A place to discuss hardware/software and diagnostic procedures

Mechanical Compression Gauge Vs Relative Compression

- John Curtis

-

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 344

- Thank you received: 109

4 years 1 month ago #38066

by John Curtis

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

Mechanical Compression Gauge Vs Relative Compression was created by John Curtis

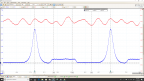

I had intermittent cylinder-specific misfire caused by intermittent low compression due to a bent rod.

Relative compression waveform looked perfect for a random amount of crank revolutions and intermittently would appear low on my misfiring cylinder.

A compression test never showed the low compression and a leak down test did not reveal the problem. I had to crank up the pressure during the leak down which actually gave me direction.

Have you guys seen this before? Without the ability of a scope I’m not sure I would’ve found the problem.

Relative compression waveform looked perfect for a random amount of crank revolutions and intermittently would appear low on my misfiring cylinder.

A compression test never showed the low compression and a leak down test did not reveal the problem. I had to crank up the pressure during the leak down which actually gave me direction.

Have you guys seen this before? Without the ability of a scope I’m not sure I would’ve found the problem.

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

The following user(s) said Thank You: Dtech494

Please Log in or Create an account to join the conversation.

- JarheadDiagnostics

-

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 11

4 years 1 month ago #38569

by JarheadDiagnostics

Replied by JarheadDiagnostics on topic Mechanical Compression Gauge Vs Relative Compression

I ran in to this one a Kia Soul with a 1.6L GDI. The cylinder walls were scratched just below the compression line. So it passed leak down test perfectly.

Please Log in or Create an account to join the conversation.

4 years 4 weeks ago #38600

by Tyler

Replied by Tyler on topic Mechanical Compression Gauge Vs Relative Compression

Been there with Chrysler Pentastar (3.6L) engines. If you did the relative compression test long enough, you'd catch one cylinder acting up.

The newest series of SD Premium talks about this phenomenon, and how a vacuum gauge + compression gauge missed a leaking intake valve. :silly:

The newest series of SD Premium talks about this phenomenon, and how a vacuum gauge + compression gauge missed a leaking intake valve. :silly:

The following user(s) said Thank You: Dtech494

Please Log in or Create an account to join the conversation.

Time to create page: 0.252 seconds