*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

A place to discuss hardware/software and diagnostic procedures

Some thoughts on diagnosing timing belt problems

- SailorBob

-

Topic Author

Topic Author

- Offline

- Elite Member

-

7 years 6 months ago - 7 years 6 months ago #19187

by SailorBob

Some thoughts on diagnosing timing belt problems was created by SailorBob

www.scannerdanner.com/scannerdanner-prem...xpanded-content.html

So, I think I've watched most of the timing chain related videos of ScannerDanner, and I've got some observations, questions and more observations. When I say chain I also mean belt interchangeably.

This is a learning exercise, I have minimal experience in this area, so please poke holes in my assumptions / observations / conclusions ( in a constructive way ).

This is all working backwards, assuming a T-belt problem with no other problems present in the vehicle.

The variables I've come up with or learned from the videos:

- timed off the crank or cam

- broken or off a few teeth or off allot of teeth

- early or late valve opening ( fixed vs. VVT )

- straight or V engine

- Single Cam or Dual Cam

-- is there a CMP sensor for each Cam?

Regarding valve timing, based on what I've read in regards to consumer ( daily driver ) vehicles, the following statements are always true at idle:

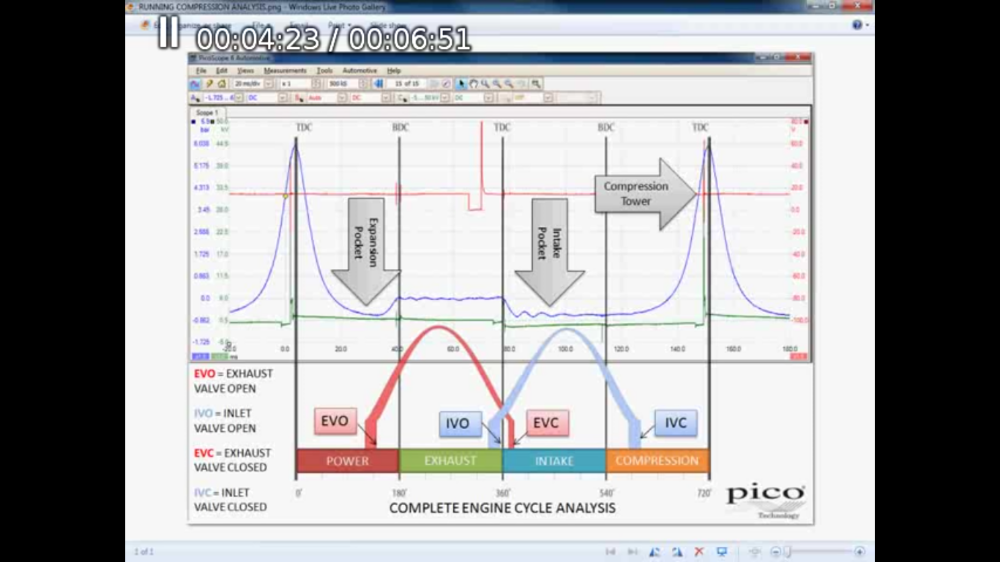

The intake valve always opens before TDC

The intake valve always closes after BDC

The exhaust valve always opens before BDC

The exhaust valve always closes after TDC

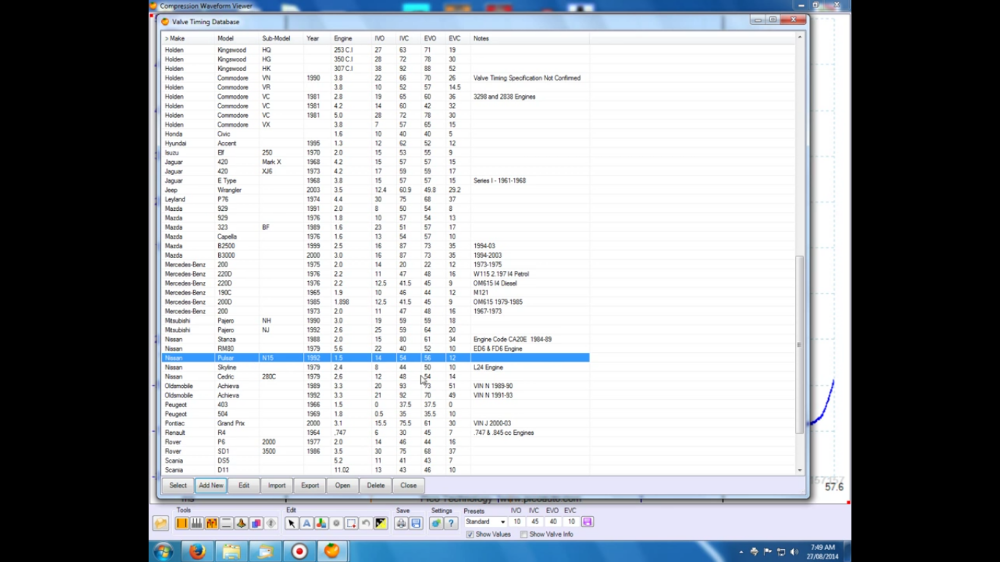

Beyond these general statements there is quite allot of variation, although a good rule of thumb are IVO 10*, IVC 45*, EVO 40*, EVC 10* ( based on Rod Maher's work ).

I'm assuming that it's standard to time the spark exactly at TDC during cranking.

I'm assuming VVT doesn't come into play during cranking and at idle, and doesn't affect the above statements.

--- The timing belt related problems / symptoms could be split into two categories, cranking no start, or running.

CRANKING NO START

-- This assumes straight block single cam

*** Car ran and now won't start:

1) belt is off so many teeth that the ignition event happens too early or late to start the engine or lack of compression ( jumped teeth )

If the timing is off that bad, it'll be seen right away on a relative compression test with spark occuring noticably way before or after TDC. I'm assuming here that during cranking, spark always occurs within a short distance of TDC, say within 5* before or after.

2) or the timing chain is broken

2.A) If the timing is driven off the crank and the belt is broken, either the valves stopped in the closed or open positions, or some are open and some are closed. There will be a cam DTC on OBDII vehicles.

2.A.1) If they all happen to be in the closed position, then the compression peak will coincide with the spark event on all cylinders and the only way to observe the problem will be with a pressure transducer looking for valve activity at the intake, exhaust or in cylinder. This situation seems unlikely, but possible.

2.A.2) If some or all valves are in the open position, then there will be missing compression humps in a relative compression test and should be obvious by counting humps between spark events.

2. If the timing is driven off the cam sensor, then there will be no CAM signal, no spark and a CAM DTC on OBDII vehicles.

If the timing is driven off the cam sensor, then there will be no CAM signal, no spark and a CAM DTC on OBDII vehicles.

2.B.1) If all valves are closed, no missing humps on a RelComp, and you're back to using a pressure transducer as above.

2.B.2) If some valves are open then you'll see missing humps on the RelComp with a long enough time base? ***NOT SURE ABOUT THIS***

I'm wondering if a broken t-belt could be detected simply using a traditional vacuum gauge on the intake to look for no or low intake vacuum during cranking?

-- How do things change on a V engine or dual cam engine?

Case 1 above changes due to the possibility that there is a single CAM, without a sensor on it, which is off by a few teeth, but the CAM with the sensor on it is timed correctly. So the CAM / Crank signals would look correct and ignition timing would be correct relative to peak pressure, yet compression could be insufficient to start the engine due to valves opening to early or late. It seems the only way to see this case would be with an in cylinder transducer ( traditional compression test also? ) looking at valve timing activity. One might be able to use the above rules of thumb, or might need the actual cam timing specs.

Case 2: I don't think anything changes.

*** Car is running with these symptoms: poor idle quality, low power, poor fuel efficiency

- reflected in + or - FTs, low or high intake vacuum

This will be similar to, but slightly different than Case 1 above.

I think I should relate here to the issue of how many degrees of crank rotation each tooth on the cam sprocket is.

I was browsing cam sprocket specs on this site: www.preferredcomponents.com/catalog.php

What I saw was quite a bit of variation, from 25 teeth up to 54. Most seemed to be in the from 36 to 48 range. At 36 each tooth is 10* of CAM rotation and 20* of CRANK rotation. At 48 each tooth is 7.5* of CAM rotation and 15* of CRANK rotation. Some of the KIA's and Hyundai's had 54, with most having 50.

So I think it's worthwhile to look at the hardest to detect case, which would be a 54 tooth cam sprocket off 1 tooth. This would give about 6.7* of CAM rotation and about 13.4* of CRANK rotation in one direction or the other.

-- Assuming a single CAM:

1) If the timing is run off the crank signal, then spark timing will be correct relative to peak compression. It's unlikely that one could see 6.7* of difference in the valve timing on a transducer unless one had the exact cam timing spec, since such a small difference falls within the range of normal, even for the IVO. The only other way to see this problem would be comparring the CAM / CRANK signals to a known good one.

2) If the timing is run off the cam signal, assuming cranking spark is always at TDC, you could measure this and see it on a pressure transducer while cranking and syncing to the spark for that cylinder, in addition to the above possibilities.

-- Assuming a V engine or dual cam

This makes things allot more complicated. As in the no start case, if the cam that is incorrectly timed is the one without the sensor, then the only option is to look up the cam spec and take exact measurements of the valve timing using the in cylinder transducer.

***** Conclusions For Diagnosing a Running Engine

This is basically covering four non invasive or minimally invasive techniques for trying to detect timing belt problems; relative compression test synced to spark, cranking transducer synced to spark, running transducer measuring valve timing, and cam / crank signal relation.

The only one that never fails is looking up the cam timing specs and taking exact running compression measurements of the valve timing.

But that's a theoretical conclusion. It seems unlikely that a car whose cam is only off by 6*-10* degrees would run poorly enough to even be noticed by the average car owner and make it into the shop. More likely to me ( theoretically as I don't have lots of experience ) is a vehicle that's off by at least 15*-20*.

In this case, it seems very likely that IVO or EVC would be off enough to be seen relative to TDC or BDC cursors on the screen on a running compression waveform. If the timing is run off the cam, then it seems it would also show up pretty clearly on a spark sync'ed relative compression test.

So what drives me in the direction of these tests? If I've got rough idle and poor performance, I've verified no air leaks, good spark and fuel delivery, ruled out a clogged exhaust and TPS, MAF or MAP issues, then I think I'd start with a spark sync'ed relative compression test, then cam / crank signals if I can quickly find a known good waveform, then spark sync'ed cranking transducer, then running transducer.

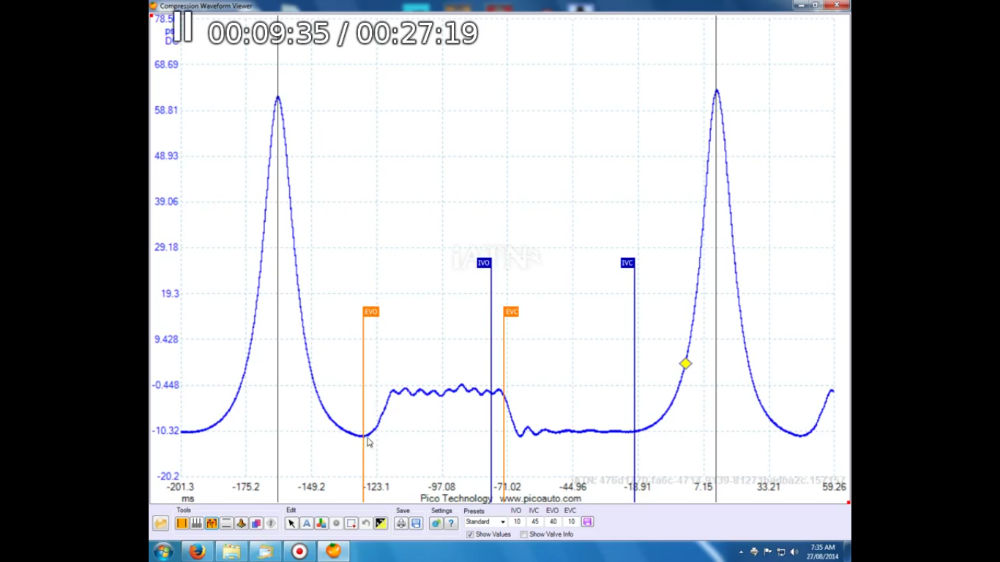

Here are some graphics for reference purposes:

So, I think I've watched most of the timing chain related videos of ScannerDanner, and I've got some observations, questions and more observations. When I say chain I also mean belt interchangeably.

This is a learning exercise, I have minimal experience in this area, so please poke holes in my assumptions / observations / conclusions ( in a constructive way ).

This is all working backwards, assuming a T-belt problem with no other problems present in the vehicle.

The variables I've come up with or learned from the videos:

- timed off the crank or cam

- broken or off a few teeth or off allot of teeth

- early or late valve opening ( fixed vs. VVT )

- straight or V engine

- Single Cam or Dual Cam

-- is there a CMP sensor for each Cam?

Regarding valve timing, based on what I've read in regards to consumer ( daily driver ) vehicles, the following statements are always true at idle:

The intake valve always opens before TDC

The intake valve always closes after BDC

The exhaust valve always opens before BDC

The exhaust valve always closes after TDC

Beyond these general statements there is quite allot of variation, although a good rule of thumb are IVO 10*, IVC 45*, EVO 40*, EVC 10* ( based on Rod Maher's work ).

I'm assuming that it's standard to time the spark exactly at TDC during cranking.

I'm assuming VVT doesn't come into play during cranking and at idle, and doesn't affect the above statements.

--- The timing belt related problems / symptoms could be split into two categories, cranking no start, or running.

CRANKING NO START

-- This assumes straight block single cam

*** Car ran and now won't start:

1) belt is off so many teeth that the ignition event happens too early or late to start the engine or lack of compression ( jumped teeth )

If the timing is off that bad, it'll be seen right away on a relative compression test with spark occuring noticably way before or after TDC. I'm assuming here that during cranking, spark always occurs within a short distance of TDC, say within 5* before or after.

2) or the timing chain is broken

2.A) If the timing is driven off the crank and the belt is broken, either the valves stopped in the closed or open positions, or some are open and some are closed. There will be a cam DTC on OBDII vehicles.

2.A.1) If they all happen to be in the closed position, then the compression peak will coincide with the spark event on all cylinders and the only way to observe the problem will be with a pressure transducer looking for valve activity at the intake, exhaust or in cylinder. This situation seems unlikely, but possible.

2.A.2) If some or all valves are in the open position, then there will be missing compression humps in a relative compression test and should be obvious by counting humps between spark events.

2.

2.B.1) If all valves are closed, no missing humps on a RelComp, and you're back to using a pressure transducer as above.

2.B.2) If some valves are open then you'll see missing humps on the RelComp with a long enough time base? ***NOT SURE ABOUT THIS***

I'm wondering if a broken t-belt could be detected simply using a traditional vacuum gauge on the intake to look for no or low intake vacuum during cranking?

-- How do things change on a V engine or dual cam engine?

Case 1 above changes due to the possibility that there is a single CAM, without a sensor on it, which is off by a few teeth, but the CAM with the sensor on it is timed correctly. So the CAM / Crank signals would look correct and ignition timing would be correct relative to peak pressure, yet compression could be insufficient to start the engine due to valves opening to early or late. It seems the only way to see this case would be with an in cylinder transducer ( traditional compression test also? ) looking at valve timing activity. One might be able to use the above rules of thumb, or might need the actual cam timing specs.

Case 2: I don't think anything changes.

*** Car is running with these symptoms: poor idle quality, low power, poor fuel efficiency

- reflected in + or - FTs, low or high intake vacuum

This will be similar to, but slightly different than Case 1 above.

I think I should relate here to the issue of how many degrees of crank rotation each tooth on the cam sprocket is.

I was browsing cam sprocket specs on this site: www.preferredcomponents.com/catalog.php

What I saw was quite a bit of variation, from 25 teeth up to 54. Most seemed to be in the from 36 to 48 range. At 36 each tooth is 10* of CAM rotation and 20* of CRANK rotation. At 48 each tooth is 7.5* of CAM rotation and 15* of CRANK rotation. Some of the KIA's and Hyundai's had 54, with most having 50.

So I think it's worthwhile to look at the hardest to detect case, which would be a 54 tooth cam sprocket off 1 tooth. This would give about 6.7* of CAM rotation and about 13.4* of CRANK rotation in one direction or the other.

-- Assuming a single CAM:

1) If the timing is run off the crank signal, then spark timing will be correct relative to peak compression. It's unlikely that one could see 6.7* of difference in the valve timing on a transducer unless one had the exact cam timing spec, since such a small difference falls within the range of normal, even for the IVO. The only other way to see this problem would be comparring the CAM / CRANK signals to a known good one.

2) If the timing is run off the cam signal, assuming cranking spark is always at TDC, you could measure this and see it on a pressure transducer while cranking and syncing to the spark for that cylinder, in addition to the above possibilities.

-- Assuming a V engine or dual cam

This makes things allot more complicated. As in the no start case, if the cam that is incorrectly timed is the one without the sensor, then the only option is to look up the cam spec and take exact measurements of the valve timing using the in cylinder transducer.

***** Conclusions For Diagnosing a Running Engine

This is basically covering four non invasive or minimally invasive techniques for trying to detect timing belt problems; relative compression test synced to spark, cranking transducer synced to spark, running transducer measuring valve timing, and cam / crank signal relation.

The only one that never fails is looking up the cam timing specs and taking exact running compression measurements of the valve timing.

But that's a theoretical conclusion. It seems unlikely that a car whose cam is only off by 6*-10* degrees would run poorly enough to even be noticed by the average car owner and make it into the shop. More likely to me ( theoretically as I don't have lots of experience ) is a vehicle that's off by at least 15*-20*.

In this case, it seems very likely that IVO or EVC would be off enough to be seen relative to TDC or BDC cursors on the screen on a running compression waveform. If the timing is run off the cam, then it seems it would also show up pretty clearly on a spark sync'ed relative compression test.

So what drives me in the direction of these tests? If I've got rough idle and poor performance, I've verified no air leaks, good spark and fuel delivery, ruled out a clogged exhaust and TPS, MAF or MAP issues, then I think I'd start with a spark sync'ed relative compression test, then cam / crank signals if I can quickly find a known good waveform, then spark sync'ed cranking transducer, then running transducer.

Here are some graphics for reference purposes:

Last edit: 7 years 6 months ago by SailorBob.

Please Log in or Create an account to join the conversation.

Time to create page: 0.383 seconds