A place to discuss hardware/software and diagnostic procedures

Comprehensive diagnostics of diesel engines

- VladimirPostolovsky

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 21

7 months 2 days ago - 7 months 2 days ago #92062

by VladimirPostolovsky

Comprehensive diagnostics of diesel engines was created by VladimirPostolovsky

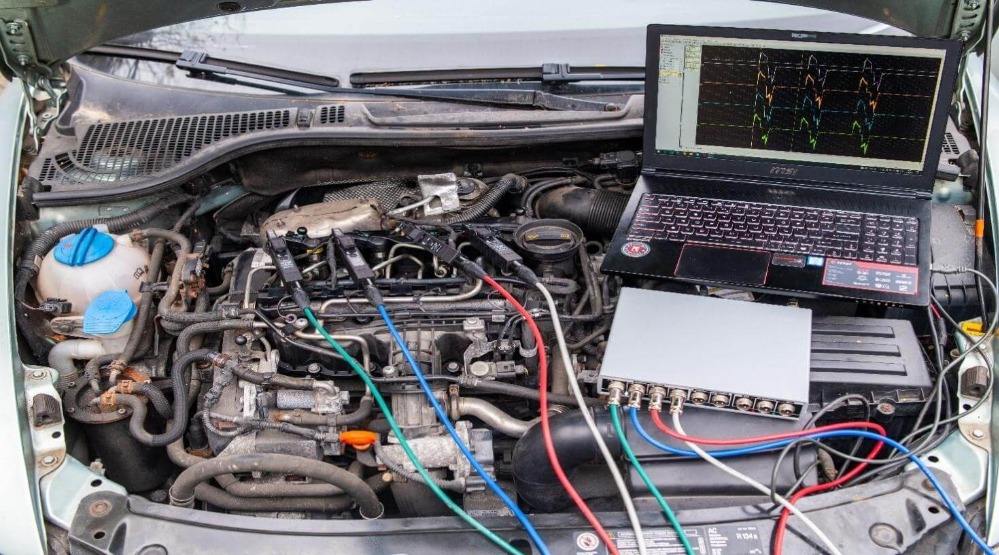

Autoscope Technology provide a comprehensive set of tools and scripts that enable technicians to quickly and accurately identify diesel engine problems.

This article explores key diagnostic methods using USB Autoscope, including the ElPower script for analyzing hard engine starting, CSS script for cylinder balance testing, camshaft-crankshaft synchronization tests, and in-depth injector waveform diagnostics.

Additionally, it covers advanced techniques such as analyzing cylinder pressure graph with the PSG200 diesel pressure sensor, using specialized adapters, and testing mechanical injection systems with the PD-6 piezo transducer. Together, these tools form a powerful approach to diesel diagnostics in both workshop and field settings.

This is especially relevant at low temperatures below 0 °C.

Within 3-5 minutes, you can check the characteristics and condition of:

Figure 1. Connection to the vehicle battery to obtain voltage and current waveform

Figure 2. Measured vehicle parameters obtained using the ElPower script

Yellow background - measured parameters deviate from the norm.

Red background - measured parameters are outside the norm.

The report of the online version of the ElPower script algorithm may display the "Compression" tab

Figure 3. Relative Compression Test. Here, individual compression values by cylinder are displayed in the form of Bar graphs

2. CSS script - Cylinder power balance test

This test is simple and fast, without disassembling the engine and its systems, it identifies cylinders that are misfiring and indicates the area of origin of the malfunction.

The express diagnostics time does not exceed 3-5 minutes.

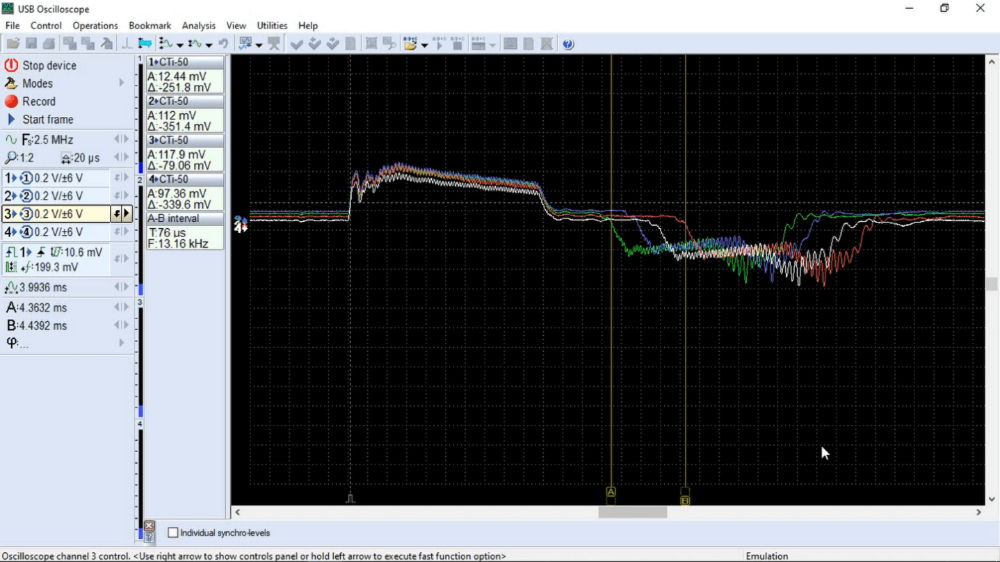

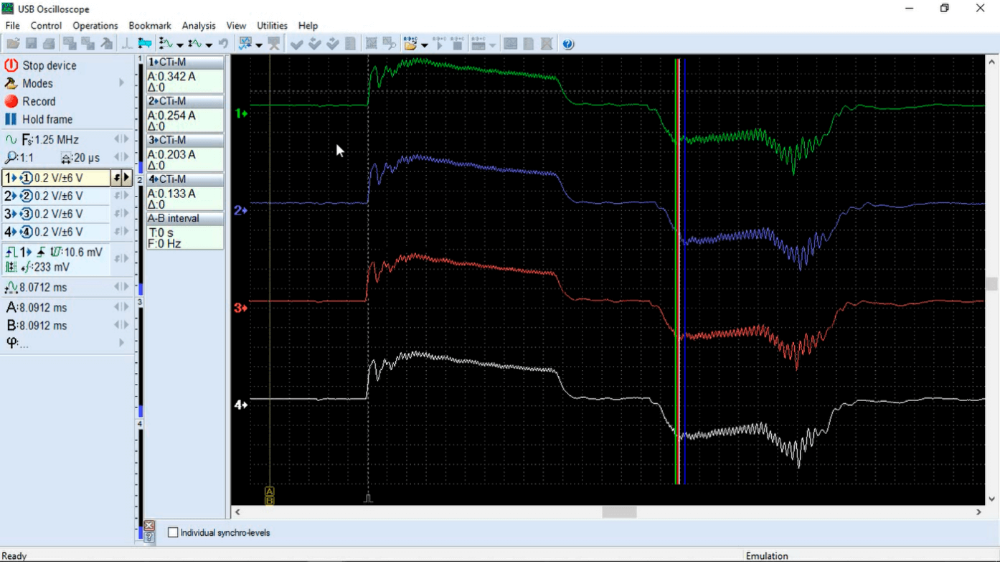

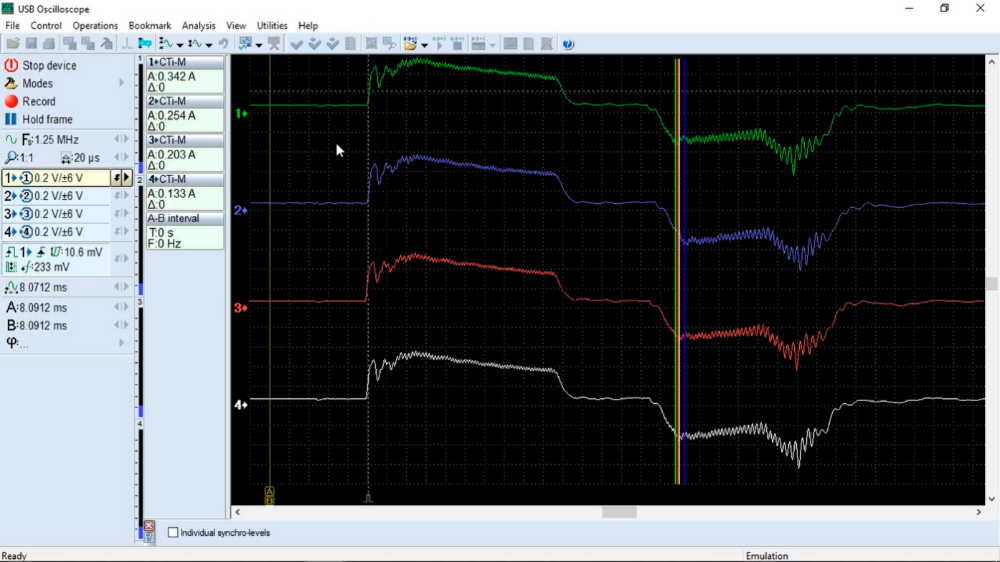

To test the CSS of modern cars, signals from the crankshaft position sensor and the injector control pulse are required.

There are two types of crankshaft position sensor: Hall sensor and inductive.

The injector control pulse can be measured using the CTi-50 current clamps. In a short time, you can check:

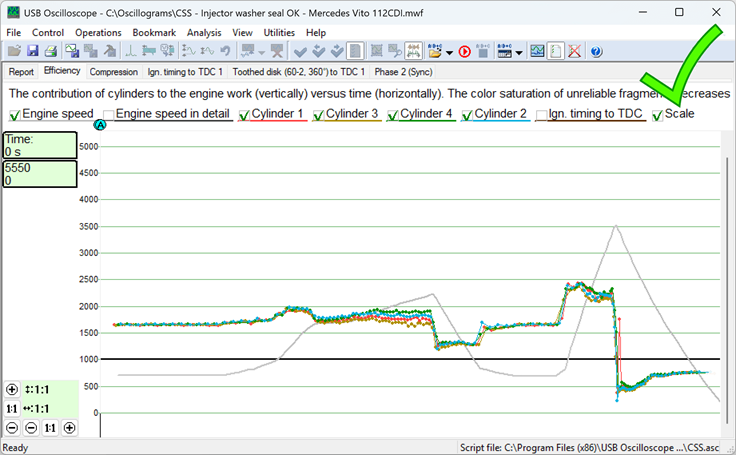

Figure 5. On this car, a wrong sealing washer was installed under the injector after repair. The first cylinder was misfiring.

Figure 6. On this car, the connecting rod of the third cylinder was bent due to a hydraulic shock. The contribution of this cylinder in some modes was very low

Figure 7. Diesel engine operation after high-quality repair. Cylinder contribution/balance at different engine speeds is almost the same.

This article explores key diagnostic methods using USB Autoscope, including the ElPower script for analyzing hard engine starting, CSS script for cylinder balance testing, camshaft-crankshaft synchronization tests, and in-depth injector waveform diagnostics.

Additionally, it covers advanced techniques such as analyzing cylinder pressure graph with the PSG200 diesel pressure sensor, using specialized adapters, and testing mechanical injection systems with the PD-6 piezo transducer. Together, these tools form a powerful approach to diesel diagnostics in both workshop and field settings.

1. ElPower script - Analysis of hard starting diesel engine

This script is used at many car service stations to analyze hard starting problem of a diesel engine at any time of the year.This is especially relevant at low temperatures below 0 °C.

Within 3-5 minutes, you can check the characteristics and condition of:

- battery

- alternator

- starter

- glow plugs

- relative compression in engine cylinders

- battery voltage

- current consumption measured using the CTi-1000 current clamp

Figure 1. Connection to the vehicle battery to obtain voltage and current waveform

Figure 2. Measured vehicle parameters obtained using the ElPower script

Red background - measured parameters are outside the norm.

The report of the online version of the ElPower script algorithm may display the "Compression" tab

Figure 3. Relative Compression Test. Here, individual compression values by cylinder are displayed in the form of Bar graphs

2. CSS script - Cylinder power balance test

The express diagnostics time does not exceed 3-5 minutes.

There are two types of crankshaft position sensor: Hall sensor and inductive.

The injector control pulse can be measured using the CTi-50 current clamps. In a short time, you can check:

- condition of a fuel injection system (uniformity of fuel injector operation)

- condition of the mechanical system of a diesel engine (filling the cylinders of an internal combustion engine with an air-fuel mixture)

- evaluate static and dynamic compression in the cylinders

- Detect faults in the diesel engine timing mechanism

Figure 5. On this car, a wrong sealing washer was installed under the injector after repair. The first cylinder was misfiring.

Figure 6. On this car, the connecting rod of the third cylinder was bent due to a hydraulic shock. The contribution of this cylinder in some modes was very low

Figure 7. Diesel engine operation after high-quality repair. Cylinder contribution/balance at different engine speeds is almost the same.

Last edit: 7 months 2 days ago by VladimirPostolovsky. Reason: add the last picture after repair

Please Log in or Create an account to join the conversation.

- VladimirPostolovsky

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 21

6 months 3 weeks ago - 6 months 3 weeks ago #92071

by VladimirPostolovsky

Replied by VladimirPostolovsky on topic Comprehensive diagnostics of diesel engines

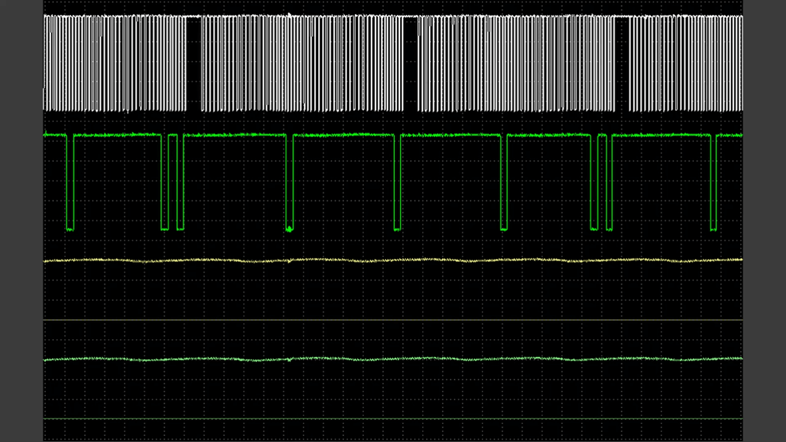

3. Testing the engine synchronization between Camshaft and Crankshaft sensors and diagnosing engine valve timingThese measurements are necessary if the engine cannot be started. These are the main signals for the control unit of a modern car.

The presence of these signals and their correct synchronization are the main ones for the ECU in controlling the fuel injection pulse. Video

In many manuals, manufacturers provide reference signals for each specific engine. Some of this information is on the website:

forum.injectorservice.com.ua

The duration of the injection pulse can be used for estimation the injection corrections in the control unit.

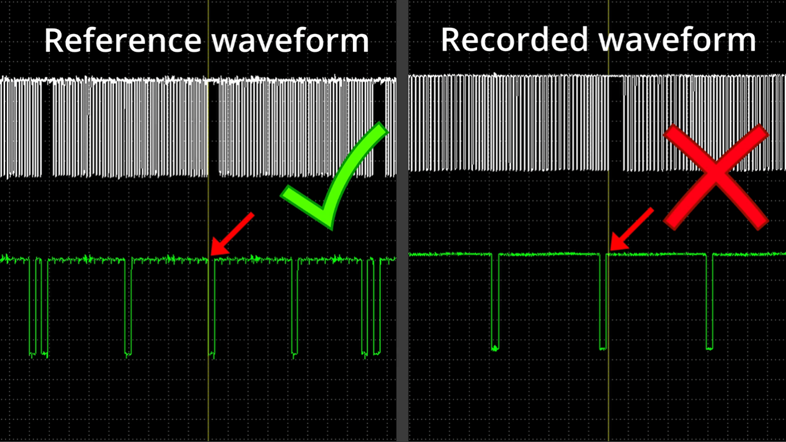

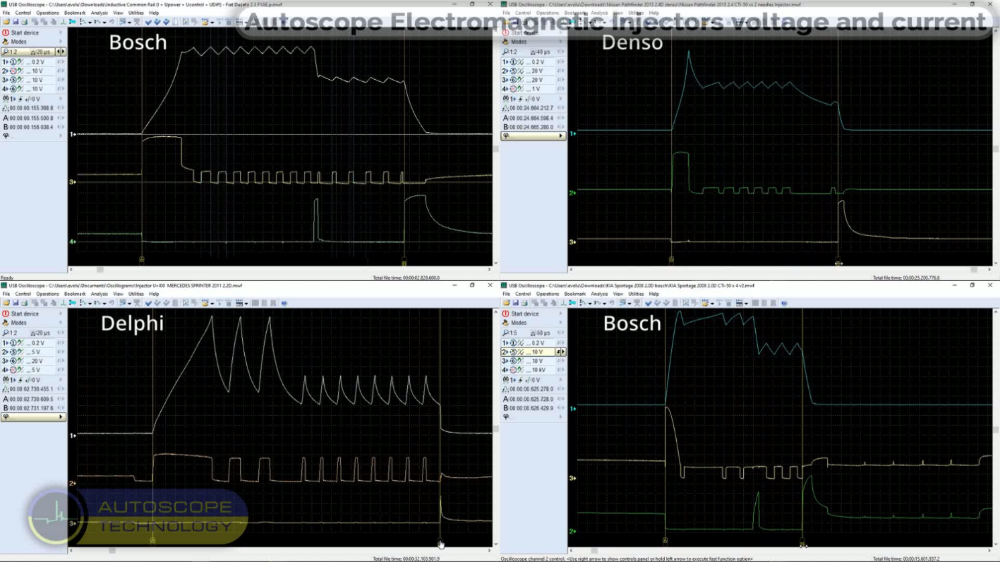

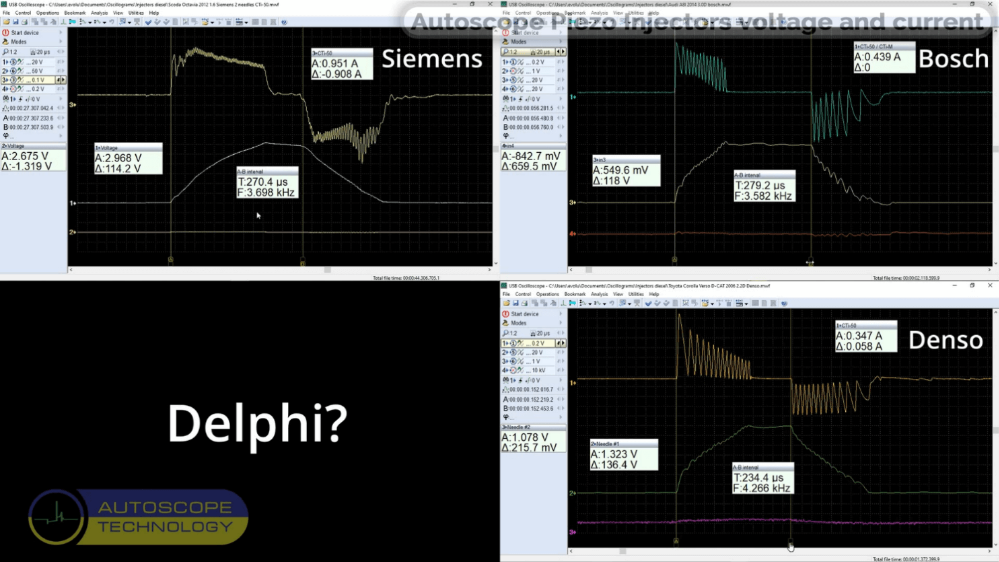

Here are shown the control signals of faulty injectors.

It is clear that there is a correction for fuel injection (different pulse durations). Control signal after replacement with new injectors. Minimal signal correction.

Control pulses of injector manufacturers Bosch, Denso, Delphi:

Figure 14. Example of the waveform of electromagnetic injectors

Video

Figure 15. Example of the waveform of piezo injectors

Video

Figure 8. Crankshaft sensor & Camshaft sensor signals

Both Crankshaft sensor and Camshaft sensor signals are present. There is no control of the fuel injectors.The presence of these signals and their correct synchronization are the main ones for the ECU in controlling the fuel injection pulse. Video

4. Diagnostics of electromagnetic injectors (piezo injectors) using the CTi-50 current clamp

This information is useful in case of replacement (or repair) of diesel injectors and their reprogramming. To do this, it is necessary to attach

CTi-50 current clamps

to the control pulse wire on the injector connector.

It should be noted that the design of the measuring part of the CTi-50 current transducer is specially made for such measurements.

Video

It is clear that there is a correction for fuel injection (different pulse durations). Control signal after replacement with new injectors. Minimal signal correction.

Control pulses of injector manufacturers Bosch, Denso, Delphi:

Figure 14. Example of the waveform of electromagnetic injectors

Video

Figure 15. Example of the waveform of piezo injectors

Video

Last edit: 6 months 3 weeks ago by VladimirPostolovsky.

Please Log in or Create an account to join the conversation.

- VladimirPostolovsky

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 21

6 months 3 weeks ago #92105

by VladimirPostolovsky

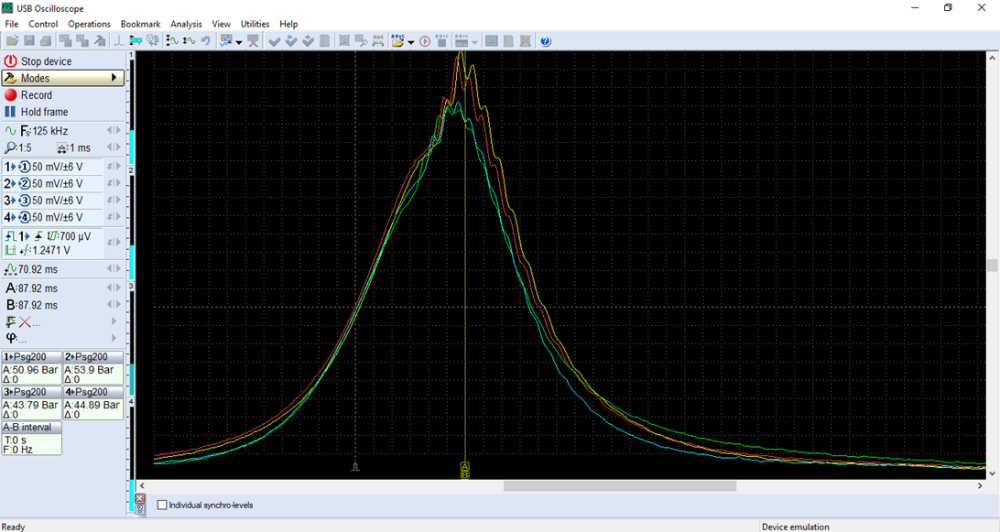

As a result, technician has the opportunity to see and compare pressure graphs in the cylinders of a running engine.

Replied by VladimirPostolovsky on topic Comprehensive diagnostics of diesel engines

5. Engine diagnostics based on the cylinder pressure graph using the PSG200 diesel pressure sensor

The pressure graph in the cylinders of a running diesel engine was, until recently, impossible for service center technicians. Standard pressure sensors are not designed for such measurements. A solution to this problem was proposed by BERU. They developed new glow plugs with built-in PSG pressure sensors.

Figure 16. PSG200 diesel pressure sensor

PSG200 pressure sensor

waveforms provide valuable data for identifying complex faults in diesel engines. In addition, they help technicians gain a deeper understanding of the processes occurring in the engine cylinder, which allows for faster and more accurate diagnostics. Using four diesel engine pressure sensors allows estimating the contribution / balance of all cylinders simultaneously. The resulting pressure graphs contain information about the combustion process of the fuel mixture, which depends on:

- Engine temperature

- Compression ratio

- Compression

- Fuel atomization quality

- Correct positioning of the injector nozzle in the combustion chamber

Figure 17. Connecting pressure sensors instead of glow plugs

Each sensor must have its own amplifier.

Article

about the examples of diesel pressure transducer use.As a result, technician has the opportunity to see and compare pressure graphs in the cylinders of a running engine.

Figure 18. Graph of pressure in the cylinders of a running engine

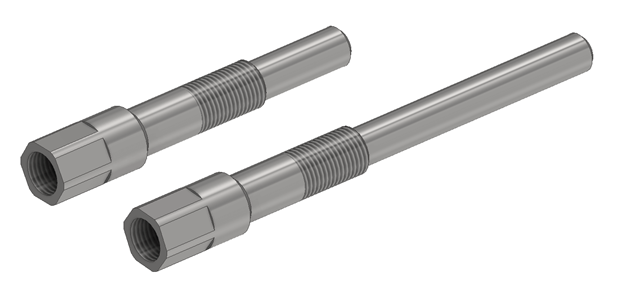

6. Adapters for the pressure sensor PSG200

To work with the pressure sensor, it is necessary to use special adapters:

Figure 19. Special adapters for PSG200 pressure sensor

These

adapters

must be installed in place of the glow plugs.

Figure 20. Adapters for diesel pressure sensor

For a high-quality analysis of the pressure graph, it is necessary to install the sensor as close as possible to the combustion chamber. Please Log in or Create an account to join the conversation.

- VladimirPostolovsky

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 21

6 months 2 weeks ago - 6 months 2 weeks ago #92128

by VladimirPostolovsky

Replied by VladimirPostolovsky on topic Comprehensive diagnostics of diesel engines

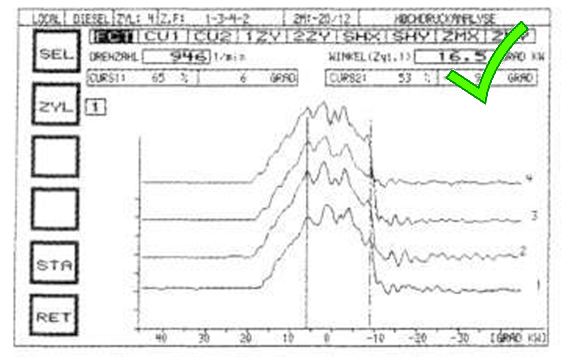

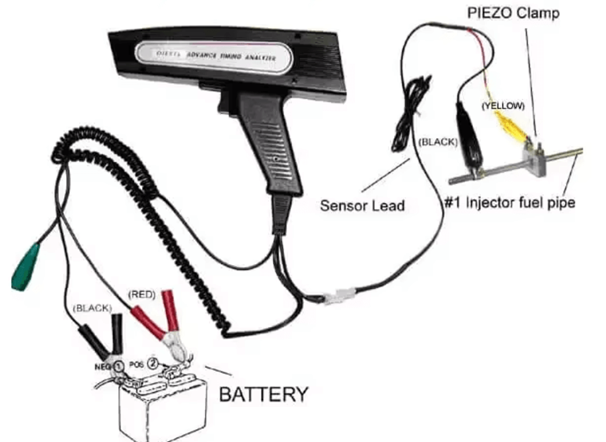

7. Diagnostics of diesel injection systems with a mechanical high-pressure fuel pump using clamp-on PD-6 piezo transducer

Figure 21. PD-6 piezo transducers

Figure 21. PD-6 piezo transducers

The

PD-6 sensor

is designed for installation on the high-pressure fuel line of diesel engines with a diameter of 6 mm, the injectors of which are not equipped with electronic control.

1. Car diagnostics using the CSS script

The sensor signal is used to perform complex diagnostics of the diesel engine and its control system using the CSS script.

Piezoelectric transducer is necessary to ensure the possibility of receiving a synchronization signal with the moment of fuel injection in the cylinder #1.The signal from the transducer must be fed to the oscilloscope input using Piezo Amplifier charge amplifier.

2. Using a piezo transducer to evaluate fuel injection pulses

By the nature of the fuel injection pulse, it is possible to evaluate:

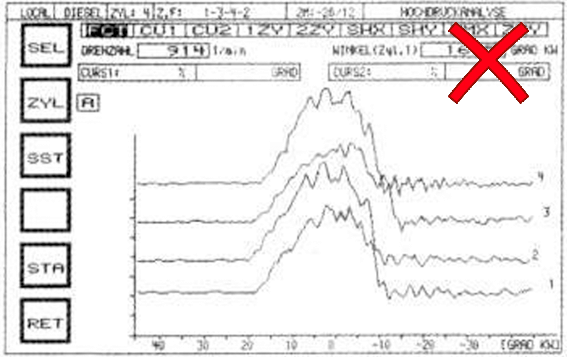

Figure 23. Injection pressure curves for a four-cylinder swirl-chamber engine with pintle-nozzle injectors (Volkswagen 1.9D): start of injection for all injectors — 6° of crankshaft rotation angle before TDC; end of injection — 9° of crankshaft rotation angle after TDC; injection duration — 15° of crankshaft rotation angle

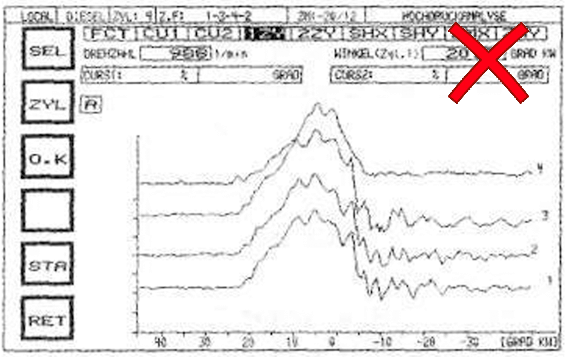

Figure 24. Reducing the injector opening pressure from 130 to 100 bar in the third cylinder

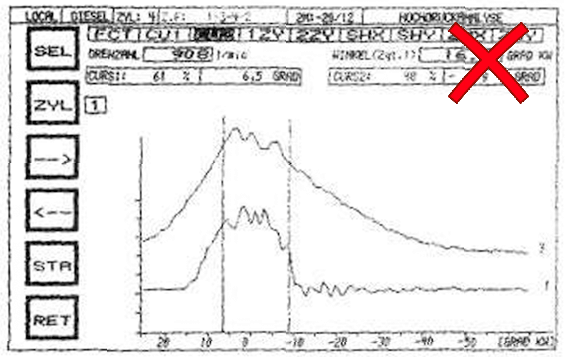

Figure 25. Insufficient sealing of the injection sprayer in the fourth cylinder

Figure 26. The delivery valve in the fuel equipment of the third cylinder is leaking, the residual pressure is zero

3. Using the PD-6 sensor for the operation of diesel stroboscopes.

This information is necessary for correct fuel injection timing using Diesel timing analyzer. 4. Using PD-6 piezoelectric transducers on diesel test benches during repairs and adjustments of high-pressure fuel pumps Conclusion

The diagnostic methods developed by Autoscope Technology allow for diagnostics of various diesel engine faults with minimal time and effort.

USB Autoscope technologies offer a powerful and efficient solution for diagnosing a wide range of diesel engine problems. From quick-start analysis with the ElPower script to in-depth cylinder pressure and injector diagnostics, these tools allow technicians to pinpoint faults without invasive procedures.

The ability to test CKP/CMP synchronization, fuel injection quality, and mechanical system integrity using advanced sensors and scripts significantly reduces diagnostic time while increasing accuracy. Whether in a repair shop or during field service, USB Autoscope equips professionals with the insights needed for reliable diesel engine maintenance and repair.

1. Car diagnostics using the CSS script

The sensor signal is used to perform complex diagnostics of the diesel engine and its control system using the CSS script.

Piezoelectric transducer is necessary to ensure the possibility of receiving a synchronization signal with the moment of fuel injection in the cylinder #1.The signal from the transducer must be fed to the oscilloscope input using Piezo Amplifier charge amplifier.

Figure 22. Installing of a piezo sensor on the fuel line of the first cylinder

Clamp sensors should be mounted on a flat section of the tube as close as possible and at the same distance from the injectors.2. Using a piezo transducer to evaluate fuel injection pulses

By the nature of the fuel injection pulse, it is possible to evaluate:

- condition of fuel injection sprayers

- condition of fuel injection pump delivery valve

- volume of fuel of the main injection and mechanical pre-injection

Figure 23. Injection pressure curves for a four-cylinder swirl-chamber engine with pintle-nozzle injectors (Volkswagen 1.9D): start of injection for all injectors — 6° of crankshaft rotation angle before TDC; end of injection — 9° of crankshaft rotation angle after TDC; injection duration — 15° of crankshaft rotation angle

Figure 24. Reducing the injector opening pressure from 130 to 100 bar in the third cylinder

Figure 25. Insufficient sealing of the injection sprayer in the fourth cylinder

Figure 26. The delivery valve in the fuel equipment of the third cylinder is leaking, the residual pressure is zero

This information is necessary for correct fuel injection timing using Diesel timing analyzer. 4. Using PD-6 piezoelectric transducers on diesel test benches during repairs and adjustments of high-pressure fuel pumps Conclusion

The diagnostic methods developed by Autoscope Technology allow for diagnostics of various diesel engine faults with minimal time and effort.

USB Autoscope technologies offer a powerful and efficient solution for diagnosing a wide range of diesel engine problems. From quick-start analysis with the ElPower script to in-depth cylinder pressure and injector diagnostics, these tools allow technicians to pinpoint faults without invasive procedures.

The ability to test CKP/CMP synchronization, fuel injection quality, and mechanical system integrity using advanced sensors and scripts significantly reduces diagnostic time while increasing accuracy. Whether in a repair shop or during field service, USB Autoscope equips professionals with the insights needed for reliable diesel engine maintenance and repair.

Last edit: 6 months 2 weeks ago by VladimirPostolovsky. Reason: Formatting text

Please Log in or Create an account to join the conversation.

Time to create page: 0.335 seconds