Compression testing with conventional gauge

- scopeman

-

Topic Author

- Offline

- Senior Member

-

- Posts: 70

- Thank you received: 3

Thanks.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

Holding the throttle plate open seems too risky, IMO. Just not worth the trouble.

Please Log in or Create an account to join the conversation.

- scopeman

-

Topic Author

- Offline

- Senior Member

-

- Posts: 70

- Thank you received: 3

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

scopeman wrote: Thanks , i have always done it with foot to floor and just cranked it .Just wondered that's all .

S'all good! I actually hesitated to answer, 'cause I'm sure that 'by the book' I should rig some way to open the throttle on those uncooperative systems. :blush: Or at least create a big vacuum leak. Maybe I spent too long on flat rate? :lol:

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

Tyler wrote:

scopeman wrote: Thanks , i have always done it with foot to floor and just cranked it .Just wondered that's all .

S'all good! I actually hesitated to answer, 'cause I'm sure that 'by the book' I should rig some way to open the throttle on those uncooperative systems. :blush: Or at least create a big vacuum leak. Maybe I spent too long on flat rate? :lol:

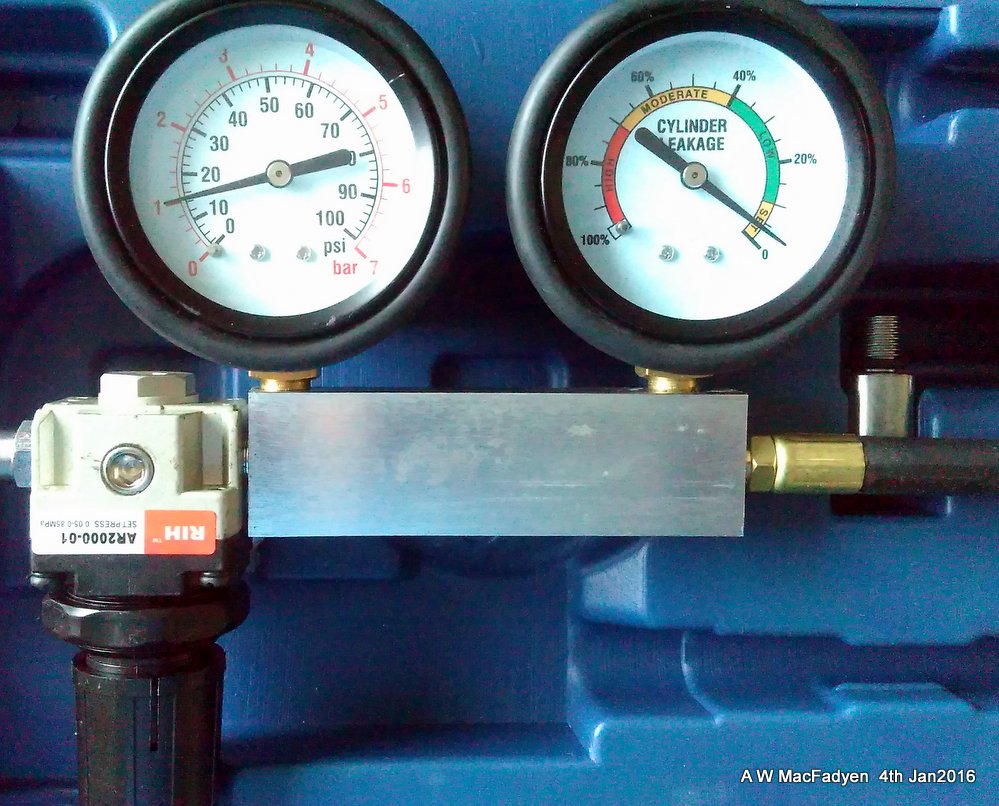

As above but personally these days I tend to go straight for a leakdown test if any cylinder is suspect, I recently bought a very low cost Bergen Tools branded leakdown tester to replace my home made one. It works at only 1 bar pressure, my old one and most older factory made ones work at 100psi. I have made a coupling up to connect it to a little 12v compressor but have yet to try it out on a bad cylinder.

Matt (SchrodingersBox) did this with an 100psi type but from his YouTube Video although worked his little compressor struggled to make enough air at 100psi.

Link I found this one on eBay UK I am pretty sure it is identical to my Bergen one but at an even cooler price got to be a bargain.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- scopeman

-

Topic Author

- Offline

- Senior Member

-

- Posts: 70

- Thank you received: 3

Please Log in or Create an account to join the conversation.

- gav09

-

- Offline

- Senior Member

-

- Posts: 60

- Thank you received: 24

"The minimum compression in any 1 cylinder should not be less than 70 percent of the highest cylinder. No cylinder should read less than 690 kPa (100 psi). For example, if the highest pressure in any 1 cylinder is 1 035 kPa (150 psi), the lowest allowable pressure for any other cylinder would be 725 kPa (105 psi). (1 035 x 70% = 725) (150 x 70% = 105)."

To me performing the test in a consistent manner is more important than whether the throttle is open or not.

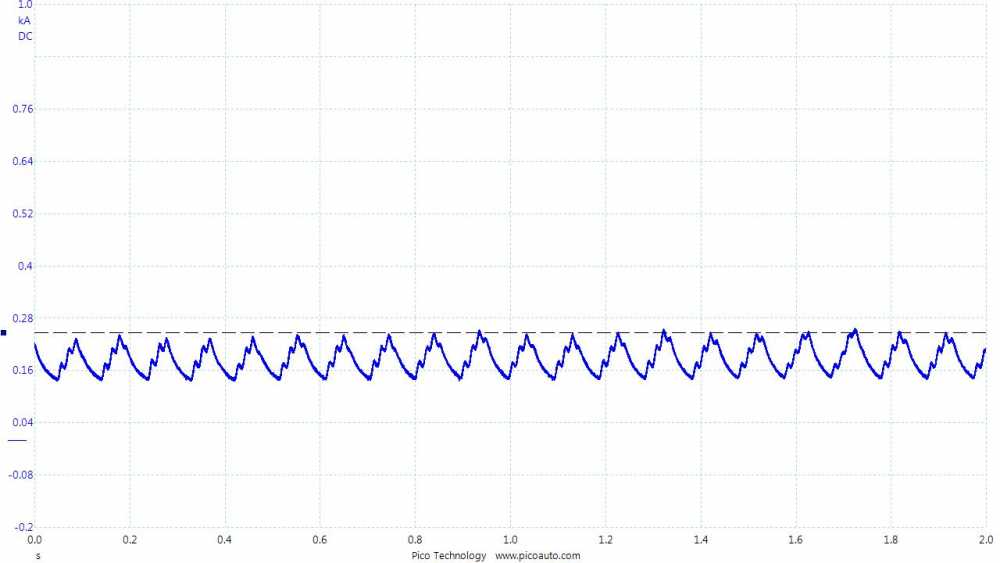

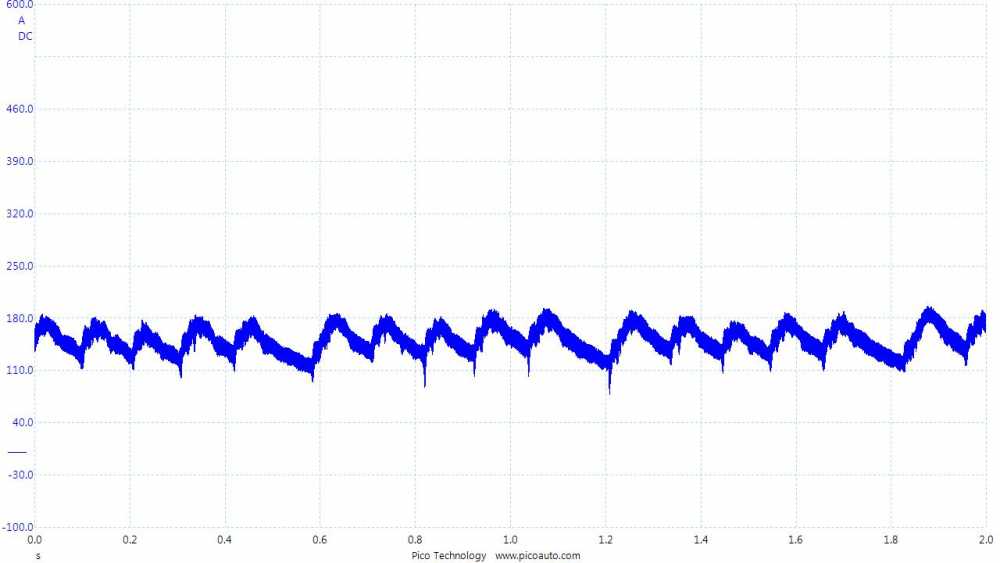

I usually do a relative compression check and then jump to cylinder leak down.

For example this one falls into the 70% range

This one on the other hand not so much.

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

I tried running from the car battery and battery jump start pack (the type with a lead acid motorcycle battery) without problem,

My little compressor generated enough pressure and flow for the test on a known good cylinder but the pump died in the process before I could get a picture or test it on a bad cylinder. I should say the 12v compressor was over 10 years old and was both tiny and the cheapest of the cheap. I am pretty sure one of those 2 cylinder versions advertised for 4x4 use would have been fine One thing I did discover was with the little compressor you really have to be 100% sure the air connections on the supply side are leak free.

For normal use I will stick to using it with the little mains voltage compressor.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

On a Ford Zetec or Rover K in good shape I expect to see 165 to 185 psi.

Back in the days of push rod cast iron engines 135 to 155 psi for say an MGB engine in good shape.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.