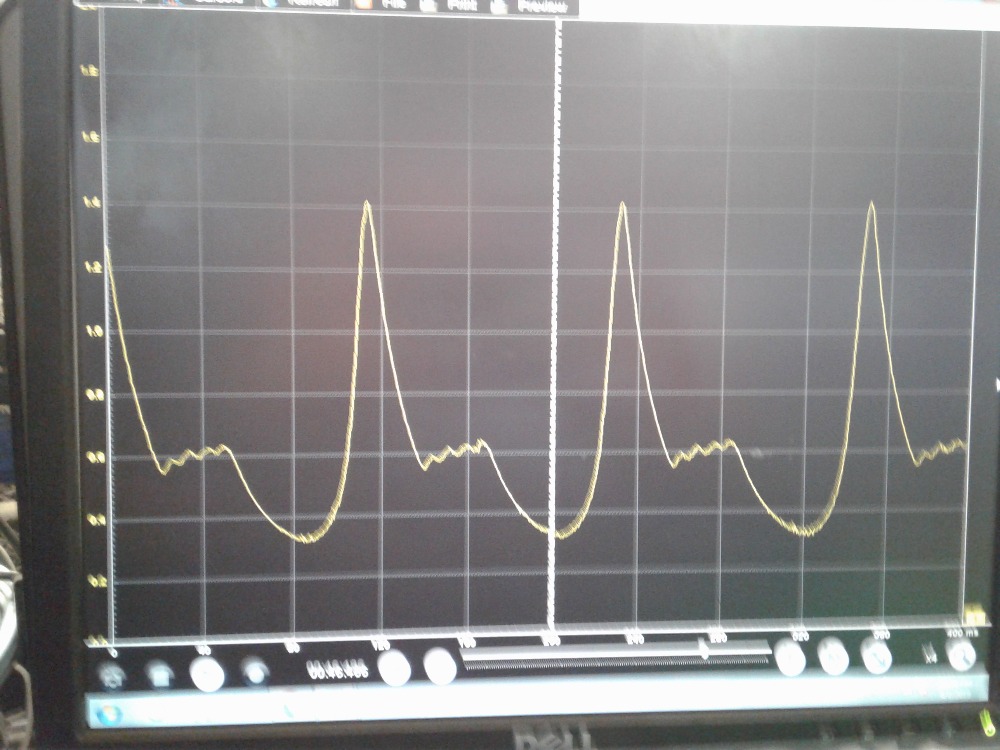

Running compression pressures at idle on gasoline engines are generally in the range 60 to 100 psi.

On diesel engines the expected in cylinder pressures will be 400 to to 500+ psi.

The important thing is to choose the pressure sensor with the most suitable range.

The sensors are listed in units of mpa, the most suitable for compression testing of petrol/gasoline engines are rated at 1.25 mpa and 2.5 mpa.

1.25 mpa is 12.5 bar roughly 180 psi

2.5 mpa is 25 bar roughly 360 psi

Cranking compression pressures on gasoline engines can be as high as 220 psi and some GDI engines may be higher. But more typically expect 160 to 180 psi on good cylinder in service engine. Also these sensors a rated to withstand a substantial over range pressure so a 1.25 mpa sensor would be OK although a 2.5 mpa sensor also gives very good resuls.

Running compression pressures at idle on gasoline engines are generally in the range 60 to 100 psi.

On diesel engines the expected in cylinder pressures will be 400 to to 500+ psi.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Last edit: 8 years 11 months ago by Andy.MacFadyen.

Please Log in or Create an account to join the conversation.

- Nandor69

-

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 5

8 years 10 months ago #7952

by Nandor69

Replied by Nandor69 on topic Home build In-Cylinder Pressure Build Details

Did you see the post where the guy used the 5v pin and the ground pin from the serial port on the Verus to power the sensor? Then all you have to do is plug the signal wire from the sensor into one of the channels.

I think it should be safe right? It would be a lot nicer to just have a a male serial port with just 2 wires going to it from the connector and then just the signal wire going to the scope than to have to carry all that around with everything else

I think it should be safe right? It would be a lot nicer to just have a a male serial port with just 2 wires going to it from the connector and then just the signal wire going to the scope than to have to carry all that around with everything else

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 3353

- Thank you received: 1037

8 years 10 months ago #7996

by Andy.MacFadyen

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Replied by Andy.MacFadyen on topic Home build In-Cylinder Pressure Build Details

I can't find a number for the curent draw of the sensors but I would be fairly confident it would be low enough for the Verus to supply. There is another option that is to run it off 9 volt battery.

This a useful link Fundamentals of pressure tranducers

This a useful link Fundamentals of pressure tranducers

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

The following user(s) said Thank You: Chad

Please Log in or Create an account to join the conversation.

- soptea

-

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

7 years 4 months ago #23360

by soptea

Replied by soptea on topic Home build In-Cylinder Pressure Build Details

Just finished my own version using an AC high pressure sensor but not really happy with result ,the lower part of waveform is missing ,| guess sensor is not able to read vacuum .

Maybe this one would perform better , seems to match your description

www.aliexpress.com/item/Wholesale-price-...a1&priceBeautifyAB=0

Thanks !

Maybe this one would perform better , seems to match your description

www.aliexpress.com/item/Wholesale-price-...a1&priceBeautifyAB=0

Thanks !

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

Topic Author

Topic Author

- Offline

- Moderator

-

Less

More

- Posts: 3353

- Thank you received: 1037

7 years 4 months ago - 7 years 4 months ago #23366

by Andy.MacFadyen

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Replied by Andy.MacFadyen on topic Home build In-Cylinder Pressure Build Details

You would be better off with a 0-200psi sensor as that gives a good range for both running in-cylinder and normal old style tests on most gasoline engines.

If you are going to be working on GDI engines then you need an even higher range.

If you get noise on the ouput to a scope use a uBec voltage converter they are tiny, dirt cheap and give a very smooth noise free ouput.

The bigest problem with home made in-cylinder sensors is the hose used to connect to the cylinder tends to collapse as few types of hose are built to withstand repeated cycling between pressure and vacuum.

If you are going to be working on GDI engines then you need an even higher range.

If you get noise on the ouput to a scope use a uBec voltage converter they are tiny, dirt cheap and give a very smooth noise free ouput.

The bigest problem with home made in-cylinder sensors is the hose used to connect to the cylinder tends to collapse as few types of hose are built to withstand repeated cycling between pressure and vacuum.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Last edit: 7 years 4 months ago by Andy.MacFadyen.

The following user(s) said Thank You: Tyler, soptea

Please Log in or Create an account to join the conversation.

- Doodah14

-

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 6

6 years 10 months ago #28384

by Doodah14

Replied by Doodah14 on topic Home build In-Cylinder Pressure Build Details

I saw this thread a few months ago and decided to build my own. I Decided to run it with a 9v battery. I put it all in a project box with pigtail connectors for the sensors and banana jacks to plug the scope into. I added a 1.5 amp glass fuse and a 5v out port for bench testing sensors. I am using an oil pressure sensor that I happened to have. I think it's a GM sensor. Not really sure. It works great for running tests but doesn't have enough detail for cranking tests. I bought a 300lbs sensor from ebay, but there was no detail at all.

The following user(s) said Thank You: Noah

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

Less

More

- Posts: 4967

- Thank you received: 1114

6 years 10 months ago #28388

by Noah

"Ground cannot be checked with a 10mm socket"

Replied by Noah on topic Home build In-Cylinder Pressure Build Details

Quality looking build!

"Ground cannot be checked with a 10mm socket"

The following user(s) said Thank You: Doodah14

Please Log in or Create an account to join the conversation.

Time to create page: 0.308 seconds